Patents

Literature

36results about How to "Has a core-shell structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of interpenetrating-network-structure water-based polyurethane nano composite material

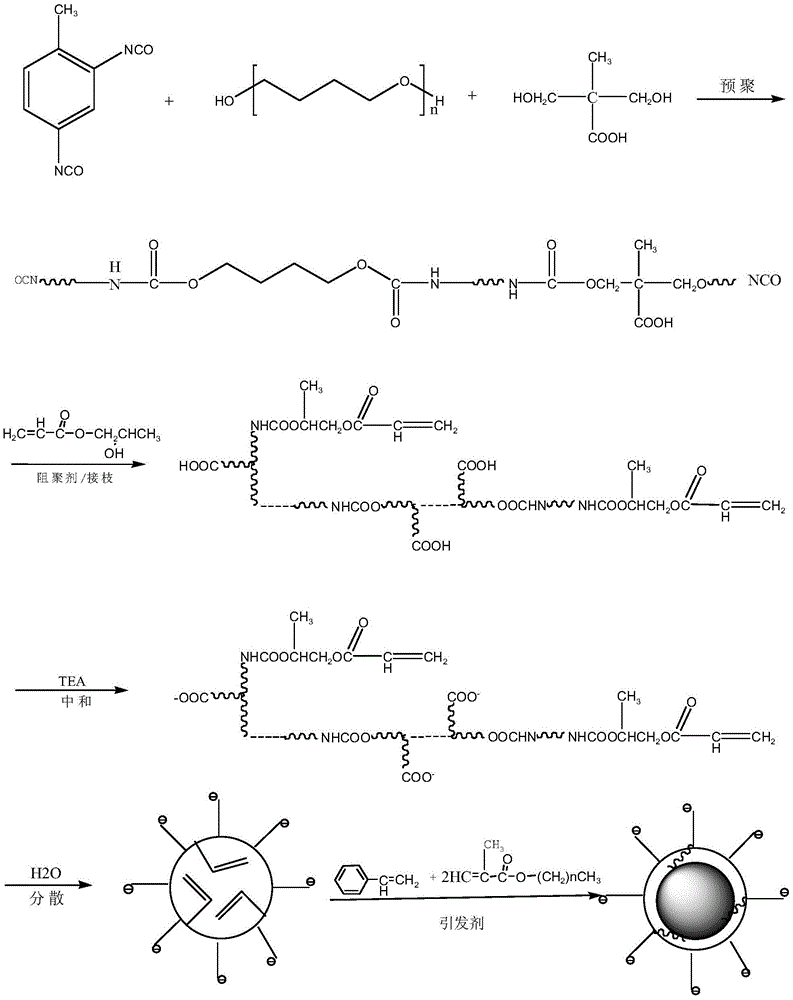

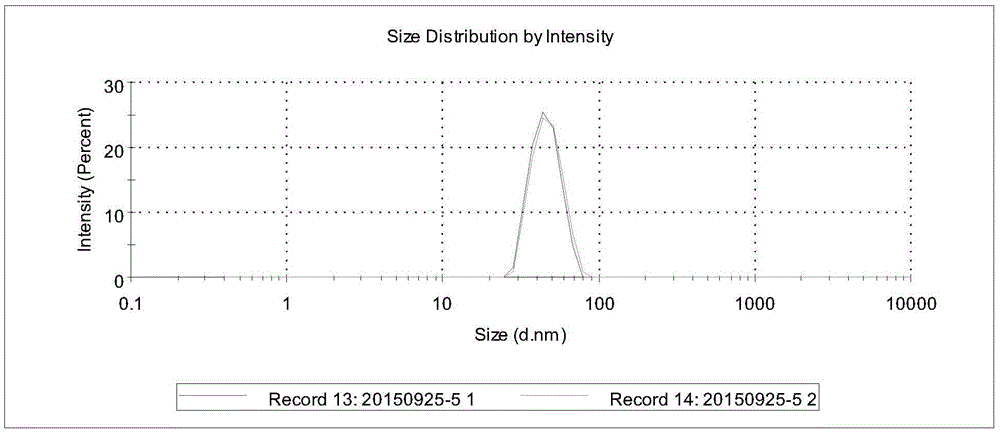

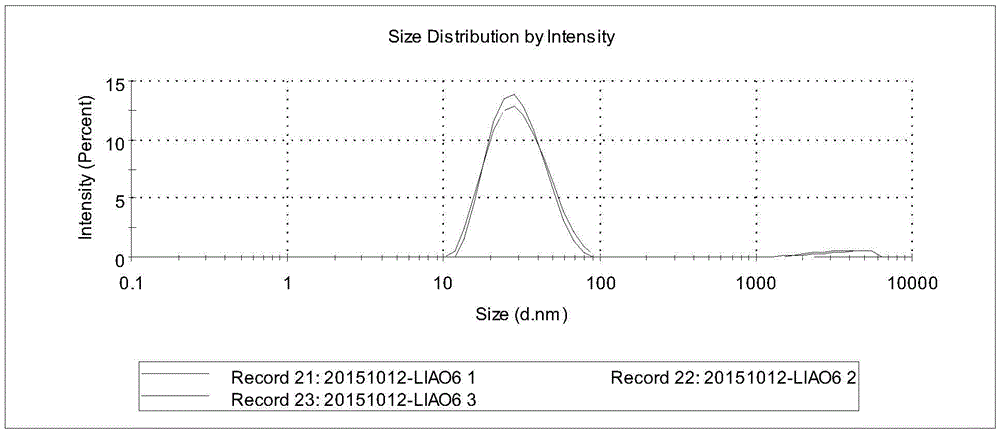

The invention provides a preparation method of an interpenetrating-network-structure water-based polyurethane nano composite material. The preparation method comprises the following steps: 1) carrying out vacuum dehydration treatment on polymer polylol and hydrophilic functional monomer; 2) adding a catalyst and diisocyanate, reacting at room temperature for 0.5-2 hours, heating to 60-80 DEG C, and carrying out the reaction for 1-5 hours while keeping the temperature; 3) cooling to 40-50 DEG C, adding a chain extender, and carrying out the reaction for 2-4 hours while keeping the temperature; 4) heating to 60-70 DEG C, and adding a reactive monomer for termination; 5) cooling to 30-50 DEG C, and adding a neutralizer to regulate the pH value; 6) heating to 60 DEG C, dropwise adding deionized water, and dispersing by stirring; and 7) heating to 60-65 DEG C, dropwise adding an initiator water solution and a nucleation monomer, carrying out programmed heating, and carrying out the reaction while keeping the temperature, thereby obtaining the interpenetrating-network-structure water-based polyurethane nano composite material. The method effectively solves the problem of VOC (volatile organic compound) discharge. The nano composite material has the characteristics in both the core-shell structure and the interpenetrating network structure, and thus, has favorable mechanical properties. The adopted continuous-process synthesis technique is beneficial to enhancing the production efficiency.

Owner:武汉弘毅共聚新材料科技有限公司

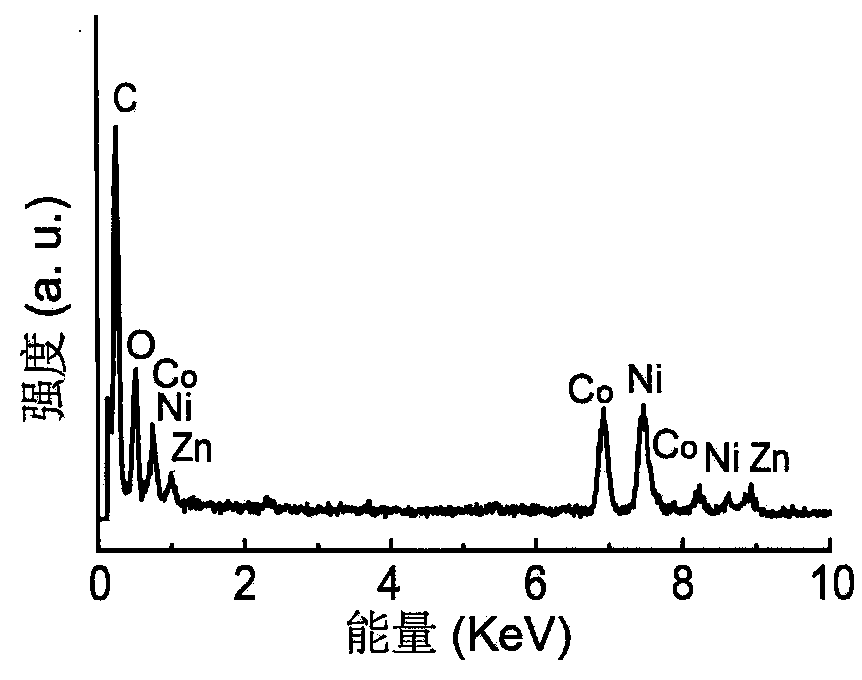

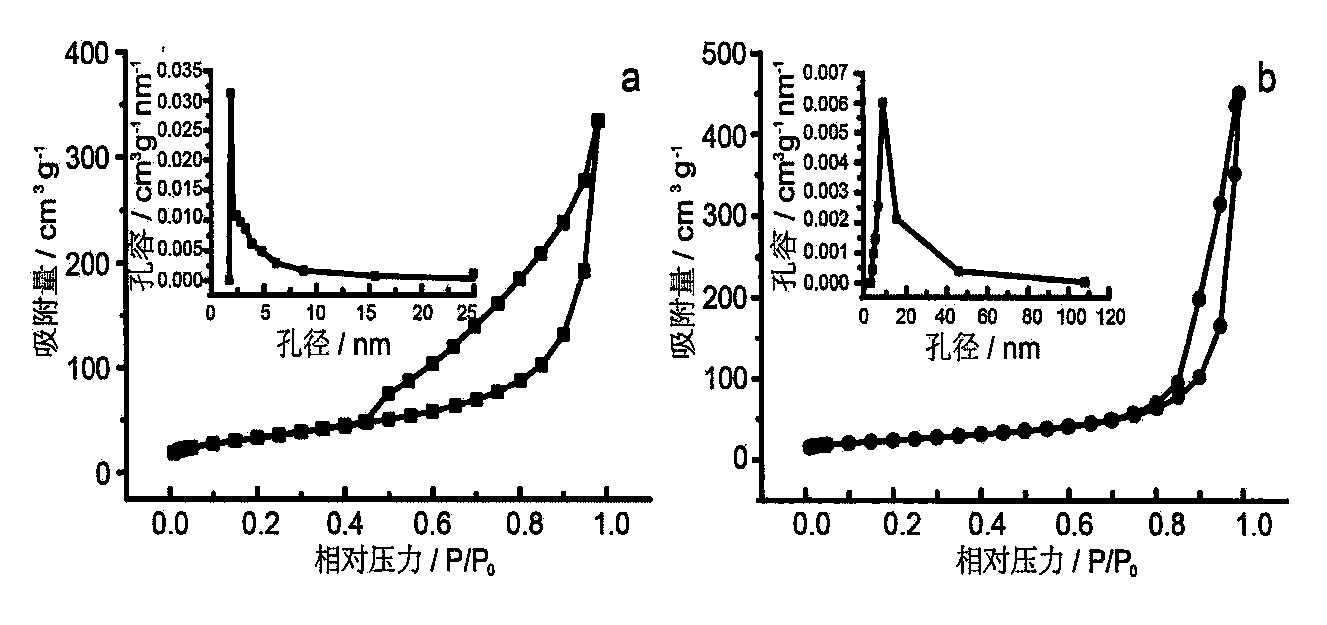

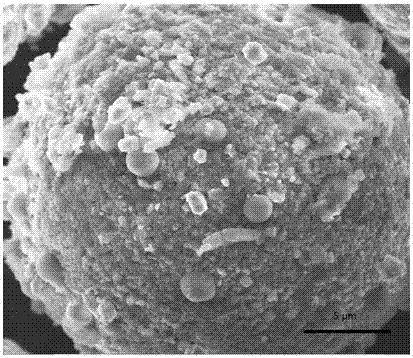

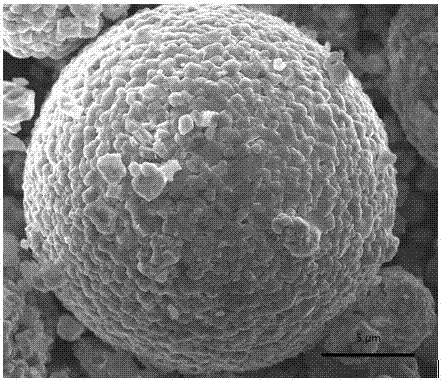

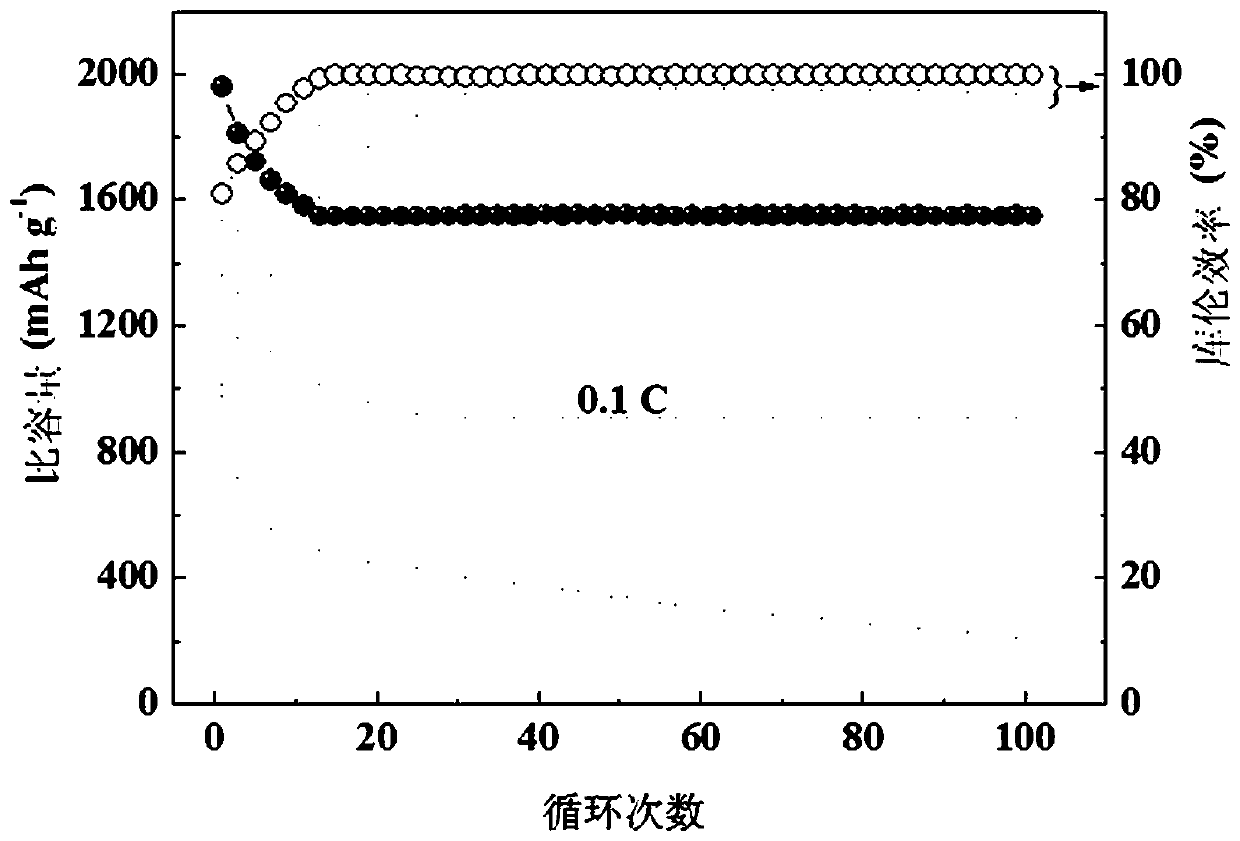

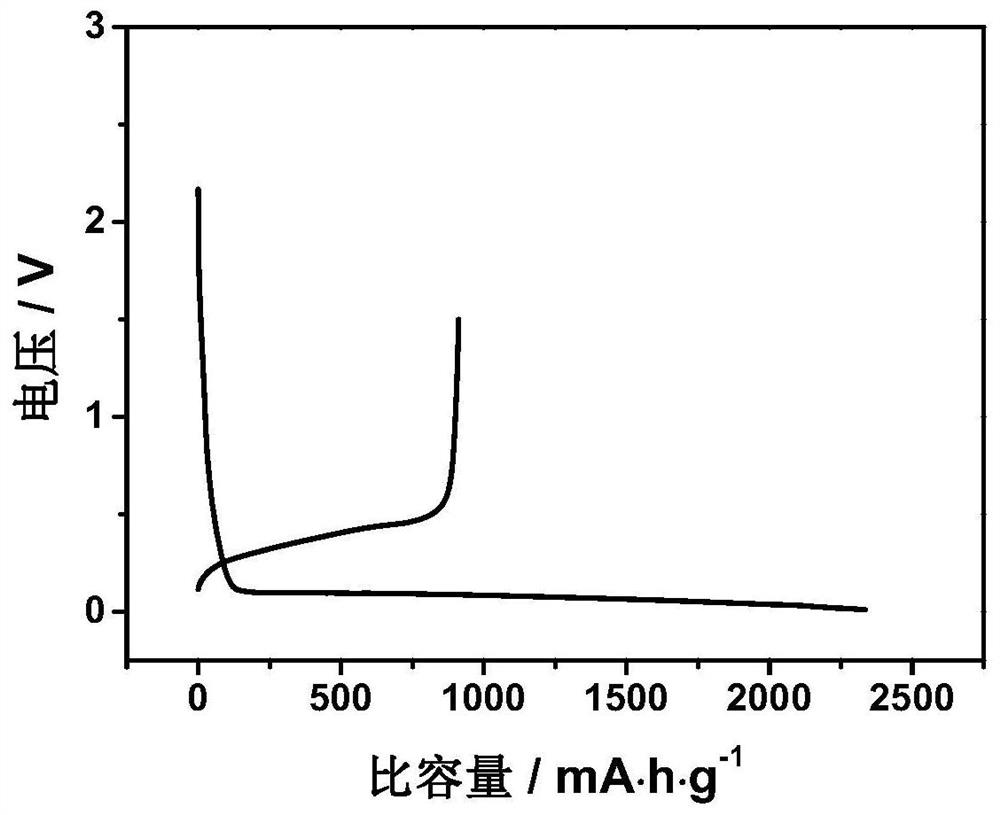

Preparation method and application of zinc cobaltate/nickel oxide core-shell nanowire array

InactiveCN103956483AOxidation resistantCorrosion resistanceDecorative surface effectsCell electrodesPeroxydisulfateCalcination

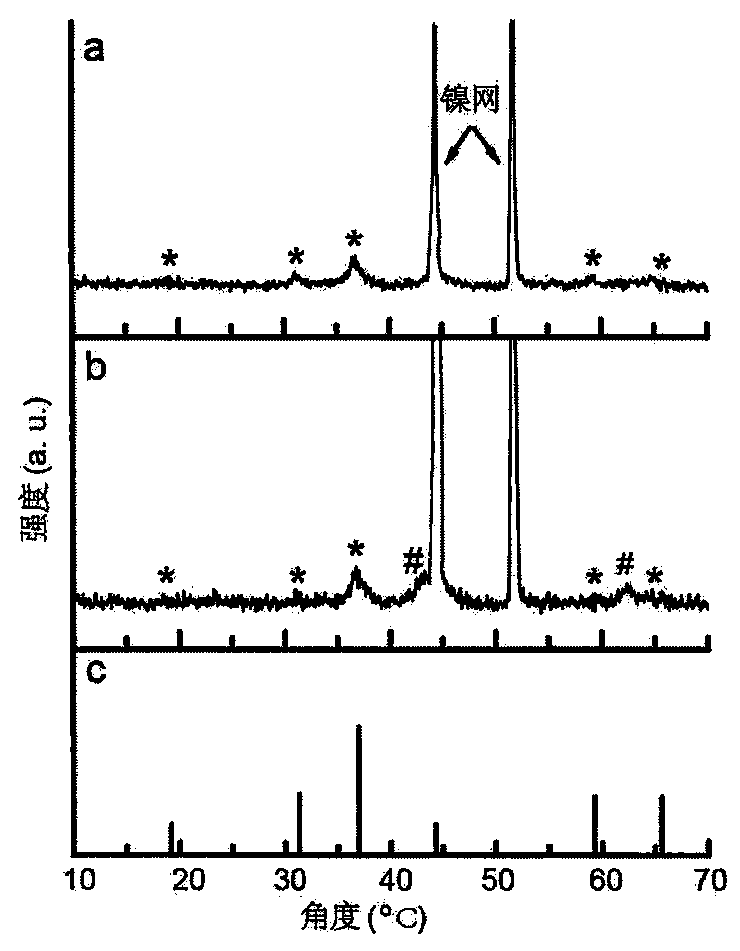

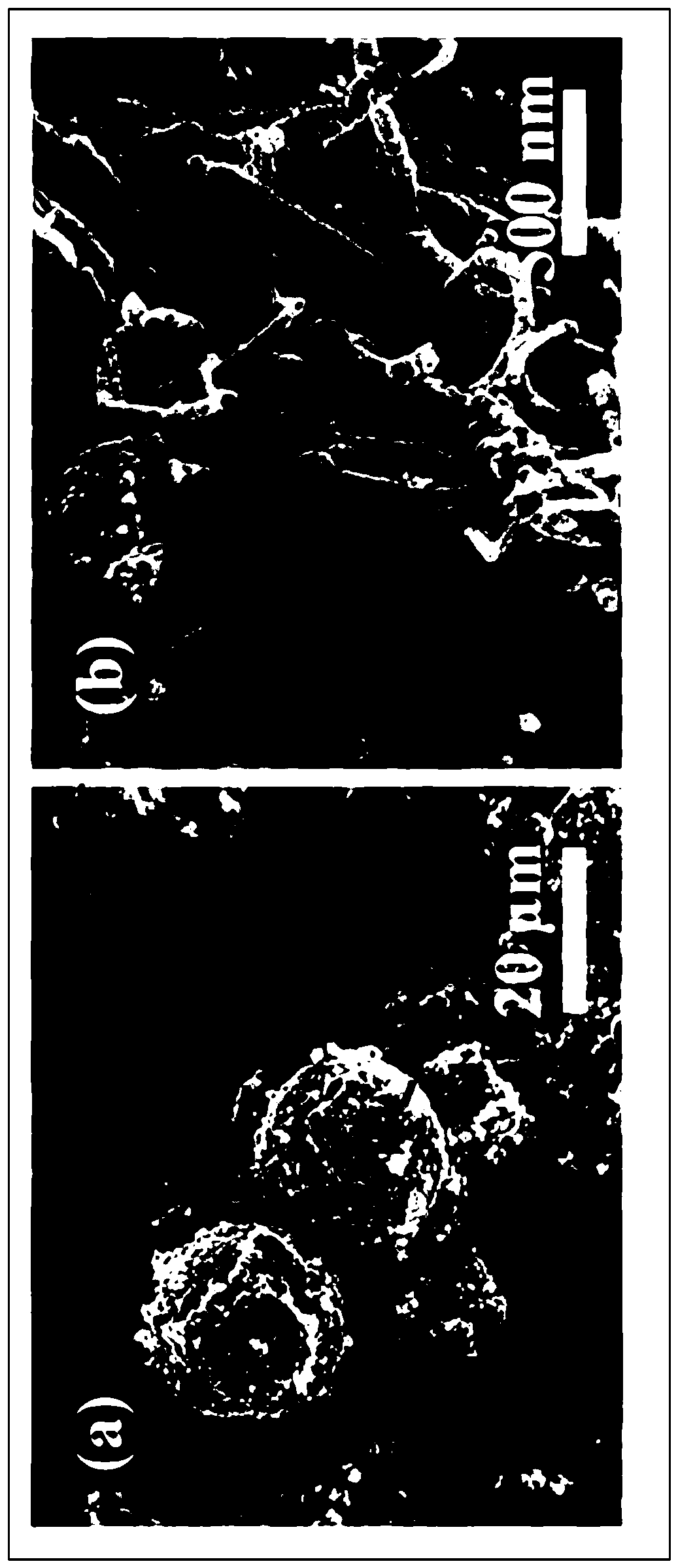

The invention relates to a preparation method and application of a zinc cobaltate / nickel oxide core-shell nanowire array. The method comprises the steps of mixing soluble cobalt salt, soluble zinc salt, ammonium fluoride, urea and water to obtain a uniform solution; after that, feeding the uniform solution into a reaction kettle, putting a clean substrate into the solution in the reaction kettle, and carrying out calcination to obtain the substrate on which a zinc cobaltate nanowire array grows; and mixing nickel sulfate, potassium peroxydisulfate and ammonia water, putting the substrate on which the zinc cobaltate nanowire array grows into the mixed liquid, and carrying out calcination to obtain the zinc cobaltate / nickel oxide core-shell nanowire array. The method is low in manufacturing cost, effective in implementation, feasible and applicable to industrialization; the zinc cobaltate / nickel oxide core-shell nanowire array obtained by the method has the advantages of being high in discharge capacity, rate capability, cycle performance, and the like when being used for preparing a negative electrode of a lithium ion battery.

