Spiral strip identification high-temperature resistance flexible electric wire and cable for aviation and preparation process thereof

An aerospace, wire and cable technology, applied in the direction of cable/conductor manufacturing, marking conductor/cable, insulated cable, etc., can solve the problems of greatly increased cost, mixed wire and cable, and difficulty in distinguishing, so as to reduce vehicle weight and facilitate Laying and installation, the effect of small weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

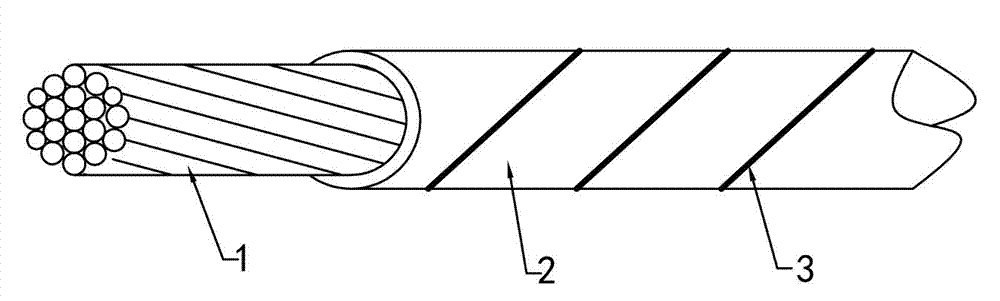

[0031] Such as figure 1 As shown, it is a structural schematic diagram of the high-temperature-resistant soft electric wire (including a single insulated core wire without a sheath layer) with a spiral stripe mark of the present invention, and the conductor 1 formed by twisting is covered with an inner and outer insulating layer. An insulating layer 2, with a spiral stripe logo 3 printed on the outside of the insulating layer 2;

[0032] Its preparation process is as follows:

[0033] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0034] 2) Insulation layer extrusion: inner and outer insulation layers are co-extruded (extrusion temperature is 245-315°C) to form a double-layer insulation layer. The rubber material of the insulation layer is X-ETFE, and the concentricity of the insulation layer is 75%. The thinnest point of the layer is 0.08mm, and the thinnest point of the outer insulating laye...

Embodiment 2

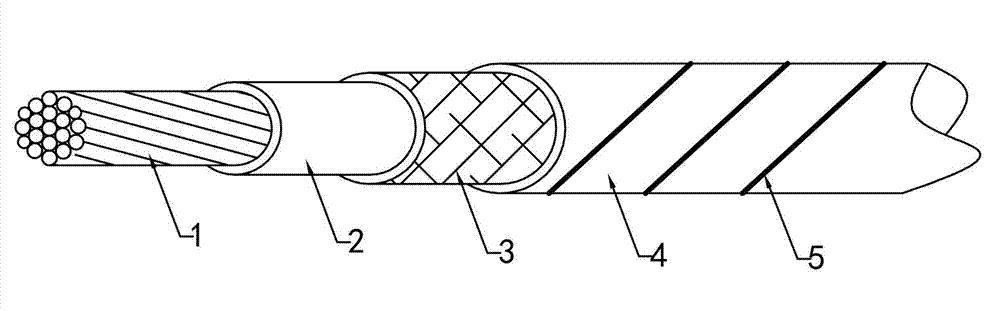

[0040] Such as figure 2 As shown, it is a structural schematic diagram of the spiral striped high-temperature-resistant flexible cable (composed of a single insulated core wire, a shielding layer and a sheath layer) of the present invention. The conductor 1 formed by twisting is covered with an insulating layer 2. A shielding layer 3 is provided outside the insulating layer 2 , and a sheath layer 4 is covered outside the shielding layer 3 , and a spiral stripe logo 5 is printed on the sheath layer 4 .

[0041] Its preparation process is as follows:

[0042] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0043] 2) Extrusion of insulating layer: high-temperature extrusion of single-layer insulation (extrusion temperature is 245-300°C), the compound of the insulating layer is X-ETFE, the concentricity of the insulating layer is 76%, and the thinnest point of the insulating layer is 0.13mm;

[00...

Embodiment 3

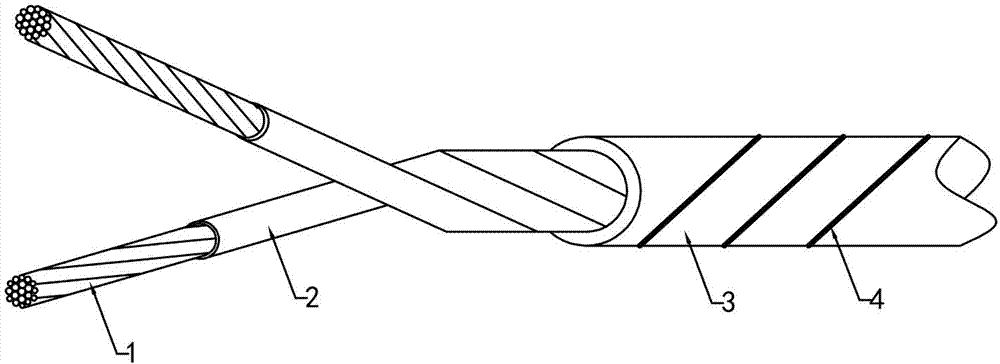

[0052] Such as image 3 As shown, it is a structural schematic diagram of the high-temperature-resistant flexible cable (composed of two insulated core wires and a sheath layer) with a spiral stripe mark of the present invention. The conductor 1 formed by twisting is covered with an insulating layer 2, and the conductor 1 and The insulating layer 2 constitutes an insulating core wire, and the insulating layer 2 is covered with a sheath layer 3 , and a spiral stripe logo 4 is printed on the surface of the sheath 3 .

[0053] Its preparation process is as follows:

[0054] 1) Conductor stranding: use annealed silver-plated (nickel) copper conductors for stranding with a pitch ratio of less than 20;

[0055] 2) Extrusion of insulating layer: high-temperature extrusion of single-layer insulation (extrusion temperature is 245-300°C), the compound of the insulating layer is X-ETFE, the concentricity of the insulating layer is 76%, and the thinnest point of the insulating layer is 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com