Carbon-coated lithium ion battery positive electrode material lithium iron phosphate and preparation method thereof

A carbon-coated technology for lithium iron phosphate and lithium ion batteries, applied in battery electrodes, chemical instruments and methods, circuits, etc., can solve the problems of low conductivity of lithium iron phosphate and lithium ion diffusion coefficient, etc. The effect of large capacity and cost reduction of production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

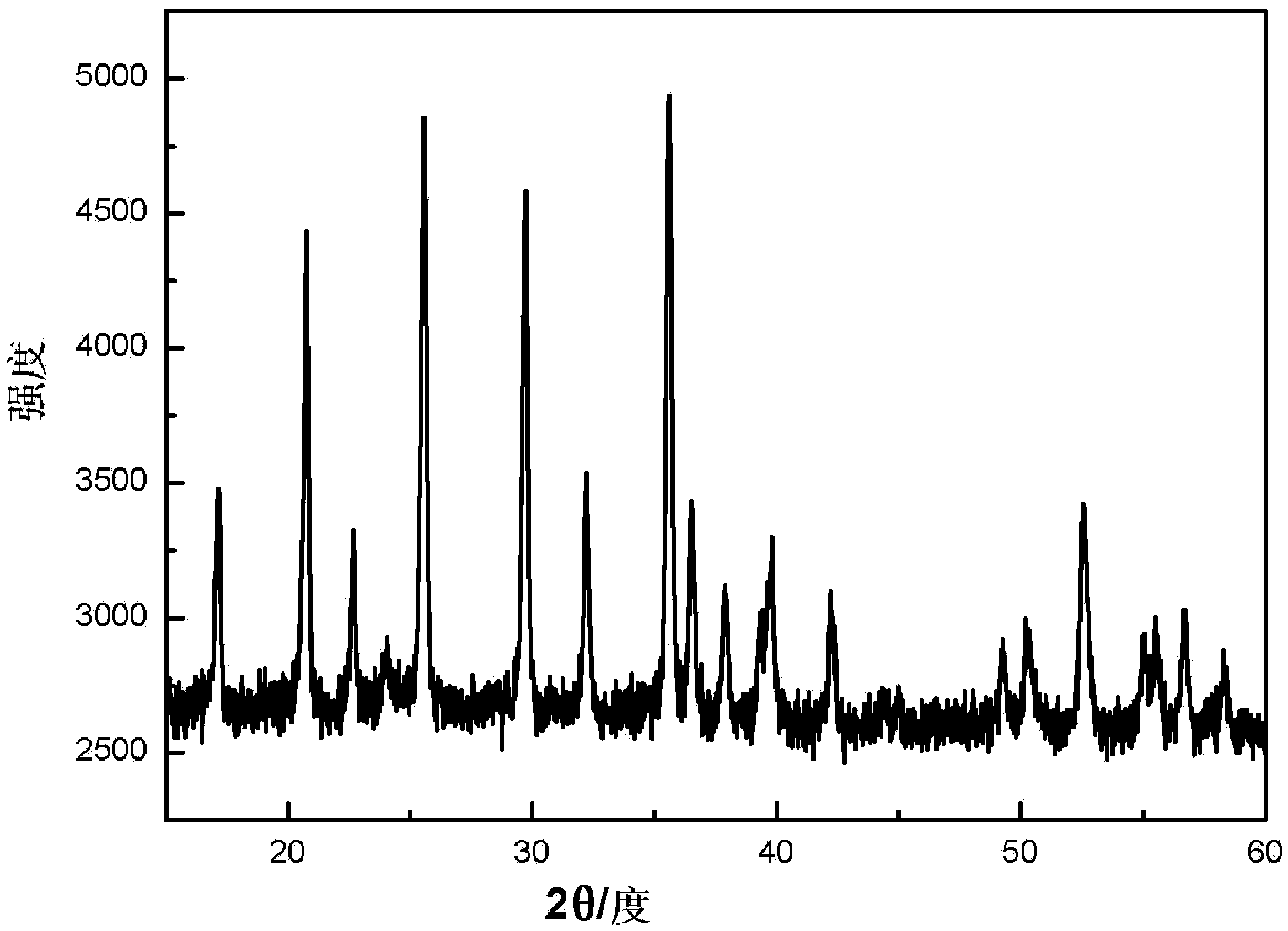

[0057] Dissolve 0.0024mol of citric acid and 0.0044mol of sucrose in 20ml of deionized water; dissolve 0.012mol of lithium carbonate in 80mL of deionized water; dissolve 0.024mol of ammonium dihydrogen phosphate and 0.024mol of ferric nitrate in 30ml and 60mL of deionized water; slowly add the lithium source, phosphorus source and ferric iron source to the mixed solution of citric acid and sucrose in turn, each solution needs to be stirred for a long enough time after adding, to ensure that each solution is added Finally, a uniformly mixed solution or suspension was obtained; the mixed solution was evaporated to dryness with magnetic stirring at a constant temperature of 80°C to obtain a precursor; the above precursor was pre-decomposed at 200°C for 2 hours; the pre-decomposed product was transferred to a high-temperature atmosphere furnace sintering at 650°C for 6h under the protection of argon or nitrogen, and cooling to room temperature with the furnace, the lithium iron pho...

Embodiment 2

[0061] Similar to Example 1, the preparation process of the precursor is exactly the same, the difference is that the condition of high temperature annealing is to sinter at 600°C for 6 hours under the protection of argon, and then cool to room temperature with the furnace to obtain the carbon-coated lithium-ion battery cathode material iron phosphate Lithium (LiFePO 4 ) nanoparticles.

