Nano hybrid filler reinforced rubber material and preparation process thereof

A technology of reinforcing rubber and hybridization, which is applied in the field of nano-hybrid filler-reinforced rubber materials and its preparation, which can solve the problems of poor dispersion, uneven performance of polymer composite materials, and obvious agglomeration, so as to increase cross-linking density and increase The effect of interaction, promoting distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] The preparation technology of described rubber material, comprises the steps:

[0046] Step 1. Add the hybrid filler, white carbon black, cerium dioxide, and asbestos fiber into tetrahydrofuran, and mechanically stir for 6-10 hours under 60-100W ultrasonic conditions, so that the hybrid filler, white carbon black, cerium dioxide, and asbestos fiber Uniformly dispersed in tetrahydrofuran to obtain a filler dispersion;

[0047] Step 2. Add natural rubber and auxiliary material rubber into the rubber mixer, mix for 1-5 minutes, raise the temperature of the mixer to 110-160°C, add filler dispersion, and continue mixing for 5-15 minutes. air drying;

[0048] Step 3. Add oil, stearic acid, nano-zinc oxide, accelerator, sulfur and anti-aging agent to the rubber internal mixer in sequence, mix for 2-5 minutes, then release the sheet, park it for 18-30 hours, and vulcanize to obtain rubber sheet;

[0049] Step 4. Put the rubber sheet on a flat vulcanizer for compression moldin...

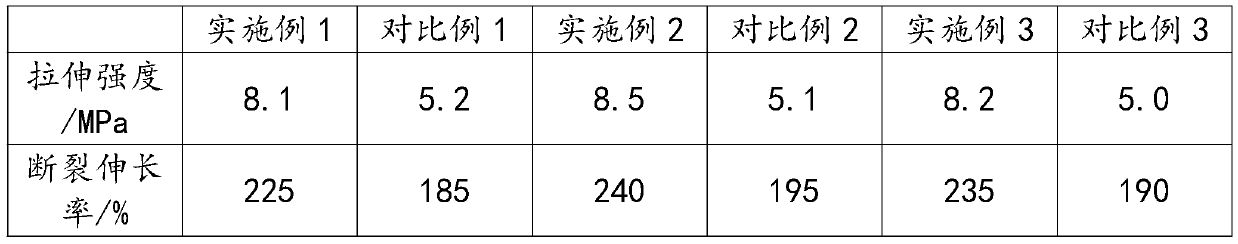

Embodiment 1

[0051] A nano-hybrid filler reinforced rubber material, prepared from the following raw materials in parts by weight: 40 parts of natural rubber, 20 parts of auxiliary rubber, 5 parts of hybrid filler, 10 parts of white carbon black, 2 parts of cerium dioxide, asbestos fiber 2 parts, 35 parts of tetrahydrofuran, 11 parts of oil, 1 part of stearic acid, 4 parts of nano zinc oxide, 0.7 parts of dibenzothiazole disulfide, 3 parts of sulfur, 2,2,4-trimethyl-1,2- 0.6 part of dihydroquinoline polymer;

[0052] The auxiliary material rubber includes EPDM rubber, nitrile rubber, fluororubber, butadiene rubber, EPDM rubber, nitrile rubber, fluororubber, and butadiene rubber in a mass ratio of 1:0.2:0.5:1.1 compounded.

Embodiment 2

[0054] A nano-hybrid filler reinforced rubber material, prepared from the following raw materials in parts by weight: 45 parts of natural rubber, 25 parts of auxiliary rubber, 6 parts of hybrid filler, 11 parts of white carbon black, 2.5 parts of cerium oxide, asbestos fiber 2.5 parts, 40 parts of tetrahydrofuran, 13 parts of oil, 1.5 parts of stearic acid, 5 parts of nano zinc oxide, 0.75 parts of N-cyclohexyl-2-benzothiazole sulfenamide, 4 parts of sulfur, 2-mercaptobenzimidazole 0.8 copies;

[0055] The auxiliary material rubber includes EPDM rubber, nitrile rubber, fluororubber, butadiene rubber, and EPDM rubber, nitrile rubber, fluororubber, and butadiene rubber are in a mass ratio of 1:0.25:0.6:1.15 compounded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com