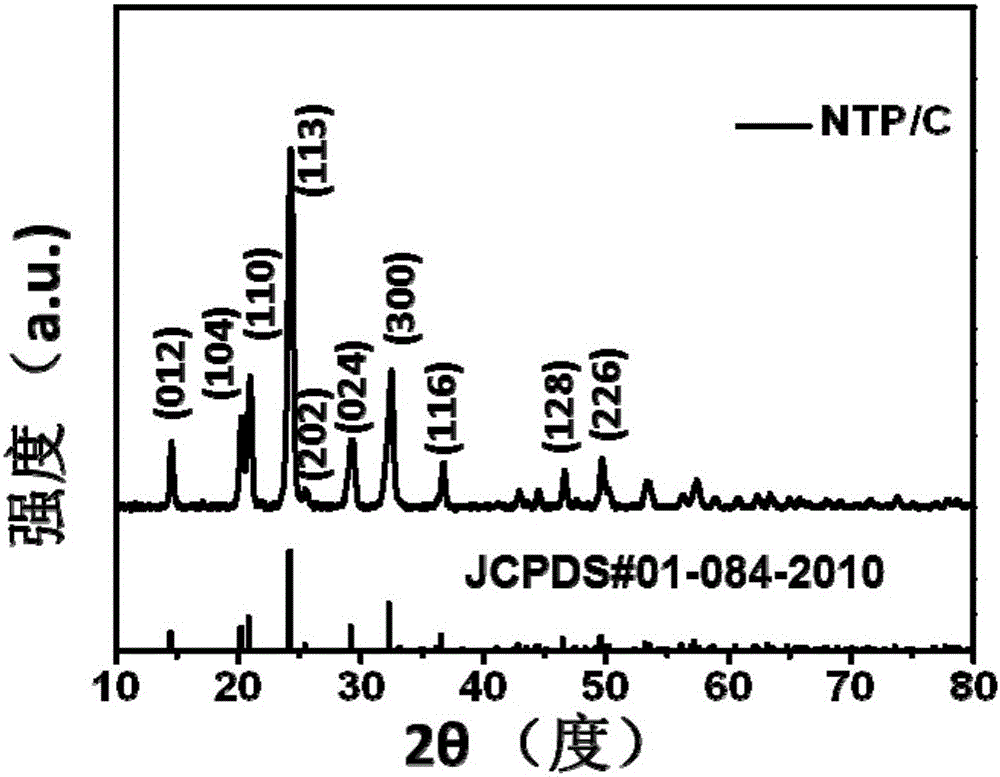

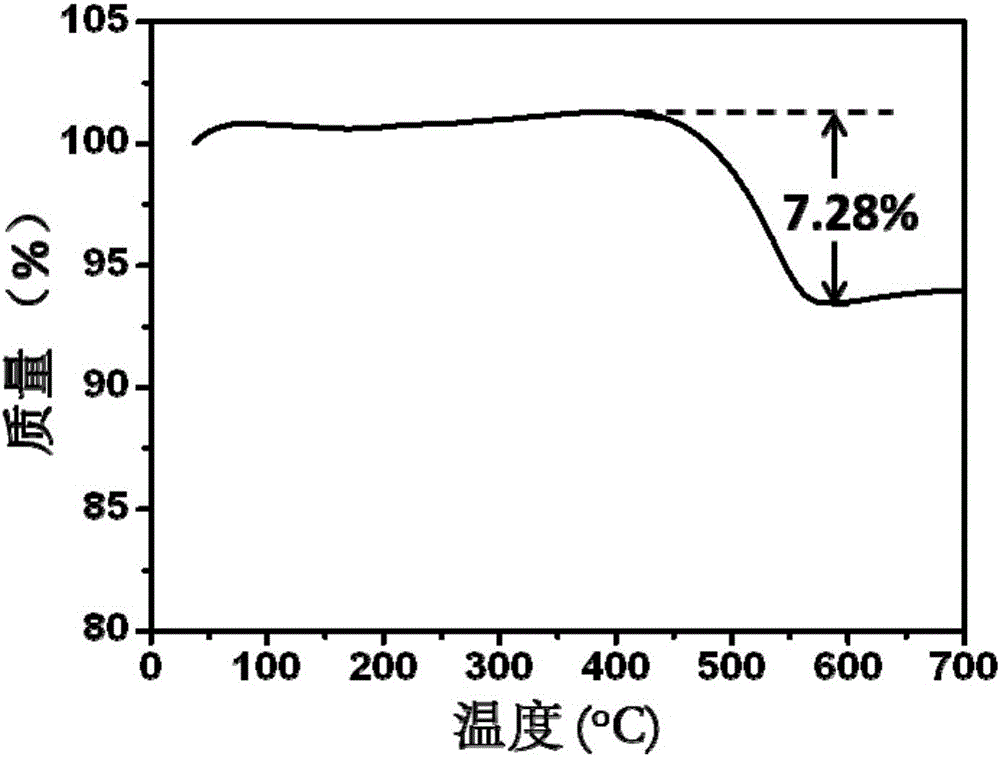

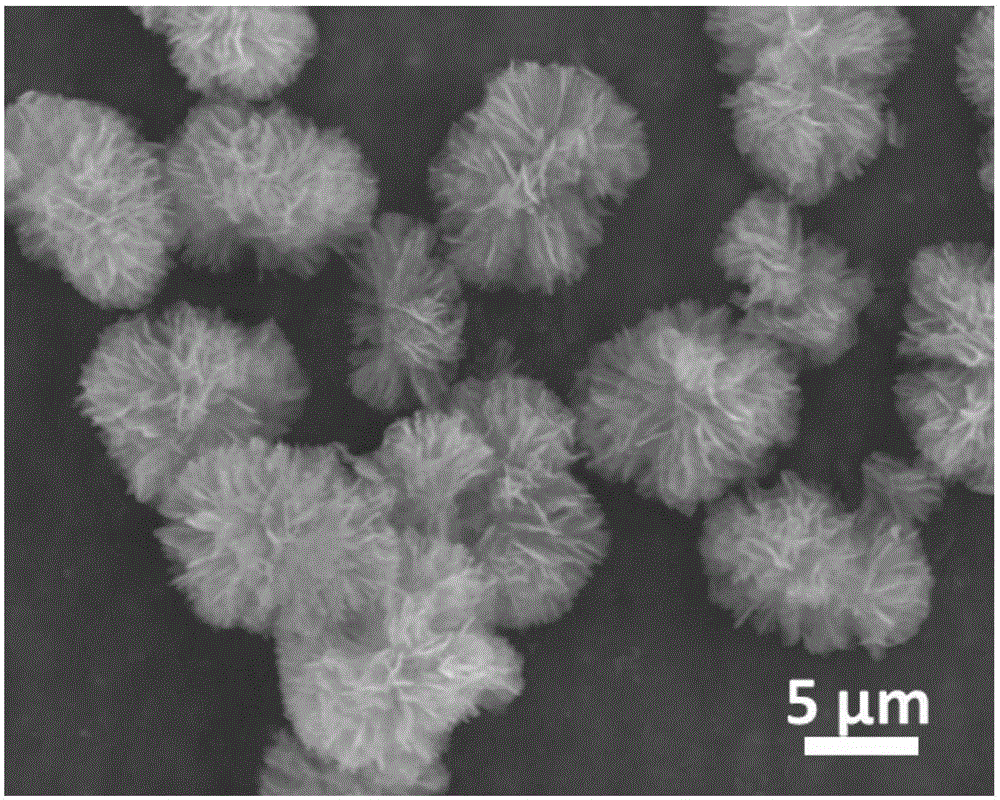

Three-dimensional graded carbon-clad NaTi<2>(PO<4>)<3>/C micrometer flower electrode material and preparation method and application thereof

A carbon-coated, micro-flower technology, applied in the fields of nanomaterials and electrochemistry, to achieve the effect of expanding production, strong feasibility and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Three-dimensional hierarchical carbon-coated NaTi 2 (PO 4 ) 3 The preparation method of / C micron flower, it comprises the steps:

[0042] 1) Add 2 mmol of tetra-n-butyl titanate dropwise to 20 mL of ethylene glycol solution, and stir for 30 minutes to obtain a colorless and transparent solution;

[0043] 2) Weigh 1mmol of NaH 2 PO 4 2H 2 O was dissolved in 10mL deionized water, and was added dropwise to the solution obtained in step 1) and stirred evenly;

[0044] 3) Measure 2mmol of 85% phosphoric acid (H 3 PO 4 ) solution, which is dripped dropwise into the mixed solution obtained in step 2), and stirred evenly;

[0045] 4) Weigh 1 mmol of glucose as a carbon source and dissolve it in 10 mL of deionized water, then dropwise add it to the mixed solution obtained in step 3) and continue to stir for 1 hour to obtain a colorless and transparent solution;

[0046] 5) Transfer the mixed solution obtained in step 4) to a 50mL reaction kettle, react under hydrotherm...

Embodiment 2

[0053] 1) Add 1 mmol of tetra-n-butyl titanate dropwise to 30 mL of ethylene glycol solution, and stir for 30 minutes to obtain a colorless and transparent solution;

[0054] 2) Weigh 0.5mmol of NaH 2 PO 4 2H 2 O was dissolved in 5mL deionized water, and was added dropwise to the solution obtained in step 1) and stirred evenly;

