Auto controlling system of sugar cane press

An automatic control system, sugarcane technology, applied in the general control system, control/regulation system, adaptive control, etc., can solve the problems of uncontrollable water temperature, poor production safety and stability, affecting extraction rate and product quality, etc., to achieve Guarantee the effect of efficient crushing and high production safety rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

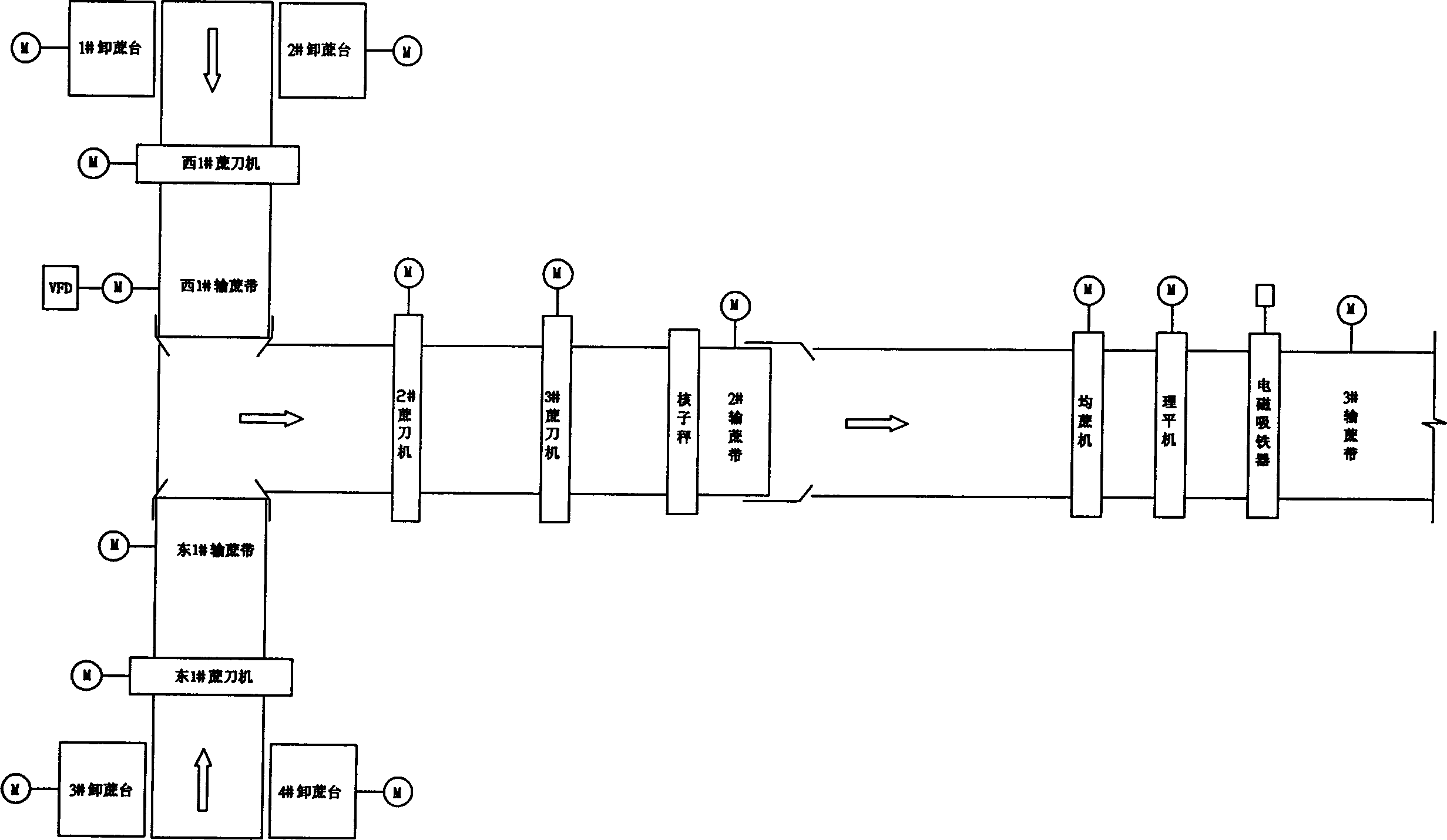

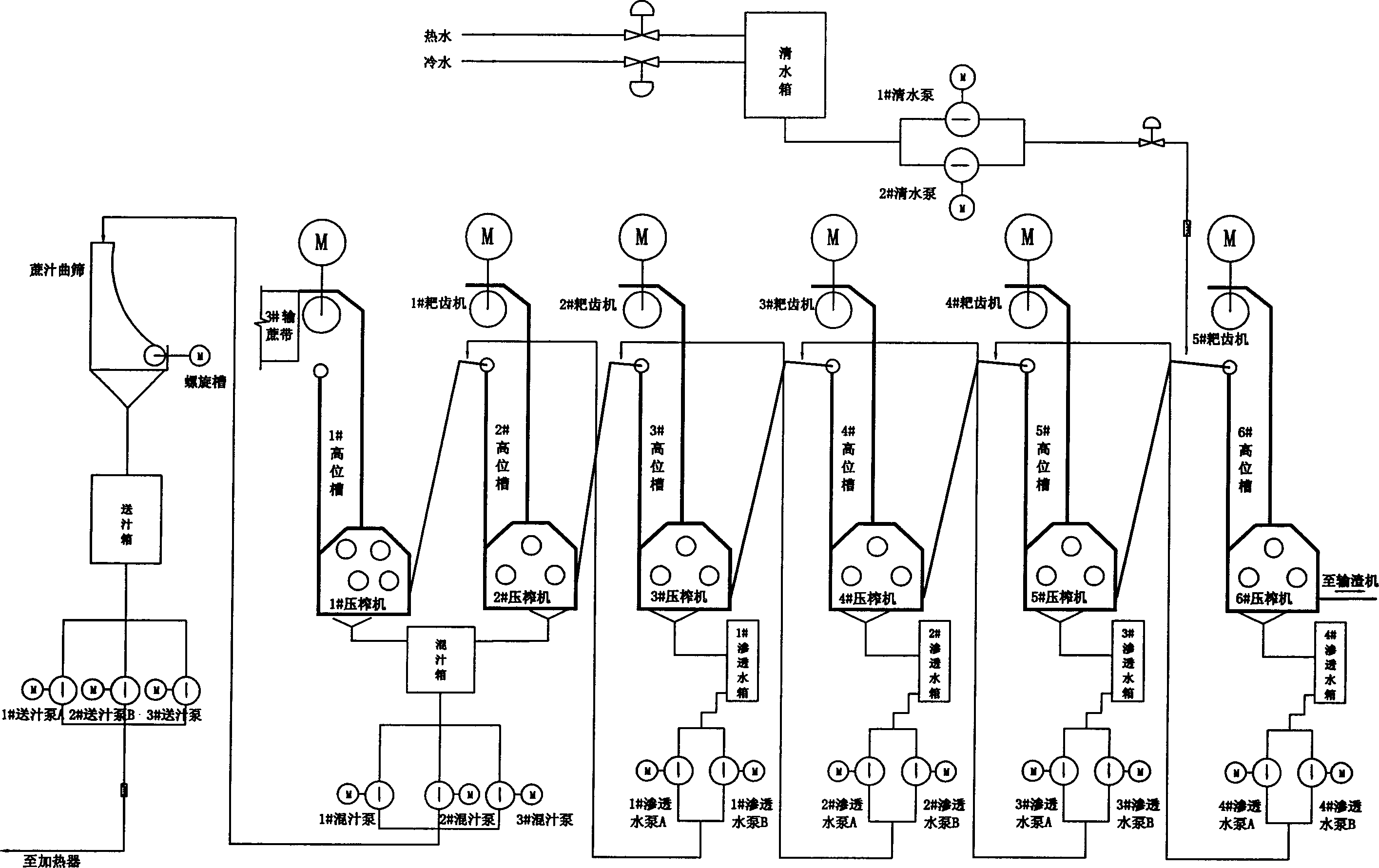

