Electrolyte for magnesium rechargeable battery and preparation method thereof

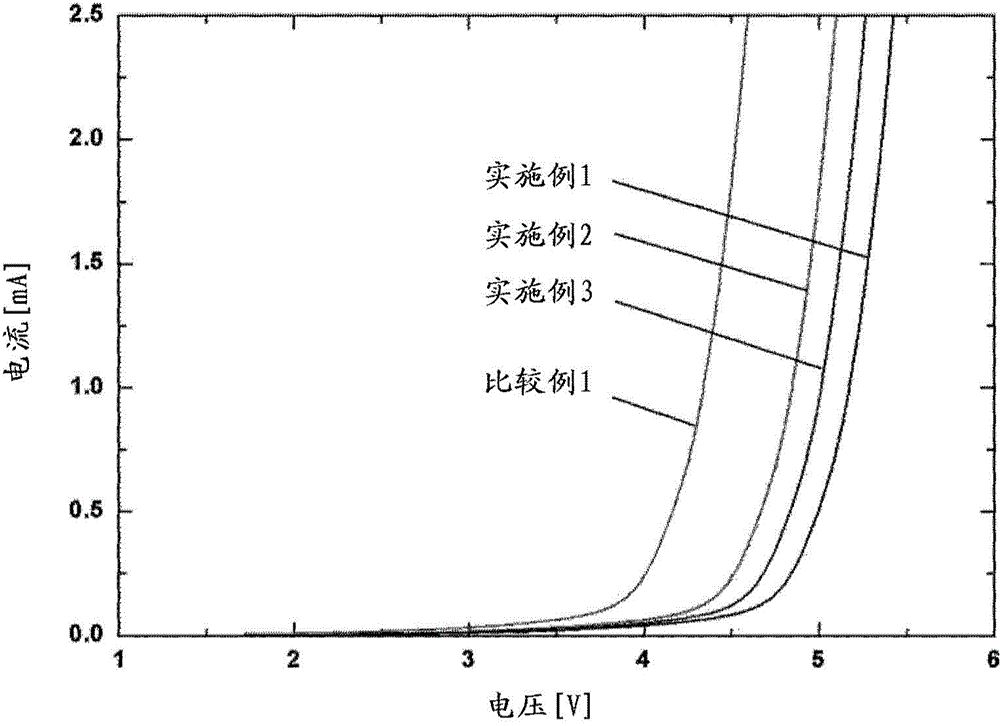

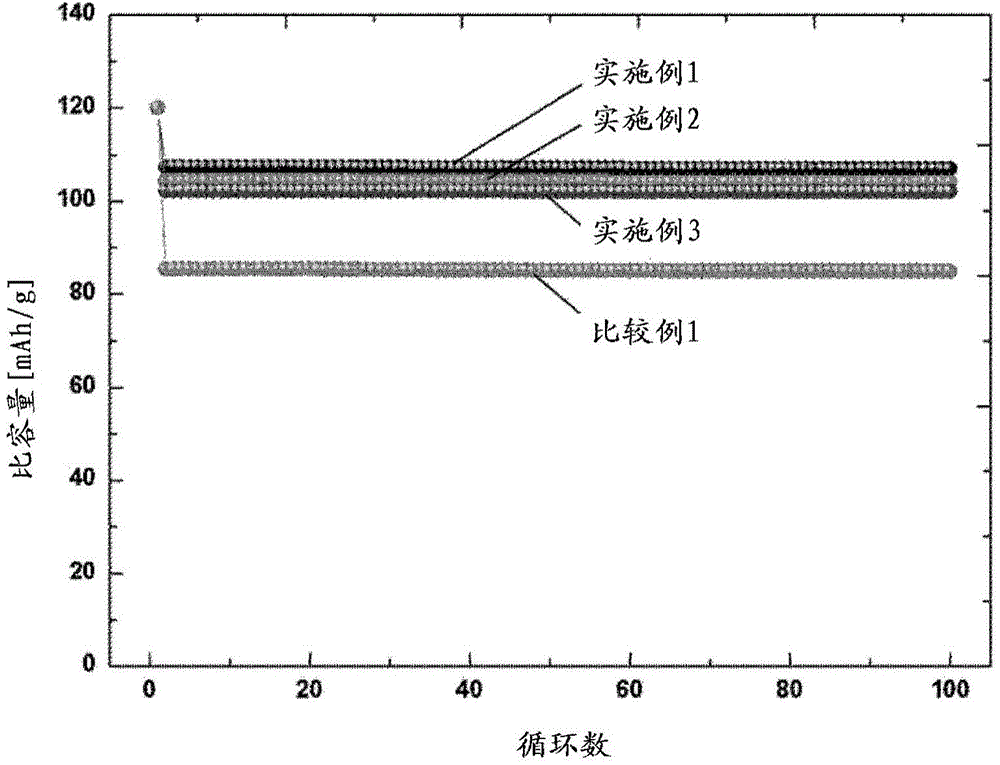

A technology for recharging and magnesium batteries, applied in the field of electrolytes and preparations for magnesium rechargeable batteries, can solve the problems of low charge/discharge rate, poor electrochemical stability, low ionic conductivity, etc., and achieve good battery life Effects of chemical stability, high discharge capacity, and high ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0052] According to another embodiment, the method further comprises: (c) adding a lithium salt to the first solution after step (a) or to the second solution after step (b) to prepare a third solution.

[0053] In another aspect, the present invention provides a magnesium battery including the electrolyte according to any one of the exemplary embodiments. The magnesium battery of the present invention may be a magnesium rechargeable battery or a magnesium hybrid battery, but is not limited thereto.

[0054] Other embodiments of the invention will be further described. However, the present invention should not be construed as being limited to the following description.

[0055] According to one embodiment of the present invention, magnesium powder is added in the organic solvent metal chloride salt such as AlCl 3 or CrCl 3 solution, which distinguishes the electrolyte of the present invention from conventional Grignard solutions. Magnesium dissolves slowly until equilibriu...

