Preparation method and application of zinc cobaltate/nickel oxide core-shell nanowire array

A technology of nanowire array and zinc cobalt oxide, which is applied in the field of lithium-ion batteries, can solve the problems of high preparation cost, cumbersome process, and complicated nanoarray method, and achieve good rate performance and cycle performance, good electrochemical performance, and high discharge The effect of capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

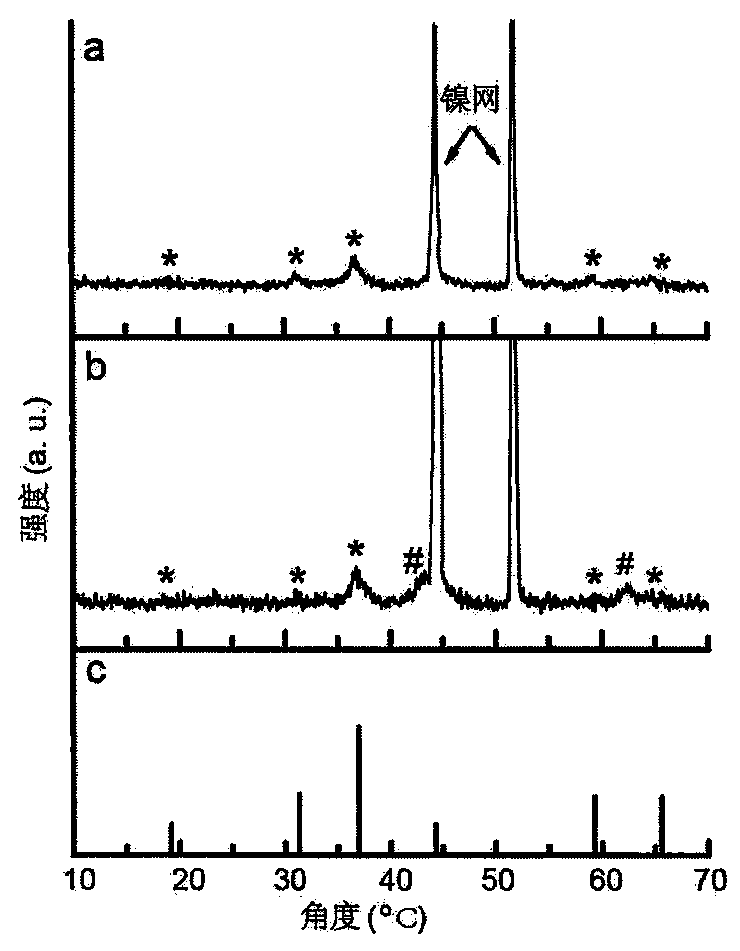

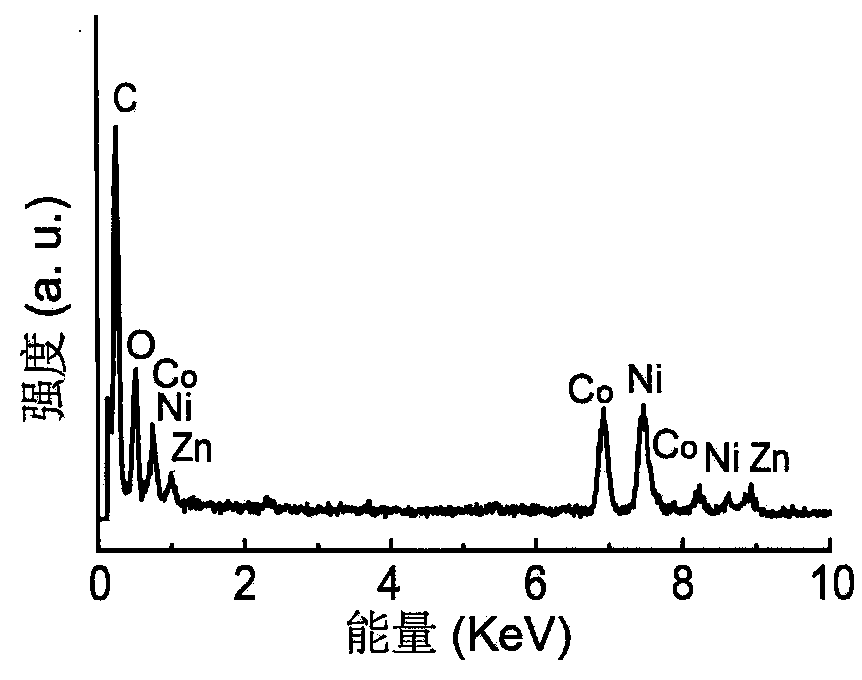

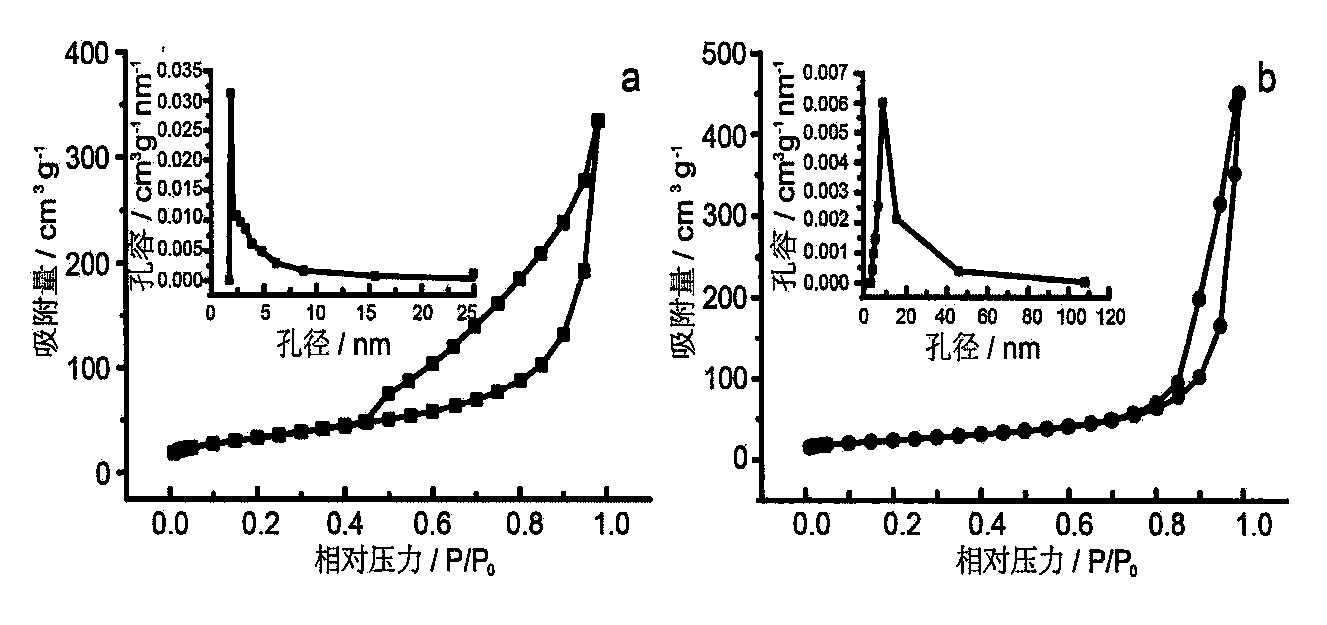

[0029] Example 1 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0030] a. At room temperature, the soluble zinc salt Zn(NO 3 ) 2 , soluble cobalt salt Co(NO 3 ) 2 , ammonium fluoride and urea in a molar ratio of 1:2:1:5 were added to 25mL water and mixed thoroughly for 10min to obtain a uniform solution. In the reaction kettle, the temperature was raised from 30°C to 120°C, the heating rate was 1°C / min, and the reaction was carried out for 5 hours to obtain a foamed nickel substrate with light green nanowire arrays grown on it;

[0031] b. The substrate grown with cyan nanowire arrays in step a is heated from 30°C to 400°C at a heating rate of 1°C / min, and calcined for 1 hour to obtain a substrate grown with dark brown zinc cobaltate nanowire arrays;

[0032] c. Place the substrate with dark brown zinc cobaltate nanowire arrays grown in step b in a mixed solution with a volume ratio of nickel sulfate: potassium peroxodisulfate: ammonia water = 5: ...

Embodiment 2