Owner:XINJIANG UYGUR AUTONOMOUS REGION PROD QUALITY SUPERVISION & INSPECTION RES INST

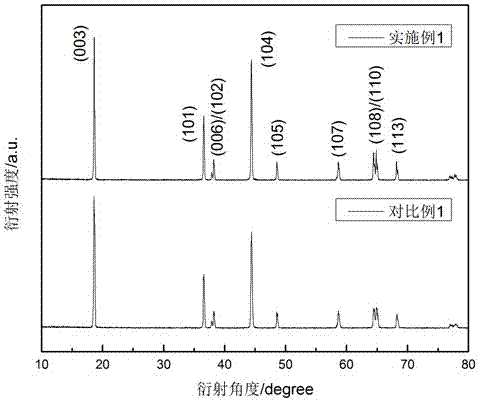

Method of lithium vanadium phosphate-coated ternary material of lithium ion battery

InactiveCN107204428AIncrease energy densityHas a core-shell structureElectrode thermal treatmentLithium vanadium phosphate batteryPhysical chemistry

The invention relates to a method of a lithium vanadium phosphate-coated ternary material of a lithium ion battery. The active electrode material of lithium vanadium phosphate is used as a coating material, and can form a uniform coating layer at the surface of the ternary material. A preparation method comprises the following steps of (1) preparing the ternary material; (2) mixing the ternary material and the lithium vanadium phosphate; (3) calcining a mixed sample under the reduction atmosphere. The method has the advantages that the transmission rate of lithium ions of the surface-coated lithium vanadium phosphate material is quick, and the large rate property of the material is improved; the lithium vanadium phosphate material has good stability, the erosion of electrolyte to the ternary material of an inner core is effectively inhibited, the coated ternary material integrates the advantages of the ternary material and the lithium vanadium phosphate, and the good rate property and cyclic property are realized.

Owner:CENT SOUTH UNIV

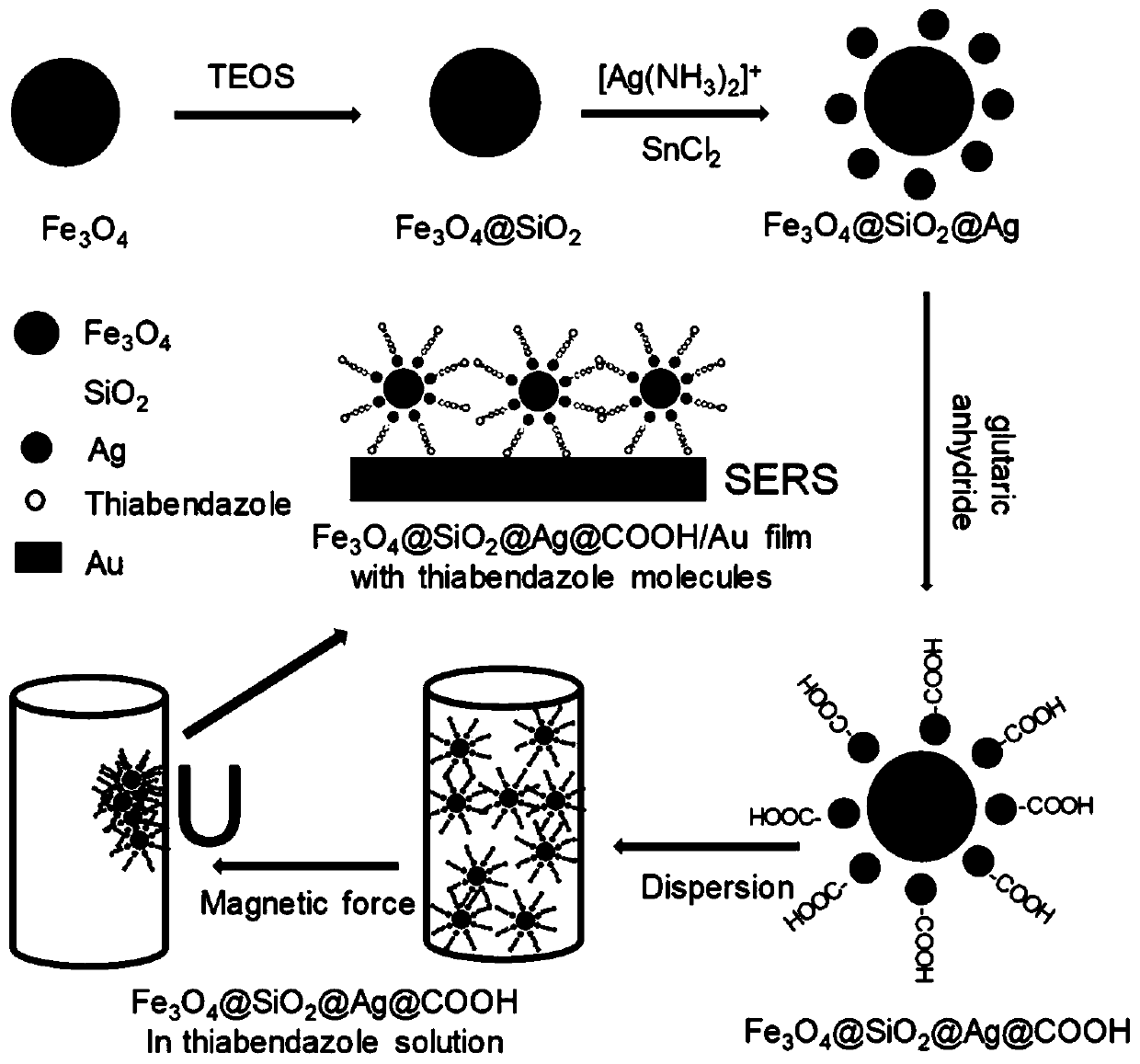

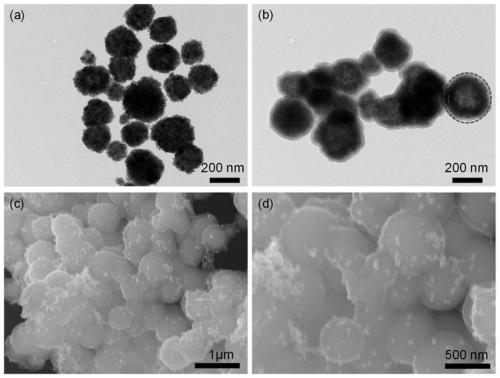

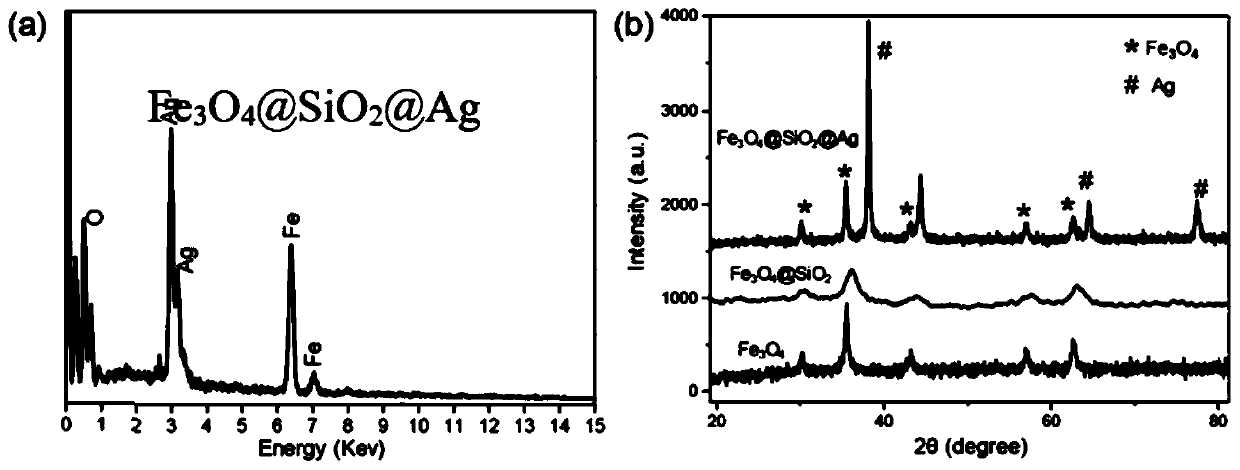

Preparation method of modified magnetic composite nano particles and application thereof in pesticide detection

The invention discloses a preparation method of modified magnetic composite nano particles and application thereof in pesticide detection. Magnetic composite Fe3O4@SiO2@Ag@COOH NPs are combined with an Au film to form an SERS substrate for effectively detecting trace thiaform bacteria. The Fe3O4@SiO2@Ag@COOH NPs have the same shape, good dispersibility and a core-shell structure, and can be quickly separated from the external magnetic field, so that thiabendazole is enriched. In addition, since LSPR of the Au film is coupled to the SPPs of the Ag particles, the SERS is further enhanced, the sensitivity of the detection is improved, and the rapid detection down to a concentration of 1[mu]g / L is realized.

