Method for preparing hierarchical structure positive pole material for lithium ion battery and application

A lithium-ion battery, hierarchical structure technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of not meeting the power supply requirements of advanced electronic equipment, unable to take advantage of LiCl modification, and unsatisfactory discharge performance. Weakening the effect of polarization phenomenon, regular micro-morphology and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

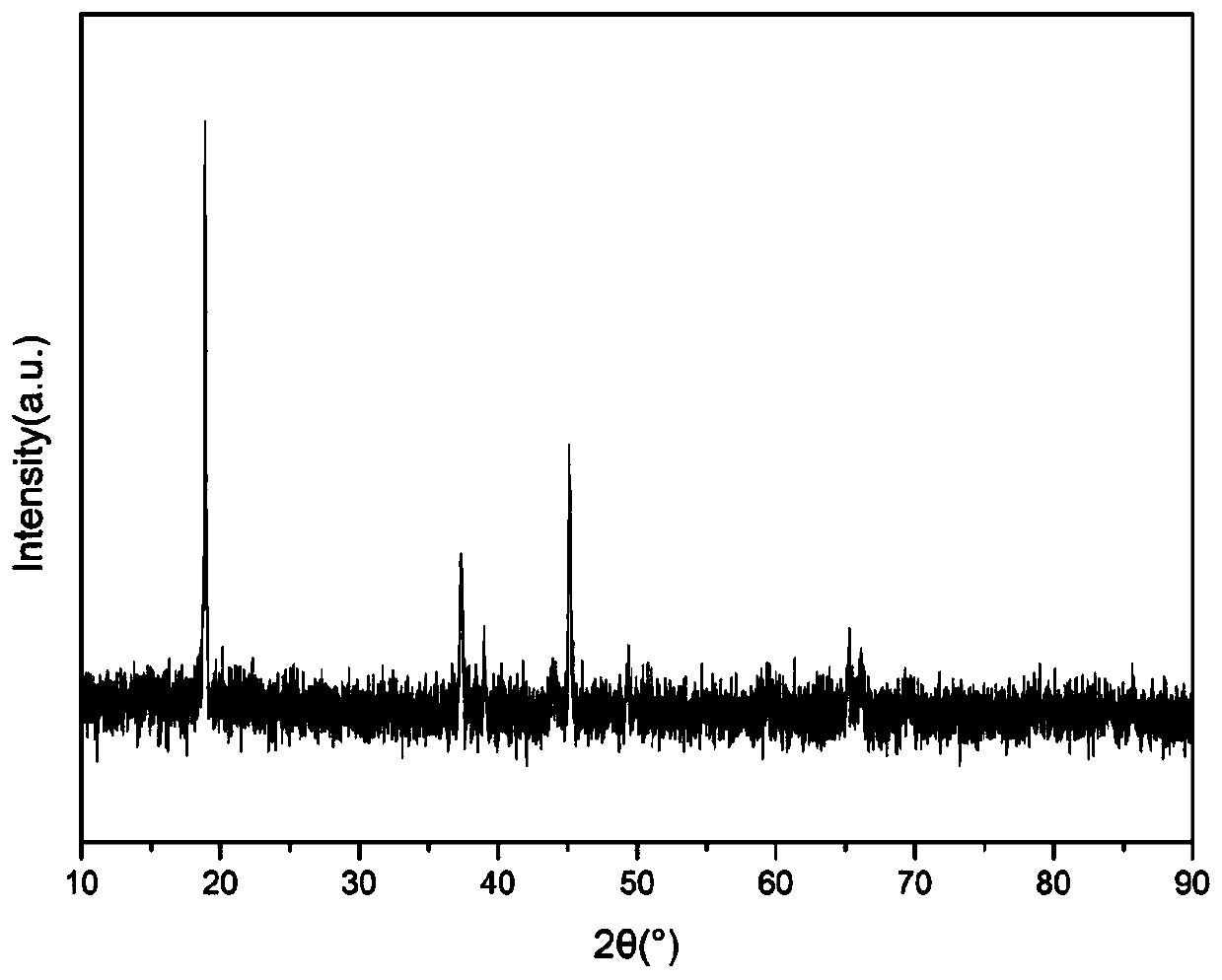

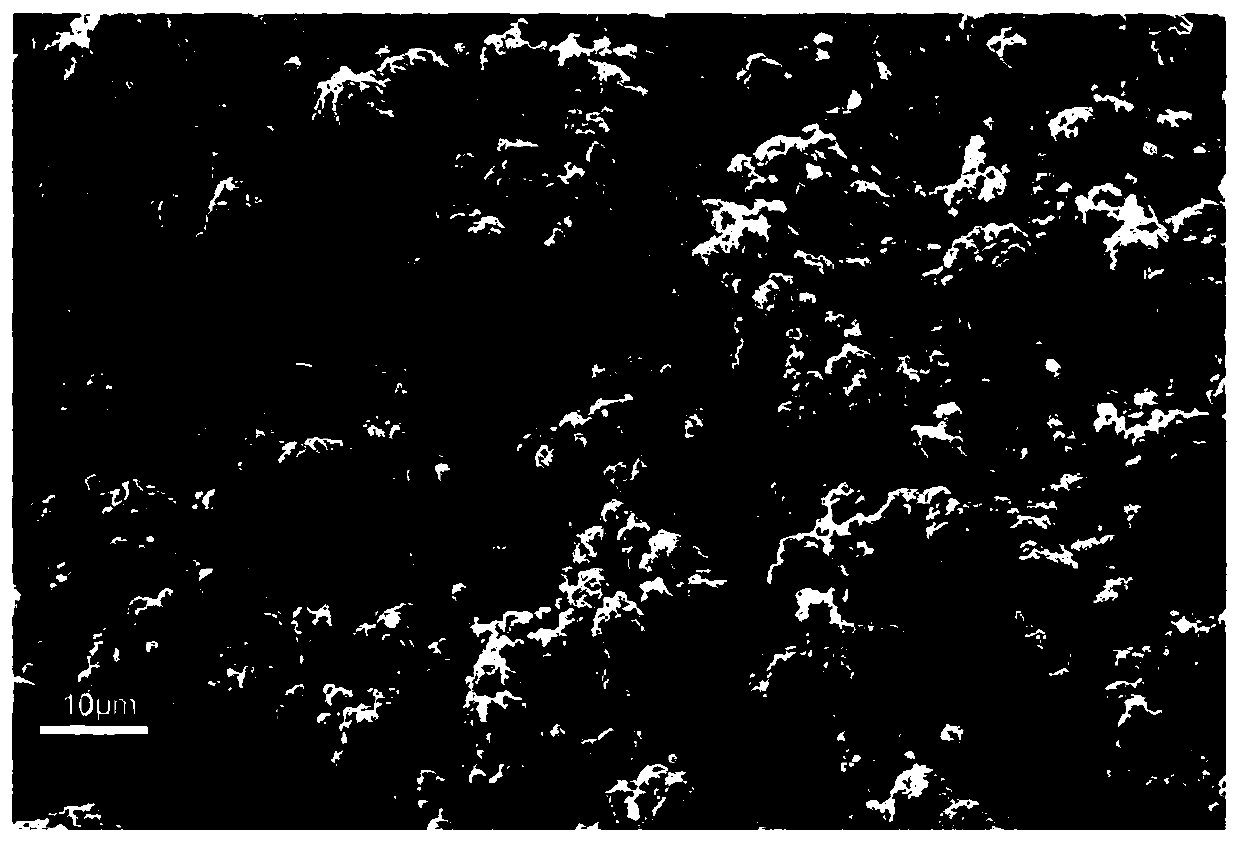

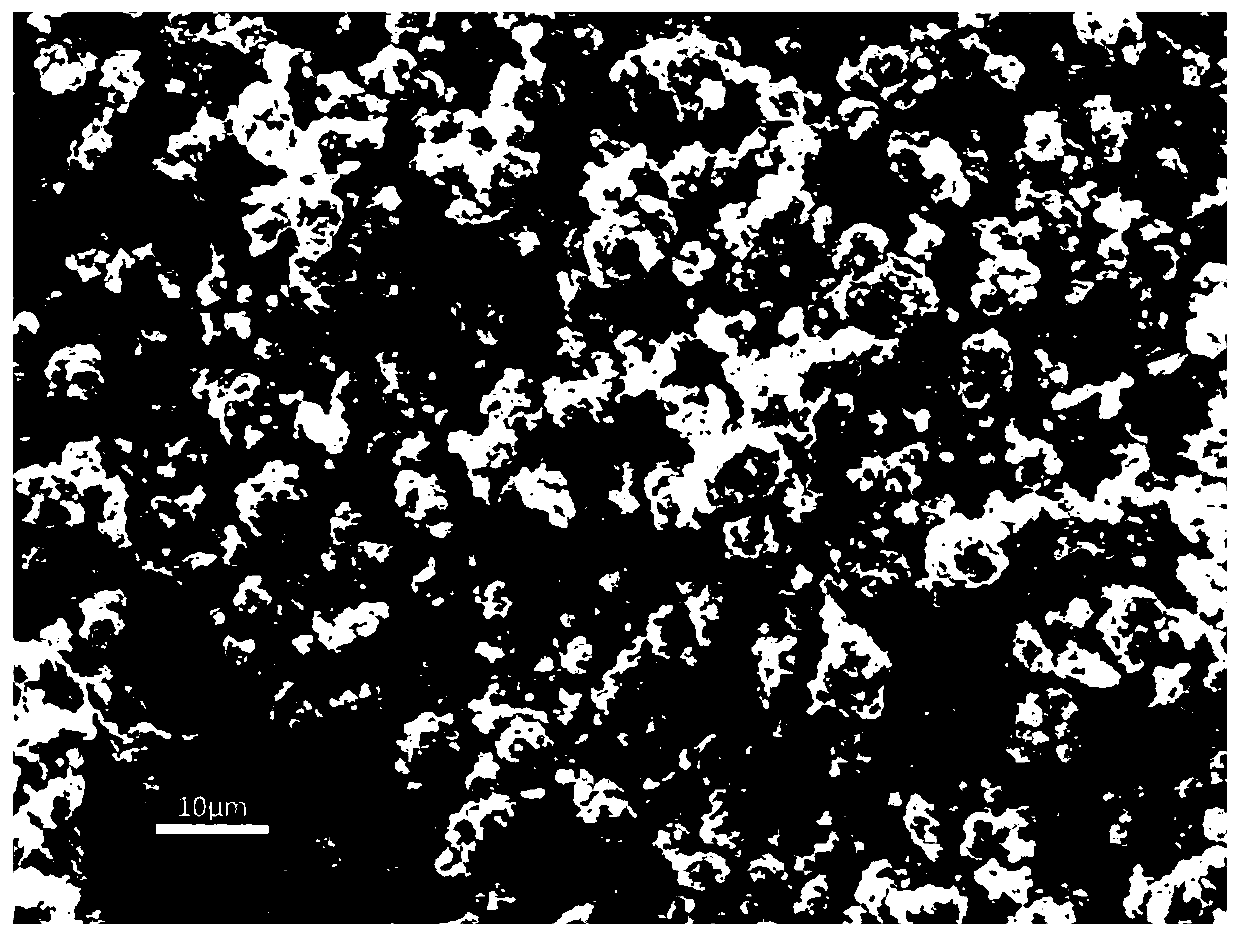

[0043] A kind of hierarchical structure cathode material for lithium-ion batteries, the specific chemical formula is LiNi 0.8 co 0.19 Al 0.01 o 1.90 Cl 0.1 ; The microscopic appearance is at least microspheres composed of 10 single-layer nanosheet stacks, and the preparation method specifically includes the following steps:

[0044] ① Weighing: Weigh lithium nitrate, nickel nitrate, cobalt nitrate, aluminum nitrate and lithium chloride in total 100g according to the molecular formula and stoichiometric ratio;

