Environment-friendly acetal preparation method

An environmentally friendly and acetal technology, which is applied in the preparation of organic compounds, chemical instruments and methods, organic chemistry, etc., can solve the problems of long reaction time, increase of reaction raw materials, and difficult environmental protection problems, and achieve easy handling and preparation process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

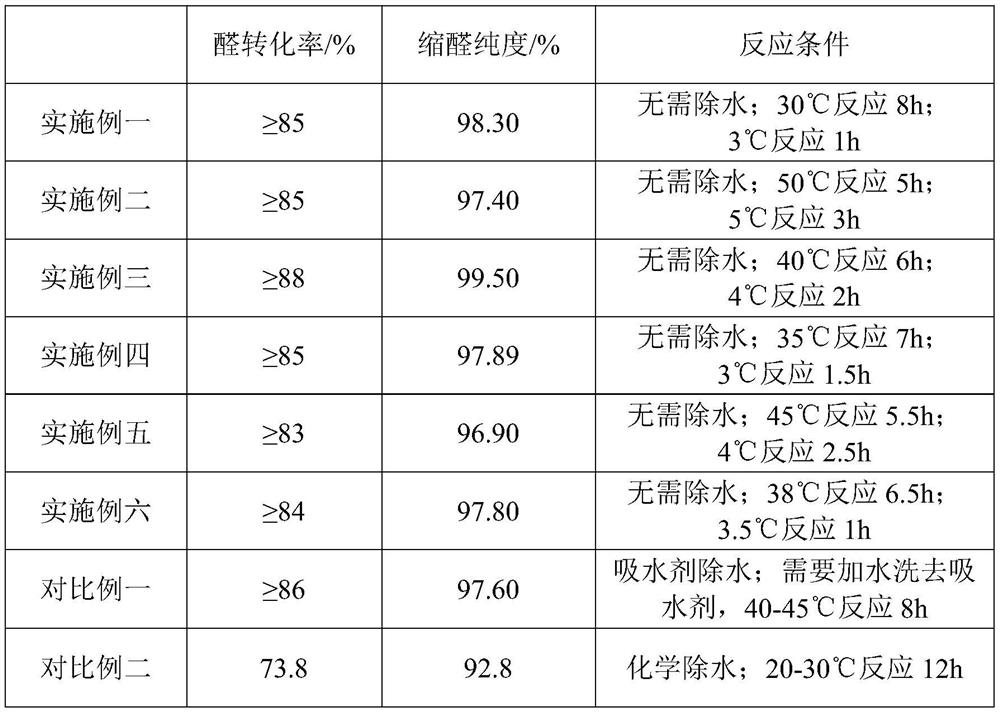

Embodiment 1

[0022] An environment-friendly preparation method of acetal, comprising the steps of:

[0023] S1, first add 175.05g of cyclohexane (2.08mol) into the four-necked flask, then add 62.48g of methanol (1.95mol) and 0.69g of formic acid (0.015mol), and stir evenly, then slowly drop into the reaction kettle Add 58.08g of propionaldehyde (1mol), continue to stir during the dropwise addition, and control the reaction temperature at 30°C and the dropwise addition time at 8h;

[0024] S2, after the dropwise addition of propionaldehyde, the temperature of the reaction solution is lowered to 3° C., and the reaction is kept for 1 hour, and the conversion rate of propionaldehyde is ≥85%.

[0025] S3, after the reaction, adjust the pH of the reaction solution to 6, and let the reaction solution stand for 0.5 h, then remove the water in the lower layer, and rectify the reaction solution in the upper layer to obtain acetal with a purity of 98.3%.

Embodiment 2

[0027] An environment-friendly preparation method of acetal, comprising the steps of:

[0028] S1, first add 129.27g of n-hexane (1.5mol) into the four-necked flask, then add 71.13g of methanol (2.22mol) and 0.29g of methanesulfonic acid (0.003mol), and stir evenly, and then slowly pour into the reaction kettle Add 72.11 g of butyraldehyde (1 mol) dropwise, continue stirring during the dropwise addition, and control the reaction temperature at 50° C., and the dropping time at 5 h;

[0029] S2, after the butyraldehyde is added dropwise, the temperature of the reaction solution is lowered to 5° C., and the reaction is kept for 3 hours; at this time, the conversion rate of butyraldehyde is ≥85%.

[0030] S3, after the reaction, adjust the pH of the reaction solution to 7, and let the reaction solution stand for 1 hour, then remove the water in the lower layer, and rectify the reaction solution in the upper layer to obtain acetal with a purity of 97.4%.

Embodiment 3

[0032] An environment-friendly preparation method of acetal, comprising the steps of:

[0033] S1, first add 250.5g of n-heptane (2.5mol) into the four-necked flask, then add 67.28g of methanol (2.10mol) and 1.12g of p-toluenesulfonic acid (0.0065mol), and stir evenly, and then add Slowly add 72.11g of isobutyraldehyde (1mol) dropwise to the mixture, continue to stir during the dropwise addition, and control the reaction temperature at 40°C and the dropwise addition time at 6h;

[0034] S2, after the isobutyraldehyde is added dropwise, the temperature of the reaction solution is lowered to 4° C., and the reaction is kept for 2 hours; at this time, the conversion rate of isobutyraldehyde is ≥88%.

[0035] S3, after the reaction, adjust the pH of the reaction solution to 6.5, and let the reaction solution stand for 40 minutes, then remove the water in the lower layer, and rectify the reaction solution in the upper layer to obtain acetal with a purity of 99.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com