Preparation method of spherical hard carbon negative electrode material of high-capacity lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, carbon preparation/purification, secondary batteries, etc., can solve the problems of complex preparation methods, difficult large-scale industrial production, and high cost, and achieves simple preparation processes and products. Stable properties and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

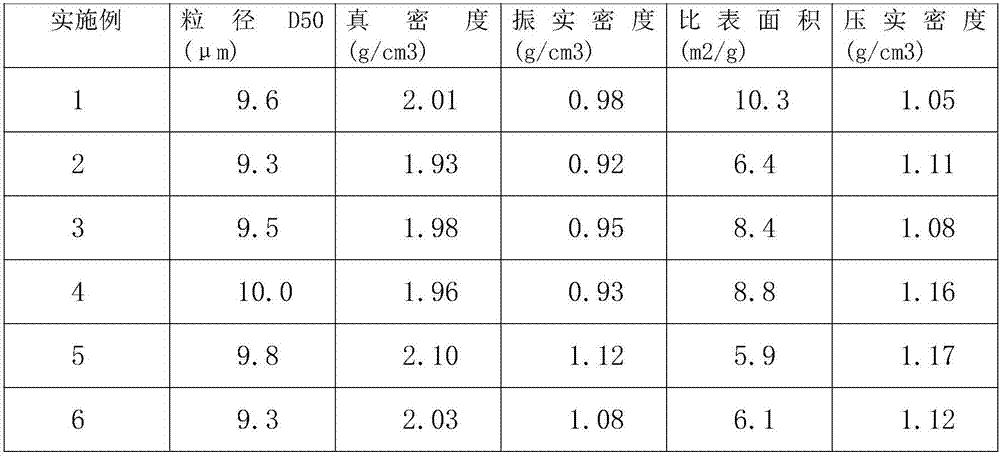

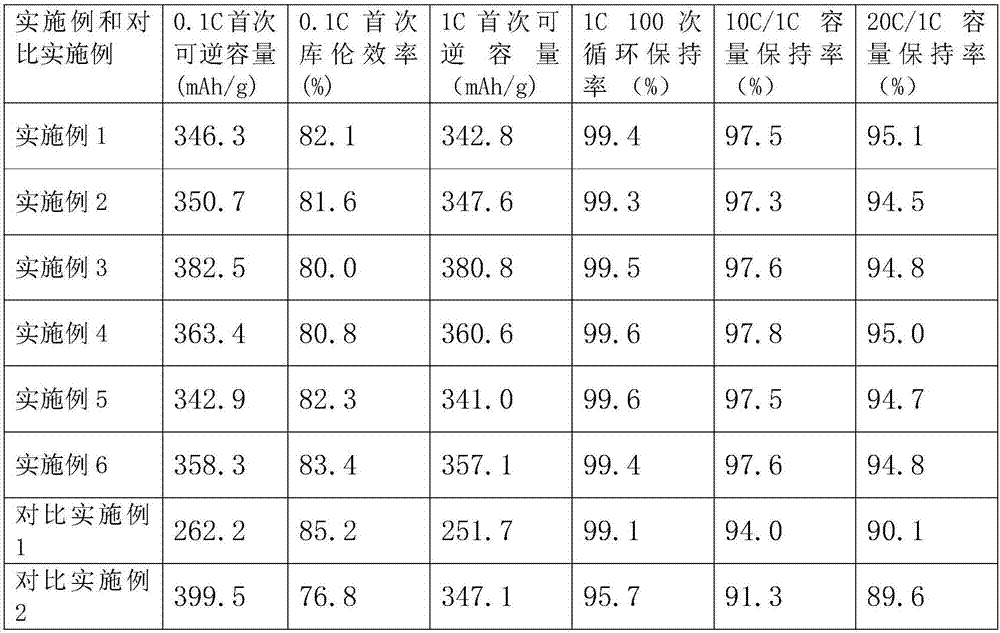

Examples

Embodiment 1

[0034] (1), 1500g petroleum residue, 900g paraformaldehyde, 75g p-toluenesulfonic acid are fed into the reactor and stirred and mixed evenly to obtain the mixture;

[0035] (2) The mixture is heated to 180° C. for pre-crosslinking polymerization reaction for 4 hours under nitrogen atmosphere and stirring conditions, and after the reaction is completed, the temperature is cooled to room temperature and the material is discharged to obtain a pre-crosslinked polymer;

[0036] (3), the pre-crosslinked polymer is then pulverized and classified by an airflow pulverization classifier, which is pulverized and classified with compressed air at 9 MPa, a feed frequency of 21 Hz and a classification frequency of 90 Hz, to obtain a polymer with a volume average particle diameter D50 of 12.0 μm Powder;

[0037] (4), then disperse the polymer powder in simethicone oil, carry out balling treatment at 250°C under stirring, and then cool down to room temperature, and filter out the silicone oil...

Embodiment 2

[0042] (1) Crushing petroleum asphalt with a softening point of 90°C through a 100-mesh sieve to obtain petroleum asphalt powder, then taking 1500g of petroleum asphalt powder, 900g of paraformaldehyde, and 75g of p-toluenesulfonic acid into a high-speed mixing mixer mix, mix

[0043](2) The temperature of the mixed material is raised to 180°C under nitrogen atmosphere and stirring conditions for cross-linking polymerization reaction for 4 hours, and after the reaction is completed, the temperature is cooled to room temperature and the material is discharged to obtain a pre-cross-linked polymer;

[0044] (3), the pre-crosslinked polymer is then pulverized and classified by an airflow pulverization classifier, which is pulverized and classified with compressed air at 9 MPa, a feed frequency of 21 Hz and a classification frequency of 90 Hz, to obtain a polymer with a volume average particle diameter D50 of 11.6 μm Powder;

[0045] (4) Then, disperse the polymer powder in simeth...

Embodiment 3

[0050] (1), crush the coumarone resin with a softening point of 120°C through a 100-mesh sieve to obtain coumarone resin powder, take 1500g of coumarone resin powder, 900g of paraformaldehyde, and 75g of p-toluenesulfonic acid and put it into high-speed stirring Mix evenly in a mixer to obtain a mixture;

[0051] (2) Put the mixed material into the reaction kettle, raise the temperature to 180° C. for cross-linking polymerization reaction under nitrogen atmosphere and stirring conditions for 4 hours, cool down to room temperature after the reaction, and discharge the material to obtain a pre-cross-linked polymer;

[0052] (3), the pre-crosslinked polymer is then pulverized and classified by an airflow pulverization classifier, which is pulverized and classified with compressed air at 9 MPa, a feed frequency of 21 Hz and a classification frequency of 90 Hz, to obtain a polymer with a volume average particle diameter D50 of 12.1 μm Powder;

[0053] (4), then disperse the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com