Patents

Literature

57 results about "Nanohybrid composite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A. A nano-hybrid composite has conventional glass and innovative nano-scaled fillers. The advantage of a nano-hybrid composite over a hybrid or microfill composite is the combination of great esthetics, exceptional polishability and high strength.

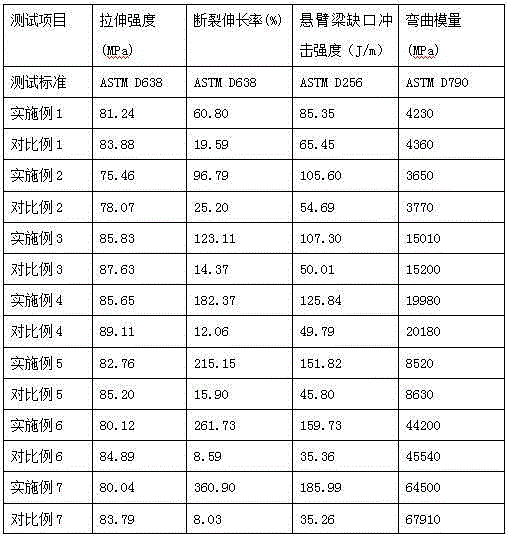

Preparation method of polypropylene nano composite material

ActiveCN102086280AGood modification effectImprove interface strengthHeat deflection temperatureMasterbatch

The application of the invention discloses a preparation method of a polypropylene nano composite material, which comprises the following steps of: (1) proportionally fusing and blending inorganic nano particles and maleic anhydride grafted polypropylene on an internal mixer, an open mill or a screw extruder to obtain a reinforcing agent master batch; (2) proportionally fusing and blending a beta crystal type nucleating agent and the maleic anhydride grafted polypropylene on the internal mixer, the open mill or the screw extruder to obtain a flexibilizer master batch; and (3) proportionally diluting and dispersing the reinforcing agent master batch and the flexibilizer master batch in a polypropylene high-polymer substrate, and carrying out injection molding to obtain the polypropylene nano composite material. With the preparation method, the technical problem that the nano particles and the nucleating agent agglomerate in the polypropylene substrate is well solved; when the flexibility of the modified polypropylene material is greatly improved, strength, rigidity, heat deflection temperature and other parameters are also improved to a certain extent, and simultaneously the density of the material is hardly increased so that a series of high-strength, high-flexibility and high-heat resistance modified polypropylene materials can be prepared.