[0062] X-ray powder diffraction analysis shows that the product is pure phase lithium iron phosphate (LiFePO 4 ); According to the scanning electron microscope analysis, the particle dispersibility of the product is good, and the particle size is about 150-220nm.

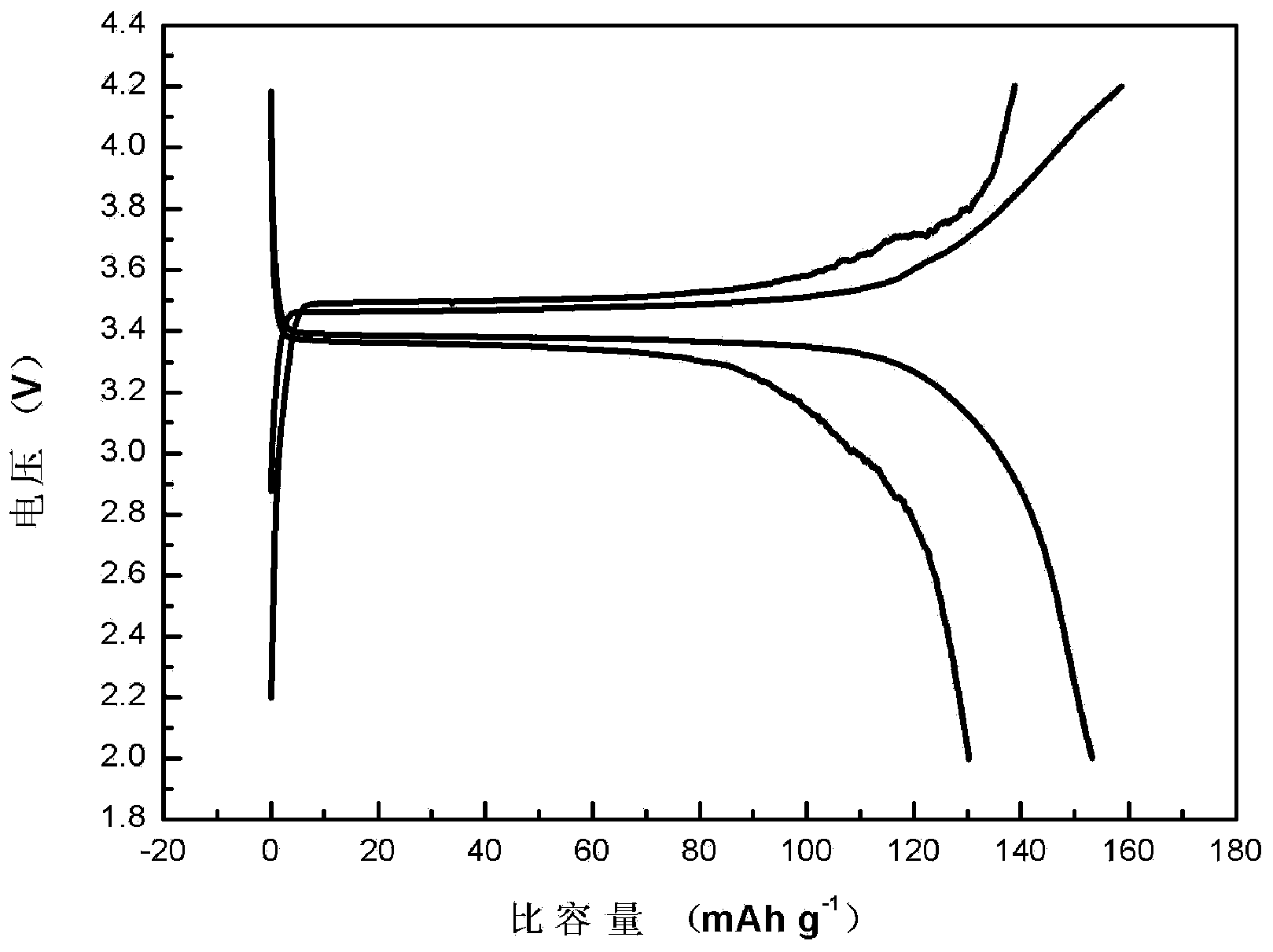

[0063] The product was used as the positive electrode material and assembled into an experimental button lithium-ion battery in an argon-protected glove box. The charge-discharge cycle was carried out between 2.0-4.2V at different rates. The 0.1C discharge capacity was 154mAh / g, and the 1C discharge capacity It is 123mAh / g, showin...

Embodiment 3

[0065] Similar to Example 1, the preparation process of the precursor is exactly the same, the difference is that the condition of high temperature annealing is to sinter at 700°C for 6 hours under the protection of argon, and then cool to room temperature with the furnace to obtain the carbon-coated lithium-ion battery cathode material iron phosphate Lithium (LiFePO 4 ) nanoparticles.

[0066] X-ray powder diffraction analysis shows that the product is pure phase lithium iron phosphate (LiFePO 4 ); According to the scanning electron microscope analysis, the particle dispersibility of the product is good, and the particle size is about 150-220nm.

[0067] The product was used as the positive electrode material, and assembled into an experimental button lithium-ion battery in an argon-protected glove box. The charge-discharge cycle was carried out between 2.0-4.2V at different rates. The 0.1C discharge capacity was 152mAh / g, and the 1C discharge capacity was 152mAh / g. It is 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com