A kind of method of lignin silicon dioxide composite modified natural rubber masterbatch

A technology of silicon dioxide and natural rubber, applied in the field of biomass energy chemical industry, can solve the problems of affecting the physical and mechanical properties of rubber, the inorganic nanoparticles are not easily dispersed, and the utilization rate of rice husks is low, so as to reduce the energy consumption of mixing and improve the physical and mechanical properties. Mechanical properties, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

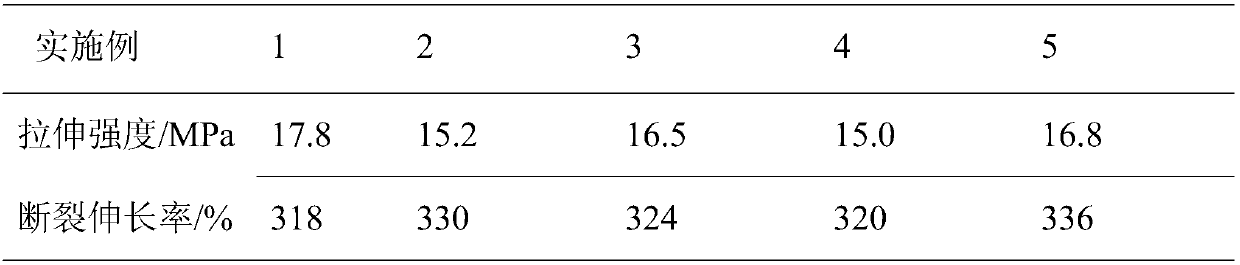

Embodiment 1

[0045] Step 1. Mix rice husk and sulfuric acid (3wt%) according to a solid-to-liquid ratio of 1kg:10L, heat to reflux and azeotrope for 2h, after filtering, wash the obtained filter residue until neutral, and dry;

[0046] Step 2. Mix the dried filter residue obtained in step 1 with sodium hydroxide (8wt%) at a solid-to-liquid ratio of 1kg:12L, heat and reflux for azeotropic 6h, and filter to obtain the filtrate;

