Low-mooney rubber material applicable to injection vulcanization and preparation method of low-Mooney rubber material

A rubber material, injection pressure vulcanization technology, applied in the field of rubber, can solve the problems of uneven distribution of fillers, inability to satisfy rapid vulcanization and crosslinking, and affect the Mooney viscosity and performance of rubber materials, so as to increase the crosslinking density and promote rubber vulcanization , Improve the effect of tensile properties and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of described rubber material, comprises the steps:

[0038] Step S1, first adjust the roller distance to 1mm, put the weighed EPDM rubber on the roller, make the raw rubber cover the roller, and ensure that there is a certain amount of rubber accumulation, plasticize for 6-10 times, and then press down Slice, cool, park for 4-8h, and then carry out the second mastication of the parked rubber material, and then slice, cool and park again;

[0039] Step S1, adjust the roller distance to 6-10mm, add anti-aging agent, zinc oxide and stearic acid to the plasticized rubber material prepared in step S1, and add white carbon black after the rubber material is mixed for 3-4 minutes , flow agent, microcrystalline paraffin and paraffin oil, continue to mix for 20-30 minutes, cut the knife left and right twice to make pre-mixed rubber;

[0040] Step S3, adding accelerators and auxiliary agents to the premixed rubber prepared in step S2, and broaching the lef...

Embodiment 1

[0043] A low Mooney rubber material suitable for injection vulcanization, made of the following raw materials in parts by weight: 80 parts of EPDM rubber, 60 parts of white carbon black, 4 parts of zinc oxide, 1 part of stearic acid, flow agent 0.5 parts, 1 part of anti-aging agent, 0.8 parts of microcrystalline paraffin, 20 parts of paraffin oil, 2 parts of accelerator; 1 part of auxiliary agent;

[0044] The rubber material is made by the following steps:

[0045] Step S1, first adjust the roller distance to 1mm, put the weighed EPDM rubber on the roller, make the raw rubber cover the roller, and ensure that there is a certain amount of rubber accumulation, masticate 6 times, and then unload, Cool, park for 4 hours, and then carry out the second mastication of the parked rubber material, and then release, cool and park again;

[0046] Step S1, adjust the roller distance to 6mm, first add anti-aging agent, zinc oxide and stearic acid to the plasticized rubber material prepar...

Embodiment 2

[0050] A low Mooney rubber material suitable for injection vulcanization, made of the following raw materials in parts by weight: 90 parts of EPDM rubber, 70 parts of white carbon black, 4.5 parts of zinc oxide, 1.5 parts of stearic acid, flow agent 0.8 parts, 1.5 parts of anti-aging agent, 0.9 parts of microcrystalline paraffin, 23 parts of paraffin oil, 2.5 parts of accelerator; 1.5 parts of auxiliary agent;

[0051] The rubber material is made by the following steps:

[0052] Step S1, first adjust the roller distance to 1mm, put the weighed EPDM rubber on the roller, make the raw rubber cover the roller, and ensure that there is a certain amount of rubber accumulation, masticating 8 times, and then the film, Cool, park for 6 hours, then carry out the second mastication of the parked rubber material, and then release, cool and park again;

[0053] Step S1, adjust the roller distance to 8mm, add anti-aging agent, zinc oxide and stearic acid to the plasticized rubber material...

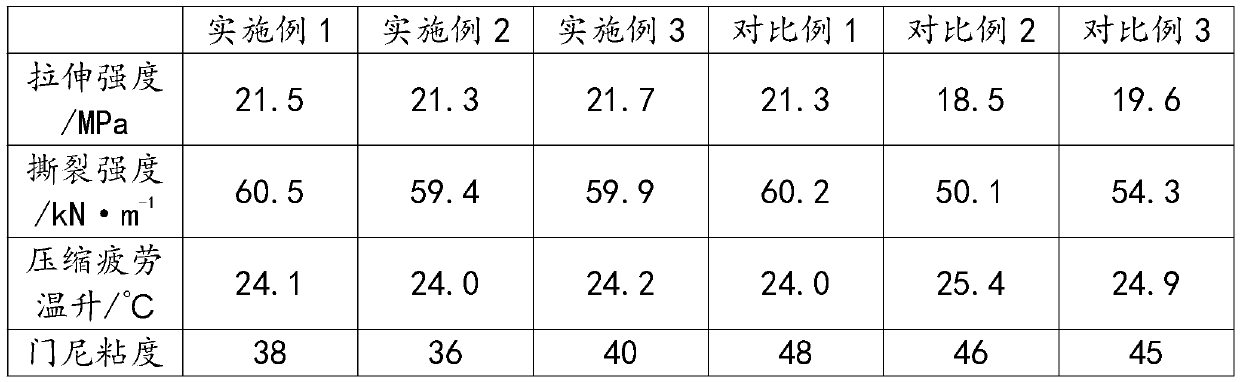

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com