Owner:深圳市农产品质量安全检验检测中心

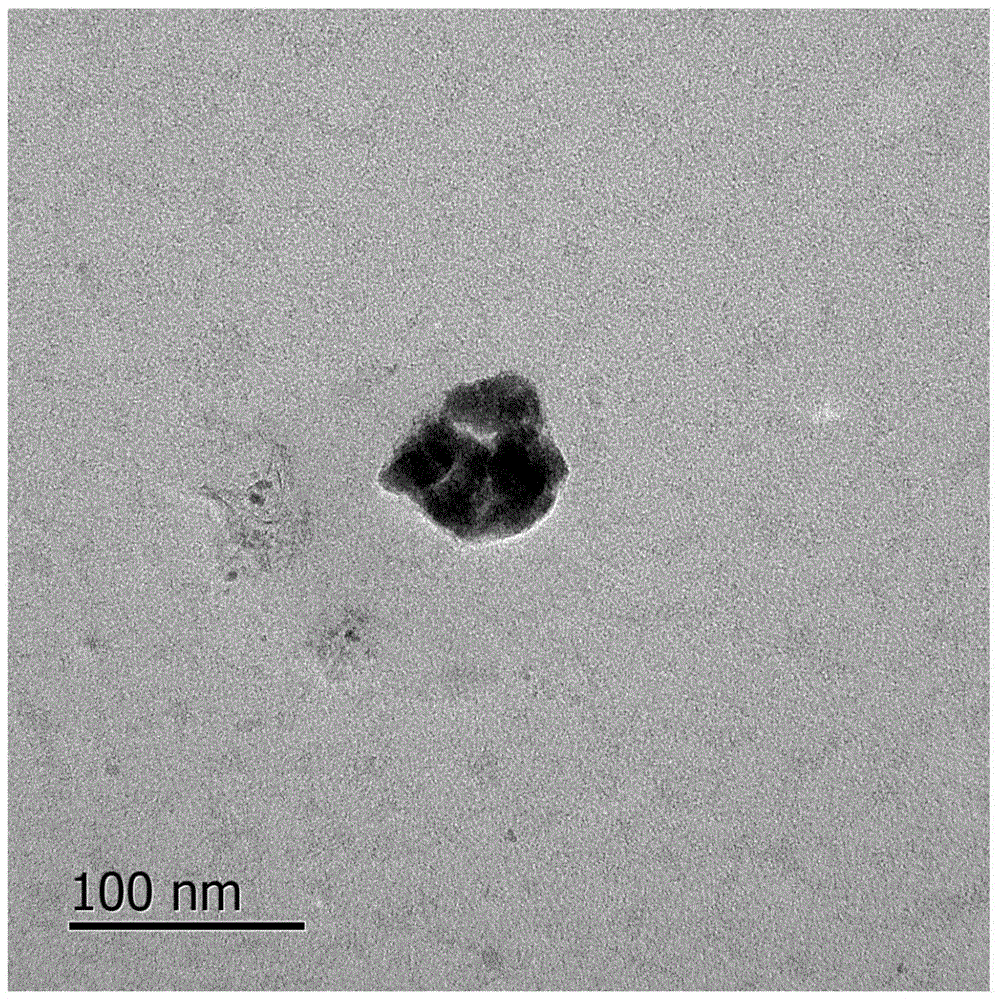

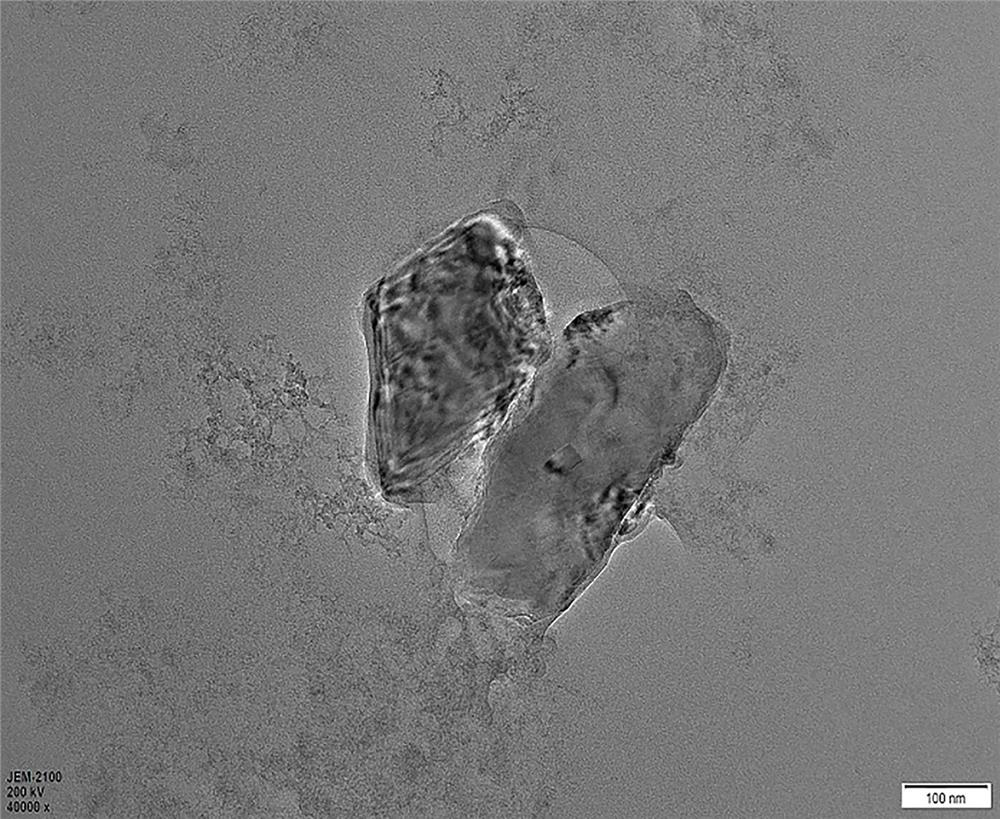

Nanocomposite particles and preparation method thereof

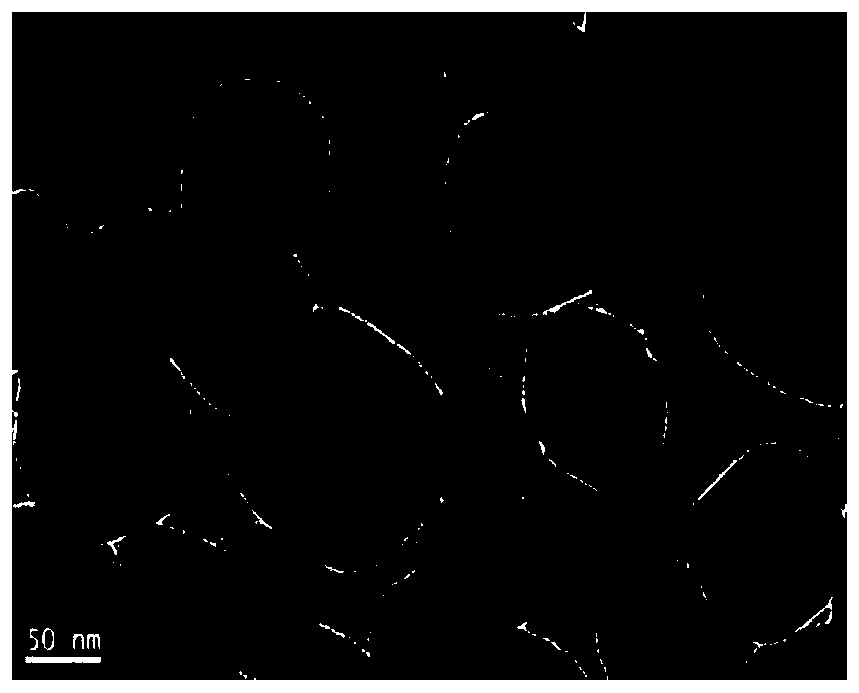

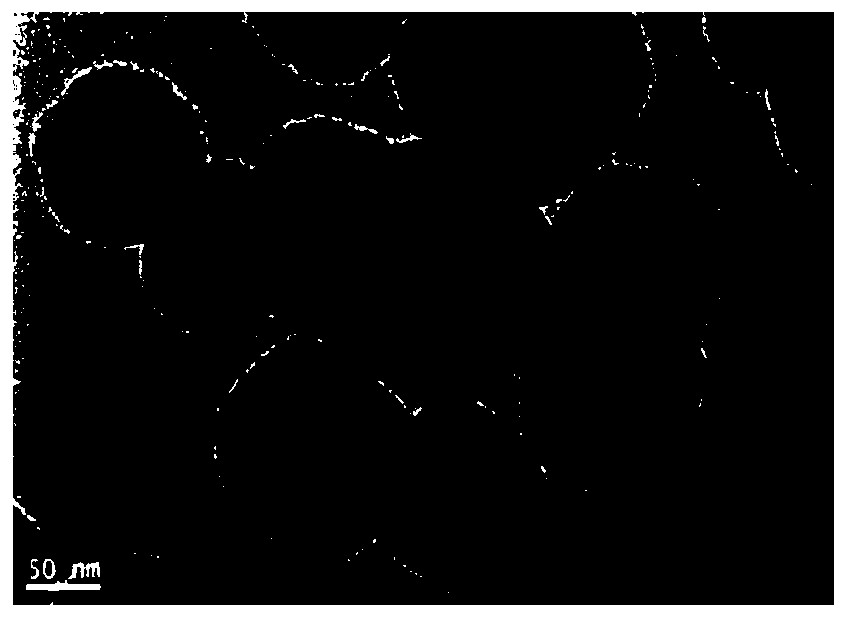

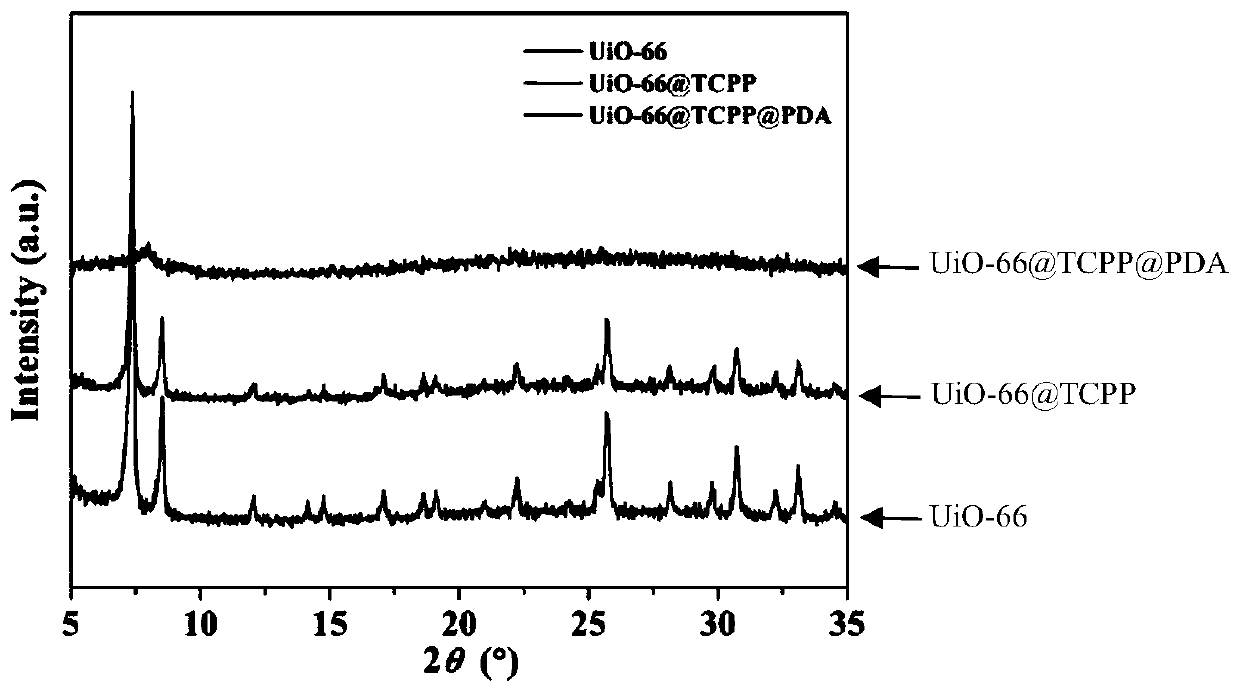

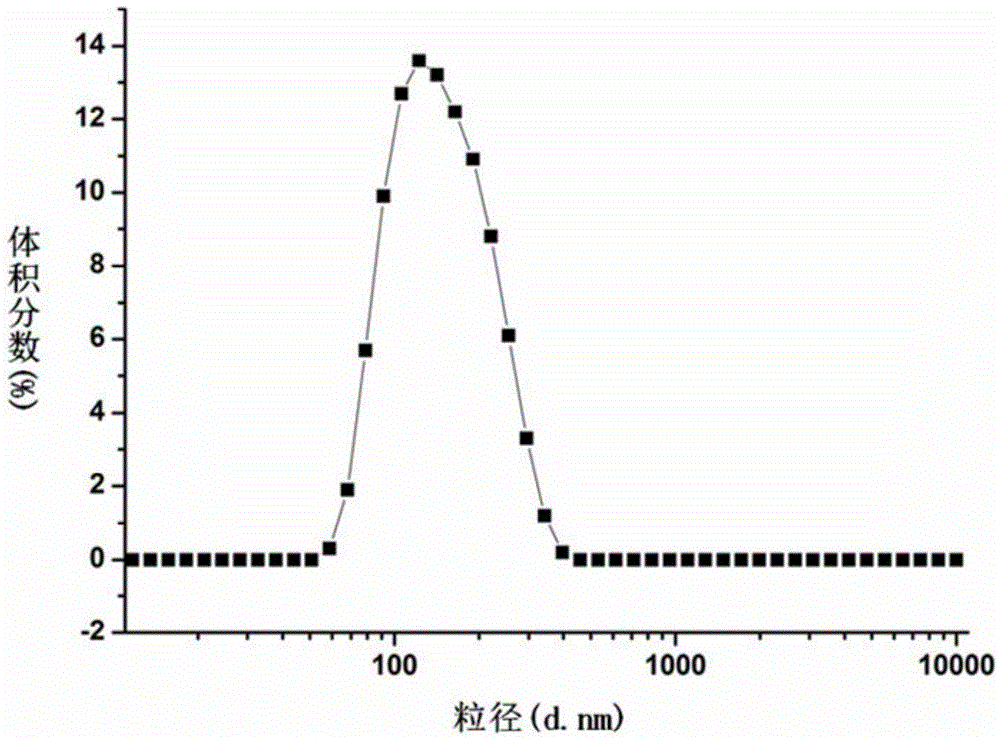

InactiveCN110025596AHas a core-shell structureUniform shapeEnergy modified materialsPharmaceutical non-active ingredientsBenzoic acidPorphyrin molecule

The invention provides nanocomposite particles and a preparation method thereof. The preparation method of the nanocomposite particles comprises the following steps: dissolving ZrCl4 in N,N-dimethylmethylamide so as to form a ZrCl4 solution; sequentially adding terephthalic acid, benzoic acid, hydrochloric acid and meso-tetra(4-carboxyphenyl)porphine into the ZrCl4 solution so as to obtain organometallic framework nanoparticles embedded with porphyrin molecules; adding the organometallic framework nanoparticles into a buffer solution; and then, adding dopamine so as to form polydopamine by polymerization of dopamine molecules, thereby wrapping outer surface of the organometallic framework nanoparticles with the polydopamine so as to form nanocomposite particles with a core-shell structure,wherein thickness of the polydopamine layers is 5-50nm and size of the nanocomposite particles is 60-500nm. The nanocomposite particles prepared by the preparation method are uniform in appearance, good in dispersivity, low in biological toxicity, and excellent in photothermal effects and photodynamic therapeutic effects; and thus, the nanocomposite particles have good curative effects on tumors.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Core-shell type double-active acrylate elastic body and preparation method thereof

The invention discloses a preparation method of a core-shell type double-active acrylate elastic body. The preparation method is characterized by specifically comprising the following steps of: adding an acrylate monomer, acrylate containing active groups, and a compound emulsifying agent in a kneading machine, heating to 60-90 DEG C, keeping a temperature and reacting for 0.8-1.2 h, and then, adding a vulcanizing agent and an oxidation-reduction initiator, under the protection of nitrogen, heating to 80-100 DEG C, keeping the temperature and reacting for 1.5-2.0 h, and finally, cooling to 40-50 DEG C to obtain the core-shell type double-active acrylate elastic body. The core-shell type double-active acrylate elastic body is obtained through an emulsion polymerization method and has a core-shell structure; the combination property of an adhesive film is favorable; the core-shell type double-active acrylate elastic body is applied to a sealing fluorine rubber; and the sealing fluorine rubber can be enabled to have higher high temperature resistance, oil resistance, ageing resistance, low temperature resistance and tear resistance performances.

Owner:GUANGZHOU GLORYSTAR CHEM

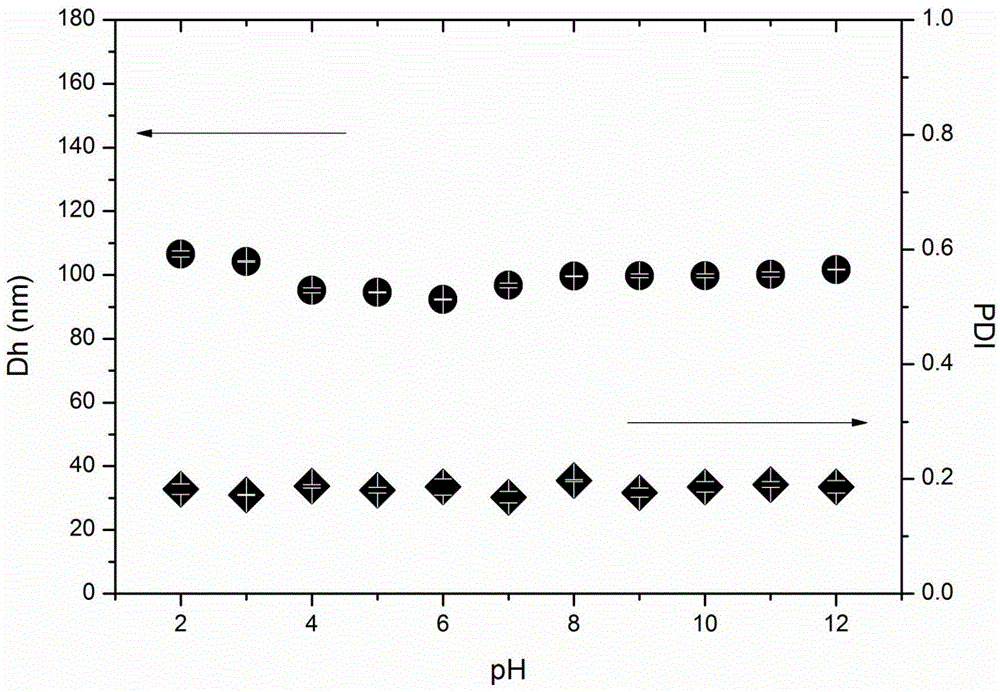

Preparation of protein-polysaccharide nano gel on basis of Maillard reaction in macromolecular crowding environment

InactiveCN105542195ALow cytotoxicityEasy to degradeFood ingredient functionsPolysaccharide/gum food ingredientsFunctional foodIon

The invention belongs to the technical field of functional food processing, and discloses preparation of a protein-polysaccharide nano gel on the basis of Maillard reaction in a macromolecular crowding environment. The preparation method comprises the following steps: dissolving protein and polysaccharide in deionized water, stirring uniformly, regulating the pH value to 6.8-7, standing in a 4-DEG C refrigerator over night to perform hydration sufficiently, stirring at 60-95 DEG C to react for 6-48 hours, drying the reaction product to obtain powder, dissolving the powder in water to obtain a solution, regulating the pH value to the protein isoelectric point, carrying out heating treatment at 80-95 DEG C for 5-60 minutes, and cooling to obtain the protein-polysaccharide nano gel. The gel has the core-shell structure, has the advantages of small size and excellent stability, can be used for carrying biological active substances, and is hopeful to become the material for preparing new functional food.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing PMMA (Polymethyl Methacrylate) microsphere with core-shell structure through soap-free emulsion polymerization

ActiveCN103342768AEliminate the effects ofImproved physical-chemical propertiesWater bathsPolymer science

The invention provides a method for preparing a PMMA (Polymethyl Methacrylate) microsphere with a core-shell structure through soap-free emulsion polymerization, and belongs to the technical field of high polymer chemistry. The method comprises the following steps of: carrying out reduced pressure distillation on an MMA (Methyl Methacrylate) monomer to obtain a fresh monomer; uniformly mixing the MMA monomer and water, heating in a water bath, then, adding a water-soluble initiator, and reacting while stirring under the condition of the water bath to obtain a colloid emulsion; filtering to remove impurities and conglobated macromolecular substances in the colloid emulsion; then, carrying out centrifugal separation, and drying the obtained solid product at constant temperature to obtain the PMMA microsphere with the core-shell structure. By using a soap-free emulsion, the affect from a micromolecular emulsifying agent is eliminated, and the physical-chemical, mechanical and adhesive properties of a polymer are improved; a defoaming agent is not used basically in the preparation process, so that the pollution of the emulsifying agent to the environment is eliminated; the microsphere with monodispersity and a clean surface can be prepared, and the microsphere is uniform in particle size and has the core-shell structure.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing nucleus/shell type microemulsion fluid of copolymer in high inherent content

A process for preparing the microemulsion of core-shell copolymer with high content of solid by ultrasonic emulsifying method features that the raw materials are sequentially added, that is, adding the monomer with low polymerizing competition power, vapor pressure and water solubility, adding trigger to polymerize core, and adding the second monomer to polymerize shell.

Owner:QINGDAO UNIV OF SCI & TECH

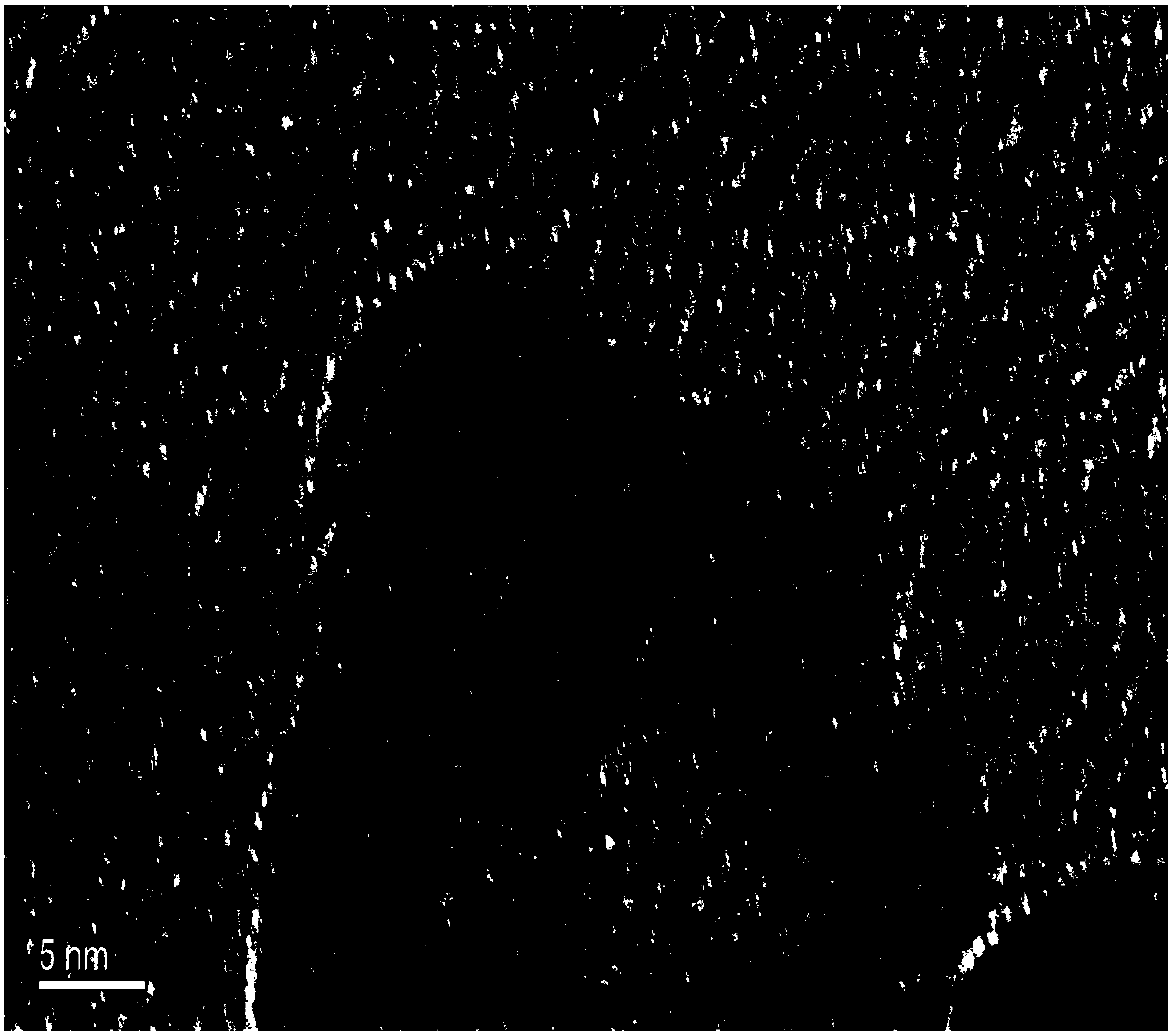

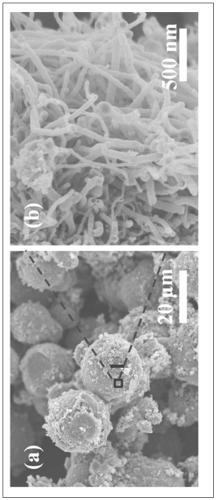

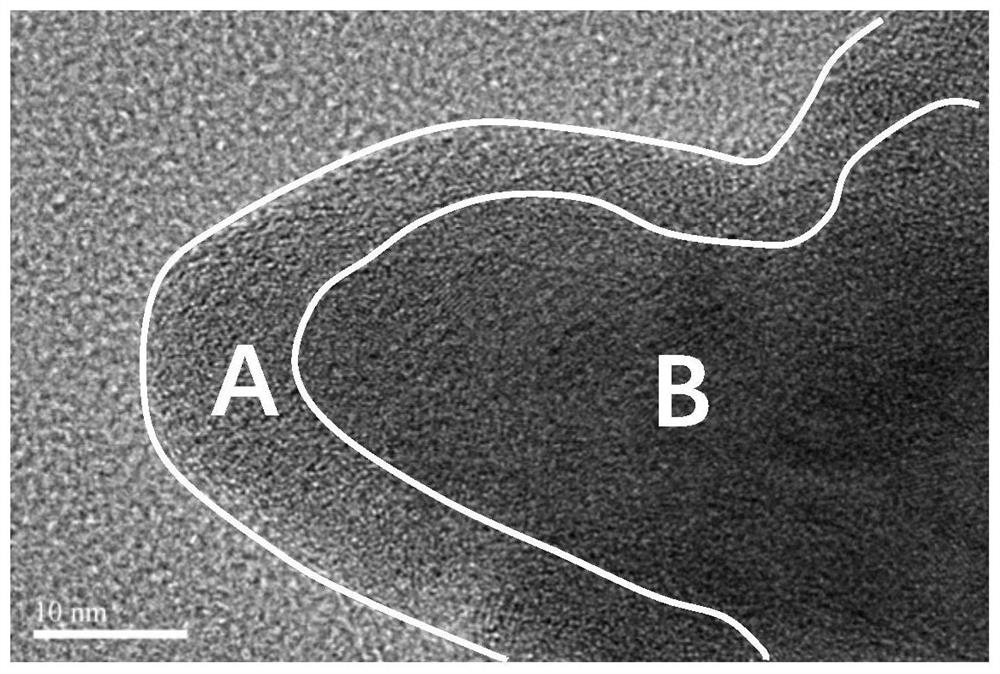

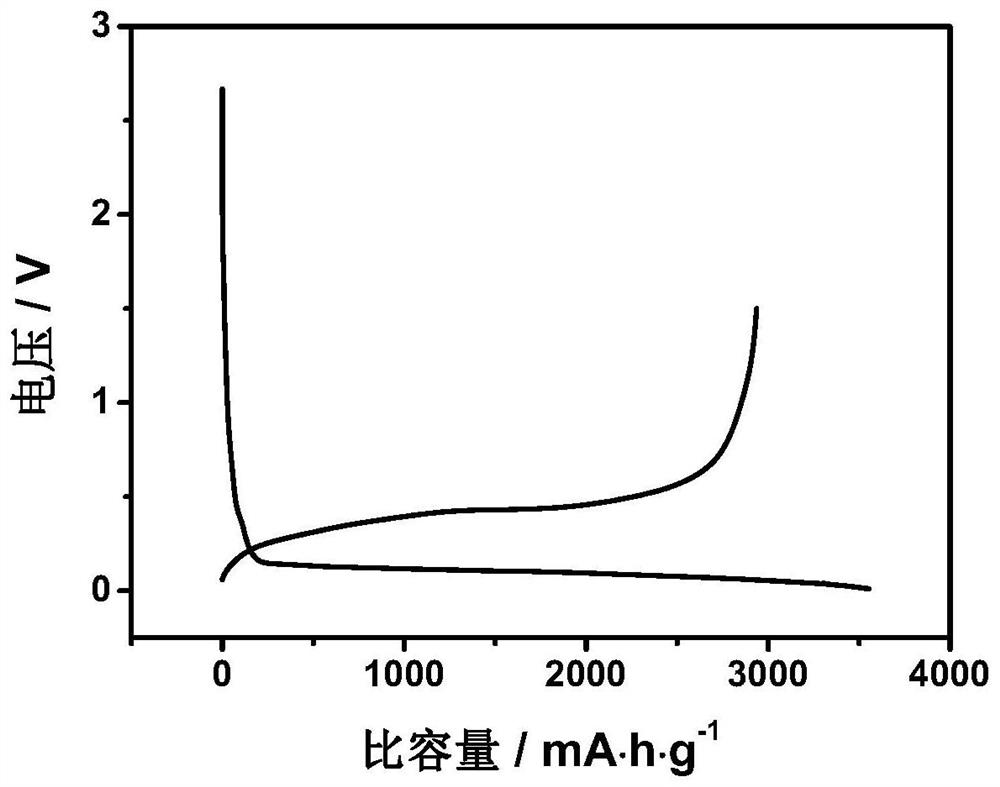

Lithium ion battery silicon/carbon negative electrode composite material and preparation method thereof

ActiveCN109755515ANovel structureHas a core-shell structureCell electrodesSecondary cellsMetal silicideCarbon nanotube

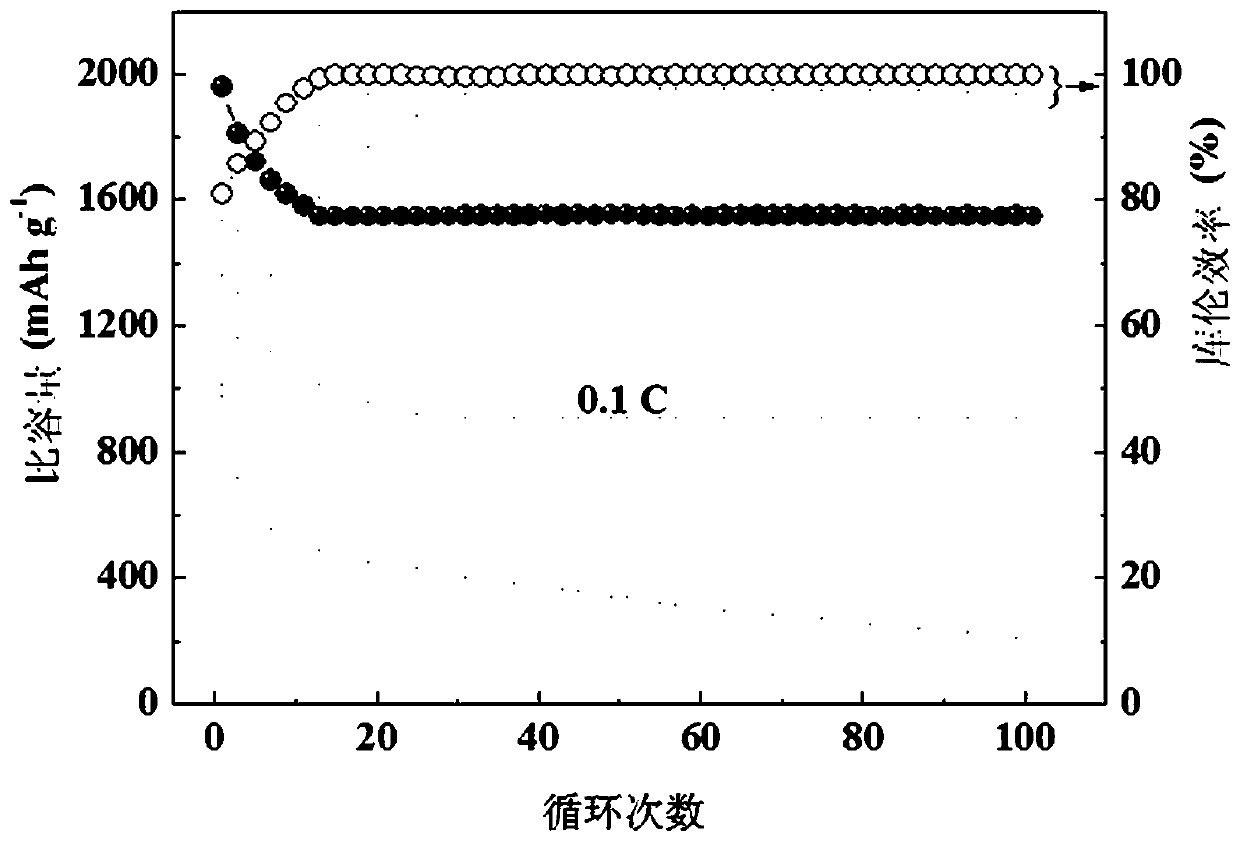

The invention discloses a lithium ion battery silicon / carbon negative electrode composite material. The lithium ion battery silicon / carbon negative electrode composite material is of a core shell structure, wherein a core is porous-structure silicon particle, a shell layer is a zigzagging carbon nanotube cluster having a large amount of gaps, and interfaces of the core and the shell layer are connected by a metal silicide. In the lithium ion battery silicon / carbon negative electrode composite material, the volume expansion of silicon during the charge-discharge process is remarkably reduced byporosity of the silicon particle, and the diffusion performance of lithium ions in the silicon is improved; with high conductivity of the carbon nanotube cluster, the defect of low conductivity of the silicon is overcome, meanwhile, the carbon nanotube cluster is used as a flexible external buffer layer, the volume expansion of the silicon is further reduced; and the metal silicide is used as a compact connection point, an electron transmission passage is built between the silicon and the carbon nanotube, and the carbon nanotube can be prevented from falling off during the charge-discharge process. The novel-structure silicon / carbon negative electrode composite material provided by the invention has the advantages of high specific capacity, good cycle property, excellent rate performanceand the like in application of a lithium ion battery and is low in fabrication cost and simple in method, and industrial production is easily achieved.

