A kind of lithium-ion battery silicon/carbon negative electrode composite material and preparation method thereof

A technology of lithium ion battery and composite material, applied in the field of lithium ion battery silicon/carbon negative electrode composite material and its preparation, can solve the problems of poor electronic conductivity and slow lithium ion diffusion, achieve high specific capacity, improve diffusion performance, and prepare low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Using perlite as raw material, put perlite in a 100ml agate ball mill jar, add 50g of agate balls with a diameter of 20mm, 40g of agate balls with a diameter of 10mm, and 10g of agate balls with a diameter of 5mm. Among them, the mass ratio of agate balls to perlite is 20:1, the ball milling speed is 450 rpm, and the ball milling takes 48 hours to obtain micron-sized perlite particles.

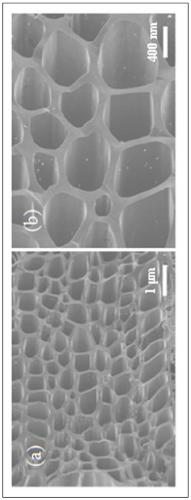

[0034] (2) at 300 oC preheat for 25 min, then at 1100 o C heating for 10s, and finally quickly transfer the material from the high temperature environment to 25 o Cool at room temperature around C, and then use 4M hydrochloric acid at 80 o C for 24 hours, washed, filtered, and dried to obtain a porous silica material.

[0035] (3) Mix 10g of porous silicon dioxide with 10g of magnesium powder at 700 o Under the atmosphere of C and Ar, the magnesothermic reduction reaction was carried out, and then treated with 1 M hydrochloric acid at 80 o C was treated for 4 hours to obtain a ...

Embodiment 2

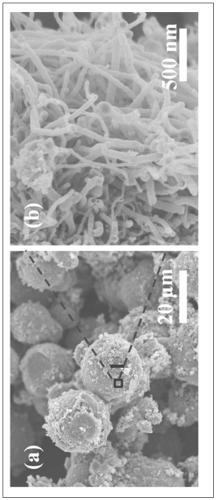

[0043] Step (1-3) is the same as the preparation process of Example 1. In step (4), 3 g of porous silicon material is mixed with 3.5 g of cobalt acetate and 7.6 g of dicyandiamide, and mixed at 700 o Baking is carried out under the atmosphere of C and Ar to obtain the silicon / carbon negative electrode composite material in which the cobalt silicide connects the carbon nanotube and the porous silicon. In the composite material, the porous silicon material accounts for 43.2% of the total mass of the composite material wt %. The electrochemical performance of the composite material is shown in Table 1.

Embodiment 3

[0045] Step (1-3) is the same as the preparation process of Example 1. In step (4), 3 g of porous silicon material, 3.2 g of ferrous oxalate and 7.6 g of urea are mixed uniformly, and mixed at 700 o Baking is carried out under the atmosphere of C and Ar to obtain the silicon / carbon negative electrode composite material in which iron silicide is connected with carbon nanotubes and porous silicon. In the composite material, the porous silicon material accounts for 40.6% of the total mass of the composite material wt %. The electrochemical performance of the composite material is shown in Table 1.

[0046] Table 1. The charging and discharging performance of silicon / carbon negative electrode composite material in the embodiment

[0047]

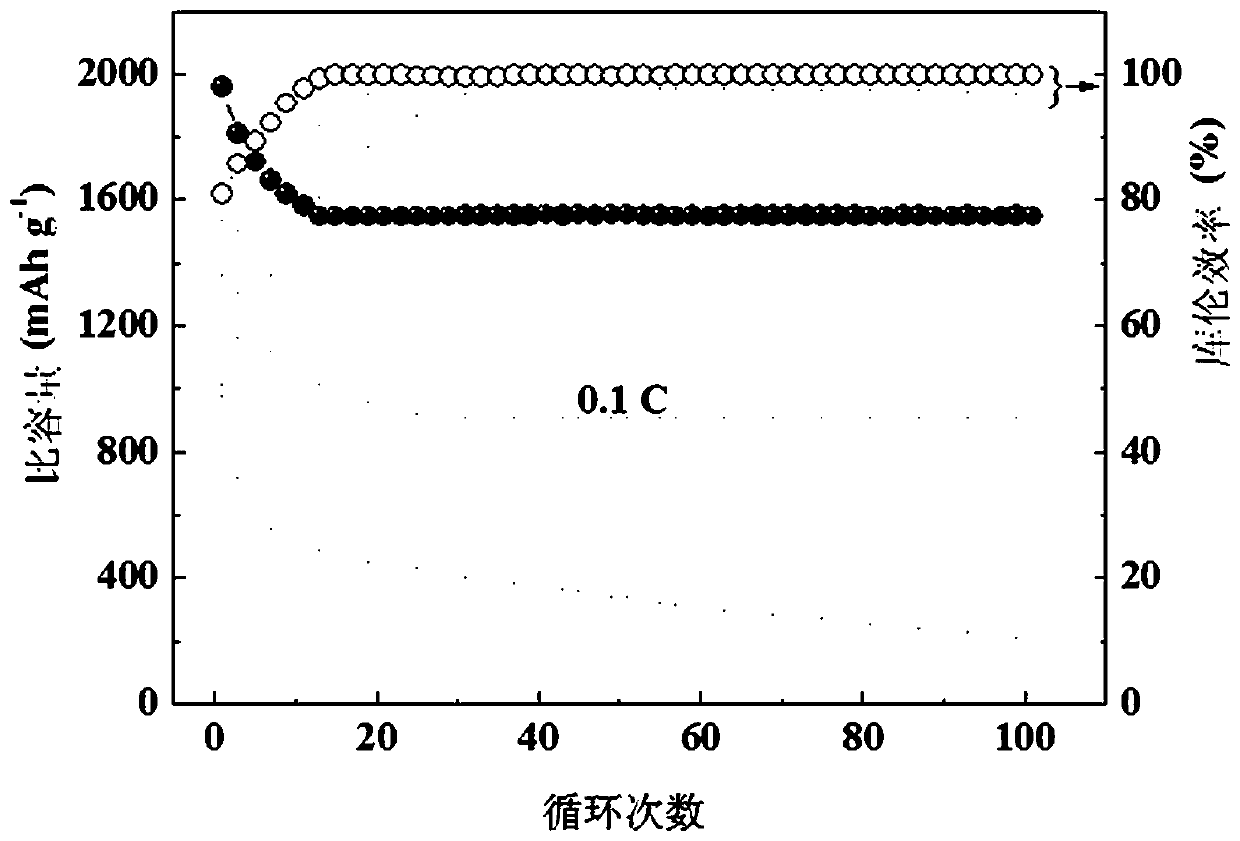

[0048] It can be seen from the above table that the silicon / carbon negative electrode composite material in the present invention has a high discharge specific capacity and excellent cycle stability, and the capacity retention rate after ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com