Embodiment 1

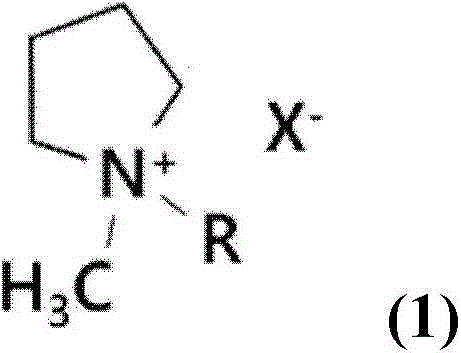

[0073] Embodiment 1: Preparation of AlCl 3 -CrCl 3 - Solution of BMPBr-magnesium ion complex-LiCl mixture

[0074] 6.667gAlCl 3 and 0.1584gCrCl 3 was dissolved in 100 mL of THF as solvent to prepare a solution in which AlCl 3 and CrCl 3 Present at concentrations of 0.5M and 0.01M, respectively. To this solution was added 3 g of magnesium powder. The mixture was kept for 24 hours to allow the AlCl 3 , CrCl 3 , metal magnesium and magnesium ions reach equilibrium, and then 0.2 g of BMPBr is dissolved in it as an ionic liquid to form a complex with magnesium ions. Finally, 2.120 g LiCl was dissolved in 100 mL of the solution containing the magnesium ion complex. The resulting solution was prepared by 0.5MAlCl 3 , 0.01MCrCl 3 , 0.2% BMPBr, magnesium ion complex and 0.5MLiCl. After removing the solid fraction from the solution, the remaining liquid fraction was collected and used as electrolyte.

Embodiment 2

[0075] Embodiment 2: Preparation of AlCl 3 -CrCl 3 -AMPCl-magnesium ion complex-LiCl mixture solution

[0076] An electrolyte was prepared in the same manner as in Example 1 except that AMPCl was used as the ionic liquid instead of BMPBr.

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic conductivity | aaaaa | aaaaa |

| ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com