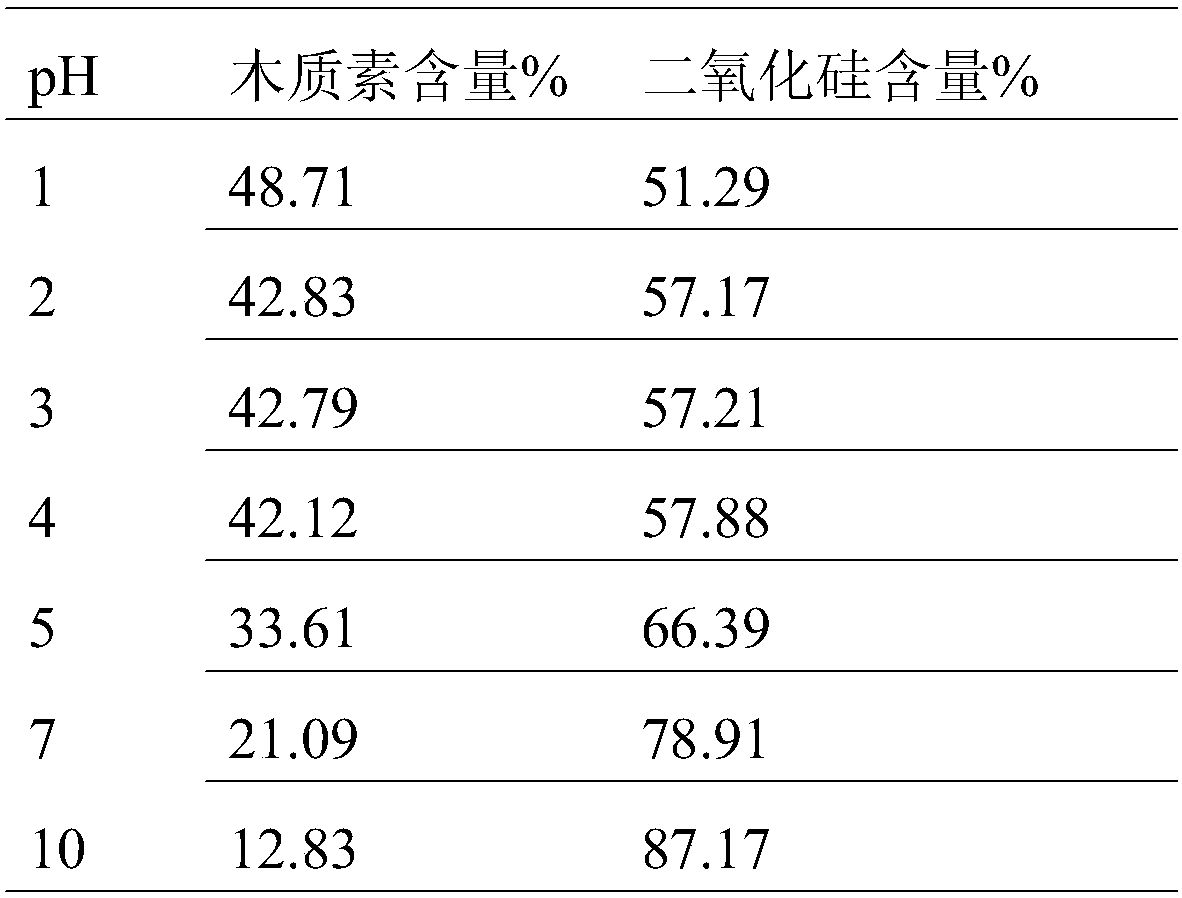

[0047] Step 3. Add sulfuric acid (15wt%) dropwise to the filtrate under stirring at 90°C, adjust the pH to 1, 2, 3, 4, 5, 7, 10 respectively, continue the reaction for 2 hours, filter, and wash the filter cake to medium properties, drying, to obtain lignin-silica composite fillers with different compositions;

[0048] Step 4, the lignin silica composite filler obtained when the pH is 3, the aqueous ethanol solution that is dissolved with KH550 (KH550: ethanol: the mass ratio of water is 10:95:5) and water are 1kg by solid-to-liquid ratio: Mix 5L:2L, ultrasonically ...

Embodiment 2

[0054] Step 1. Mix rice husk and sulfuric acid (3wt%) according to a solid-to-liquid ratio of 1kg:10L, heat and reflux azeotropically for 3h, filter, and wash the obtained filter residue until neutral, and dry;

[0055] Step 2. Mix the dried filter residue obtained in step 1 with sodium hydroxide (8wt%) in a mass ratio of 1kg:12L, heat and reflux for azeotropic 4h, and filter to obtain the filtrate;

[0056] Step 3. Add sulfuric acid (15wt%) dropwise to the filtrate under stirring at 90° C., adjust the pH to 10, continue the reaction for 2 hours, filter, wash the filter cake until neutral, and dry to obtain a lignin-silica composite filler;

[0057] Step 4. Mix lignin silica composite filler, ethanol aqueous solution dissolved with KH570 (the mass ratio of KH570:ethanol:water is 20:95:5) and water according to the solid-to-liquid ratio of 1kg:10L:2L, and ultrasonically disperse 30min, obtain modified solution;

[0058] Step 5. Stir the modified liquid and natural latex with a...

Embodiment 3

[0061] Step 1. Mix rice husks with sulfuric acid (1 wt%) at a solid-to-liquid ratio of 1kg:7L, heat and reflux azeotropically for 2h, filter, and wash the obtained filter residue until neutral, then dry;

[0062] Step 2. Mix the dried filter residue in step 1 with sodium hydroxide (5.2wt%) at a solid-to-liquid ratio of 1kg:10L, heat to reflux and azeotrope for 4h, and filter to obtain the filtrate;

[0063] Step 3. Add sulfuric acid (10wt%) dropwise to the filtrate under stirring at 90°C, adjust the pH to 7, and age for 2 hours to obtain an alkaline mixed solution, filter, wash the filter cake until neutral, and dry to obtain woody Plain silica composite filler;

[0064] Step 4, mix the lignin silica composite filler, the aqueous ethanol solution with Si69 dissolved (the mass ratio of Si69:ethanol:water is 15:95:5) and water according to the solid-to-liquid ratio of 1kg:8L:2L, and ultrasonically disperse 25min, obtain modified solution;

[0065] Step 5. Stir the modified liq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com