Owner:XINYANG NORMAL UNIVERSITY

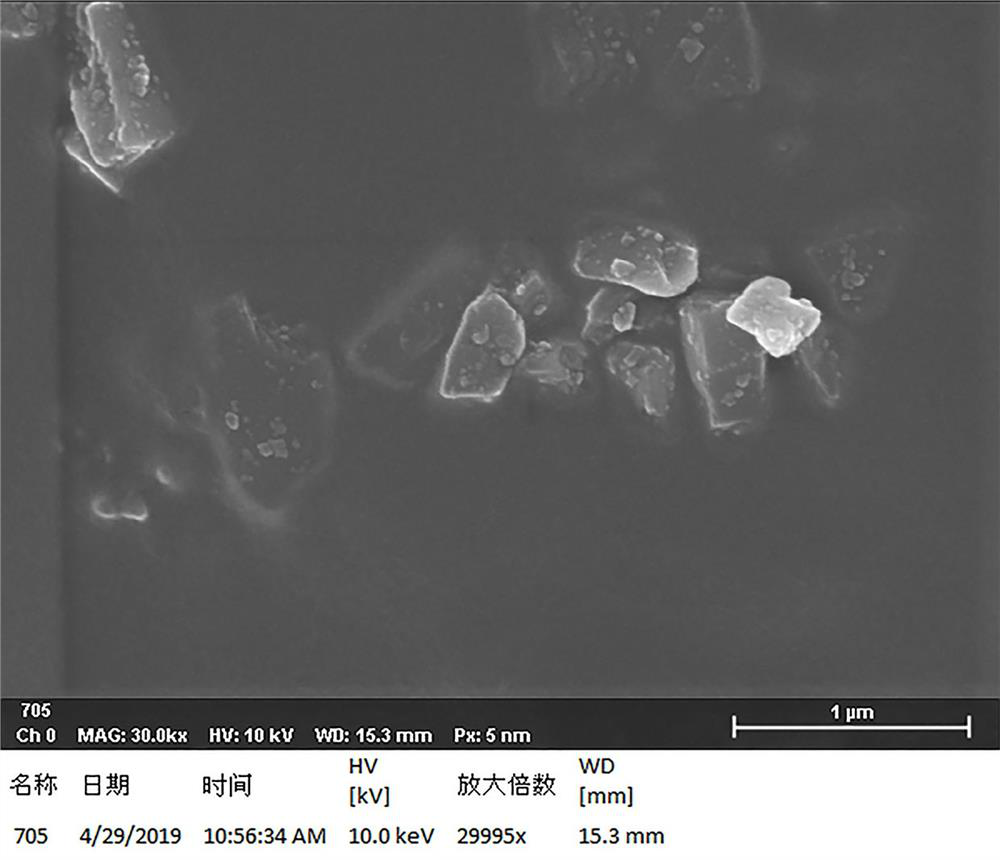

Aluminum oxide coated cubic boron nitride composite powder and preparation method thereof

The invention relates to aluminum oxide coated cubic boron nitride composite powder and a preparation method thereof. The preparation method comprises the following steps of: (1) mixing cubic boron nitride and ethanol according to a certain proportion, adding lauryl sodium sulfate and polyethylene glycol at a certain temperature under a stirring condition, uniformly mixing to obtain a solution, cooling the solution, centrifugally separating the solution, and washing to obtain modified nano c-BN; (2) mixing the modified nano c-BN with absolute ethyl alcohol according to a certain proportion under a stirring condition, uniformly dispersing to obtain a solution A, adding aluminum nitrate into the solution A, and uniformly mixing to obtain a solution B; and (3) slowly adding a mixed solution of ammonia water and ethanol into the solution B obtained in the step (2) until the pH value of the solution is 7-12, continuously stirring until the reaction is finished, standing and aging the obtained product, centrifugally separating the solid product, and heating and dehydrating to obtain the aluminum oxide coated cubic boron nitride composite powder. The preparation method disclosed by the invention has the characteristics of simple process and low cost, the prepared composite powder is good in dispersity, good in coating effect, high in coating rate and uniform in particle size, and thesurface characteristics of cubic boron nitride particles are improved.

Owner:QILU UNIV OF TECH

Composite nanoparticle with calcium fluoride coated with aluminum oxide and preparation method thereof

The invention discloses a composite nanoparticle with calcium fluoride coated with aluminum oxide and a preparation method thereof. The preparation method comprises the following steps of (1) mixing polyvinylpyrrolidone and ethyl alcohol according to a certain ratio, stirring, adding xylene, uniformly mixing, and separating into two parts, namely a solution B and a solution C; (2) adding nanometercalcium fluoride powder into the solution B under the stirring condition, and uniformly dispersing, so as to obtain a solution B'; adding aluminum nitrate into the solution C, and uniformly mixing, so as to obtain a solution C'; (3) mixing the solution B' and the solution C', slowly adding an ammonium hydroxide and ethyl alcohol mixed solution until the pH (potential of hydrogen) value of the solution is 7 to 12, continuing to stir until reaction is finished, standing and aging the obtained product, centrifuging and separating a solid product, heating and dewatering, so as to obtain the composite nanoparticle with calcium fluoride coated with aluminum oxide. The preparation method has the characteristics that the technology is simple, and the cost is low. The prepared nanometer compositepowder has the advantages that the dispersivity is better, the coating effect is better, the coating rate is higher, the particle size is uniform, and the surface characteristic of the calcium fluoride particle is well improved.

