Clay powder for improving vulcanization processability of rubber and preparation method for same

A processing performance, rubber vulcanization technology, applied in the direction of dyeing organosilicon compound treatment, dyeing low molecular organic compound treatment, fibrous filler, etc. Small problems, to achieve the effects of easy spray drying, reduced energy consumption, and easy dissociation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

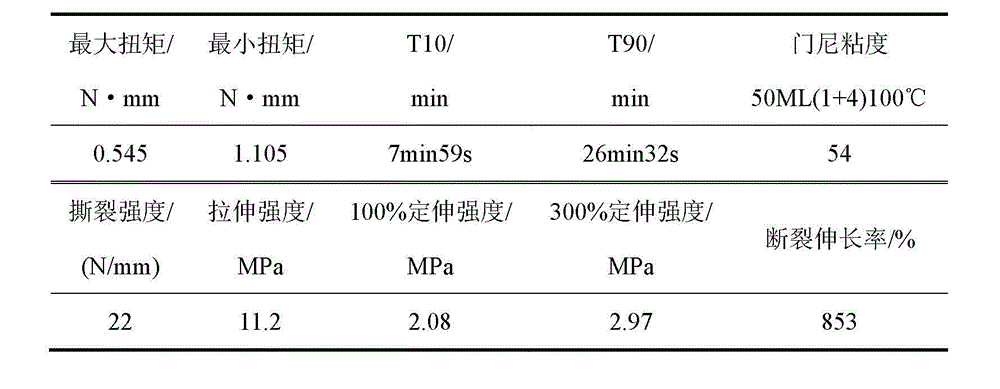

Embodiment 1

[0030] Take 1 kg of kaolin raw material and 1 kg of sodium bentonite raw material, and mix them evenly. Make a suspension of uniformly mixed clay powder and water at a solid content of 20%, add 20g (1.0% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 600r / Min, to fully disperse the clay powder in water; set aside for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and peeling machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 1.5h. Filter and extract the ground and stripped slurry; spray dry the extracted slurry to obtain a compound clay...

Embodiment 2

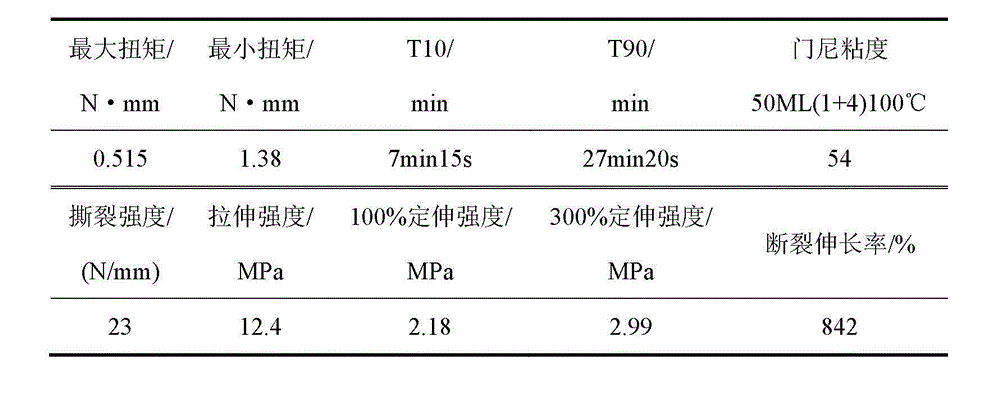

[0032]Take 2 kg of kaolin raw material and 1 kg of sodium bentonite raw material, and mix them evenly. Make the uniformly mixed clay powder and water into a suspension with a solid content of 25%, add 24g (0.8% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 500r / Min, to fully disperse the clay powder in water; set aside for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and peeling machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 1.5h. Filter and extract the ground and stripped slurry; spray dry the extracted slurry to obtain a compou...

Embodiment 3

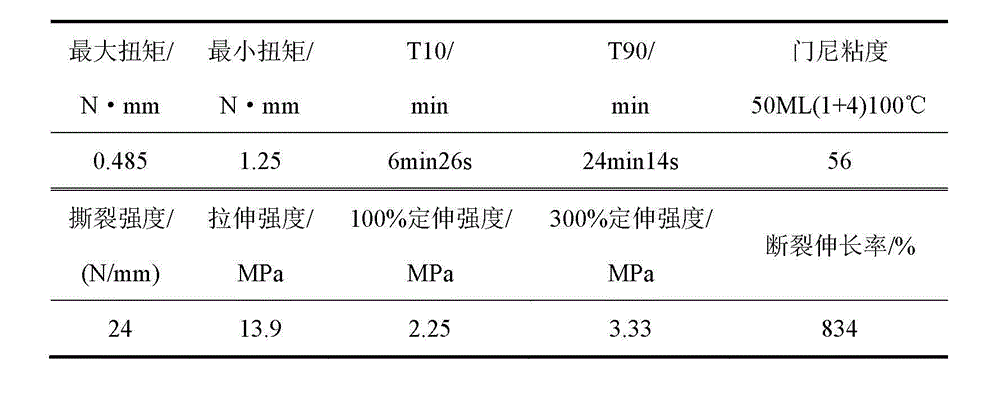

[0034] Take 4 kg of kaolin raw material and 1 kg of calcium-based bentonite raw material, and mix them evenly. Make a suspension of uniformly mixed clay powder and water at a solid content of 30%, add 30g (0.6% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 500r / Min, to fully disperse the clay powder in water; set aside for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and peeling machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 2h. Filter and extract the milled and stripped slurry; spray dry the extracted slurry to obtain a compound...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com