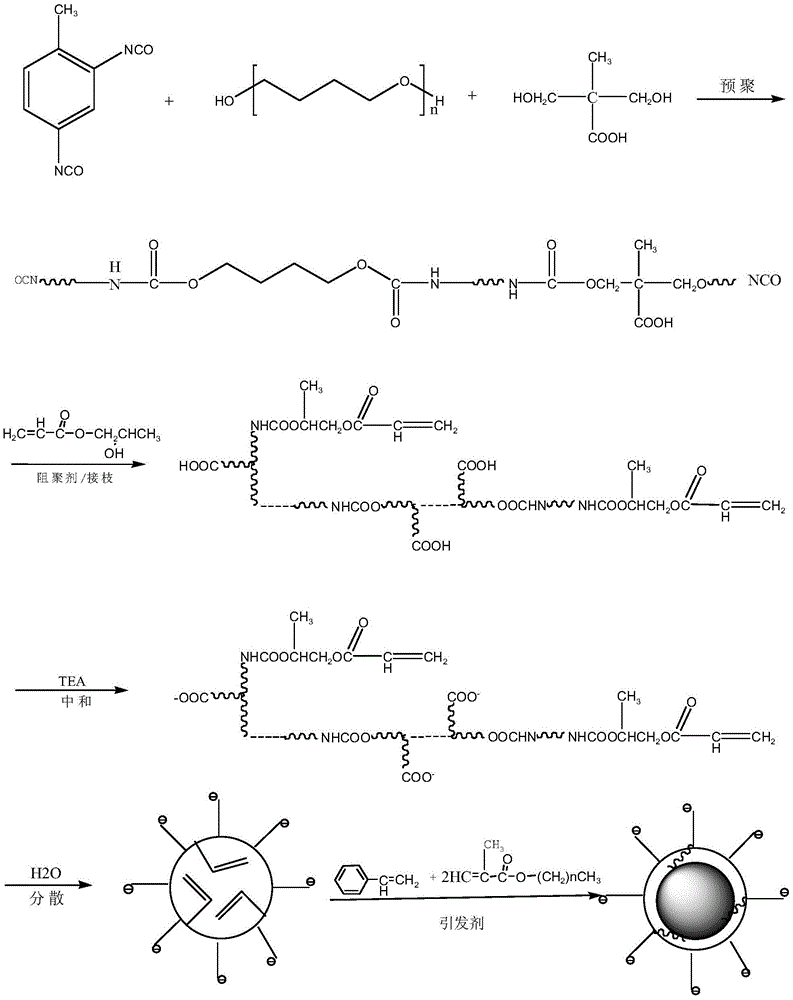

Preparation method of interpenetrating-network-structure water-based polyurethane nano composite material

A nanocomposite material and interpenetrating network structure technology, which is applied in the field of preparation of interpenetrating network structure waterborne polyurethane nanocomposite materials, can solve the problems of organic solvent pollution, high production cost, poor temperature resistance, etc. Health hazards, control of VOC emissions, effects of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

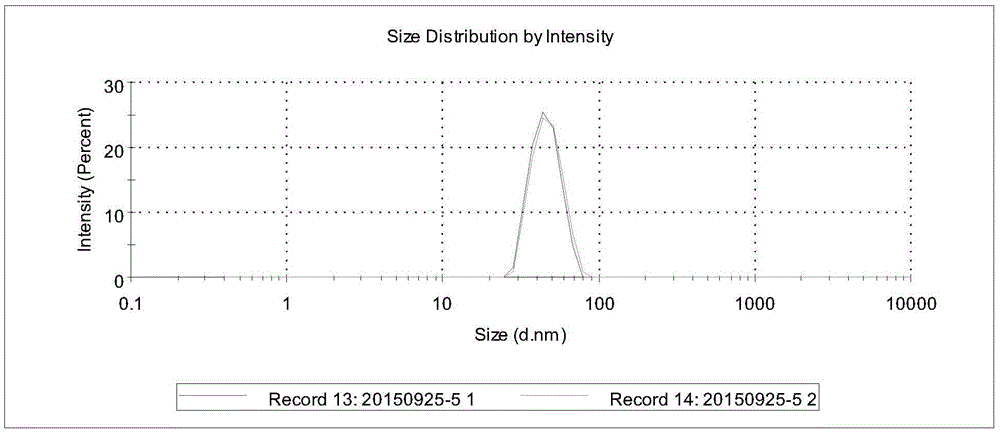

Embodiment 1

[0062] A preparation method of an interpenetrating network structure waterborne polyurethane nanocomposite, wherein, each component is by weight:

