High-elasticity low-heat-generation environment-friendly reclaimed rubber material and preparation method thereof

A technology with low heat generation and high elasticity, applied in the field of rubber materials, can solve the problems of limited promotion and expansion of application, poor rubber resilience, poor stability, etc. The effect of elasticity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

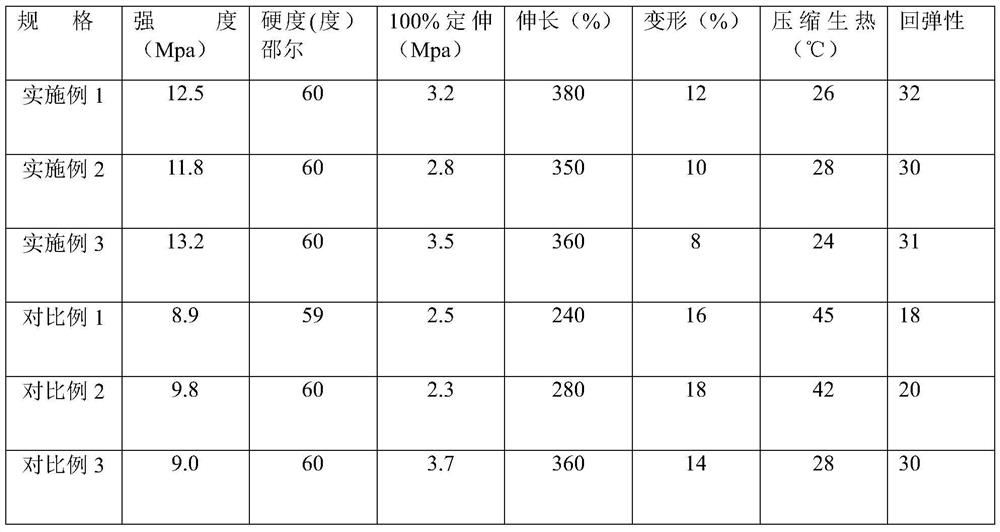

Examples

Embodiment 1

[0022] Raw materials (by weight): tire crown rubber powder: 100 parts; liquid isoprene rubber LIR30: 5 parts; environmental naphthenic oil: 10 parts; activator 520: 0.5 parts; rosin: 0.45 parts; water: 0.12 parts share.

[0023] Stir the tire crown rubber powder, liquid isoprene rubber LIR30, activator 520, rosin, and environmentally friendly naphthenic oil evenly, then put them into an electrically heated desulfurization tank, then add water, and feed 1.35Mpa high-pressure steam until the temperature reaches Keep at 225°C for 2.5 hours to obtain desulfurized rubber powder; cool the desulfurized rubber powder to below 45°C through a cooling conveyor; then refine the desulfurized rubber powder through a refiner and then release it into pieces to obtain environmentally friendly reclaimed rubber with high elasticity and low heat generation Gum.

Embodiment 2

[0025] Raw materials (by weight): tire crown rubber powder: 100 parts; liquid isoprene rubber LIR30: 15 parts; environmental naphthenic oil: 10 parts; activator 520: 0.5 parts; rosin: 0.45 parts; water: 0.12 parts share.

[0026] Stir the tire crown rubber powder, liquid isoprene rubber LIR30, activator 520, rosin, and environmentally friendly naphthenic oil evenly, then put them into an electrically heated desulfurization tank, then add water, and feed 1.35Mpa high-pressure steam until the temperature reaches Keep at 225°C for 2.5 hours to obtain desulfurized rubber powder; cool the desulfurized rubber powder to below 45°C through a cooling conveyor; then refine the desulfurized rubber powder through a refiner and then release it into pieces to obtain environmentally friendly reclaimed rubber with high elasticity and low heat generation Gum.

Embodiment 3

[0028] Raw materials (by weight): tire crown rubber powder: 100 parts; liquid isoprene rubber LIR30: 13 parts; environmental naphthenic oil: 10 parts; activator 520: 0.5 parts; rosin: 0.45 parts; water: 0.12 parts share.

[0029] Stir the tire crown rubber powder, liquid isoprene rubber LIR30, activator 520, rosin, and environmentally friendly naphthenic oil evenly, then put them into an electrically heated desulfurization tank, then add water, and feed 1.35Mpa high-pressure steam until the temperature reaches Keep at 225°C for 2.5 hours to obtain desulfurized rubber powder; cool the desulfurized rubber powder to below 45°C through a cooling conveyor; then refine the desulfurized rubber powder through a refiner and then release it into pieces to obtain environmentally friendly reclaimed rubber with high elasticity and low heat generation Gum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com