Pre-dispersed rubber auxiliary master batch as well as preparation method and application thereof

A technology of rubber additives and pre-dispersion, which is applied in the field of pre-dispersed rubber additives masterbatch, can solve problems such as poor quality stability during storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

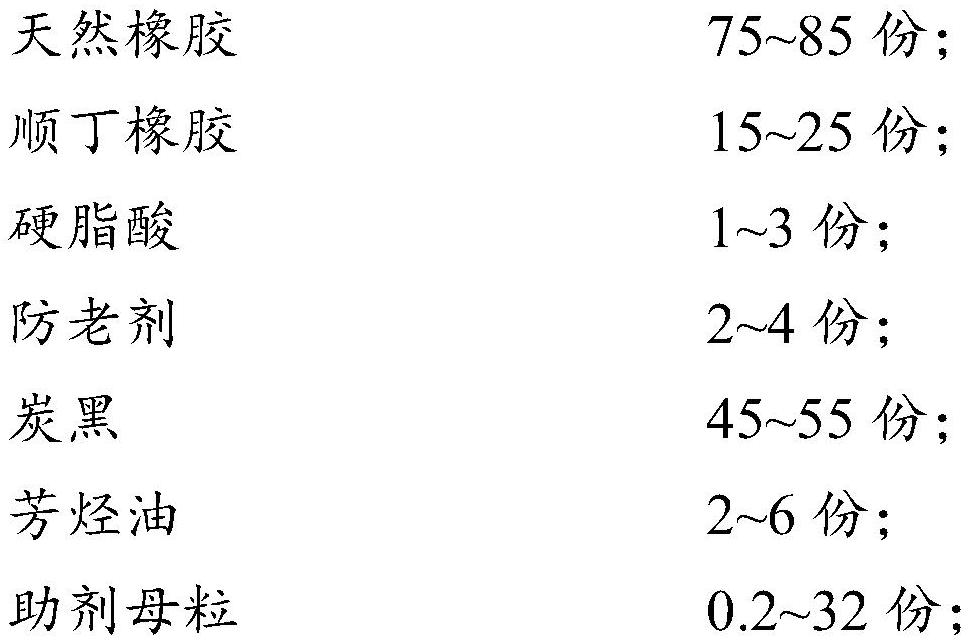

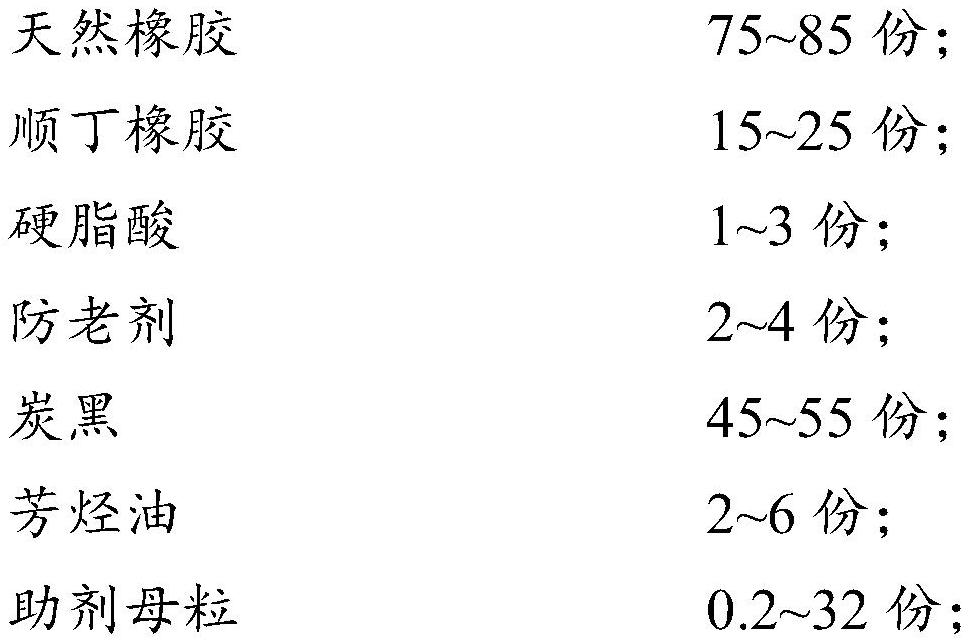

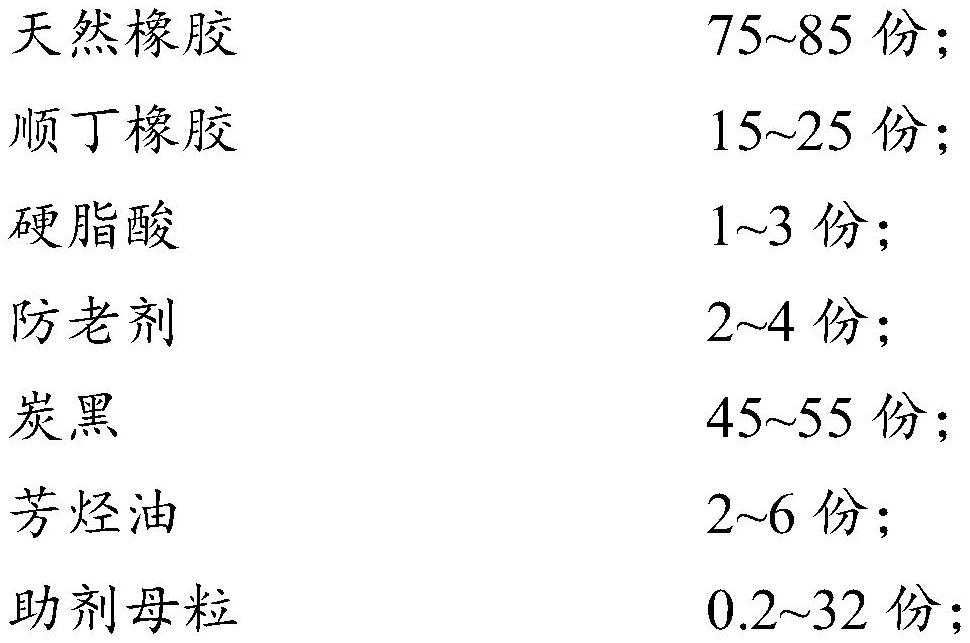

Method used

Image

Examples

preparation example Construction

[0049] The present invention also provides a preparation method of pre-dispersed rubber auxiliary master batch, comprising the following steps:

[0050] After the low Mooney trans-1,4-diene copolymer and the rubber auxiliary are mixed, extruded and granulated, the pre-dispersed rubber auxiliary master batch is obtained.

[0051] In some embodiments of the present invention, the temperature of the internal mixing is 55-65° C., the rotational speed is 45-55 rpm, and the time is 5-10 min. In some embodiments of the present invention, the temperature of the internal mixing is 60° C., the rotational speed is 50 rpm, and the time is 5 min.

[0052]In some embodiments of the present invention, the temperature of the extrusion granulation is 65-75° C., and the rotation speed is 15-25 rpm. In some embodiments of the present invention, the temperature of the extrusion granulation is 70° C., and the rotation speed is 20 rpm.

[0053] In the present invention, the preparation of the pre...

Embodiment 1

[0129] Preparation of pre-dispersed rubber additive masterbatch:

