A kind of method utilizing soap-free emulsion polymerization to prepare PMMA microspheres

A soap-free emulsion polymerization and microsphere technology, applied in the field of polymer chemistry, can solve the problems of reducing film water resistance, emulsifier migration, reducing surface energy, etc., and achieve the effect of improving adhesion performance, improving mechanical properties, and eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Distill the commercially available MMA monomer under reduced pressure at a pressure of 600 mm Hg and a temperature of 20°C until the distillation product is 90% of the mass of the MMA monomer to obtain fresh monomer;

[0027] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:5, then heat the mixture in a water bath at 30°C for 30 minutes, and then add 1% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water-bath conditions with 100r / min speed stirring to react, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

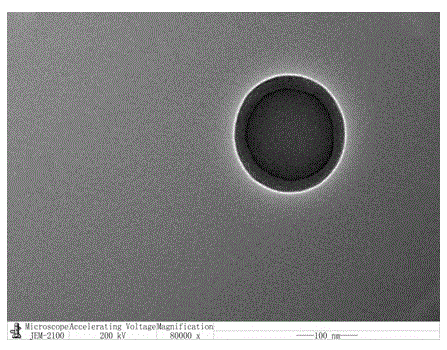

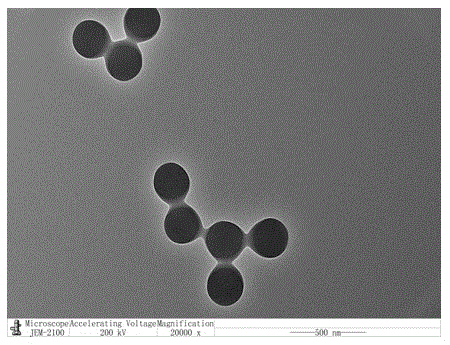

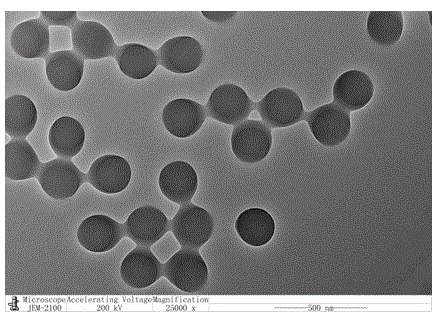

[0028] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 10,000r / min for 30min, and then put the resulting solid product in Dry at a constant temperature of 100°C for 12 hours to obtain PMMA microspheres with a core-shell...

Embodiment 2

[0030] (1) Carry out vacuum distillation of commercially available MMA monomer at a pressure of 700 mm Hg and a temperature of 30°C until the distillation product is 80% of the mass of MMA monomer, and stop distillation to obtain fresh monomer;

[0031] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:20, then heat the mixture in a water bath at 80°C for 10 minutes, then add 5% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water-bath conditions with 500r / min speed stirring to react, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

[0032] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 5000r / min for 10min, and then put the resulting solid product in Dry at a constant temperature of 80°C for 18 hours to obtain PMMA microspheres with a...

Embodiment 3

[0034] (1) Distill the commercially available MMA monomer under reduced pressure at a pressure of 800 mm Hg and a temperature of 60°C until the distillation product is 50% of the mass of the MMA monomer to obtain fresh monomer;

[0035] (2) Mix the fresh monomer obtained in step (1) with water at a volume ratio of 1:1, then heat the mixture in a water bath at 95°C for 50 minutes, and then add 10% water-soluble MMA monomer mass Initiator potassium persulfate, and kept under water-bath conditions with 1000r / min speed stirring to react, to avoid the colloidal emulsion synthesized from agglomeration, to obtain the colloidal emulsion;

[0036] (3) Filter the colloidal emulsion obtained in step (2) in a Buchner funnel to remove impurities and agglomerated macromolecular substances; then perform centrifugation at a speed of 1000r / min for 60min, and then put the resulting solid product in Dry at a constant temperature of 20°C for 24 hours to obtain PMMA microspheres with a core-shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com