Clay powder for improving vulcanization processability of rubber and preparation method for same

A processability and rubber vulcanization technology, which is applied in the treatment of dyed organic silicon compounds, dyed low-molecular organic compounds, and fibrous fillers. Small problems, to achieve the effect of reducing energy consumption, easy to spray dry, easy to dissociate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

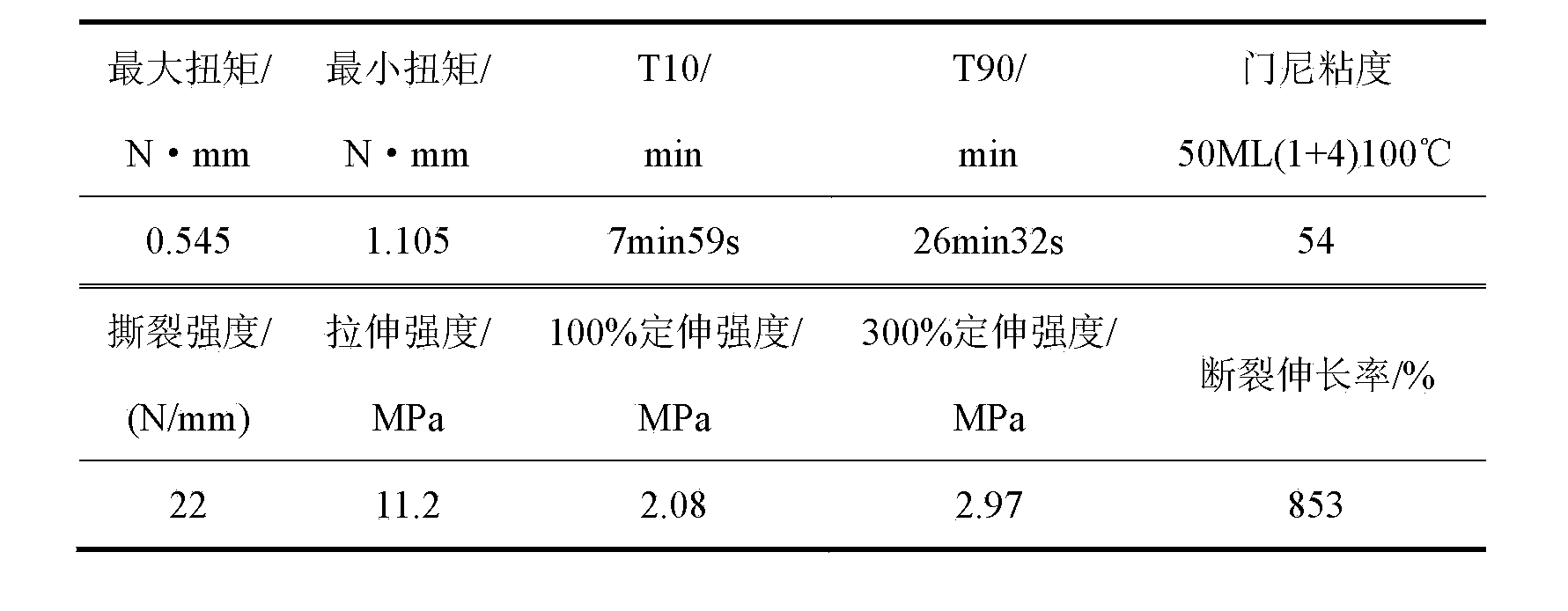

Embodiment 1

[0030] Take 1 kg of kaolin raw material and 1 kg of sodium bentonite raw material, and mix them evenly. Make a suspension of uniformly mixed clay powder and water at a solid content of 20%, add 20g (1.0% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 600r / Min, to fully disperse the clay powder in water; settle and stand for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and stripping machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 1.5h. Filter and extract the ground and peeled slurry; spray dry the extracted slurry to obtain a compou...