[0045] ②Water mixing: add lithium nitrate, nickel nitrate, cobalt nitrate, and aluminum nitrate weighed in step ① into a blender with 1000g of distilled water, and stir evenly at a speed of 80r / min until a clear solution is obtained, which is an aqueous solution for use;

[0046] ③ Molten salt mixing: Put LiCl in a ceramic container and heat it to clear liquid A at 620°C; then pour the aqueous solution obtained in step ② into the ceramic container, and heat it in a ...

Embodiment 2

[0051] A kind of hierarchical structure cathode material for lithium-ion batteries, the specific chemical formula is LiNi 0.37 co 0.6 Al 0.03 o 1.95 Cl 0.05 ; The microscopic appearance is at least microspheres composed of 10 single-layer nanosheet stacks, and the preparation method specifically includes the following steps:

[0052] ① Weighing: Weigh lithium nitrate, nickel nitrate, cobalt nitrate, aluminum nitrate and lithium chloride in total 500g according to the molecular formula and stoichiometric ratio;

[0053] ②Water mixing: add lithium nitrate, nickel nitrate, cobalt nitrate, and aluminum nitrate weighed in step ① into a blender with 3500g of ultrapure water, and stir evenly at a speed of 180r / min until a clear solution is obtained, that is, an aqueous solution spare;

[0054] ③ Molten salt mixing: Put LiCl in a ceramic container and heat it to clear liquid A at 670°C; then pour the aqueous solution obtained in step ② into the ceramic container and heat it in a ...

Embodiment 3

[0059] A kind of hierarchical structure cathode material for lithium-ion batteries, the specific chemical formula is LiNi 0.35 co 0.6 Al 0.05 o 1.9 Cl 0.1 ; The microscopic appearance is at least microspheres composed of 10 single-layer nanosheet stacks, and the preparation method specifically includes the following steps:

[0060] ① Weighing: Weigh lithium nitrate, nickel nitrate hexahydrate, cobalt nitrate hexahydrate, aluminum nitrate nonahydrate and lithium chloride in total 500g according to the molecular formula and stoichiometric ratio.

[0061] ②Water mixing: Add lithium nitrate, nickel nitrate hexahydrate, cobalt nitrate, and aluminum nitrate weighed in step ① into a stirrer and add 1500g of distilled water, and stir evenly at 200r / min until a clear solution is obtained, that is, an aqueous solution for use ;

[0062] ③ Molten salt mixing: Put LiCl in a ceramic container and heat it to clear liquid A at 670°C; then pour the aqueous solution obtained in step ② int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com