Owner:QILU UNIV OF TECH

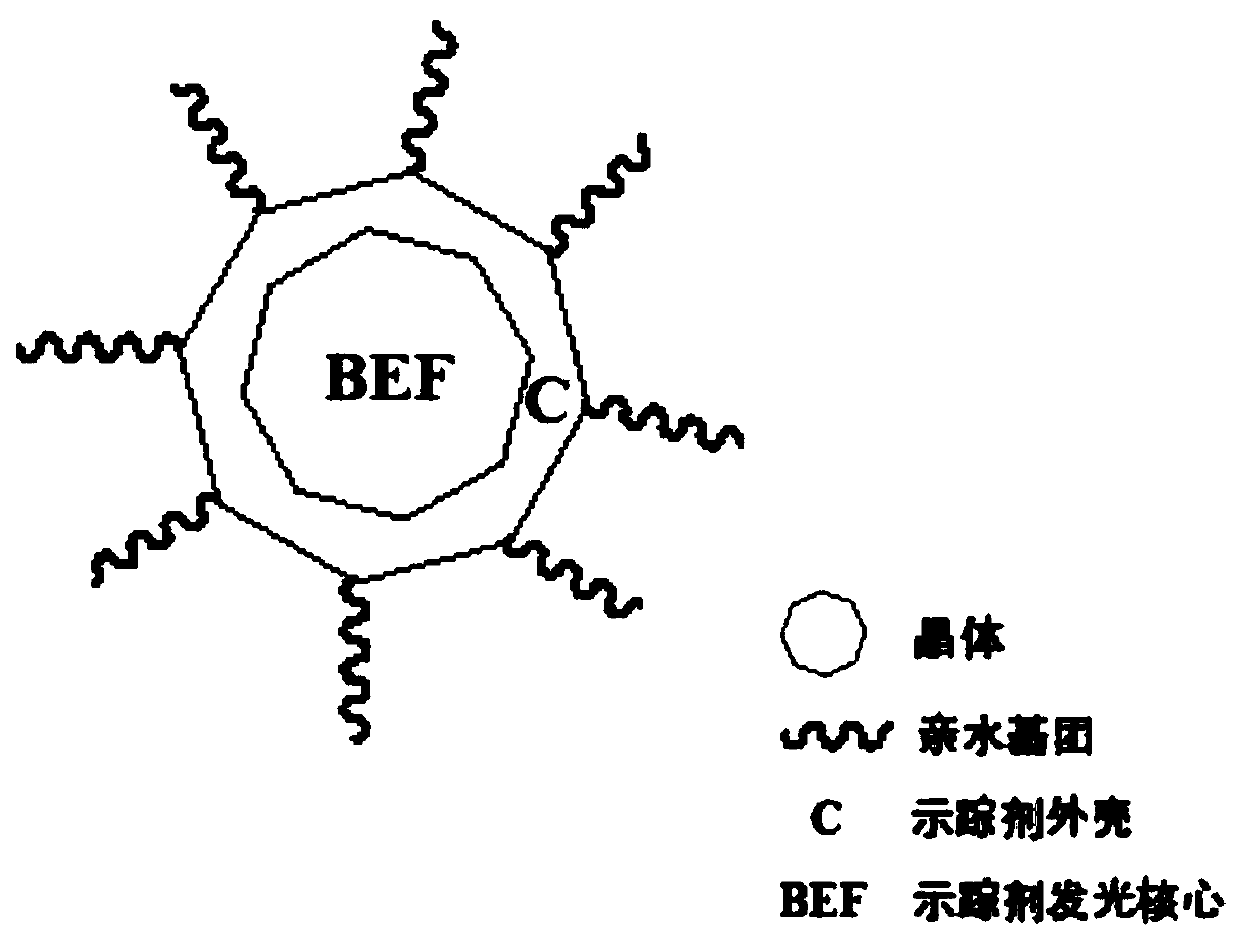

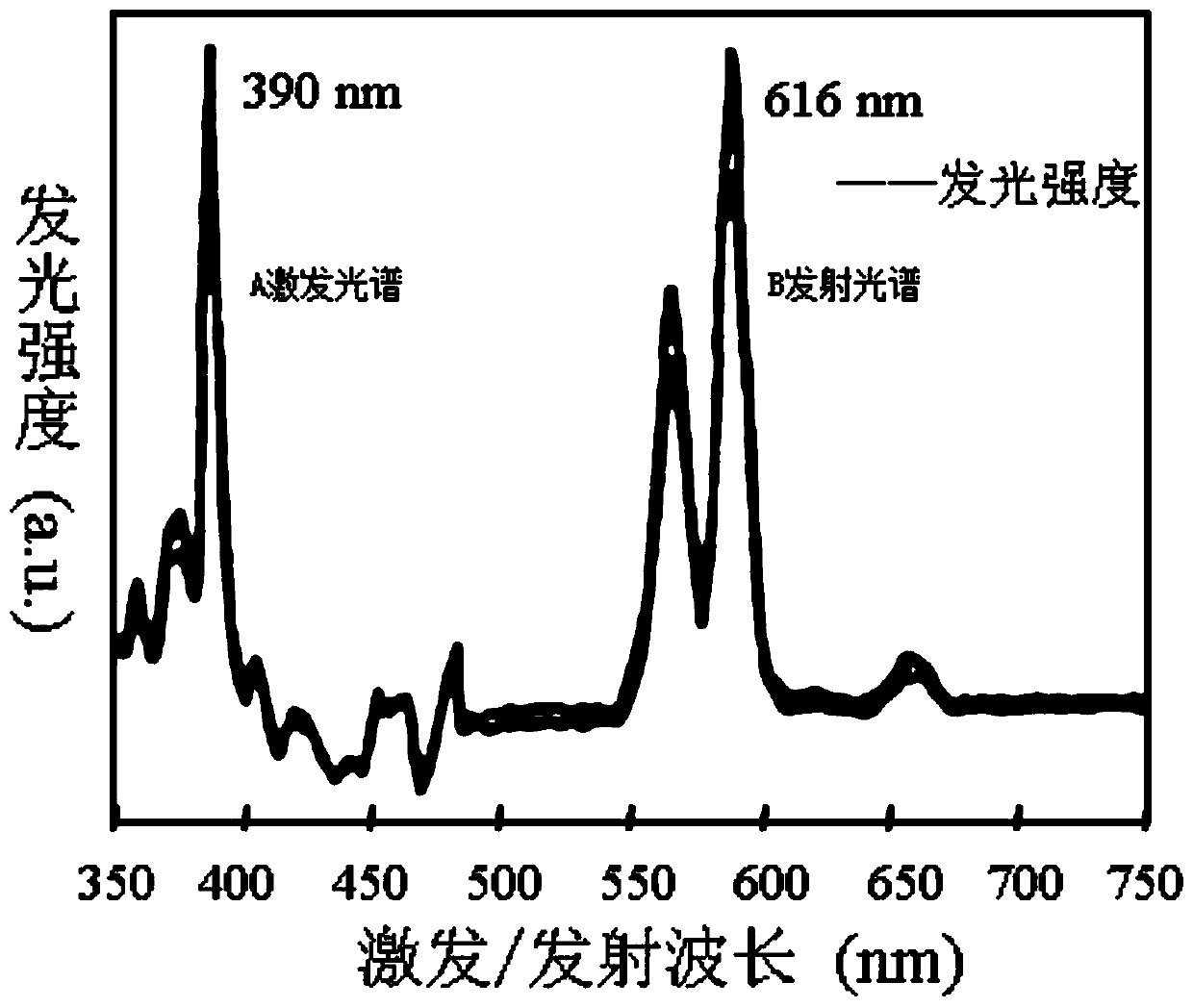

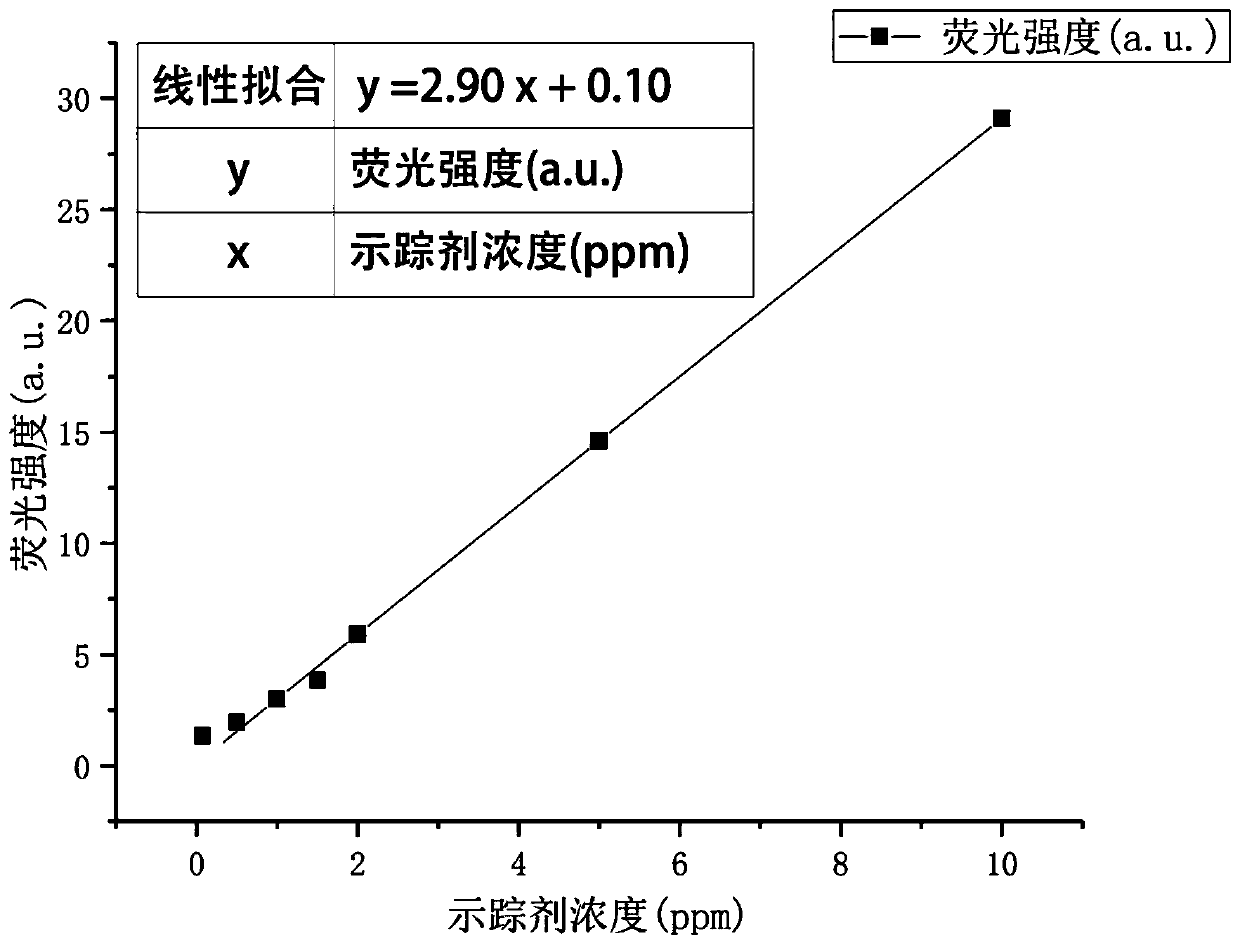

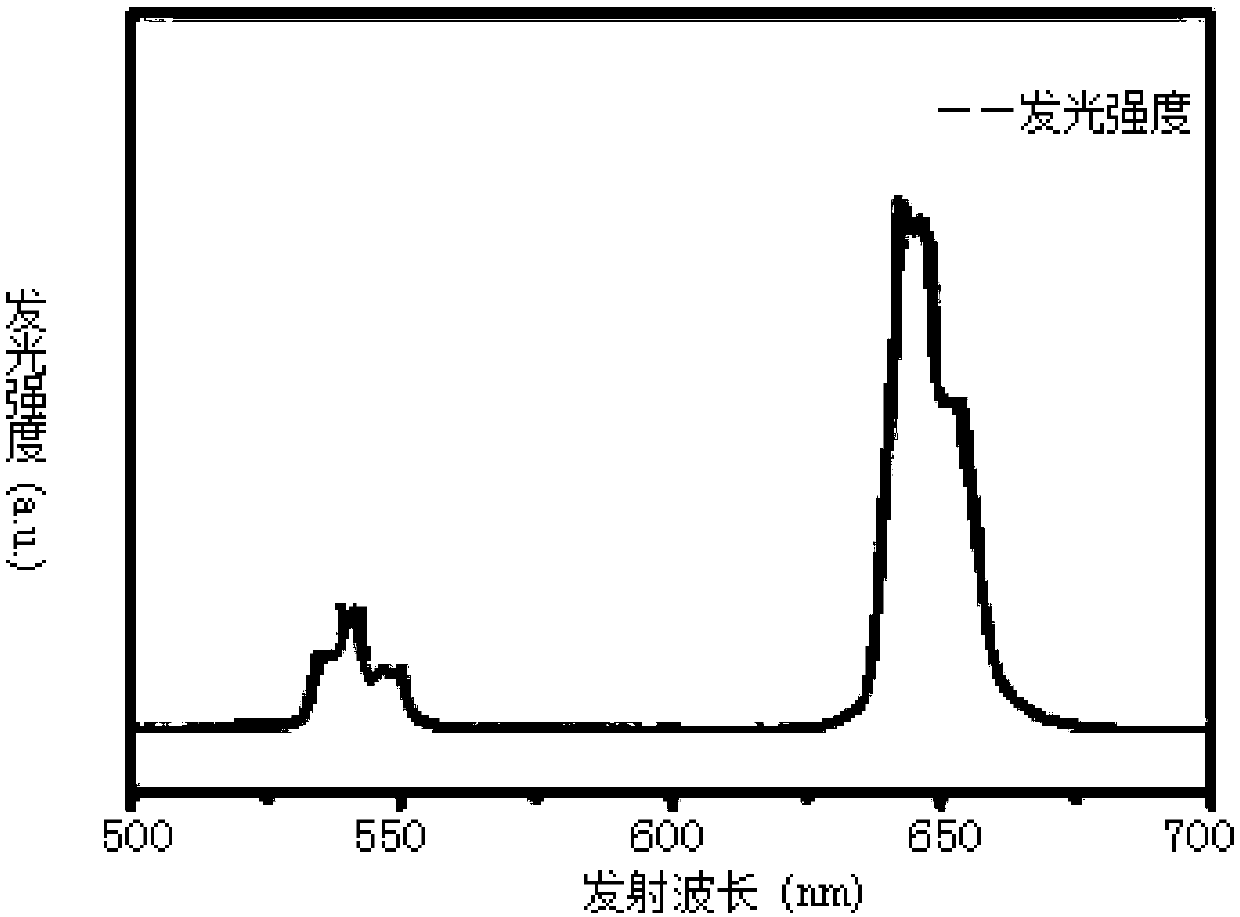

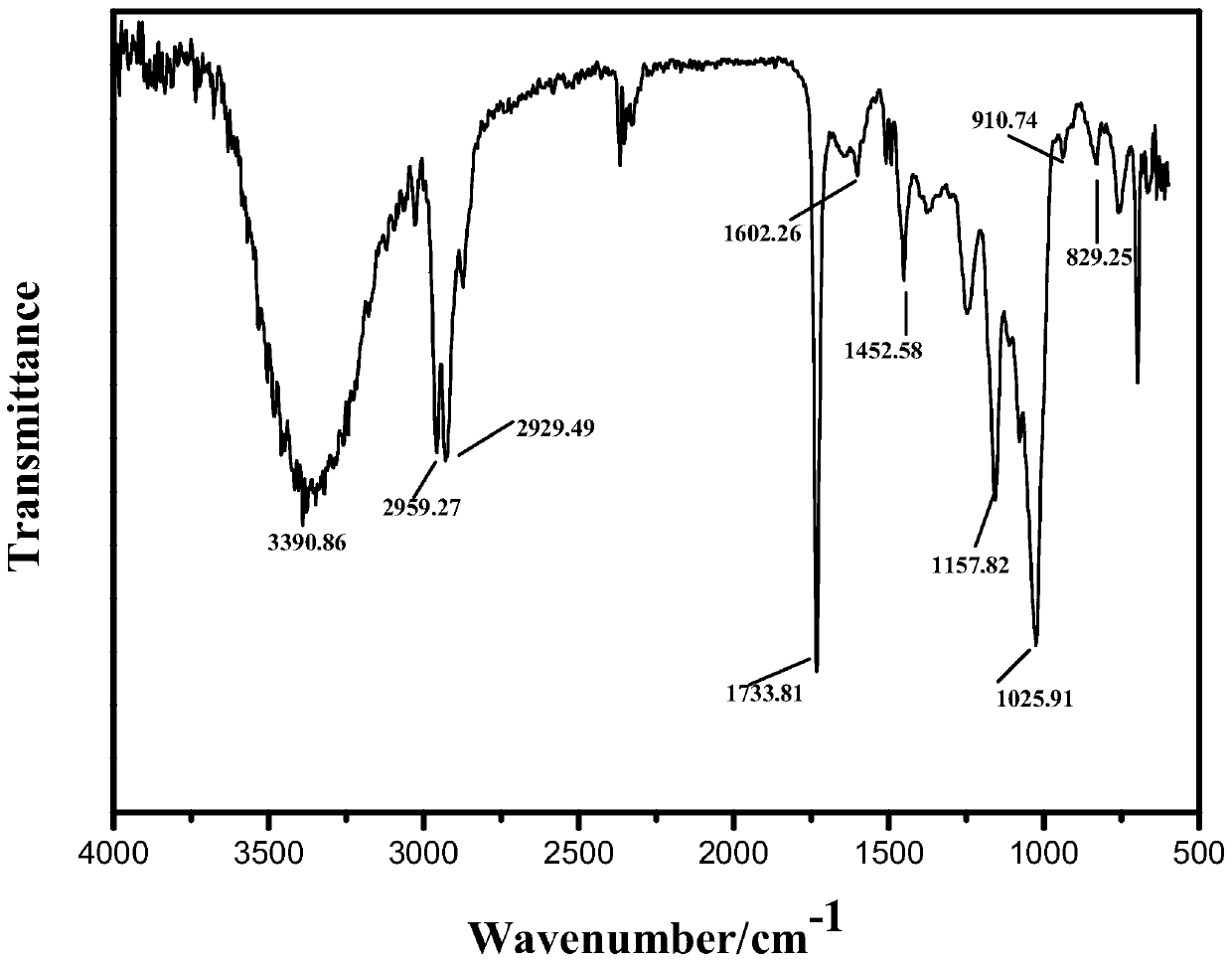

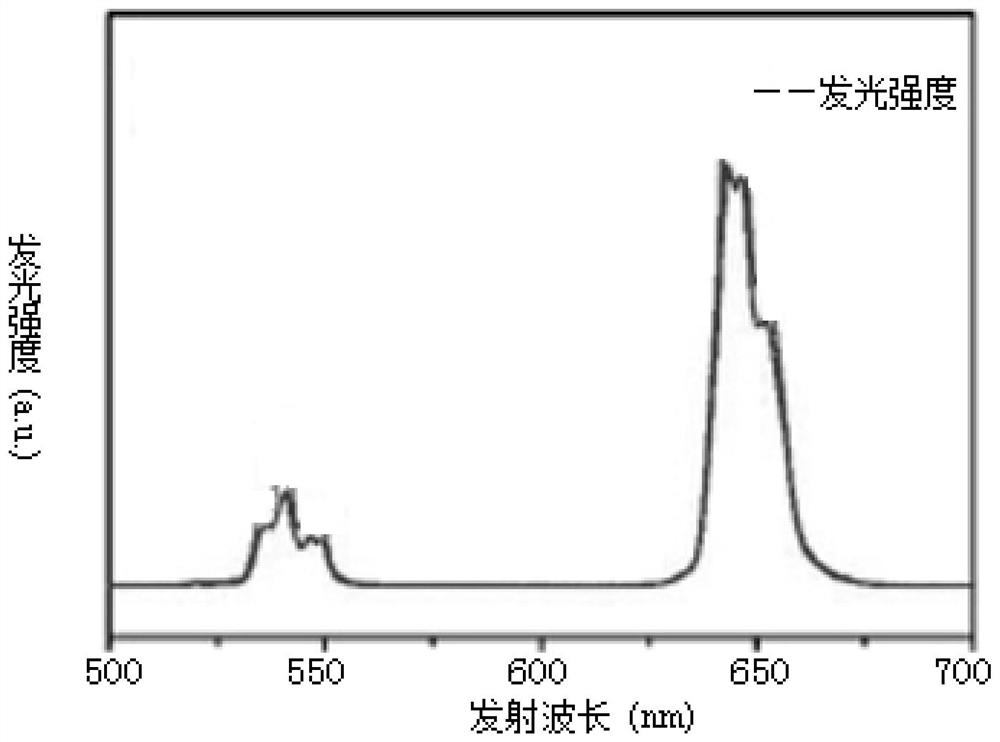

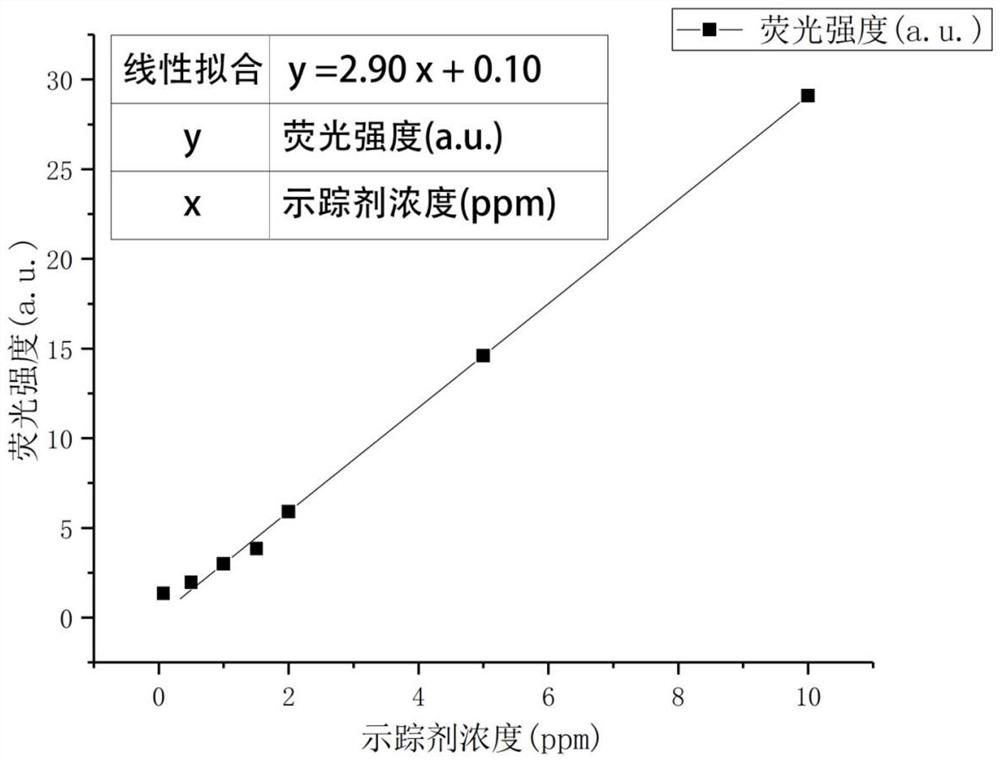

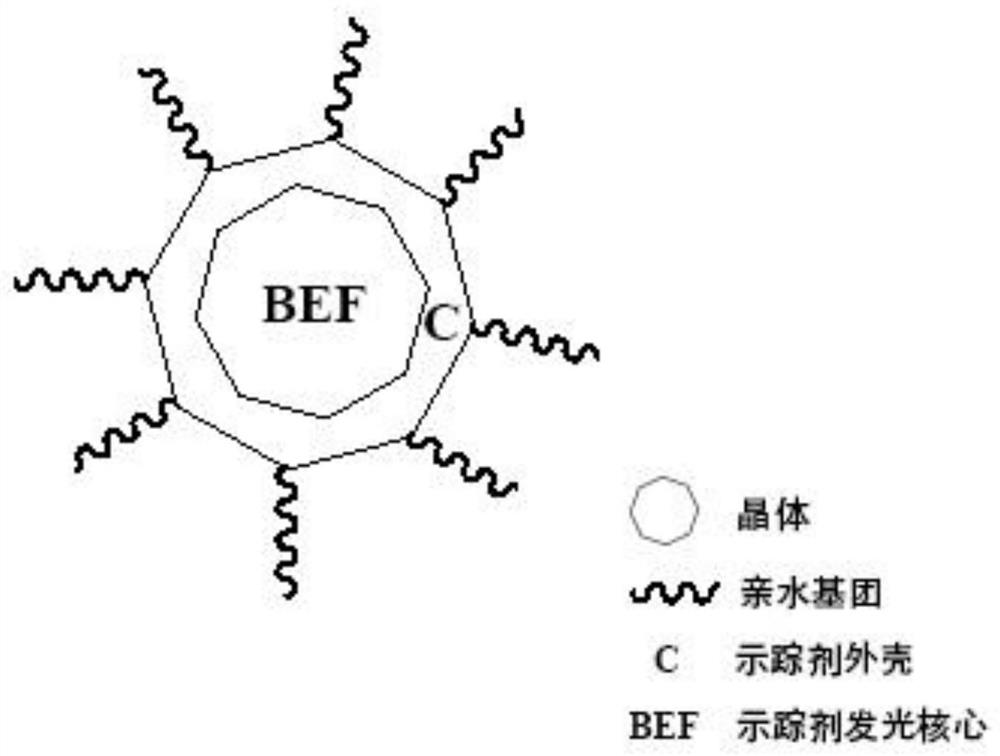

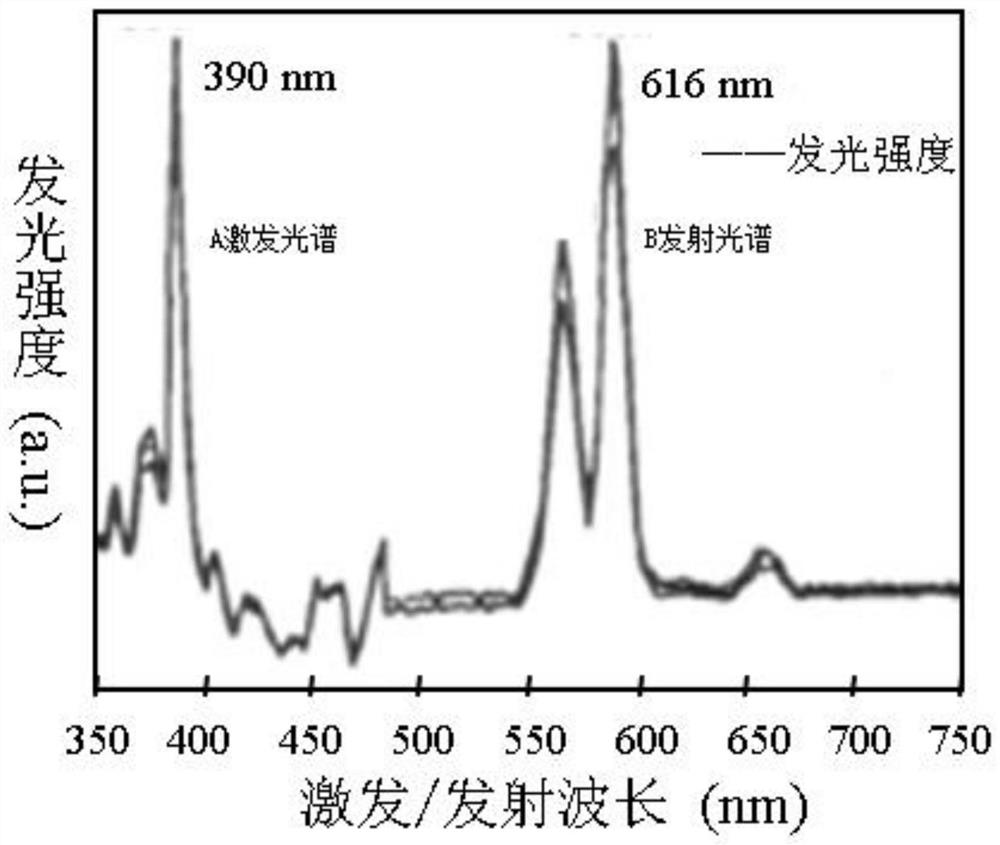

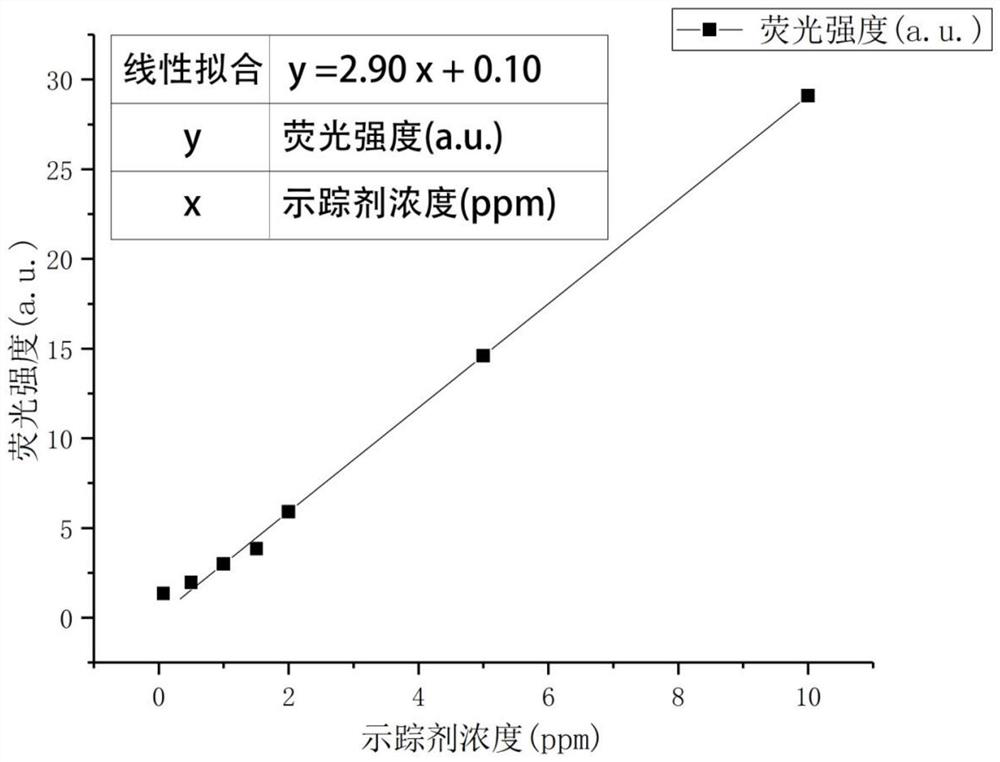

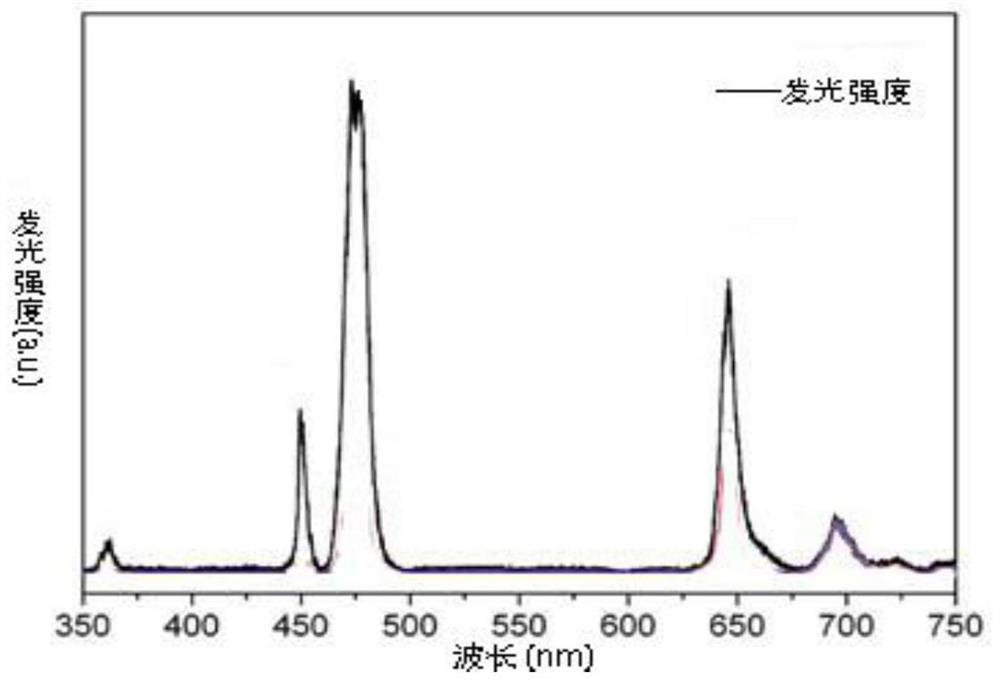

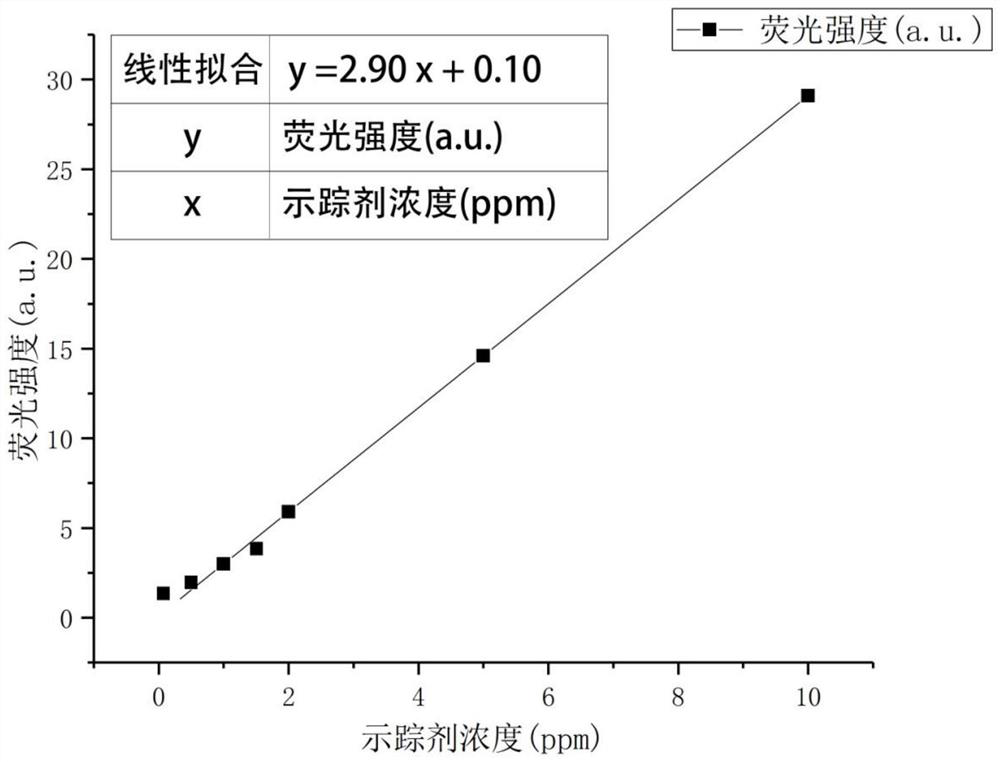

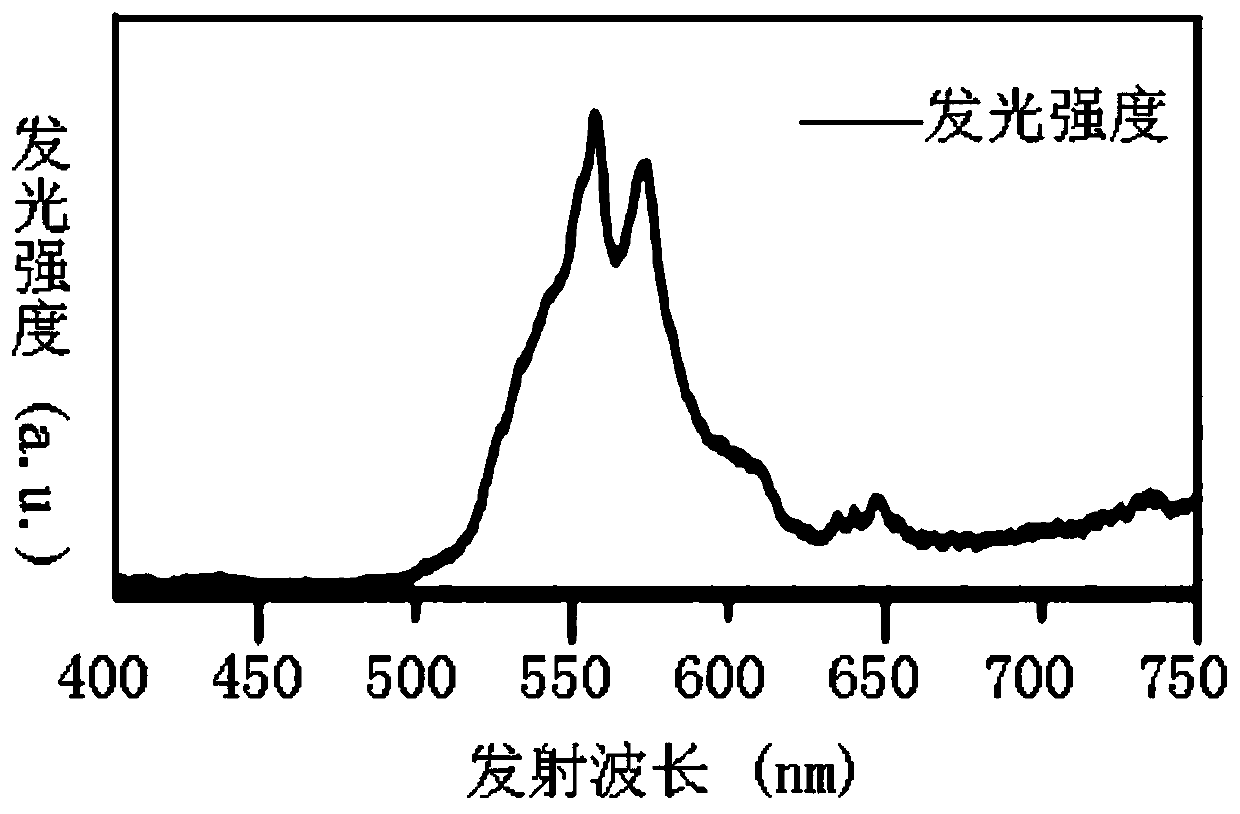

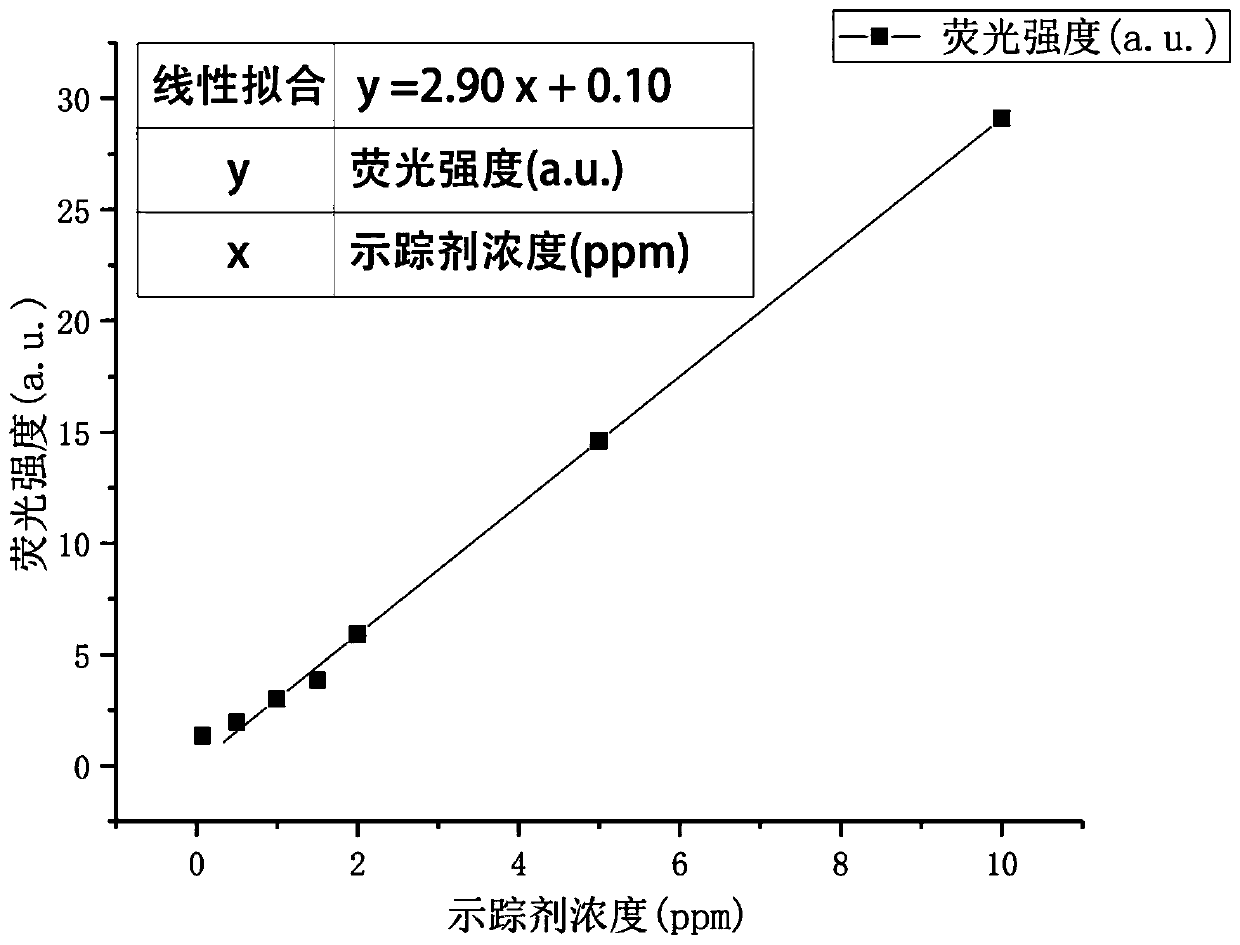

Synthetic method and application of BEFC tracer

ActiveCN109735336AReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementSolubility

The invention relates to a synthetic method and application of a BEFC tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A NaBiF4:Eu3+@C4H4Na2O6 fluorescent nano material with core-shell structure is synthesized herein and may act as an oilfield tracer, named as BEFC tracer. The tracer herein has the advantages of good water solubility, low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility with polymers, and zero impact on polymer flooding. The application of the BEFC tracer as one fluorescent nano material in the field of oilfield detection is innovatively achieved herein; afeasible operating scheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

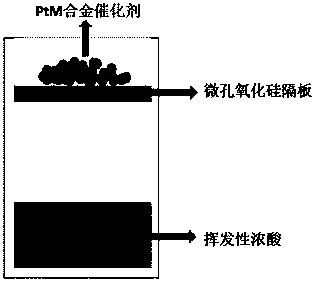

A method for mass-preparing platinum-based dealloyed electrocatalysts for fuel cell cathodes

Owner:BEIJING UNIV OF CHEM TECH

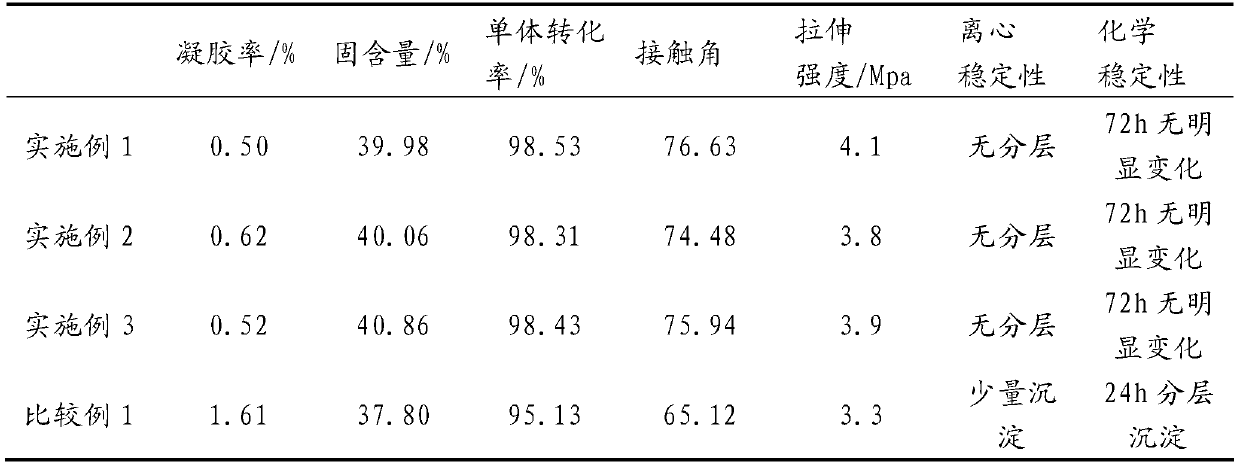

Production process of core/shell emulsion for environment-friendly wood coatings

The invention discloses a production process of a core / shell emulsion for environment-friendly wood coatings. A core / shell polymerization technology is adopted, so that the aims of reducing the film-forming temperature and reducing the amount of film-forming aids are achieved. A pre-emulsification process and a semi-continuous seeded emulsion polymerization mode are adopted, and acrylate emulsion with a core / shell structure and excellent performance is prepared and can be used for environment-friendly wood coatings.

Owner:QINGDAO SHOUSHENG IND

A kind of lithium-ion battery silicon/carbon negative electrode composite material and preparation method thereof

ActiveCN109755515BNovel structureHas a core-shell structureCell electrodesSecondary cellsMetal silicideCarbon nanotube

