Preparation of protein-polysaccharide nano gel on basis of Maillard reaction in macromolecular crowding environment

A nanogel and macromolecule technology, applied in the field of protein-polysaccharide nanogel preparation, can solve the problems of high cytotoxicity, unfavorable production and application, easy aggregation of protein nanoparticles, etc., and achieve low cytotoxicity and easy degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve soybean protein isolate and soybean polysaccharide with a mass ratio of 1:1 in water to a concentration of 50g / L, stir and disperse for 6 hours, adjust the pH to 6.8 with dilute hydrochloric acid, and hydrate overnight in a refrigerator at 4°C. The solution was placed in a water bath at 60° C. for 30 hours, and then freeze-dried, and the obtained powder was the soybean protein isolate-soybean polysaccharide covalent complex. Dissolve the above powder in water to make a homogeneous solution with a concentration of 1mg / mL, adjust the pH of the solution to an isoelectric point of 4.8 with 0.1mol / L HCl solution, heat in a water bath at 80°C for 50min, and after cooling, it will be soybean protein isolate -Soy polysaccharide nanogel.

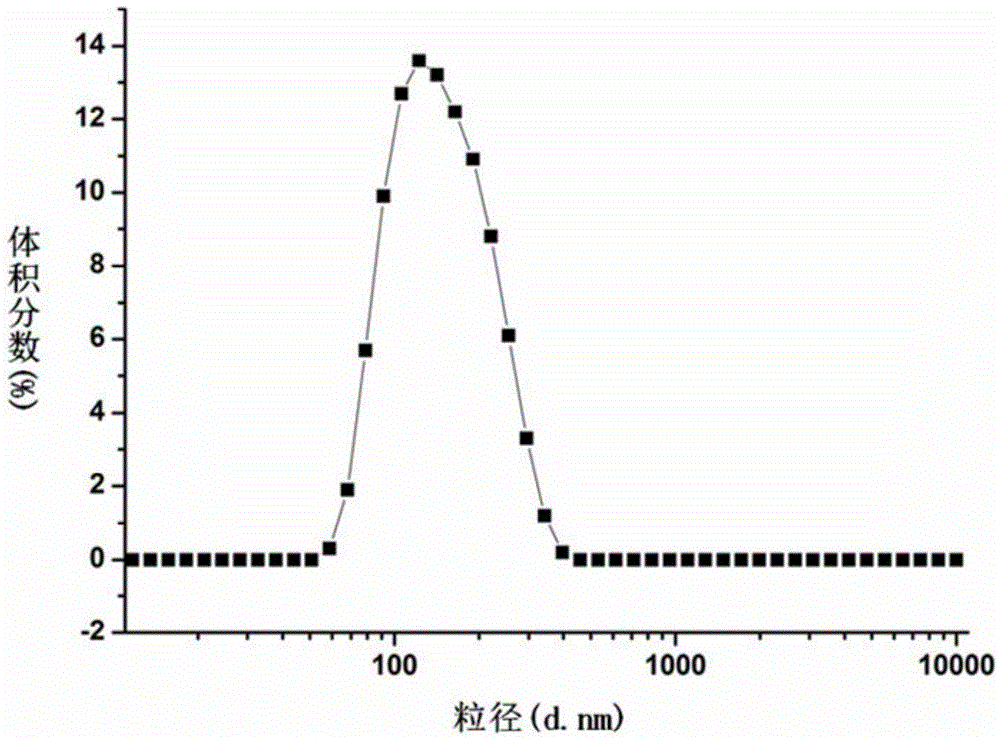

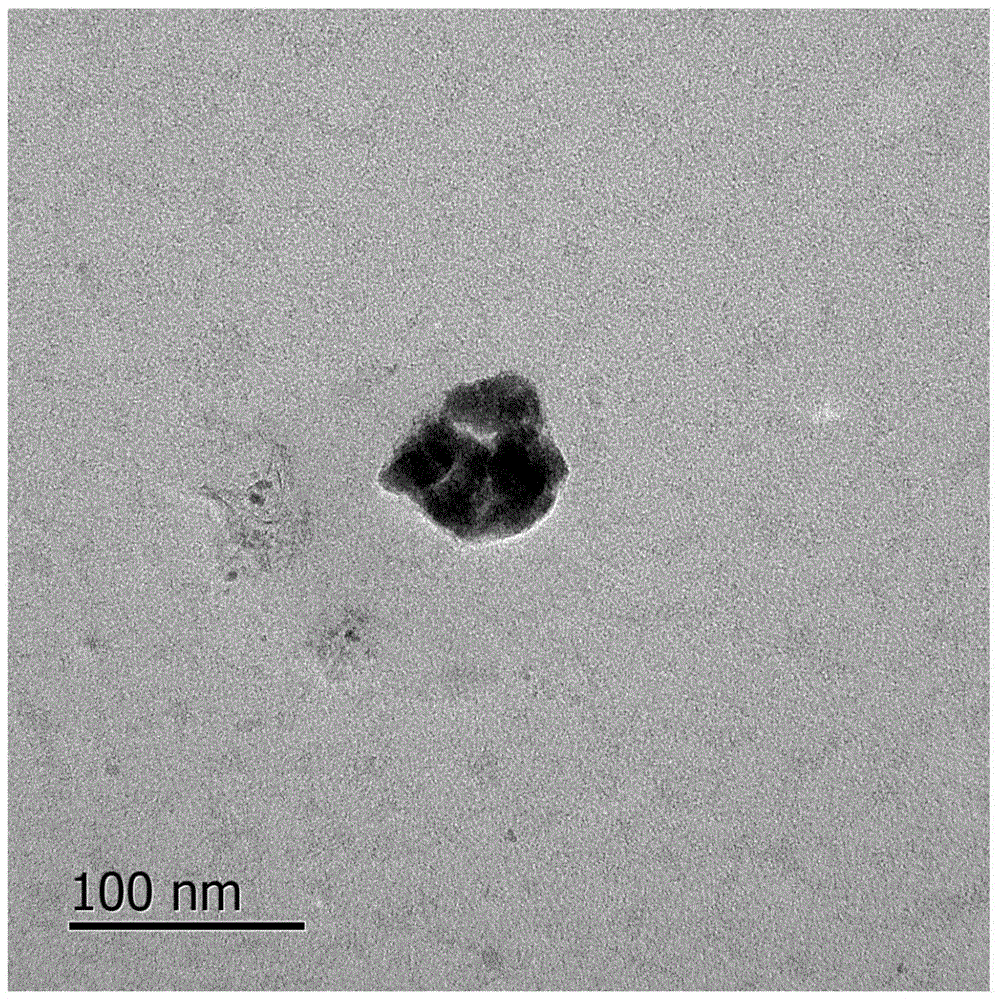

[0033] The soybean protein isolate-soybean polysaccharide nanogel obtained in this example is analyzed by a ZetasizerNano-ZS laser dynamic particle size scanner. It can be seen that its particle size is between 59-459nm, and its PDI v...

Embodiment 2

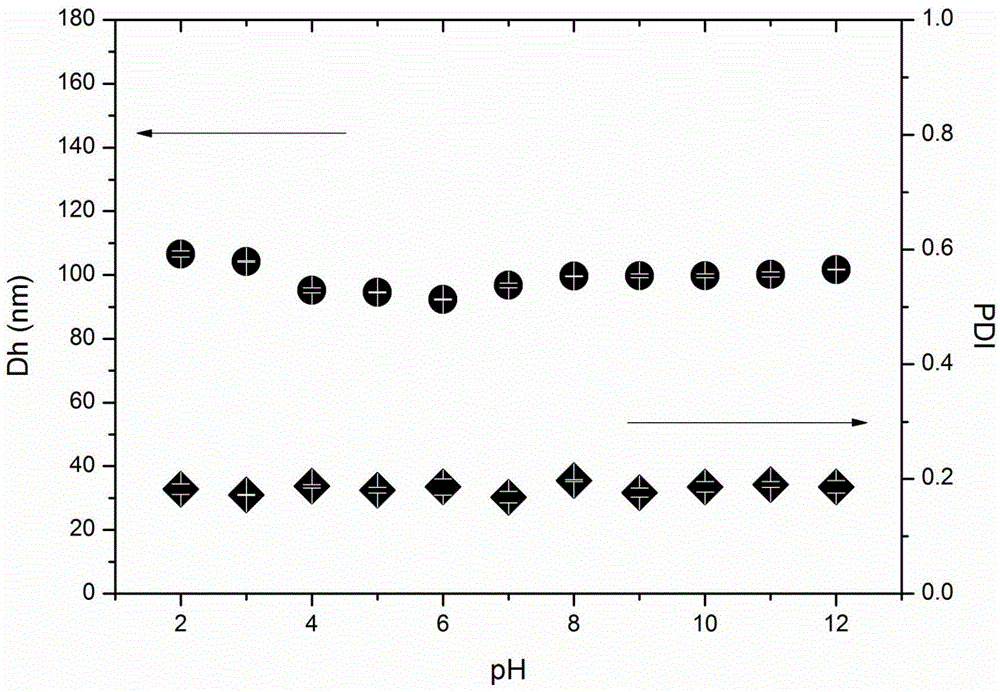

