Carbon/carbon composite material for sodium-ion battery and preparation method thereof

A technology of carbon composite materials and porous carbon, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of low first-cycle Coulombic efficiency, weak sodium storage capacity, and low degree of graphitization and other problems, to achieve broad industrial application prospects, increase the carbon layer spacing, and improve the effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

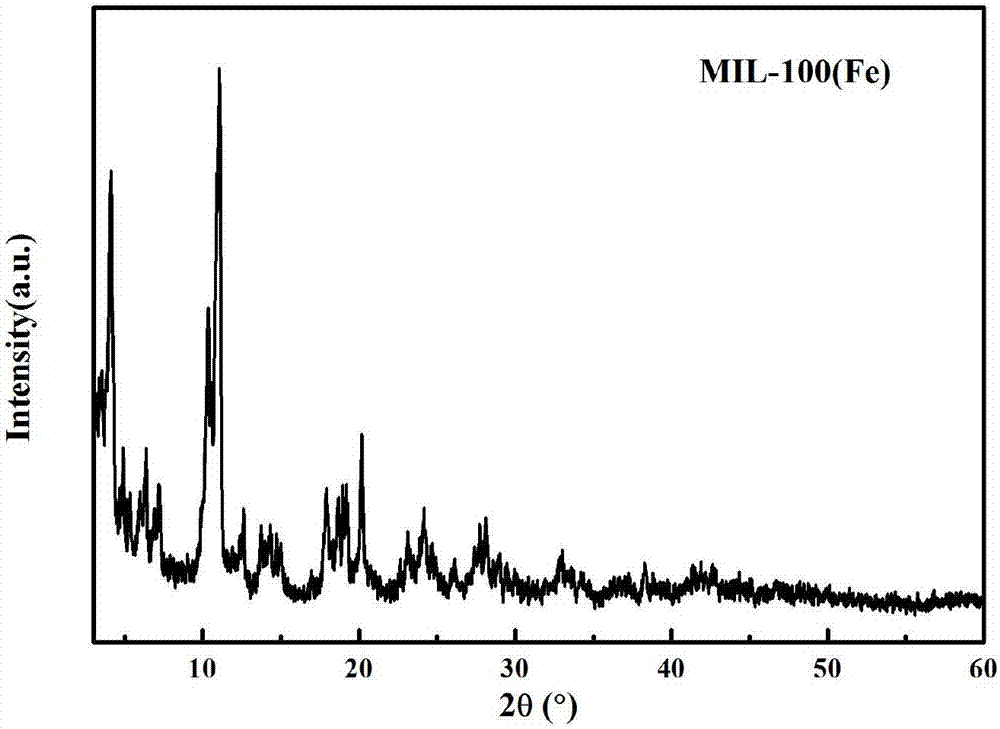

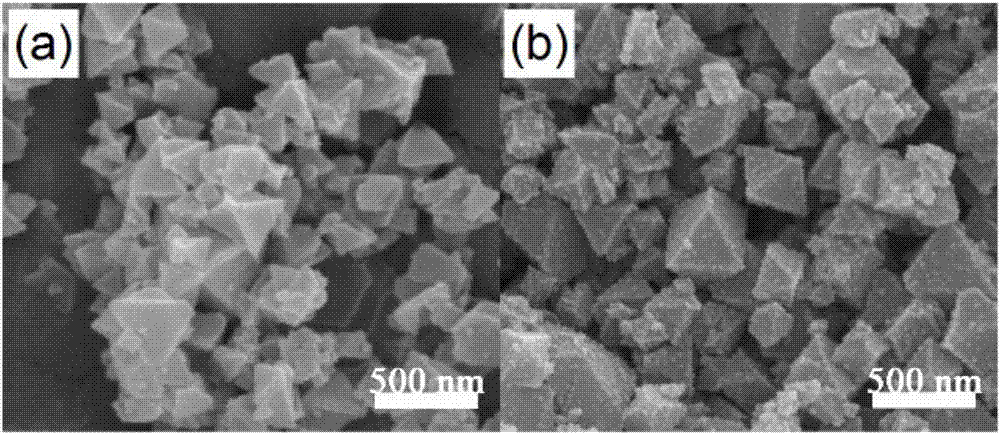

[0050] First weigh 2.457g ferric chloride (9mmol) and 1.275g trimesic acid (6mmol) to make it fully dissolved in 40mL deionized water, then measure the hydrofluoric acid solution of 18mmol (mass percentage concentration is 30%) And 5.42mmol (90% by mass concentration) concentrated nitric acid solution was added dropwise to the above solution. Then, after the above-prepared mixed solution was continuously magnetically stirred for 1 h at room temperature, it was transferred into a hydrothermal reaction kettle to perform a hydrothermal reaction at 170° C. for 18 h. Finally, the tan precipitate obtained from the reaction was repeatedly washed with ethanol and deionized water by centrifugation, and dried to obtain the precursor of the iron-based metal organic framework material MIL-100.

