Preprocessing method of fluorine-containing iron ore

A pretreatment and iron ore technology, applied in the field of chemical metallurgy, can solve the problems of poor control of fluorine elements, complicated operating procedures, and many influencing factors, and achieve the effects of low roasting temperature, simple process, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

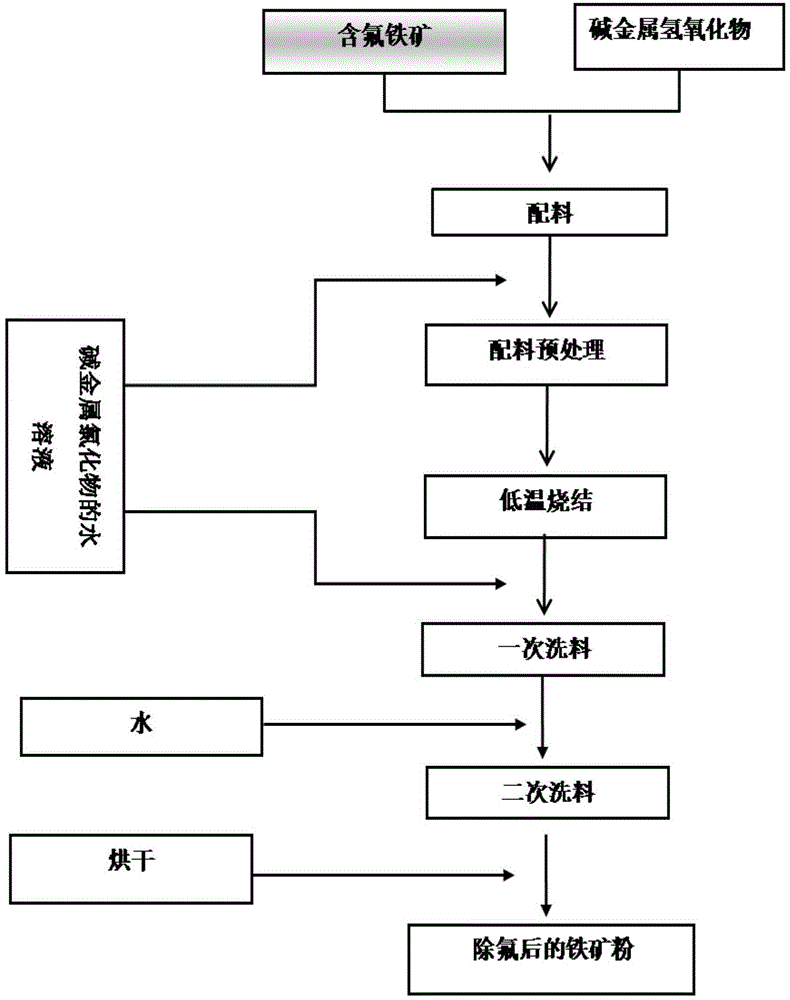

Method used

Image

Examples

Embodiment 1

[0027] (1) Ingredients:

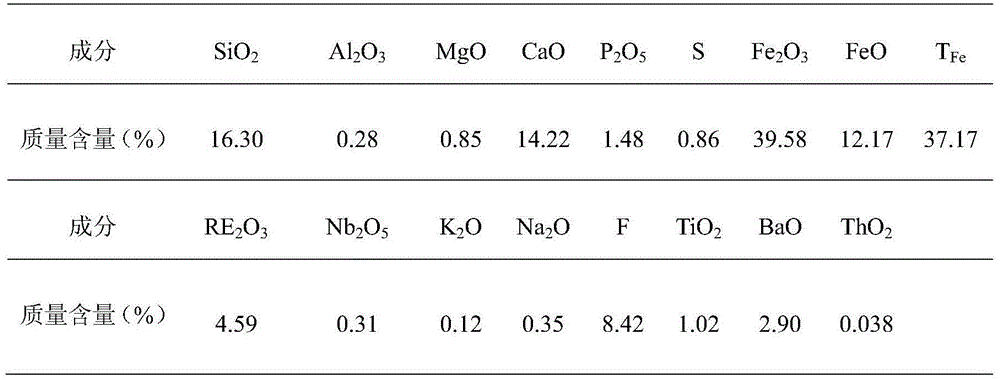

[0028] The Baiyan Obo fluoride-containing iron ore with the composition shown in Table 1 is initially crushed, and 1 kg of the initially crushed Baiyun Obo fluoride-containing iron ore and 1.2 kg of sodium hydroxide are added to a ball mill for blending and grinding until the particle size of the material is 200 mesh. the following;

[0029] (2) Pretreatment of ingredients:

[0030] Add 0.8kg of seawater with a weight percentage of 3.5% sodium chloride to the above-mentioned ground ingredients, stir and mix, then control the temperature at 80-100°C, and dry;

[0031] (3) Low temperature sintering:

[0032] Put the above-mentioned pretreated ingredients into the furnace, control the temperature at 200°C for sintering, and the sintering time is 50 minutes;

[0033] (4) Primary wash:

[0034] According to the proportion of 125g / 1L of the material after low-temperature sintering treatment and seawater with 3.5% by weight of sodium chloride, seawater w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com