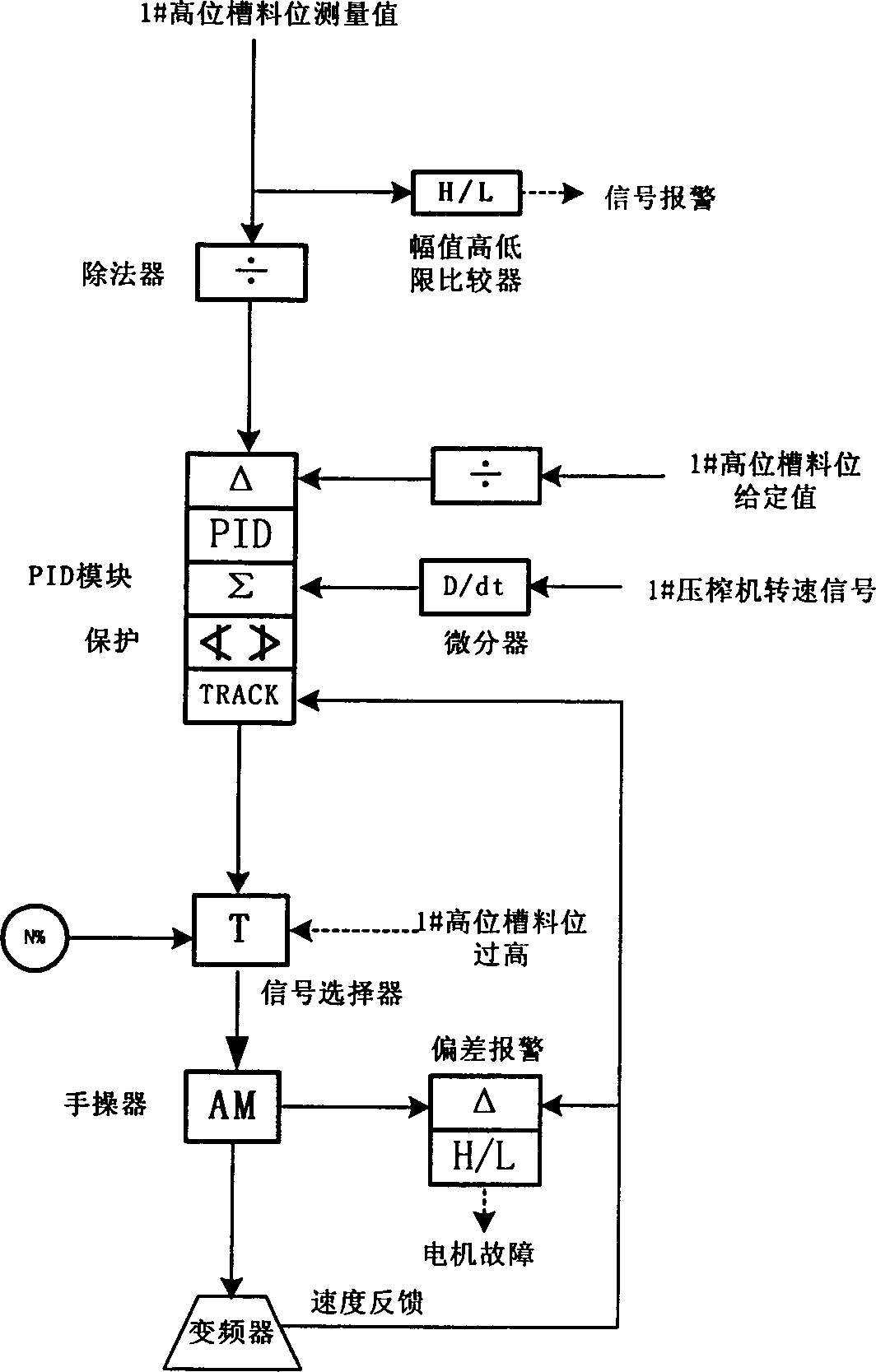

[0032] To use the automatic control system to achieve the balance and stability of the entire pressing process, the selection of the control mode, the setting of the adjustment loop, and the selection of the adjusted amount and the adjustment amount of each adjustment loop are very important. Figure 1A and Figure 1B Taking the crushing production line in , as an example, the automatic control method for sugarcane crushing and the corresponding system in the embodiment of the present invention will be described in detail.

[0033] In this embodiment, the rotational speed of the 1# press is manually set without automatic adjustment, and the set value is set according to the planned production output. The purpose of balanced production is met through the adaptive regulation of other regulation loops.

[0034] The analog quantity control of the cane conveying system includes the speed regulation loops of the 1# cane conveying belt, the 2# cane conveying belt and the 3# cane conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com