Method for preparing graphene-metal composite material based on pulse magnetic oscillation

A metal composite material, graphene technology, applied in graphene, nano carbon and other directions, can solve the problem of poor bonding strength between graphene and metal, and achieve the effects of stable product quality, strong convection, and metal grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

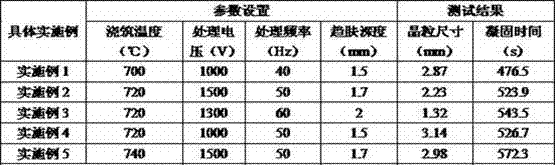

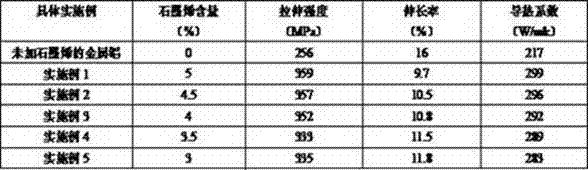

Embodiment 1

[0030] A method for preparing graphene-metal composite materials based on pulsed magnetic oscillation, the specific process of preparing graphene-metal composite materials is as follows:

[0031] First, add 5kg of natural flake graphite to 2kg of concentrated sulfuric acid, then add 7kg of acetic anhydride, 0.5kg of hydrogen peroxide and 0.6kg of potassium dichromate in sequence, stir continuously, react at 40°C for 70min, wash until neutral, and Dry at 60°C. It is then exfoliated at a high temperature of 900 °C to obtain expanded graphite. Then, heat and melt 100kg of metal aluminum in a resistance furnace, and preheat the crucible equipped with a temperature acquisition device at the same time. After pouring the molten aluminum into the crucible at 700°C, add the pretreated expanded graphite Disperse evenly on the surface of metal aluminum melt and keep it warm for 30min. When the temperature of the metal aluminum melt drops below the liquidus line, the crucible is placed ...

Embodiment 2

[0034] A method for preparing graphene-metal composite materials based on pulsed magnetic oscillation, the specific process of preparing graphene-metal composite materials is as follows:

[0035] First, add 5kg of natural flake graphite to 2.5kg of concentrated sulfuric acid, then add 7.6kg of acetic anhydride, 0.4kg of hydrogen peroxide and 0.7kg of potassium dichromate in sequence, keep stirring, react at 50°C for 60min, and wash until neutral. and dried at 60°C. It is then exfoliated at a high temperature of 900 °C to obtain expanded graphite. Then, heat and melt 111kg of metal aluminum in a resistance furnace, and preheat the crucible equipped with a temperature acquisition device at the same time, pour the molten aluminum into the crucible at 720°C, add the pretreated expanded graphite Disperse evenly on the surface of metal aluminum melt and keep it warm for 30min. When the temperature of the metal aluminum melt drops below the liquidus line, the crucible is placed in ...

Embodiment 3

[0038] A method for preparing graphene-metal composite materials based on pulsed magnetic oscillation, the specific process of preparing graphene-metal composite materials is as follows:

[0039] First, add 5kg of natural flake graphite to 3kg of concentrated sulfuric acid, then add 6.8kg of acetic anhydride, 0.6kg of hydrogen peroxide and 0.6kg of potassium dichromate in sequence, stir continuously, react at 55°C for 50min, wash until neutral, and Dry at 60°C. It is then exfoliated at a high temperature of 900 °C to obtain expanded graphite. Then, heat and melt 125kg of metal aluminum in a resistance furnace, and preheat the crucible equipped with a temperature acquisition device at the same time. After pouring the molten aluminum into the crucible at 720°C, add the pretreated expanded graphite Disperse evenly on the surface of metal aluminum melt and keep it warm for 30min. When the temperature of the metal aluminum melt drops below the liquidus line, place the crucible in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com