[0063] 2,4-Toluene diisocyanate (TDI): 37.5

[0064] Polytetrahydrofuran ether polyol (PTMEG2000): 72.5

[0065] Dimethylolpropionic acid (DMPA): 2.5

[0066] Methyl methacrylate (MMA): 65

[0067] Styrene (St): 32.5

[0068] Hydroxypropyl methacrylate (HPA): 7.5

[0069] 1,4-Butanediol (BDO): 2

[0070] Trimethylolpropane (TMP): 0.25

[0071] Triethylenediamine (TEDA): 0.25

[0072] Dibutyltin dilaurate (DBTL): 0.3

[0073] 2,6-di-tert-butyl-4-methylphenol (antioxidant 264): 0.25

[0074] Triethylamine (TEA): 4

[0075] Ammonium persulfate (APS): 0.5

[0076] Deionized water (H2O): 275

[0077] A preparation method of interpenetrating network structure water-based polyurethane nanocomposite, the preparation process is as follows: dehydration treatment of polyol PTMEG (polymer polyol) and DMPA (hydrophilic functional mon...

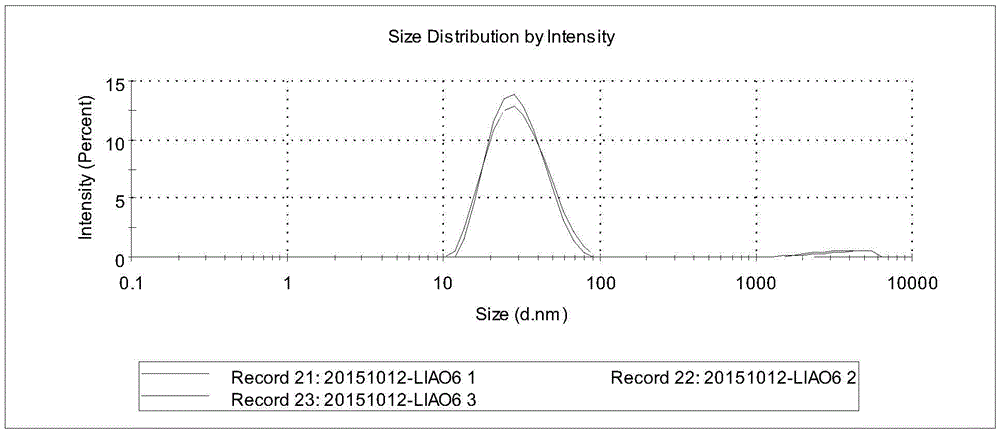

Embodiment 2

[0085] A preparation method of an interpenetrating network structure waterborne polyurethane nanocomposite, wherein, each component is by weight:

[0086] Isophorone diisocyanate (IPDI): 62.5

[0087] Polytetrahydrofuran ether polyol (PTMEG1000): 37.5

[0088] Dimethylolbutyric acid (DMBA): 5

[0089] Methyl methacrylate (MMA): 40

[0090] Butyl Acrylate (BA) 25

[0091] Styrene (St): 30

[0092] Hydroxyethyl Acrylate (HEA): 10

[0093] Ethylene glycol (ED): 2.5

[0094] Trimethylolpropane (TMP): 0.5

[0095] Bis(dimethylaminoethyl)ether: 0.25

[0096] Dibutyltin dilaurate (DBTL): 0.3

[0097] Hydroquinone: 0.5

[0098] Ammonia: 5

[0099] Potassium persulfate: 0.75

[0100] Deionized water (H2O): 275

[0101] A preparation method of interpenetrating network structure water-based polyurethane nanocomposite, the preparation process is as follows: dehydration treatment of polyol PTMEG and DMBA at 120°C for 1-2 hours, then add catalyst TEDA and DBTL after cooling to r...

Embodiment 3

[0109] A preparation method of interpenetrating network structure waterborne polyurethane nanocomposite, wherein, each group is by weight:

[0110] Diphenylmethane diisocyanate (MDI): 70

[0111] Polyoxyethylene polyol (PEG1000): 40

[0112] Dimethylolbutyric acid (DMBA): 5

[0113] Methyl methacrylate (MMA): 35

[0114] Methacrylic acid (AA) 10

[0115] Butyl Acrylate (BA) 25

[0116] Styrene (St): 25

[0117] Hydroxyethyl Acrylate (HEA): 10

[0118] 1,6-Hexanediamine (HMD): 2.5

[0119] Trimethylolpropane (TMP): 0.5

[0120] Dibutyltin dilaurate (DBTL): 0.5

[0121] 2-(2-Dimethylamino-ethoxy)ethanol 0.2

[0122] Phosphite: 0.5

[0124] Ammonium persulfate (APS): 0.75

[0125] Deionized water (H2O): 275

[0126] A preparation method of interpenetrating network structure water-based polyurethane nanocomposite, the preparation process is as follows: dehydration treatment of polyol PEG and DMBA at 120°C for 1-2 hours, after cooling to ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com