7-aminocephalosporanic acid production wastewater treatment method

A technology for the production of aminocephalosporanic acid and waste water, which is applied in water/sewage treatment, neutralized water/sewage treatment, multi-stage water/sewage treatment, etc. It can solve the problems of low treatment efficiency and unstable discharge of ammonia nitrogen, and achieve the goal of treatment High efficiency, small amount of work, simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

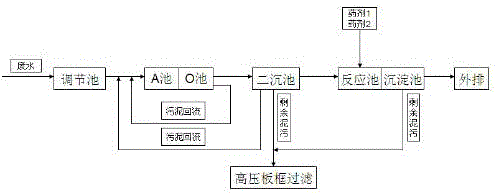

[0021] A kind of treatment method of 7-aminocephalosporanic acid production waste water, production process such as figure 1 As shown, it includes the following steps: injecting 7-aminocephalosporanic acid production wastewater into the regulating tank, adjusting the pH to 6; then injecting into the anoxic biochemical pool of section A--the aerobic biochemical pool of section O, and performing A / O process biochemical Treatment; MLSS in A / O process can reach 8500mg / L; in nitrification reaction, TKN / MLSS loading rate can reach 0.06gTKN / (gMLSS·d); sludge loading rate can reach 0.2KgBOD 5 / KgMLSS·d; the sludge age can be 3 times of the generation time of nitrifying bacteria; the total nitrogen concentration of sewage influent can reach 500mg / L; in the anoxic biochemical pool of section A, the DO value is controlled at 0-0.2mg / L; O In the aerobic biochemical pool, the DO value is 2-4 mg / L; the hydraulic retention time of nitrification reaction is 6h, and the denitrification hydraul...

Embodiment 2

[0023] A kind of treatment method of 7-aminocephalosporanic acid production waste water, production process such as figure 1 As shown, it includes the following steps: injecting 7-aminocephalosporanic acid production wastewater into the regulating tank, adjusting the pH to 8; then injecting into the anoxic biochemical pool of the A section-the aerobic biochemical pool of the O section, and performing the A / O process biochemical Treatment; MLSS in A / O process can reach 8500mg / L; in nitrification reaction, TKN / MLSS loading rate can reach 0.06gTKN / (gMLSS·d); sludge loading rate can reach 0.2KgBOD 5 / KgMLSS·d; the sludge age can be 3 times of the generation time of nitrifying bacteria; the total nitrogen concentration of sewage influent can reach 500mg / L; in the anoxic biochemical pool of section A, the DO value is controlled at 0-0.2mg / L; O In the aerobic biochemical pool section, the DO value is 2-4 mg / L; the hydraulic retention time of nitrification reaction is 6h, and the deni...

Embodiment 3

[0025] A kind of treatment method of 7-aminocephalosporanic acid production waste water, production process such as figure 1 As shown, it includes the following steps: injecting 7-aminocephalosporanic acid production wastewater into the regulating tank, and adjusting the pH to 10; Treatment; MLSS in A / O process can reach 8500mg / L; in nitrification reaction, TKN / MLSS loading rate can reach 0.06gTKN / (gMLSS·d); sludge loading rate can reach 0.2KgBOD 5 / KgMLSS·d; the sludge age can be 3 times of the generation time of nitrifying bacteria; the total nitrogen concentration of sewage influent can reach 500mg / L; in the anoxic biochemical pool of section A, the DO value is controlled at 0-0.2mg / L; O In the aerobic biochemical pool, the DO value is 2-4 mg / L; the hydraulic retention time of nitrification reaction is 6h, and the denitrification hydraulic retention time is 2h; the optimum pH of nitrification reaction is 8.4, and the optimum pH value of denitrification reaction is 7.5; The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com