[0035] Dissolve whey protein and dextran with a mass ratio of 1:3 in water to make the concentrations 50g / L and 150g / L respectively, stir and disperse for 2 hours, adjust the pH to 7.0 with dilute hydrochloric acid, and hydrate in a refrigerator at 4°C overnight. The solution was placed in a water bath at 95° C. for 6 h, and then spray-dried to obtain a powder. Dissolve the above powder in water to make a homogeneous solution with a concentration of 0.1 mg / mL, adjust the pH of the solution to an isoelectric point of 5.2 with 0.1 mol / L HCl solution, heat in a water bath at 95°C for 5 minutes, and after cooling, it will become whey Protein-dextran nanogel, the pH stability figure of the whey protein-soybean polysaccharide nanogel prepared in this embodiment is as follows image 3 shown by image 3 It can be seen that the nanogel obtained in the present invention has no secondary aggregation phenomenon in the range of pH 2-10, and its particle size does not change much.

Embodiment 3

[0037] Dissolve pea protein and soybean polysaccharide with a mass ratio of 1:2 in water so that the concentration of pea protein is 100g / L, stir and disperse for 5 hours, adjust the pH to 6.9 with dilute hydrochloric acid, and hydrate overnight in a refrigerator at 4°C. The solution was placed in a water bath at 65° C. for 48 hours, and then freeze-dried, and the obtained powder was the pea protein-soybean polysaccharide covalent complex. Dissolve the above powder in water to make a uniform solution with a concentration of 10 mg / mL, adjust the pH of the solution to an isoelectric point of 5.2 with 0.1 mol / L HCl solution, heat in a water bath at 90°C for 30 minutes, and after cooling, it becomes pea protein- For soybean polysaccharide nanogels, freeze-drying and reconstitution had little effect on the particle size of nanogels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com