The invention discloses a lithium ion battery silicon / carbon negative electrode composite material. The lithium ion battery silicon / carbon negative electrode composite material is of a core shell structure, wherein a core is porous-structure silicon particle, a shell layer is a zigzagging carbon nanotube cluster having a large amount of gaps, and interfaces of the core and the shell layer are connected by a metal silicide. In the lithium ion battery silicon / carbon negative electrode composite material, the volume expansion of silicon during the charge-discharge process is remarkably reduced byporosity of the silicon particle, and the diffusion performance of lithium ions in the silicon is improved; with high conductivity of the carbon nanotube cluster, the defect of low conductivity of the silicon is overcome, meanwhile, the carbon nanotube cluster is used as a flexible external buffer layer, the volume expansion of the silicon is further reduced; and the metal silicide is used as a compact connection point, an electron transmission passage is built between the silicon and the carbon nanotube, and the carbon nanotube can be prevented from falling off during the charge-discharge process. The novel-structure silicon / carbon negative electrode composite material provided by the invention has the advantages of high specific capacity, good cycle property, excellent rate performanceand the like in application of a lithium ion battery and is low in fabrication cost and simple in method, and industrial production is easily achieved.

Owner:XINYANG NORMAL UNIVERSITY

Electrode material lithium supplementing additive, preparation method and application thereof and lithium ion battery

ActiveCN112635720AHas a core-shell structureStable in natureCell electrodesSecondary cellsCarbon filmLithium-ion battery

The invention relates to the field of lithium ion batteries, and discloses an electrode material lithium supplement additive, a preparation method and application thereof, and a lithium ion battery, the electrode material lithium supplement additive comprises polymer lithium salt and a carbon film coating the surface of the polymer lithium salt. The preparation method of the electrode material lithium supplementing additive comprises the following steps: (1), mixing polymer lithium salt, a carbon source and a solvent; (2), carrying out solid-liquid separation on the material obtained by mixing in the step (1); and (3), carrying out heat treatment on the solid substance obtained by solid-liquid separation. The electrode material lithium supplement additive provided by the invention is convenient to store, has no special requirements on use conditions, and can improve the specific capacity of the material when being used in the electrode material.

