Rubber hose inner rubber layer for ethanol resistant gasoline oiling machine and preparation method of rubber hose inner rubber layer

A technology for a rubber hose and a fuel dispenser, which is applied in the field of rubber hose preparation, can solve the problems of poor processing technology of chloroether rubber, high price of chloroether rubber, and high requirements for flame retardancy, and achieves shortening of mixing time and compatibility. Good, improved calendering and extrusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

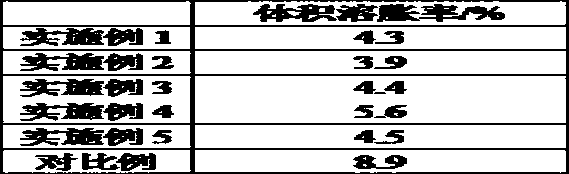

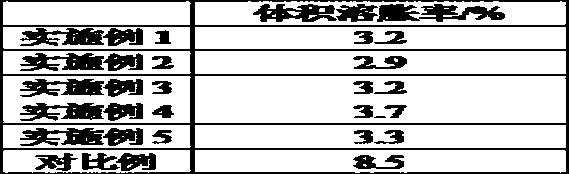

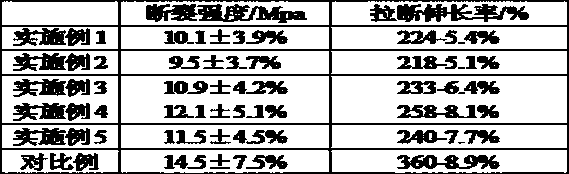

Examples

Embodiment 1

[0052] An inner rubber layer of a rubber hose for an ethanol-resistant gasoline fuel dispenser is made of the following raw materials in parts by weight: 65Kg of nitrile rubber, 26Kg of chlorosulfonated polyethylene rubber, 8Kg of leveling agent, 3Kg of zinc oxide, and stearic acid 1.5Kg, antioxidant 2Kg, carbon black 9.2Kg, white carbon black 8Kg, silica powder 17Kg, light calcium carbonate 10Kg, dioctyl ester 7Kg, sulfur 1.2Kg, accelerator 0.7Kg, vulcanization accelerator 0.9Kg, viscose Mixture 5.5Kg.

[0053] The preparation method comprises the following steps,

[0054] Step 1, masticating, add nitrile rubber, chlorosulfonated polyethylene rubber, and leveling agent in sequence to the internal mixer, control the speed of the internal mixer to 33r / min, and discharge the glue when the temperature of the internal mixer rises to 100°C, and obtain Mixed glue;

[0055] Step 2, thin pass, the temperature of the front roller and the rear roller of the open mill is raised to 58 °...

Embodiment 2

[0063] An inner rubber layer of a rubber hose for an ethanol-resistant gasoline fuel dispenser is made of the following raw materials in parts by weight: nitrile rubber 72Kg, chlorosulfonated polyethylene rubber 31Kg, leveling agent 11Kg, zinc oxide 3.5Kg, stearin Acid 1.2Kg, antioxidant 3.1Kg, carbon black 8.9Kg, white carbon black 10Kg, silica powder 18Kg, light calcium carbonate 11Kg, dioctyl fat 9Kg, sulfur 1.5Kg, accelerator 0.6Kg, vulcanization accelerator 0.8Kg , Adhesive 6.2Kg.

[0064] The preparation method comprises the following steps,

[0065] Step 1, masticating, add nitrile rubber, chlorosulfonated polyethylene rubber, and leveling agent in sequence to the internal mixer, control the speed of the internal mixer to 33r / min, and discharge the glue when the temperature of the internal mixer rises to 100°C, and obtain Mixed glue;

[0066] Step 2, thin pass, the temperature of the front roller and the rear roller of the open mill is raised to 56°C, the gap between ...

Embodiment 3

[0073] An inner rubber layer of a rubber hose for an ethanol-resistant gasoline fuel dispenser is made of the following raw materials in parts by weight: nitrile rubber 75Kg, chlorosulfonated polyethylene rubber 33Kg, leveling agent 12Kg, zinc oxide 3.8Kg, stearin Acid 1.5Kg, antioxidant 3.6Kg, carbon black 8Kg, white carbon black 11Kg, silica powder 23Kg, light calcium carbonate 12.5Kg, dioctyl fat 10Kg, sulfur 1.3Kg, accelerator 0.8Kg, vulcanization accelerator 1.0 Kg , Adhesive 6.8Kg.

[0074] The preparation method comprises the following steps,

[0075] Step 1, masticating, add nitrile rubber, chlorosulfonated polyethylene rubber, and leveling agent in sequence to the internal mixer, control the speed of the internal mixer to 33r / min, and discharge the glue when the temperature of the internal mixer rises to 100°C, and obtain Mixed glue;

[0076] Step 2, thin pass, the temperature of the front roller and the rear roller of the open mill is raised to 58 ° C, the gap betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com