[0055] 3) Measure 1mmol of 85% phosphoric acid (H 3 PO 4 ) solution, which is dripped dropwise into the mixed solution obtained in step 2), and stirred evenly;

[0056] 4) Weigh 0.5 mmol of glucose as a carbon source and dissolve it in 5 mL of deionized water, then dropwise add it to the mixed solution obtained in step 3) and continue to stir for 2 hours to obtain a colorless and transparent solution;

[0057] 5) Transfer the mixed solution obtained in step 4) to a 50mL reactor, react under hydrothermal conditions at 140°C for 24 hours, then cool to room temperature naturally, collect the product and place it in an oven at 120°C for direct drying...

Embodiment 3

[0062] 1) Add 4 mmol of tetra-n-butyl titanate dropwise to 40 mL of ethylene glycol solution, and stir for 30 minutes to obtain a colorless and transparent solution;

[0063] 2) Weigh 2mmol of NaH 2 PO 4 2H 2 O was dissolved in 10mL deionized water, and was added dropwise to the solution obtained in step 1) and stirred evenly;

[0064] 3) Measure 4mmol of 85% phosphoric acid (H 3 PO 4 ) solution, which is dripped dropwise into the mixed solution obtained in step 2), and stirred evenly;

[0065] 4) Weigh 3 mmol of glucose as a carbon source and dissolve it in 5 mL of deionized water, then dropwise add it to the mixed solution obtained in step 3) and continue to stir for 4 hours to obtain a colorless and transparent solution;

[0066] 5) Transfer the mixed solution obtained in step 4) to a 50mL reactor, react under hydrothermal conditions at 160°C for 15 hours, then cool to room temperature naturally, collect the product and place it in an oven at 120°C for direct drying to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com