All-steel radial tire shoulder wedge and preparation method thereof

A radial tire and tire shoulder pad rubber technology, applied in the field of all-steel radial tire shoulder pad rubber and its preparation, can solve the problems of reduced compression heat generation, mixed rubber hardness, poor viscosity, difficult processing applications, hardness and modulus stress Lowering and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a preparation method of the all-steel radial tire shoulder pad rubber described in the above technical solution, comprising the following steps:

[0044] a) banburying natural rubber, trans-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, reinforcing agent, dispersant, tackifying resin, accelerator, sulfur, anti-scorch agent and silane coupling agent, to obtain Mixed rubber;

[0045] b) kneading the banbury rubber to obtain the final rubber mix;

[0046] c) vulcanizing the final rubber mix to obtain shoulder pad rubber.

[0047] Wherein, the types and types of natural rubber, trans-butadiene rubber, zinc oxide, stearic acid, anti-aging agent, reinforcing agent, dispersant, tackifying resin, accelerator, sulfur, anti-scorch agent and silane coupling agent Consumption etc. are all consistent with described in the above-mentioned technical scheme, do not repeat them one by one here.

[0048] In the present invention, said...

Embodiment 1

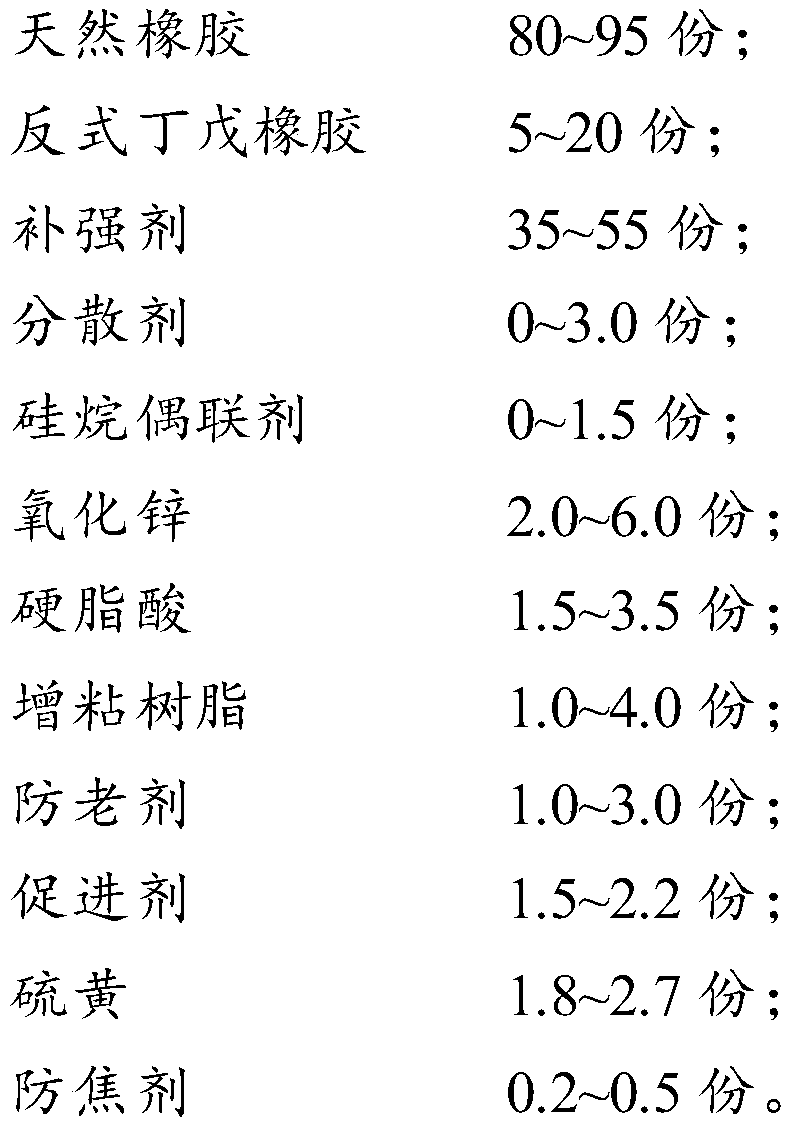

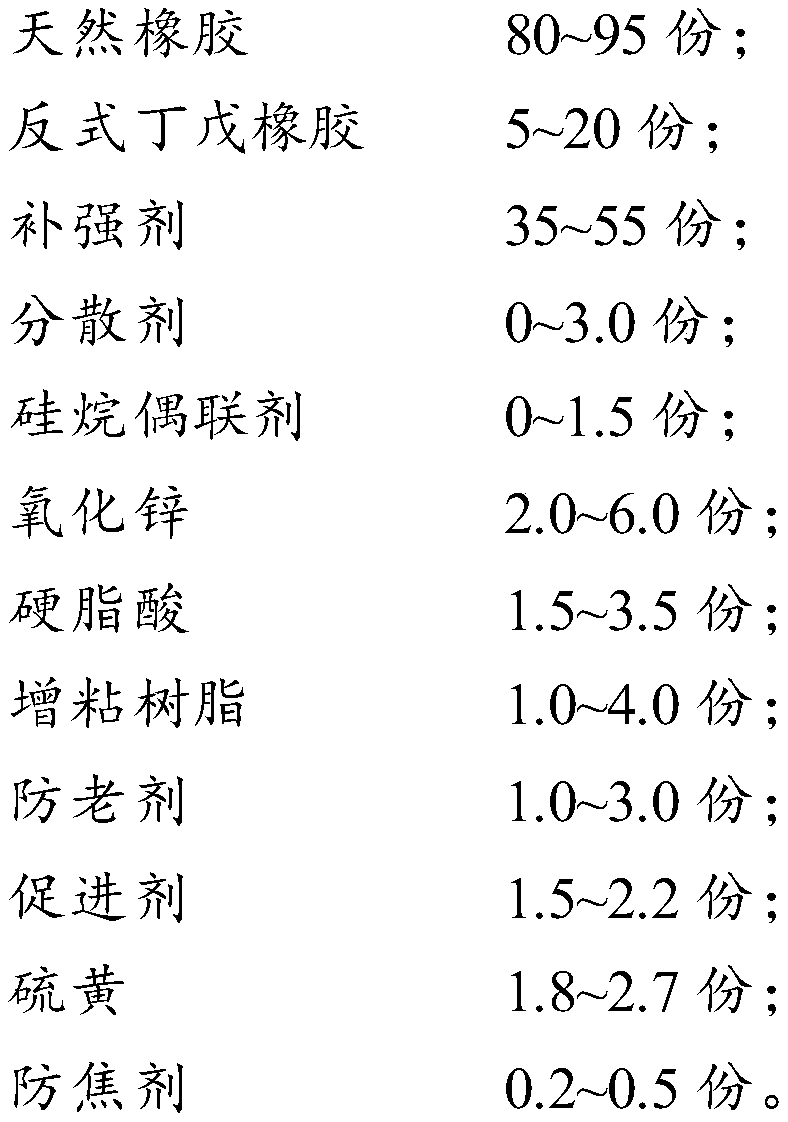

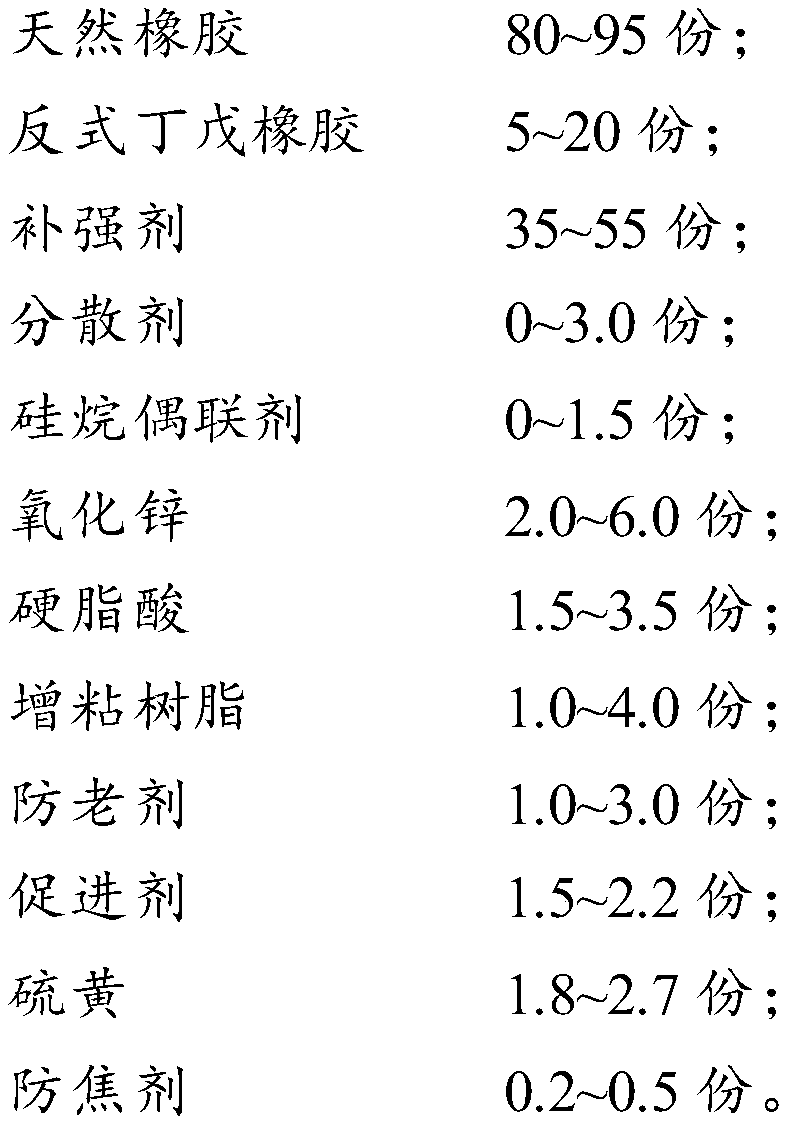

[0059] 1.1 Raw material

[0060] 95 parts of natural rubber SCR WF, 5 parts of trans-butylene rubber TBIR-1, 3.5 parts of zinc oxide, 3.0 parts of stearic acid, 45 parts of carbon black (22.5 parts of carbon black N375+22.5 parts of carbon black N660), 1.5 parts of carbon Black dispersant Adhesive AR-105, 1.7 parts of anti-aging agent (1.2 parts of anti-aging agent 4020+0.5 part of anti-aging agent RD), 3.5 parts of phenolic tackifying resin, 1.8 parts of accelerator TBBS, 2.25 parts of sulfur, 0.4 parts of anti-scorch agent CTP.

[0061] 1.2 Preparation:

[0062] S1. One stage of internal refining:

[0063] The initial temperature of the internal mixer is 70°C, the rotational speed of the internal mixer is 70rpm, and the feeding coefficient is 0.75.

[0064] The natural rubber and trans-butadiene rubber were banburyed for 1 minute, and active agents such as zinc oxide and stearic acid, anti-aging agent, reinforcing agent and dispersant were added to continue banburying for...

Embodiment 2

[0075] According to the raw materials and preparation of Example 1, the difference is that the trans-butadiene rubber TBIR-1 is replaced by trans-butadiene rubber TBIR-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com