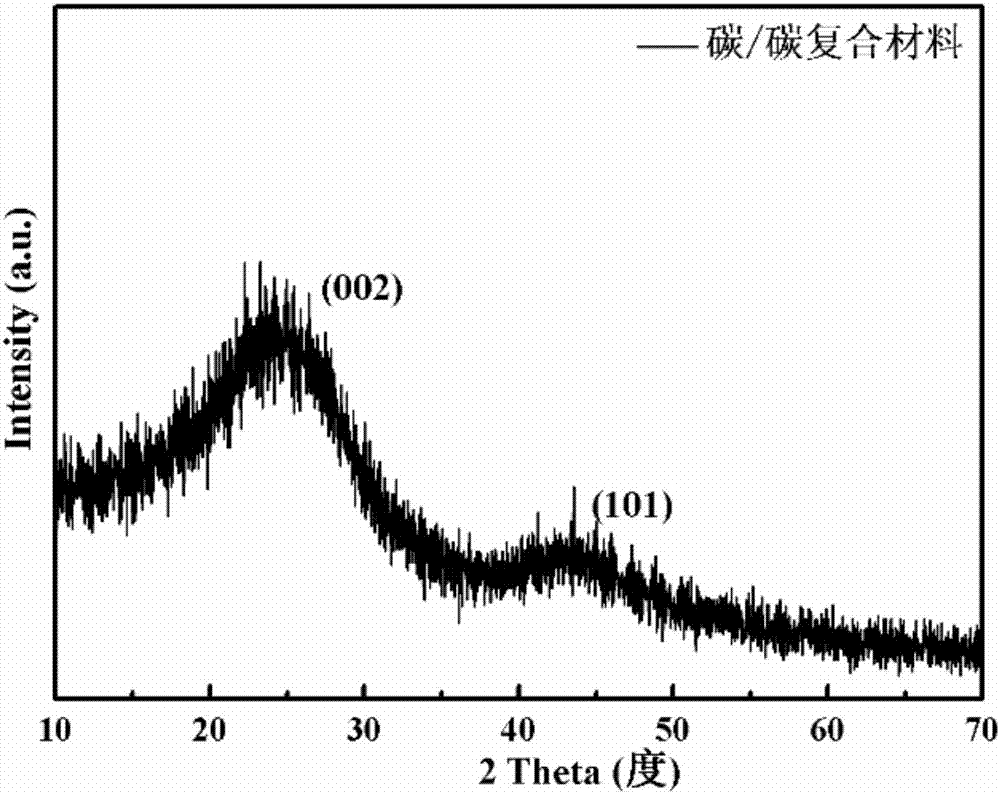

[0051] Weigh 1 g of iron-based metal-organic framework material MIL-100, grind it into powder, and fully disperse it in 300 mL of sucrose solution with a molar concentration of 0.75 mol / L. Subseq...

Embodiment 2

[0059] First weigh 2.457g ferric chloride (9mmol) and 1.913g trimesic acid (9mmol) to make it fully dissolved in 40mL deionized water, then measure the hydrofluoric acid solution of 18mmol (mass percentage concentration is 30%) And 5.42mmol (90% by mass concentration) concentrated nitric acid solution was added dropwise to the above solution. Then, after the above-prepared mixed solution was continuously magnetically stirred for 1 h at room temperature, it was transferred into a hydrothermal reaction kettle to perform a hydrothermal reaction at 150° C. for 18 h. Finally, the tan precipitate obtained from the reaction was repeatedly washed with ethanol and deionized water by centrifugation, and dried to obtain the precursor of the iron-based metal organic framework material MIL-100.

[0060] Weigh 1 g of iron-based metal-organic framework material MIL-100, grind it into powder, and fully disperse it in 300 mL of sucrose solution with a molar concentration of 0.75 mol / L. Subseq...

Embodiment 3

[0063] First take by weighing 2.457g ferric chloride (9mmol) and 2.550g trimesic acid (12mmol) and make it fully dissolved in 40mL deionized water, then measure the hydrofluoric acid solution of 18mmol (mass percentage concentration is 30%) And 5.42mmol (mass percentage concentration: 90%) of concentrated nitric acid solution was added dropwise to the above solution. Then, after the above-prepared mixed solution was continuously magnetically stirred for 1 h at room temperature, it was transferred into a hydrothermal reaction kettle to perform a hydrothermal reaction at 190° C. for 18 h. Finally, the tan precipitate obtained from the reaction was repeatedly washed with ethanol and deionized water by centrifugation, and dried to obtain the precursor of the iron-based metal organic framework material MIL-100.

[0064] Weigh 1 g of iron-based metal-organic framework material MIL-100, grind it into powder, and fully disperse it in 300 mL of sucrose solution with a molar concentrati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com