Method for preparing PMMA (Polymethyl Methacrylate) microsphere with core-shell structure through soap-free emulsion polymerization

A soap-free emulsion polymerization, core-shell structure technology, applied in the field of polymer chemistry, can solve the problems of emulsifier migration, reduce film water resistance, slow film formation rate, etc. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

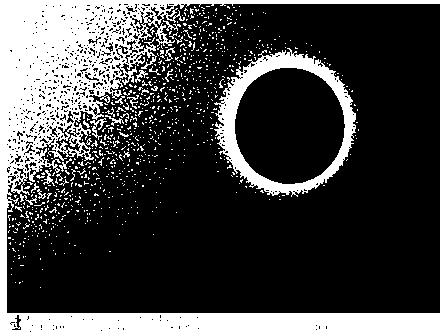

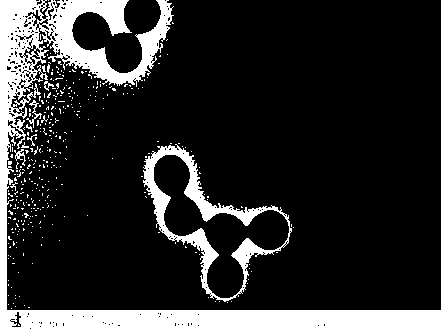

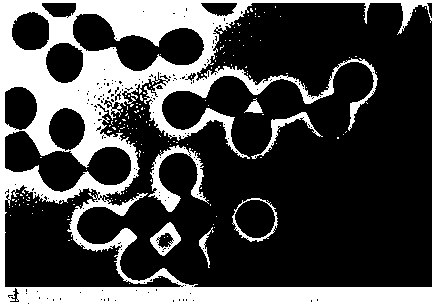

Image

Examples

Embodiment 1

[0026] (1) Distill the commercially available MMA monomer under reduced pressure at a pressure of 600 mm Hg and a temperature of 20°C until the distillation product is 90% of the mass of the MMA monomer to obtain fresh monomer;

[0027] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:5, then heat the mixture in a water bath at 30°C for 30 minutes, and then add 1% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water-bath conditions with 100r / min speed stirring to react, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

[0028] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 10,000r / min for 30min, and then put the resulting solid product in Dry at a constant temperature of 100°C for 12 hours to obtain PMMA microspheres with a core-shell...

Embodiment 2

[0030] (1) Carry out vacuum distillation of commercially available MMA monomer at a pressure of 700 mm Hg and a temperature of 30°C until the distillation product is 80% of the mass of MMA monomer, and stop distillation to obtain fresh monomer;

[0031] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:20, then heat the mixture in a water bath at 80°C for 10 minutes, then add 5% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water bath conditions with 500r / min speed stirring to react, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

[0032] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 5000r / min for 10min, and then put the resulting solid product in Dry at a constant temperature of 80°C for 18 hours to obtain PMMA microspheres with a...

Embodiment 3

[0034] (1) Carry out vacuum distillation of the commercially available MMA monomer at a pressure of 800 mm Hg and a temperature of 60°C until the distillation product is 50% of the mass of the MMA monomer to obtain fresh monomer;

[0035] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:1, then heat the mixture in a water bath at 95°C for 50 minutes, and then add 10% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water-bath conditions with 1000r / min speed stirring for reaction, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

[0036] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 1000r / min for 60min, and then put the resulting solid product in Dry at a constant temperature of 20°C for 24 hours to obtain PMMA microspheres with a core-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com