Embodiment 2

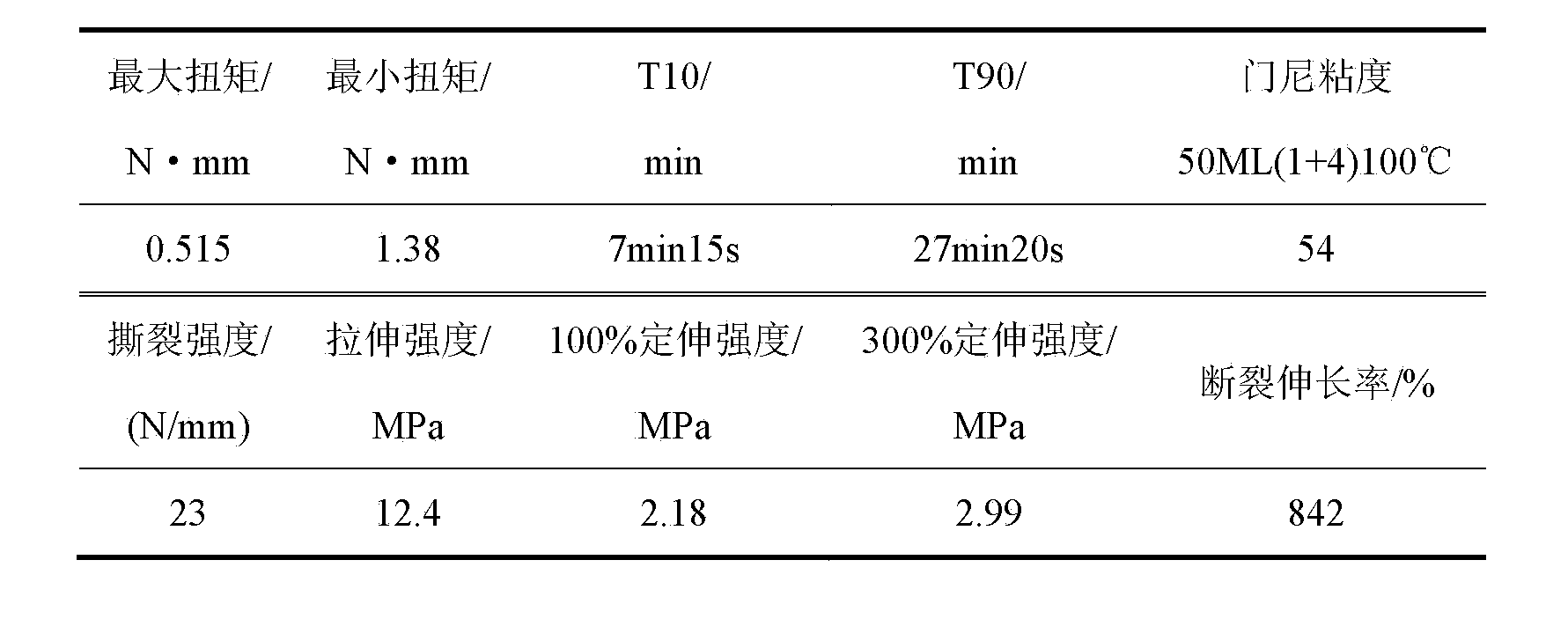

[0032]Take 2 kg of kaolin raw material and 1 kg of sodium bentonite raw material, and mix them evenly. Make the uniformly mixed clay powder and water into a suspension with a solid content of 25%, add 24g (0.8% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 500r / Min, to fully disperse the clay powder in water; set aside for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and peeling machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 1.5h. Filter and extract the ground and stripped slurry; spray dry the extracted slurry to obtain a compou...

