Lithium titanate/porous carbon composite material and preparation method of lithium titanate/porous carbon composite material

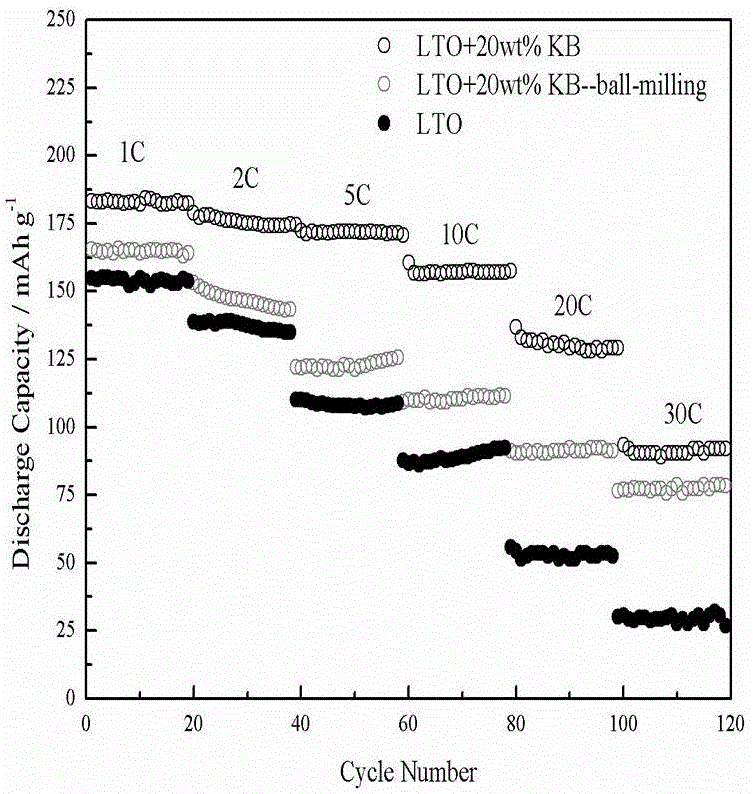

A composite material, porous carbon technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve the problems of low electrical conductivity, poor high rate performance, etc., to improve electronic conductivity, improve rate and low temperature performance, The effect of shortening the migration path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