[0130] The low Mooney trans-butadiene rubber (the molar content of the butadiene structural unit is 20% and the Mooney viscosity is 30) and the accelerator N-tert-butyl-2-benzothiazole sulfenamide (NS) according to the mass ratio 50:50 into the internal mixer, internal mixing for 5min, internal mixer speed: 50 rev / min, initial temperature 60 ℃, then extrude and granulate in a twin-screw extruder, screw temperature 70 ℃, speed 20 rpm, make Substance b1 (NS-50 sample) was obtained.

[0131] The mass ratio of the low Mooney trans-butadiene rubber and the accelerator N-tert-butyl-2-benzothiazole sulfenamide (NS) was replaced by 20:80, and the remaining steps were all carried out according to the above steps to obtain Substance b2 (NS-80 sample).

Embodiment 2

[0133] Preparation of pre-dispersed rubber additive masterbatch:

[0134] Put the low Mooney trans-butadiene rubber (the molar content of the butadiene structural unit is 5% and the Mooney viscosity is 5) and zinc oxide (ZnO) into the internal mixer according to the mass ratio of 40:60, and mix for 5 minutes. Machine rotation speed: 50 rev / min, initial temperature 60°C, then extruding and pelletizing in a twin-screw extruder, screw temperature 70°C, rotation speed 20rpm, to obtain material a1 (ZnO-60 sample).

[0135] The mass ratio of the low Mooney trans-butadiene rubber to zinc oxide was replaced with 20:80, and the rest of the steps were carried out according to the above steps to obtain substance a2 (ZnO-80 sample).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com