Owner:CHINA PETROLEUM & CHEM CORP +1

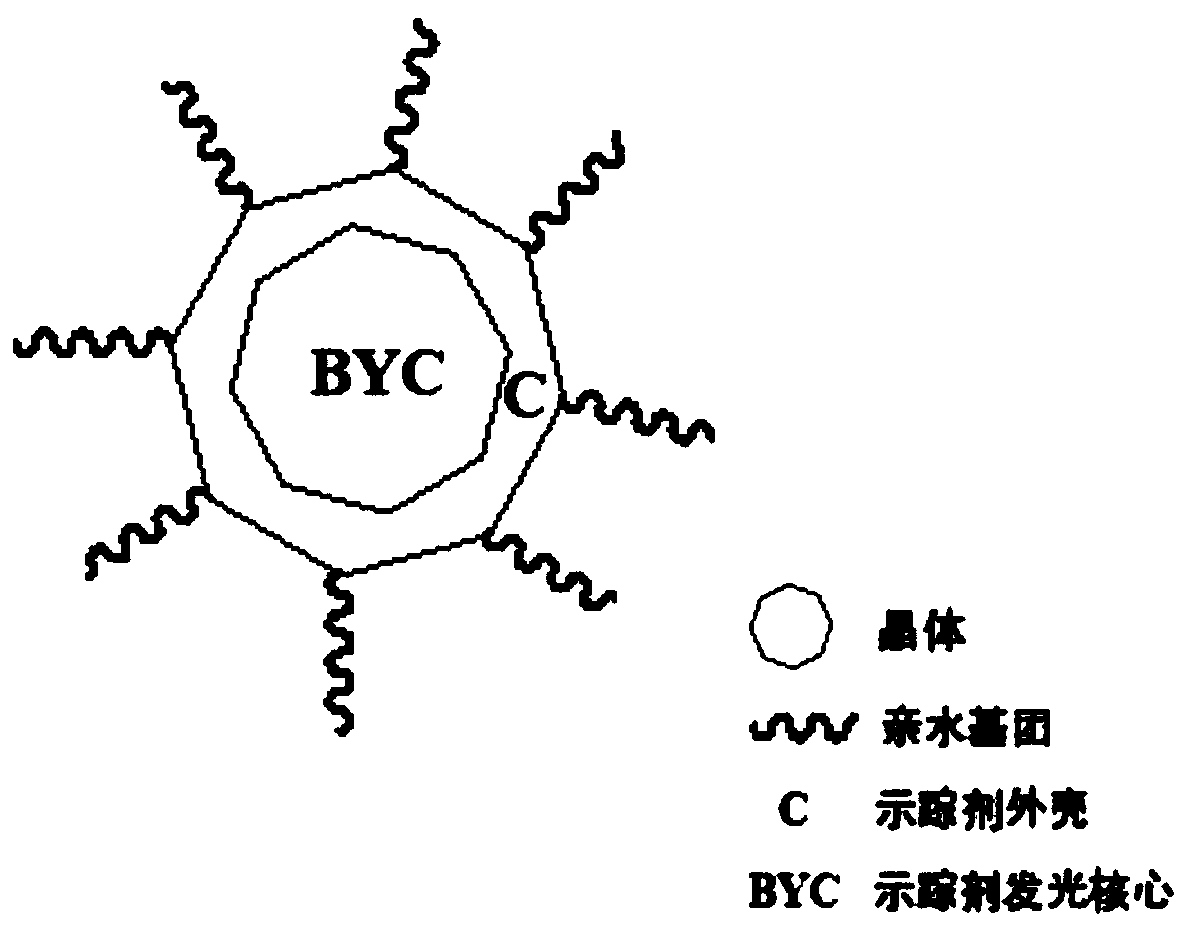

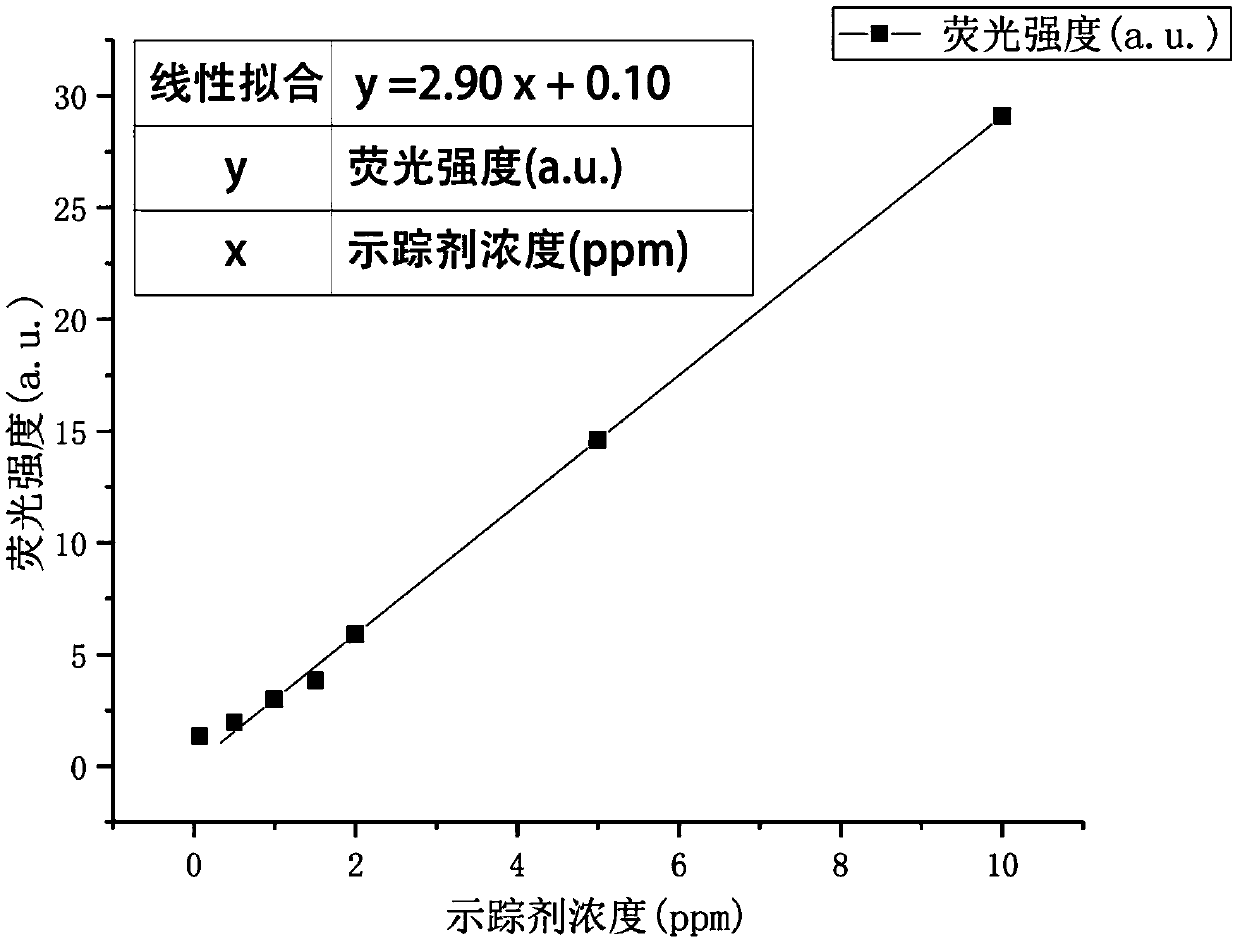

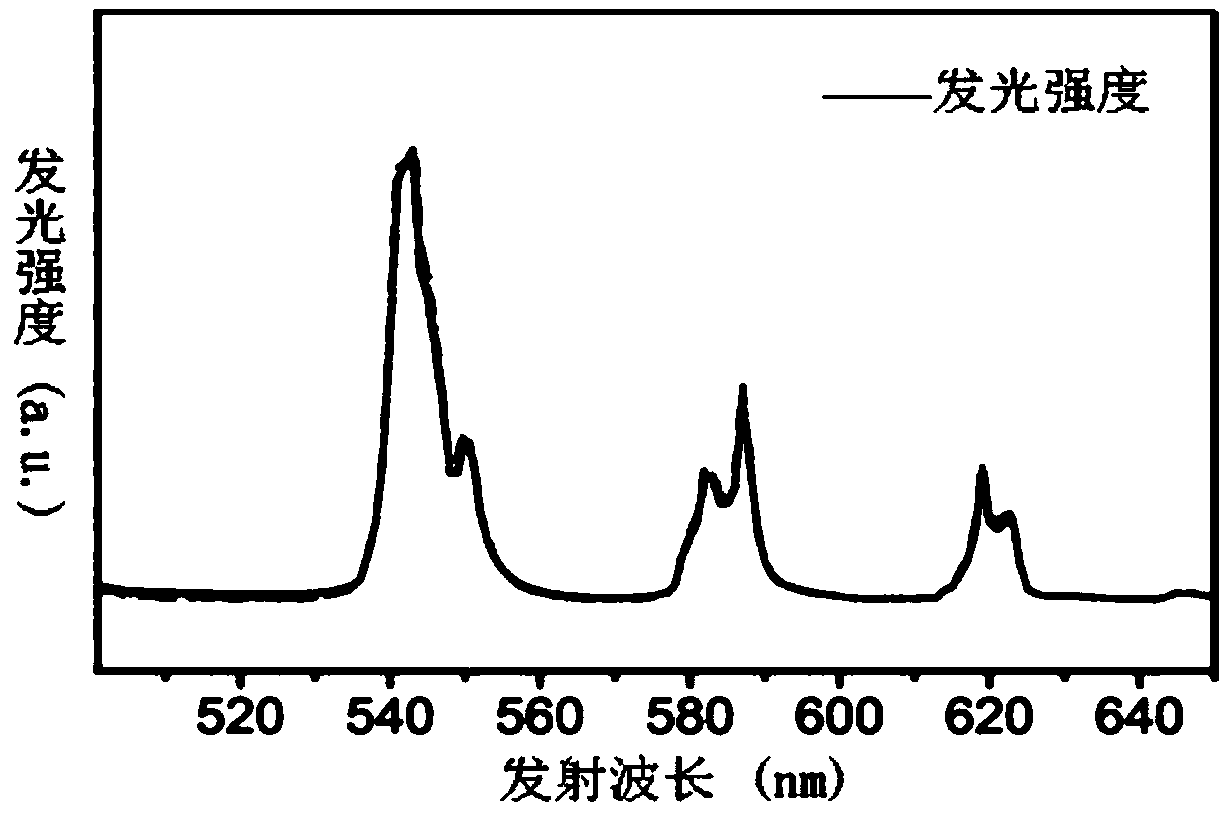

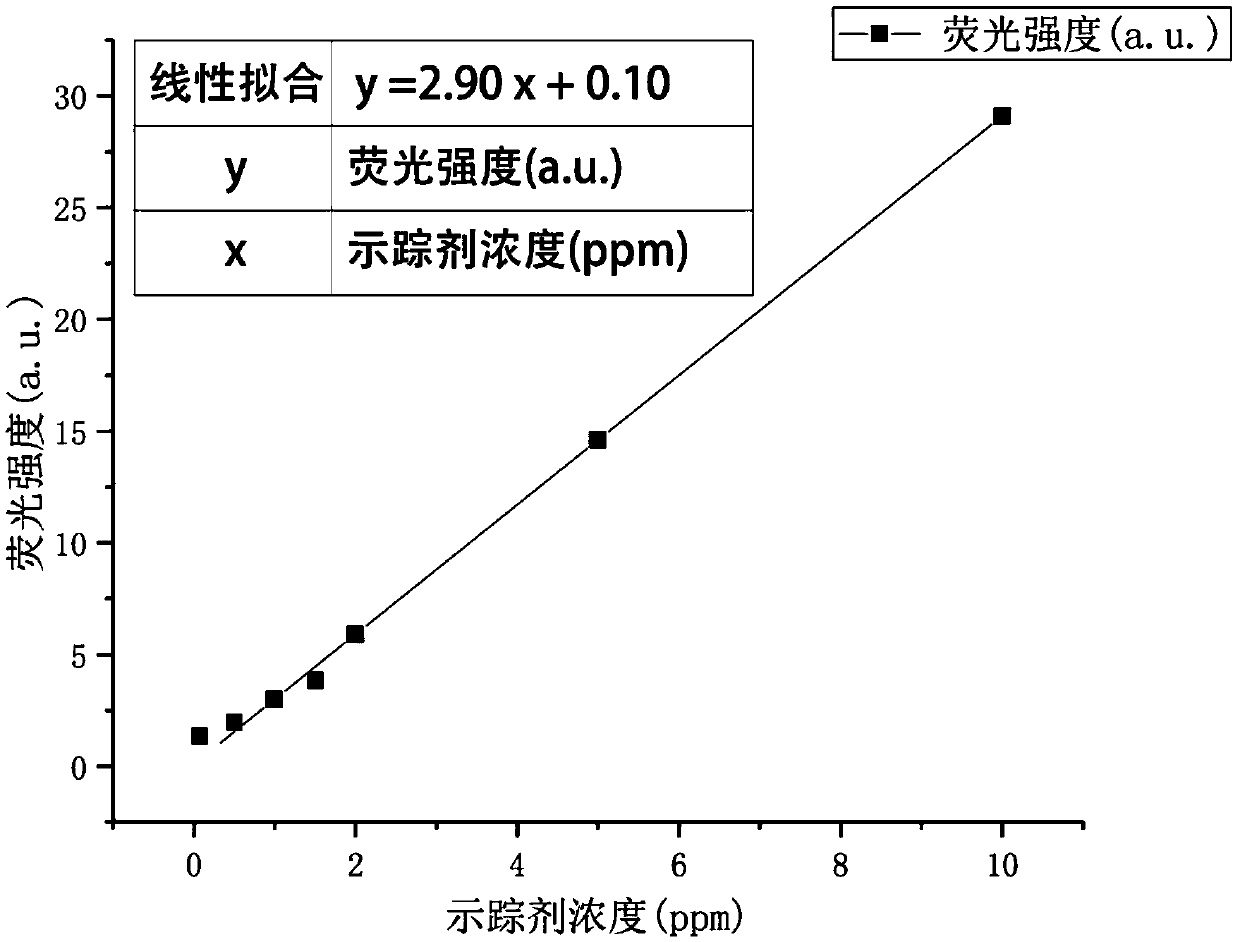

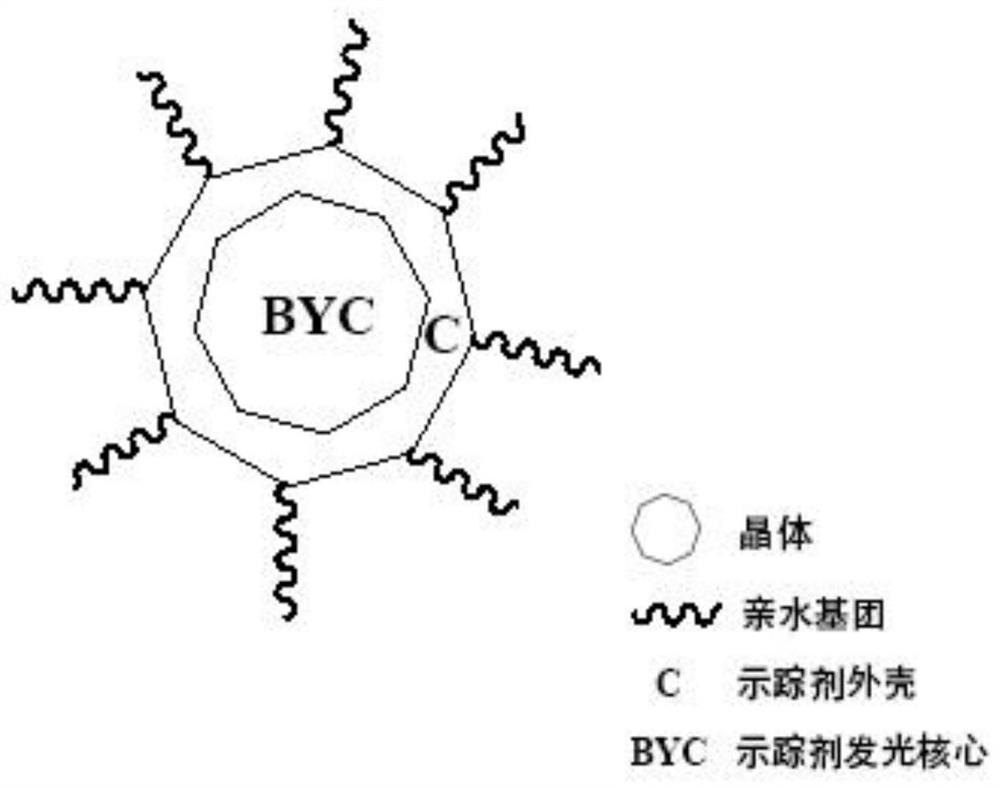

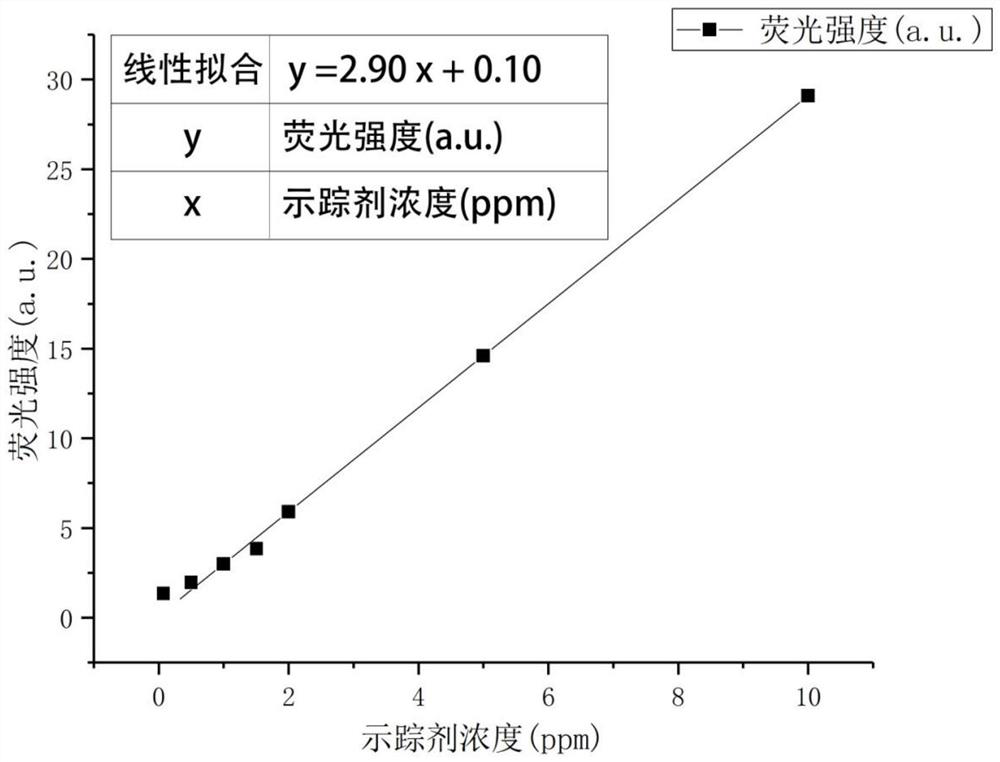

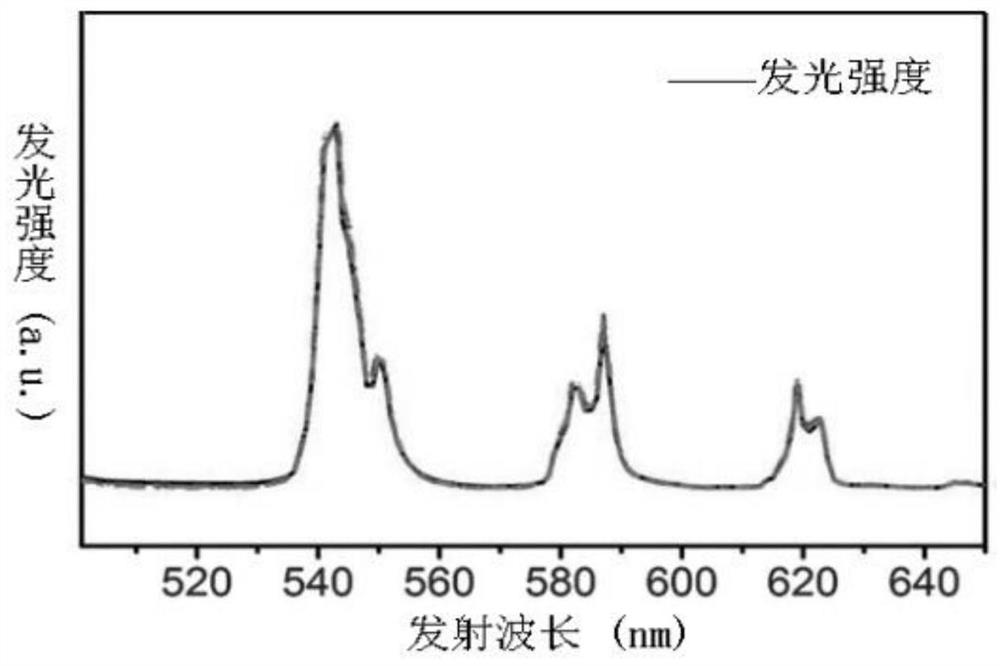

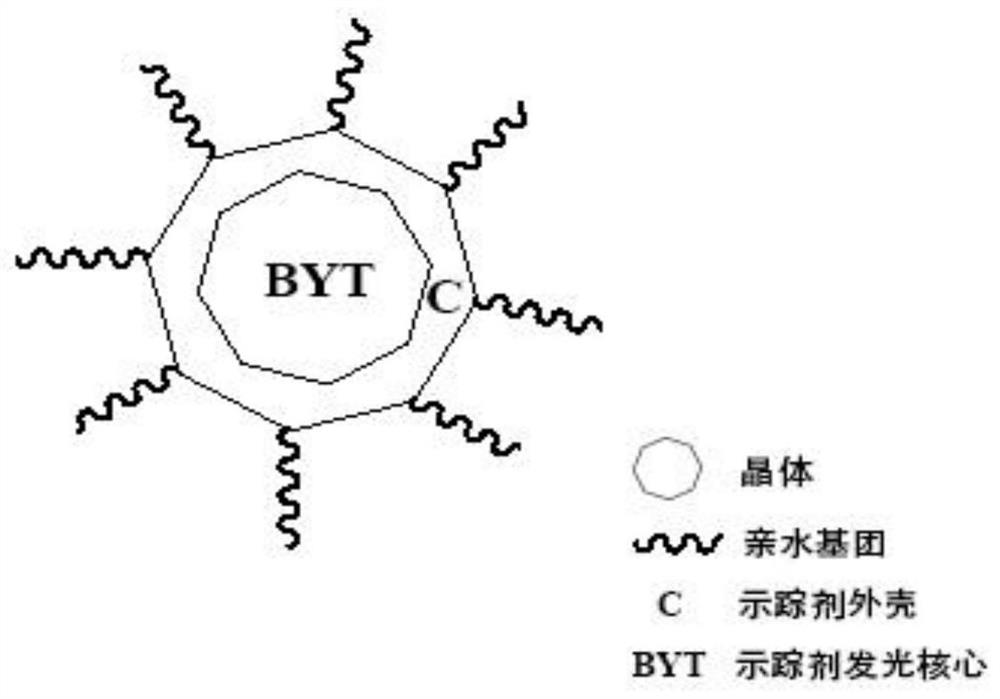

Synthetic method and application of 'BYC tracer agent'

ActiveCN109628091AReduce adsorptionImprove detection accuracyConstructionsFluorescence/phosphorescenceRare-earth elementChemistry

The invention relates to a synthetic method and application of a 'BYC tracer agent'. A rare earth element tracer method is one of effective methods to detect oil reservoirs in oil fields. A fluorescent nanomaterial with a core-shell structure is synthesized and can be used as an oil field tracer agent which is named as the 'BYC tracer agent'. The tracer agent has the advantages that the water solubility is good, the use amount is small, the exploration demand quantity of water samples is few, the analytical method is simple and convenient, and the analysis sensitivity is high; the tracer agenthas no radioactivity, low toxicity and a minimal impact on the environment; the degree of mineralization is not affected, the compatibility with polymers is good, and oil displacing of the polymers is not affected; the application of the BYC tracer agent, that is, the fluorescent nanomaterial in the field of oil field exploration is creatively achieved, and a feasible operation scheme is proposed.

Owner:BEIJING UNIV OF CHEM TECH +1

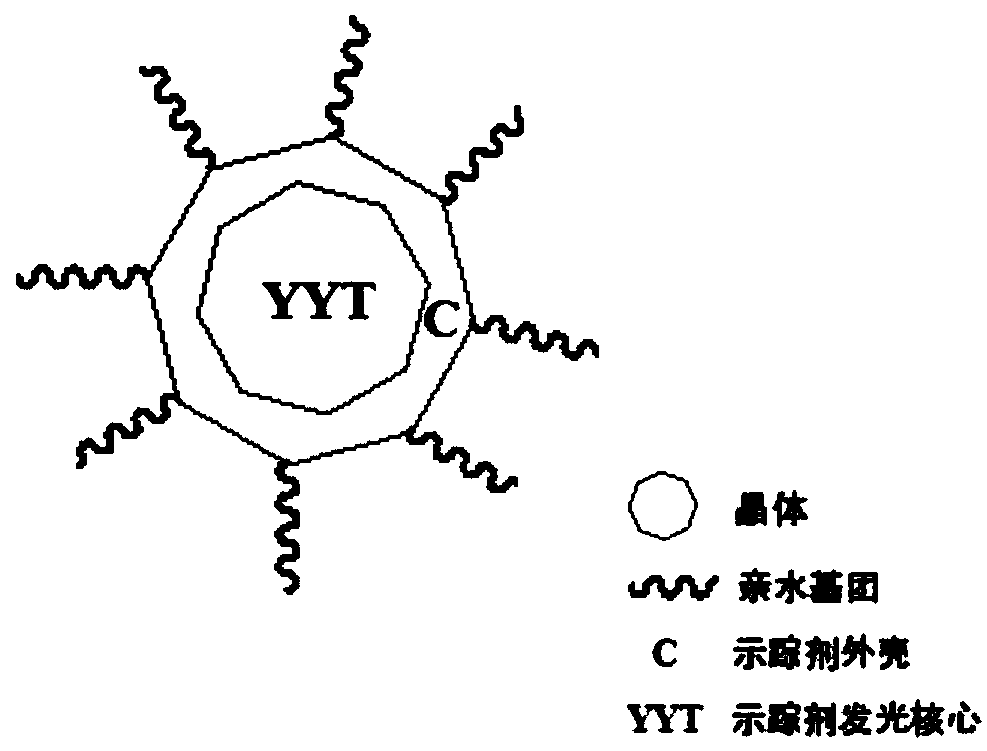

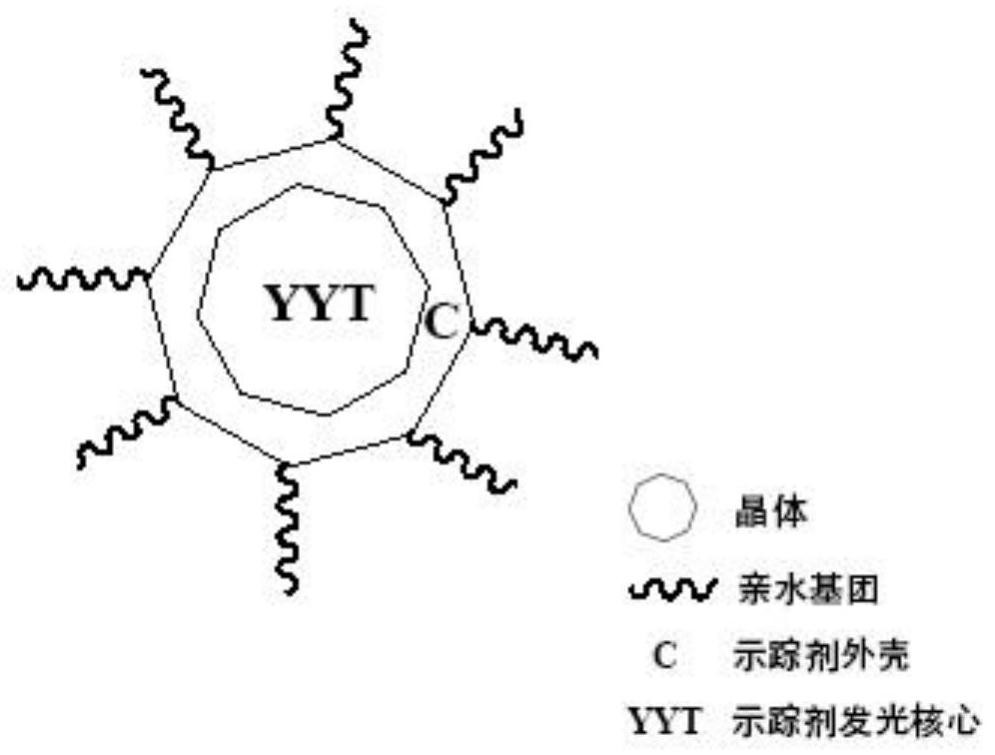

Synthetic method and application of 'YYTC tracer agent'

ActiveCN109628094AReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementSolubility

The invention relates to a synthetic method and application of a 'YYTC tracer agent'. A rare earth element tracer method is one of effective methods to detect oil reservoirs in oil fields. A fluorescent nanomaterial with good water solubility and a core-shell structure is synthesized and can be used as an oil field tracer agent which is named as the 'YYTC tracer agent'. The tracer agent has the advantages that the use amount is small, the exploration demand quantity of water samples is few, the analytical method is simple and convenient, and the analysis sensitivity is high; the tracer agent has no radioactivity, low toxicity and a minimal impact on the environment; the degree of mineralization is not affected, the compatibility with polymers is good, and oil displacing of the polymers isnot affected; the application of the BYC tracer agent, that is, the fluorescent nanomaterial in the field of oil field exploration is creatively achieved, and a feasible operation scheme is proposed.

Owner:BEIJING UNIV OF CHEM TECH +1

Green synthesis method of epoxy modified starch-based emulsion

The invention relates to the field of new materials, and in particular discloses a green synthesis method of epoxy modified starch-based emulsion. The method comprises the following steps: (1) firstly, heating starch or starch derivatives in presence of a catalyst to obtain a gelatinized liquid; (2) diluting and dispersing the epoxy resin and a polymerized monomer in a certain ratio without using an organic solvent so as to obtain a uniformly dispersed mixed liquid of the epoxy resin and the polymerized monomer; (3) dropwise adding part of the polymerized monomer and an initiator into the gelatinized liquid at a certain temperature at the same time to prepare a core layer polymer; (4) continuing to dropwise add a polymerized monomer containing the epoxy resin and the initiator to prepare a shell layer polymer; (5) carrying out a heat preservation reaction to obtain the epoxy modified starch-based emulsion. The emulsion is not only environmentally-friendly, but also has a core-shell structure, and is prepared without using an organic solvent and an emulsifying agent; not only is the emulsion environmentally-friendly, but all properties of the emulsion, especially the chemical resistance and water resistance, are also obviously improved, so that the emulsion can be widely applied to the fields of papermaking, textile and water-based paint.