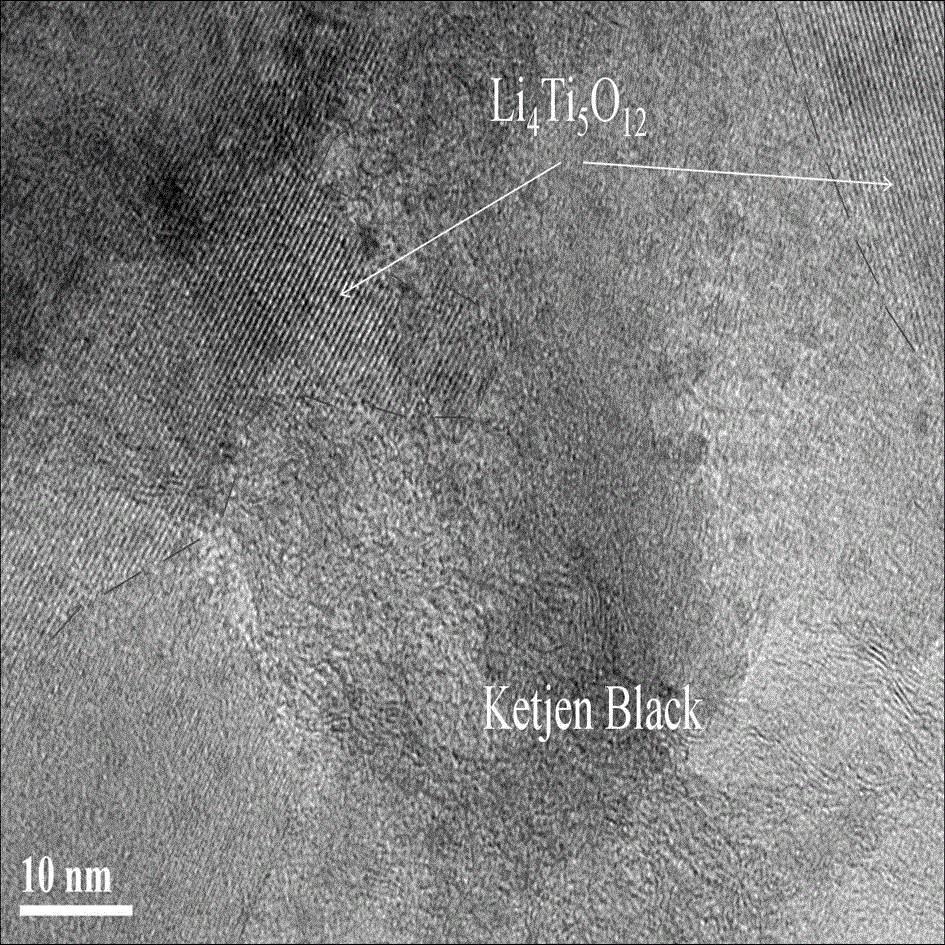

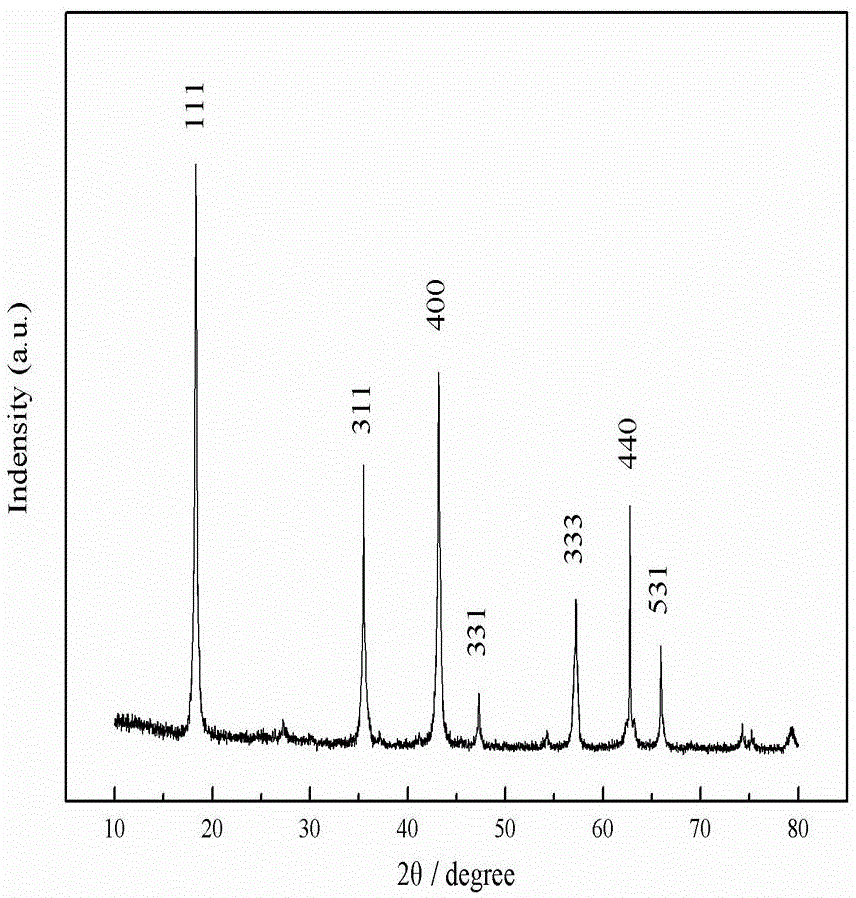

[0019] Weigh 1.7mL of tetrabutyl titanate, 1.89g of lithium hydroxide monohydrate and 0.1148g of Ketjen black, add 20mL of absolute ethanol, stir magnetically for 12 hours in a relatively dry environment, add 20mL of deionized water, and stir for 1 Minutes later, it was transferred to a hydrothermal reaction kettle, and reacted at 180°C for 36 hours to obtain a precursor slurry. Then, the precursor slurry was washed 3 times with absolute ethanol and deionized water, dried at 85°C for 6 hours, and ground Obtain the precursor powder; place the above precursor powder in an argon atmosphere and raise the temperature to 350°C at a rate of 5°C / min, keep it warm for 2 hours, then raise the temperature to 600°C at a rate of 5°C / min, and keep it warm for 6 After hours, the temperature was lowered to 350°C at a rate of 5°C / min, kept at a temperature of 2 hours, then naturally cooled to room temperature, and sieved to obtain the target lithium titanate / ketjen black composite material.

Embodiment 2

[0021] Weigh 1.7mL tetrabutyl titanate, 1.89g lithium hydroxide monohydrate and 0.0861g carbon airgel, add 20mL absolute ethanol, stir magnetically for 12 hours in a relatively dry environment, add 20mL deionized water, and stir again After 1 minute, transfer to a hydrothermal reaction kettle, react at 180°C for 36 hours to obtain a precursor slurry, then wash the precursor slurry 3 times with absolute ethanol and deionized water, dry at 85°C for 6 hours, and grind Finally, the precursor powder is obtained; the above-mentioned precursor powder is placed in an argon atmosphere and heated to 350°C at a rate of 5°C / min, kept for 2 hours, and then heated to 600°C at a rate of 5°C / min, kept After 6 hours, the temperature was lowered to 350°C at a rate of 5°C / min, kept for 2 hours, then naturally cooled to room temperature, and the target product lithium titanate / carbon airgel composite material was obtained after sieving.

Embodiment 3

[0023] Weigh an appropriate amount of hair, cut it into small sections of 2-5mm, wash it with deionized water and isopropanol, dry it in an oven at 80°C, and sinter the dried hair at 300°C for 2 hours in an argon atmosphere. The sintered material was ground evenly with potassium hydroxide at a mass ratio of 1:2, and then sintered at 800°C for 2 hours in an argon atmosphere. Finally, the sintered product was fully washed with 1mol / L hydrochloric acid, and dried in an oven at 80°C for later use.

[0024] Weigh 1.7mL tetrabutyl titanate, 1.89g lithium hydroxide monohydrate and 0.0574g treated carbonized hair, add 20mL absolute ethanol, stir magnetically for 12 hours in a relatively dry environment, add 20mL deionized water, and stir again After 1 minute, transfer to a hydrothermal reaction kettle, react at 180°C for 36 hours to obtain a precursor slurry, then wash the precursor slurry 3 times with absolute ethanol and deionized water, dry at 85°C for 6 hours, and grind Finally, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com