Embodiment 3

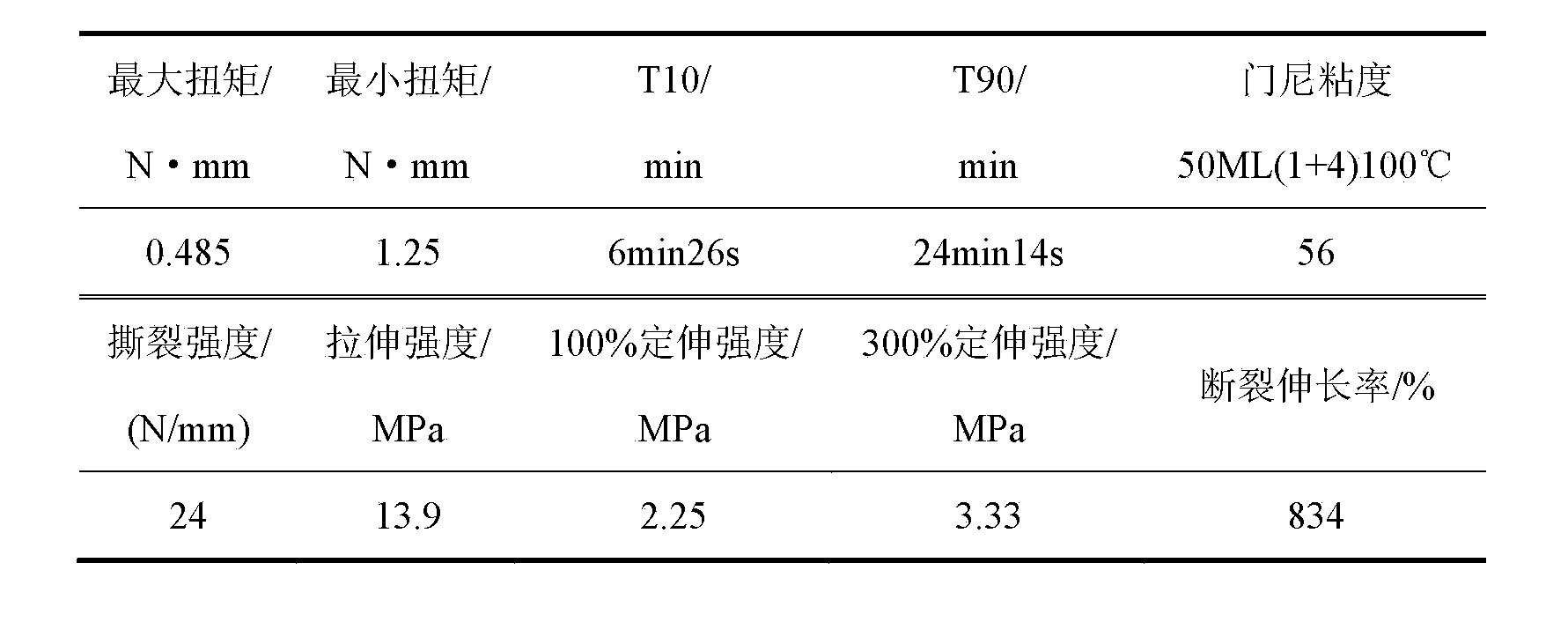

[0034] Take 4 kg of kaolin raw material and 1 kg of calcium-based bentonite raw material, and mix them evenly. Make a suspension of uniformly mixed clay powder and water at a solid content of 30%, add 30g (0.6% of the mass of the clay powder) of sodium polyacrylate as a dispersant, and stir in a mechanical stirrer for 0.5h at a stirring speed of 500r / Min, to fully disperse the clay powder in water; set aside for 10 hours, extract the suspension in the upper layer, put the suspension into a grinding and peeling machine and stir at a high speed for 1 hour at a stirring speed of 1000r / min. Then weigh the medium balls with the same mass as the suspension. The particle diameters of the medium balls are 0.6~0.8mm, 0.8~1.0mm, 1.0~1.2mm respectively, and the ratio is 3:2:1. The rotating speed of the grinding and peeling machine is 1200r / min, and the grinding and peeling time is 2h. Filter and extract the milled and stripped slurry; spray dry the extracted slurry to obtain a compound...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com