Owner:QINGDAO UNIV OF SCI & TECH

Synthesis method and application of "byc tracer"

ActiveCN109628091BReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceOil fieldPolymer flood

The invention relates to a synthetic method and application of a 'BYC tracer agent'. A rare earth element tracer method is one of effective methods to detect oil reservoirs in oil fields. A fluorescent nanomaterial with a core-shell structure is synthesized and can be used as an oil field tracer agent which is named as the 'BYC tracer agent'. The tracer agent has the advantages that the water solubility is good, the use amount is small, the exploration demand quantity of water samples is few, the analytical method is simple and convenient, and the analysis sensitivity is high; the tracer agenthas no radioactivity, low toxicity and a minimal impact on the environment; the degree of mineralization is not affected, the compatibility with polymers is good, and oil displacing of the polymers is not affected; the application of the BYC tracer agent, that is, the fluorescent nanomaterial in the field of oil field exploration is creatively achieved, and a feasible operation scheme is proposed.

Owner:BEIJING UNIV OF CHEM TECH +1

Synthesis method and application of "yytc tracer"

ActiveCN109628094BReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceOil fieldEnvironmental engineering

Owner:BEIJING UNIV OF CHEM TECH +1

Core-shell type double active acrylate elastomer and preparation method thereof

The invention discloses a preparation method of a core-shell type double-active acrylate elastic body. The preparation method is characterized by specifically comprising the following steps of: adding an acrylate monomer, acrylate containing active groups, and a compound emulsifying agent in a kneading machine, heating to 60-90 DEG C, keeping a temperature and reacting for 0.8-1.2 h, and then, adding a vulcanizing agent and an oxidation-reduction initiator, under the protection of nitrogen, heating to 80-100 DEG C, keeping the temperature and reacting for 1.5-2.0 h, and finally, cooling to 40-50 DEG C to obtain the core-shell type double-active acrylate elastic body. The core-shell type double-active acrylate elastic body is obtained through an emulsion polymerization method and has a core-shell structure; the combination property of an adhesive film is favorable; the core-shell type double-active acrylate elastic body is applied to a sealing fluorine rubber; and the sealing fluorine rubber can be enabled to have higher high temperature resistance, oil resistance, ageing resistance, low temperature resistance and tear resistance performances.

Owner:GUANGZHOU GLORYSTAR CHEM

Synthesis method and application of "befc tracer"

ActiveCN109735336BReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementFluorescence

The invention relates to a synthetic method and application of a BEFC tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A NaBiF4:Eu3+@C4H4Na2O6 fluorescent nano material with core-shell structure is synthesized herein and may act as an oilfield tracer, named as BEFC tracer. The tracer herein has the advantages of good water solubility, low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility with polymers, and zero impact on polymer flooding. The application of the BEFC tracer as one fluorescent nano material in the field of oilfield detection is innovatively achieved herein; afeasible operating scheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

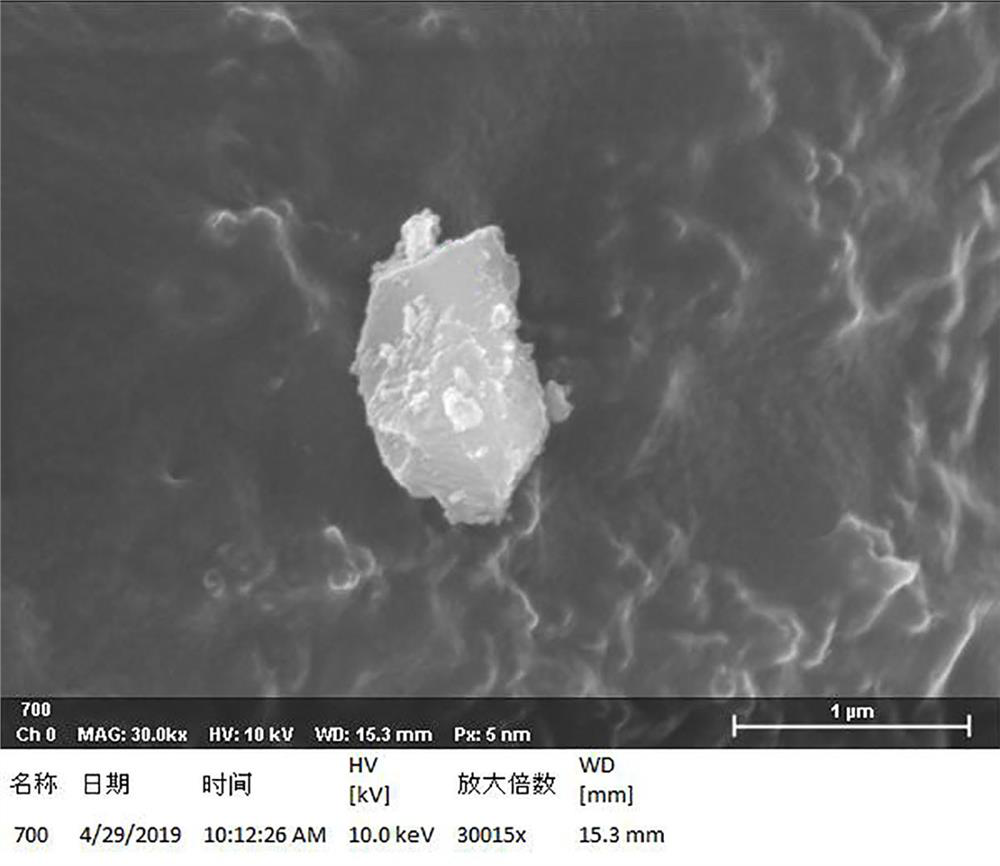

Magnetic silicon dioxide compound microballoon of core-shell structure and preparation method thereof

InactiveCN101444711BMagnetically responsiveHas a core-shell structureInorganic material magnetismMicroballoon preparationMicrosphereHYDROSOL

The invention relates to a magnetic silicon dioxide compound microballoon of a core-shell structure and a preparation method thereof. The compound microballoon takes a metallic ion complexing polymer microballoon as a core, and then ortho-silicate alkyl ester is taken as a precursor, and the silicon dioxide compound microballoon with the core-shell structure is prepared by adopting a gel-sol method, and the magnetic silicon dioxide compound microballoon is obtained by pyrolyzing the compound microballoon; wherein, the core is a metallic nano-particle / carbon compound microballoon, and the shell is the silicon dioxide. The method is simple and effective, and the preparation is convenient; therefore, the method is a novel method for preparing the magnetic silicon dioxide compound microballoon of the core-shell structure.

Owner:EMERGING THERAPEUTICS SHANGHAI CO LTD

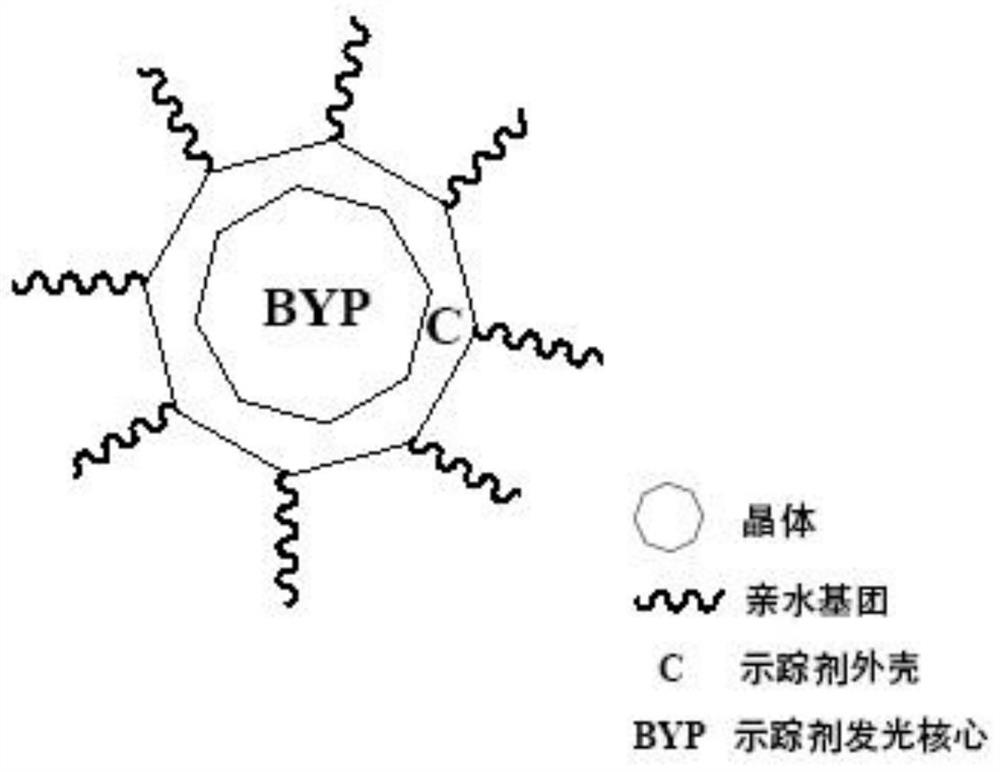

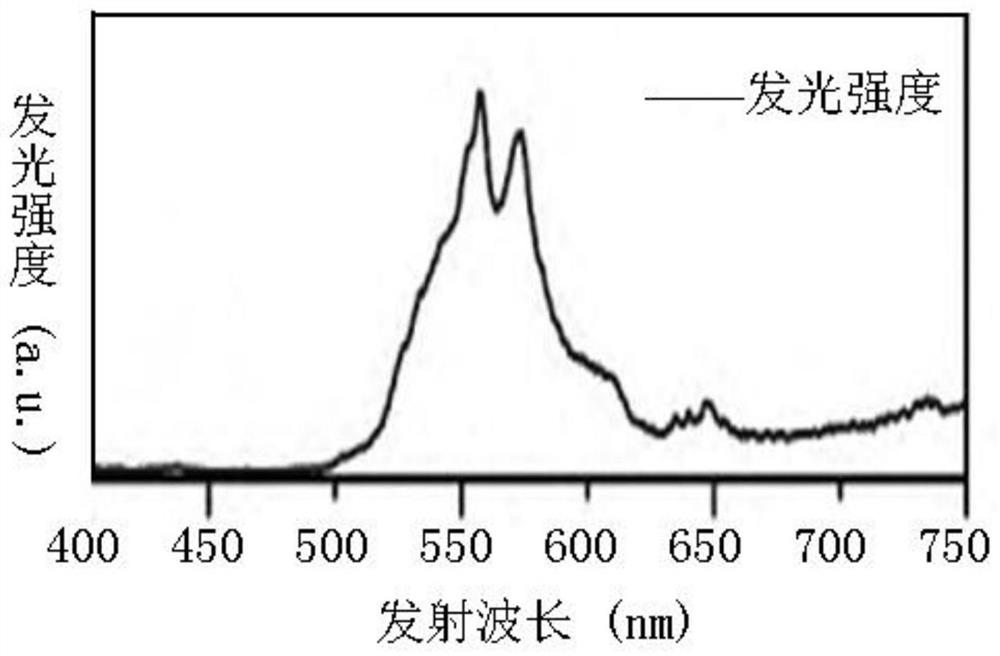

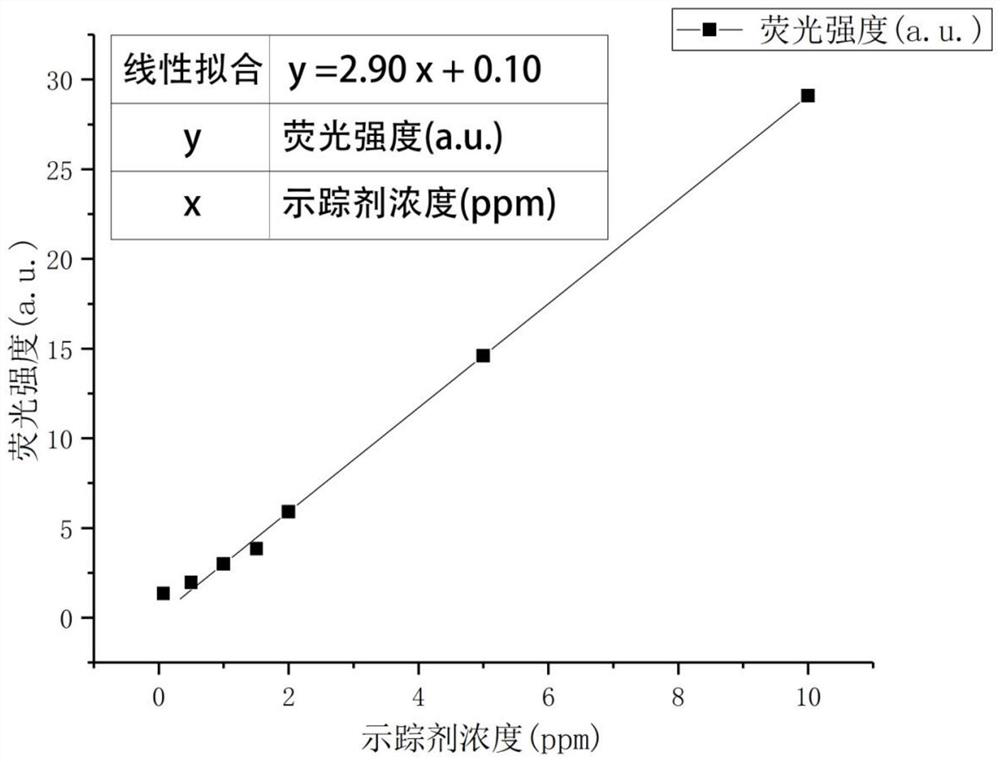

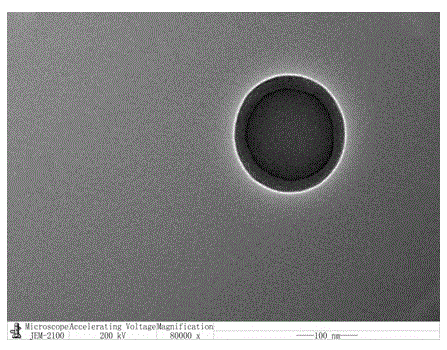

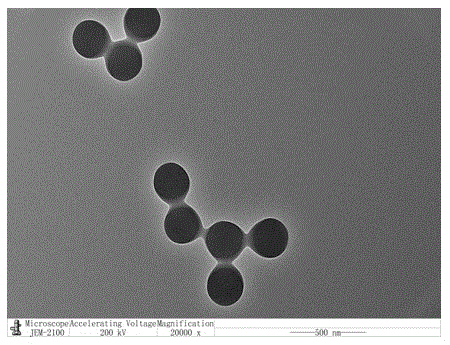

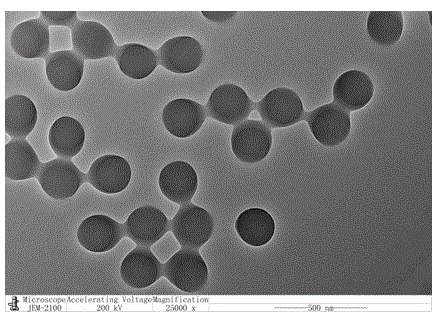

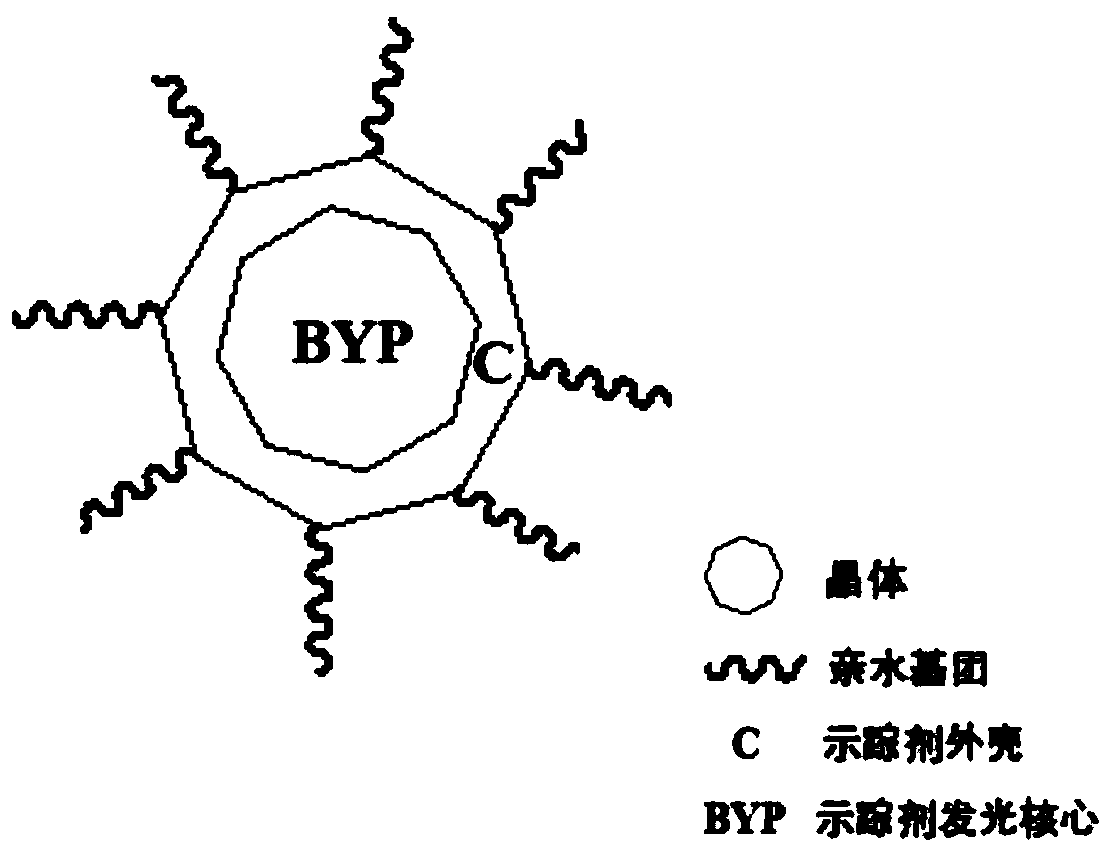

Synthesis method and application method of "BYP tracer"

ActiveCN109735334BReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementOil field

The invention relates to a synthetic method and application method of a BYP tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A fluorescentnano material with good water solubility and core-shell structure is synthesized herein and may act as an oilfield tracer, named as BYP tracer. The tracer herein has the advantages of low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility withpolymers, and zero impact on polymer flooding. The application of the BYP tracer as one nano material in the field of oilfield detection is innovatively achieved herein; a feasible operating scheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

Core-shell particles with acroleic acid esterified polyurethane as main body of core and making method and use thereof

The invention relates to a core-shell particle having a main core body of acrylic acid ester polyurethane, the process for preparation and use, wherein the core-shell particle uses the copolymer of acrylated polyurethane monomer and acrylic ester category soft monomers as the core, and uses the outer grafted upper acrylic ester type hard monomers as shell, while the preparation process comprises the steps of, (1) preparing acrylated polyurethane, (2) re-emulsifying to obtain water-based acrylated polyurethane emulsion, (3)A. charging acrylic ester type soft monomer into the emulsion to obtain seed emulsion, B. charging acrylic ester type hard monomer into the emulsion to obtain core-shell emulsion, (4) demulsifying with sodium chloride saturated solution, freezing, filtering by suction, scouring, drying, grinding thus obtaining the core-shell particle with a main core body of acrylic acid ester polyurethane.

Owner:GUANGZHOU CHEM GROUTING CO LTD CAS

Synthesis method and application of "byt tracer"

ActiveCN109735335BReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementOil field

The invention relates to a synthetic method and application method of a BYT tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A fluorescentnano material with core-shell structure is synthesized herein and may act as an oilfield tracer, named as BYT tracer. The tracer herein has the advantages of good water solubility, low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility with polymers, and zero impact on polymer flooding. The application of the BYT tracer as one fluorescent nano material in the field of oilfield detection is innovatively achieved herein; a feasible operatingscheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

A kind of method utilizing soap-free emulsion polymerization to prepare PMMA microspheres

ActiveCN103342768BEliminate the effects ofImproved physical-chemical propertiesWater bathsPolymer science

The invention provides a method for preparing a PMMA (Polymethyl Methacrylate) microsphere with a core-shell structure through soap-free emulsion polymerization, and belongs to the technical field of high polymer chemistry. The method comprises the following steps of: carrying out reduced pressure distillation on an MMA (Methyl Methacrylate) monomer to obtain a fresh monomer; uniformly mixing the MMA monomer and water, heating in a water bath, then, adding a water-soluble initiator, and reacting while stirring under the condition of the water bath to obtain a colloid emulsion; filtering to remove impurities and conglobated macromolecular substances in the colloid emulsion; then, carrying out centrifugal separation, and drying the obtained solid product at constant temperature to obtain the PMMA microsphere with the core-shell structure. By using a soap-free emulsion, the affect from a micromolecular emulsifying agent is eliminated, and the physical-chemical, mechanical and adhesive properties of a polymer are improved; a defoaming agent is not used basically in the preparation process, so that the pollution of the emulsifying agent to the environment is eliminated; the microsphere with monodispersity and a clean surface can be prepared, and the microsphere is uniform in particle size and has the core-shell structure.

Owner:KUNMING UNIV OF SCI & TECH

Synthetic method and application method of BYP tracer

ActiveCN109735334AReduce adsorptionLower surfaceConstructionsFluorescence/phosphorescenceRare-earth elementSolubility

The invention relates to a synthetic method and application method of a BYP tracer. Rare-earth element tracing method is one of effective measures to detect oil reservoirs in oilfields. A fluorescentnano material with good water solubility and core-shell structure is synthesized herein and may act as an oilfield tracer, named as BYP tracer. The tracer herein has the advantages of low usage, low water sample demand, good analytical simplicity, high analytical sensitivity, zero radiation, low toxicity, every low environmental impact, zero impact on mineralization degree, good compatibility withpolymers, and zero impact on polymer flooding. The application of the BYP tracer as one nano material in the field of oilfield detection is innovatively achieved herein; a feasible operating scheme is provided as well.

Owner:BEIJING UNIV OF CHEM TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com