Preparation method of acidic soil conditioner containing water-soluble humic acid

A water-soluble humic acid, acid soil technology, applied in soil conditioning materials, chemical instruments and methods, organic fertilizers, etc., can solve the problems of difficult application, complex equipment, large investment, and complicated steps, so as to reduce the symptoms of deficiency and improve the Crop yield, effect of improving soil structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

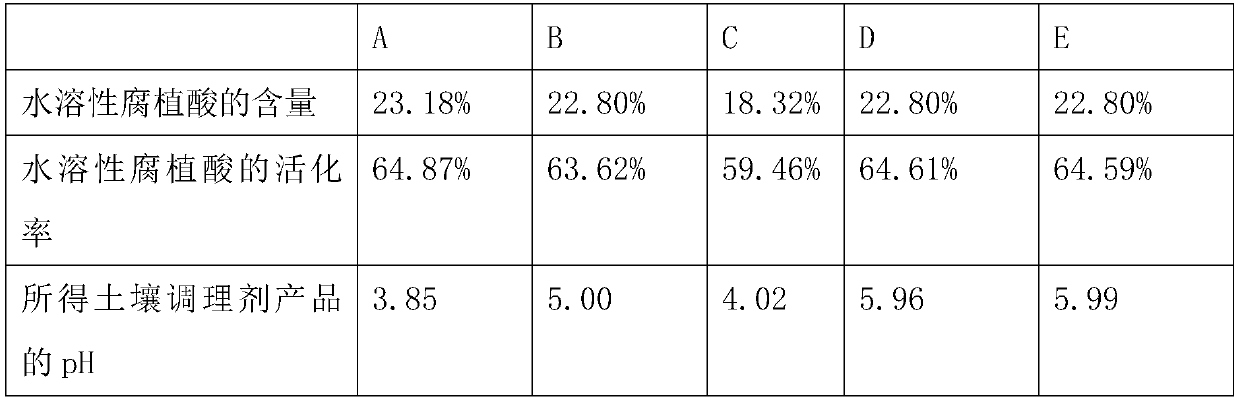

Embodiment 1

[0026] A preparation method of an acidic soil conditioner containing water-soluble humic acid: Grind 100g of weathered coal to 70 mesh, then add 30g of ammonium citrate and 80g of water, stir evenly, and react under 220r / min mechanical stirring at 80°C After 2 hours, the reactant was dried to prepare 130 g of acidic soil conditioner A containing water-soluble humic acid.

Embodiment 2

[0028] A preparation method of an acidic soil conditioner containing water-soluble humic acid: grind 100g of lignite to 40 mesh, then add 20g of potassium citrate and 60g of water, stir evenly, and react at 60°C with 180r / min mechanical stirring for 0.5 h, the reactant was dried to prepare 120g of acidic soil conditioner B containing water-soluble humic acid.

Embodiment 3

[0030] A preparation method of an acidic soil conditioner containing water-soluble humic acid: Grind 100g of peat to 100 mesh, then add 10g of sodium citrate and 100g of water, stir evenly, and react under mechanical stirring at 100°C and 260r / min After 24 hours, the reactant was dried to prepare 110 g of acidic soil conditioner C containing water-soluble humic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com