[0035] Example 2 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0036] a. At room temperature, the soluble zinc salt Zn(NO 3 ) 2 , soluble cobalt salt Co(CH 2 CH 3 ) 2 , ammonium fluoride and urea in a molar ratio of 1:2:1:6 were added to 25mL water and mixed thoroughly for 10 minutes to obtain a homogeneous solution. Then, the clean nickel substrate was put into a 40mL reaction kettle, and the homogeneous solution was added to In the reaction kettle, the temperature was raised from 30°C to 120°C, the heating rate was 2°C / min, and the reaction was carried out for 8 hours to obtain a nickel sheet substrate with a light green nanowire array grown on it;

[0037] b. Heat up the nickel sheet substrate with cyan nanowire arrays grown in step a at a temperature of 30° C. to 400° C. at a heating rate of 1° C. / min, and bake for 2 hours to obtain a substrate grown with dark brown zinc cobaltate nanowire arrays ;

[0038] c. Place the substrate with dark ...

Embodiment 3

[0041] Example 3 Preparation of zinc cobaltate / nickel oxide core-shell nanowire arrays:

[0042] a. At room temperature, the soluble zinc salt Zn(CH 2 CH 3 ) 2 , soluble cobalt salt CoCl 2 , ammonium fluoride and urea in a molar ratio of 1:2:1.2:6 were added to 25mL of water and mixed thoroughly for 10min to obtain a homogeneous solution. Add it into the reaction kettle, raise the temperature from 30°C to 130°C, the heating rate is 3°C / min, and react for 6 hours to obtain a carbon cloth substrate with light green nanowire arrays grown on it;

[0043] b. Heat up the carbon cloth substrate with cyan nanowire arrays grown in step a at a temperature of 30°C to 400°C at a heating rate of 1°C / min, and bake for 2 hours to obtain a substrate with dark brown zinc cobaltate nanowire arrays grown on it ;

[0044] c. Place the substrate with dark brown zinc cobaltate nanowire arrays grown in step b in a mixed solution with a volume ratio of nickel sulfate: potassium peroxodisulfate: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com