Process for efficiently modifying waste polypropylene in green manner

A technology for waste polypropylene and polypropylene particles, which is applied in the field of green and efficient modification of waste polypropylene, can solve problems such as insignificant effects, and achieve the effects of avoiding secondary pollution, excellent performance indicators, and obvious enhancement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with the examples.

[0027] A green and high-efficiency modification process for waste polypropylene, which comprises the following steps:

[0028] (1) Crushing waste polypropylene and making polypropylene granules through a granulator, drying the polypropylene granules at a set temperature for two hours;

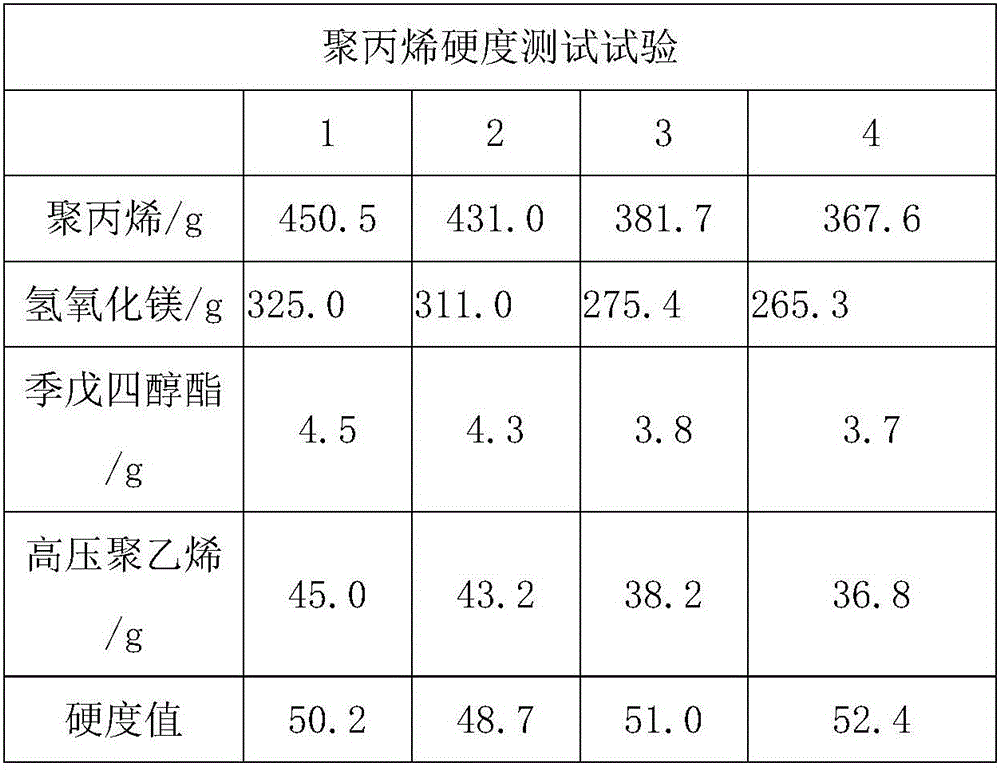

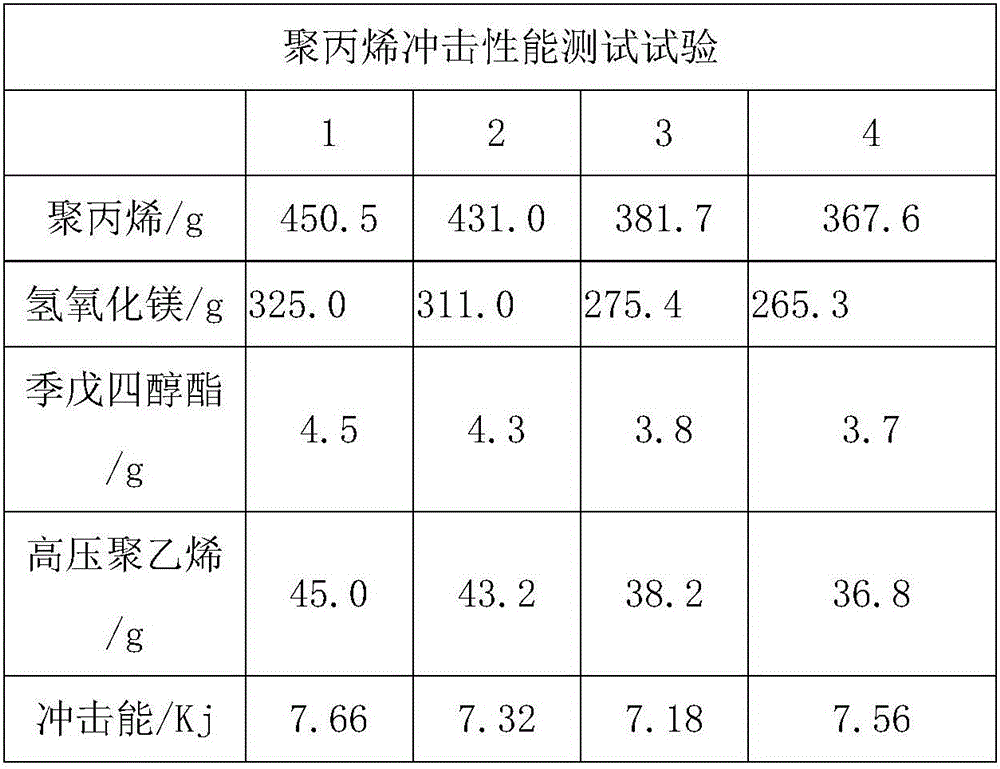

[0029] (2) Mix magnesium hydroxide, pentaerythritol ester, and high-pressure polyethylene with polypropylene particles according to the set addition amount;

[0030] (3) add the dispersant of setting mass percentage in the mixture of step (2) gained and stir it and make it mix;

[0031] (4) set the temperature and the screw speed of the twin-screw extruder, add the final compound formed in the step (3) into the twin-screw extruder and mix and extrude continuously;

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com