Owner:CHINA PETROLEUM & CHEM CORP +1

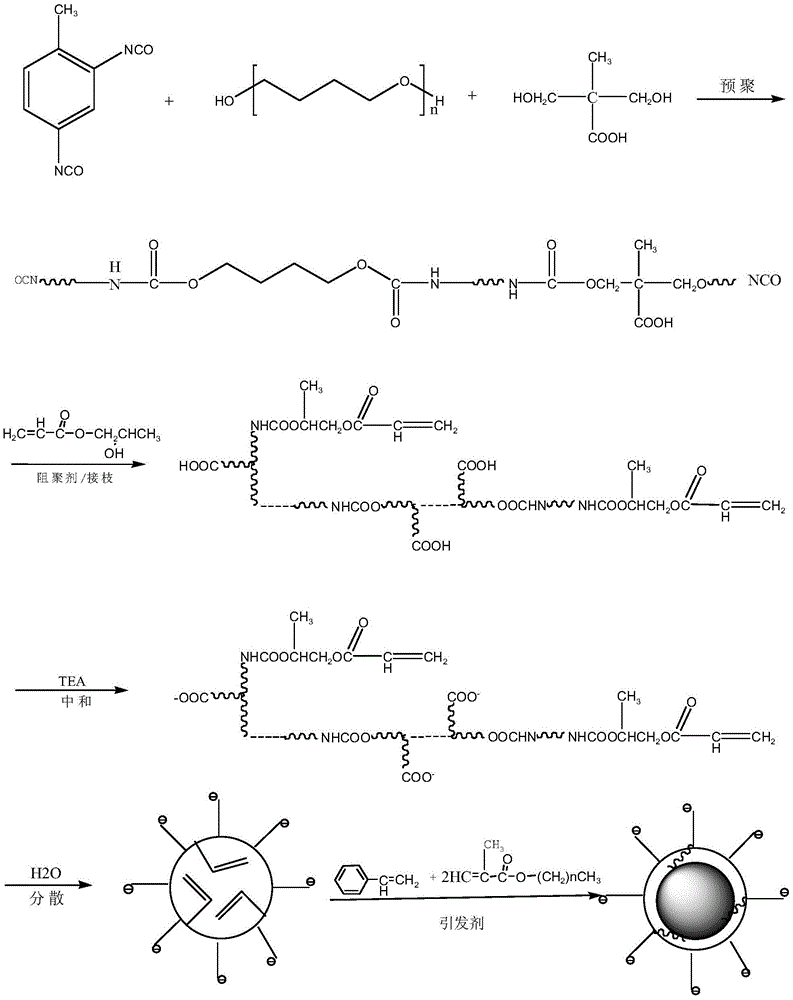

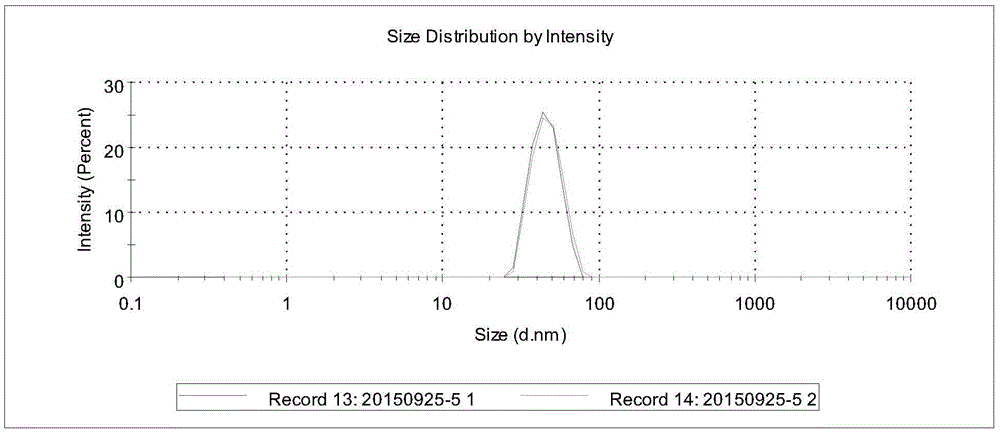

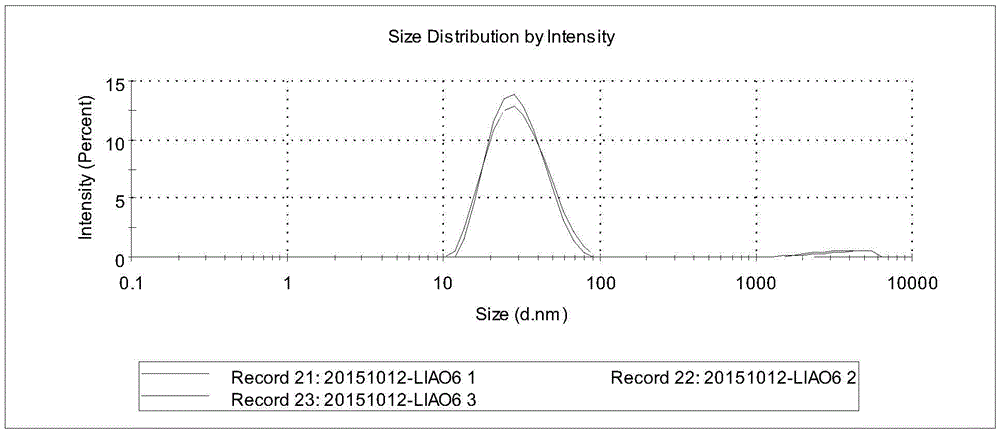

Preparation method of interpenetrating-network-structure water-based polyurethane nano composite material

The invention provides a preparation method of an interpenetrating-network-structure water-based polyurethane nano composite material. The preparation method comprises the following steps: 1) carrying out vacuum dehydration treatment on polymer polylol and hydrophilic functional monomer; 2) adding a catalyst and diisocyanate, reacting at room temperature for 0.5-2 hours, heating to 60-80 DEG C, and carrying out the reaction for 1-5 hours while keeping the temperature; 3) cooling to 40-50 DEG C, adding a chain extender, and carrying out the reaction for 2-4 hours while keeping the temperature; 4) heating to 60-70 DEG C, and adding a reactive monomer for termination; 5) cooling to 30-50 DEG C, and adding a neutralizer to regulate the pH value; 6) heating to 60 DEG C, dropwise adding deionized water, and dispersing by stirring; and 7) heating to 60-65 DEG C, dropwise adding an initiator water solution and a nucleation monomer, carrying out programmed heating, and carrying out the reaction while keeping the temperature, thereby obtaining the interpenetrating-network-structure water-based polyurethane nano composite material. The method effectively solves the problem of VOC (volatile organic compound) discharge. The nano composite material has the characteristics in both the core-shell structure and the interpenetrating network structure, and thus, has favorable mechanical properties. The adopted continuous-process synthesis technique is beneficial to enhancing the production efficiency.

Owner:武汉弘毅共聚新材料科技有限公司

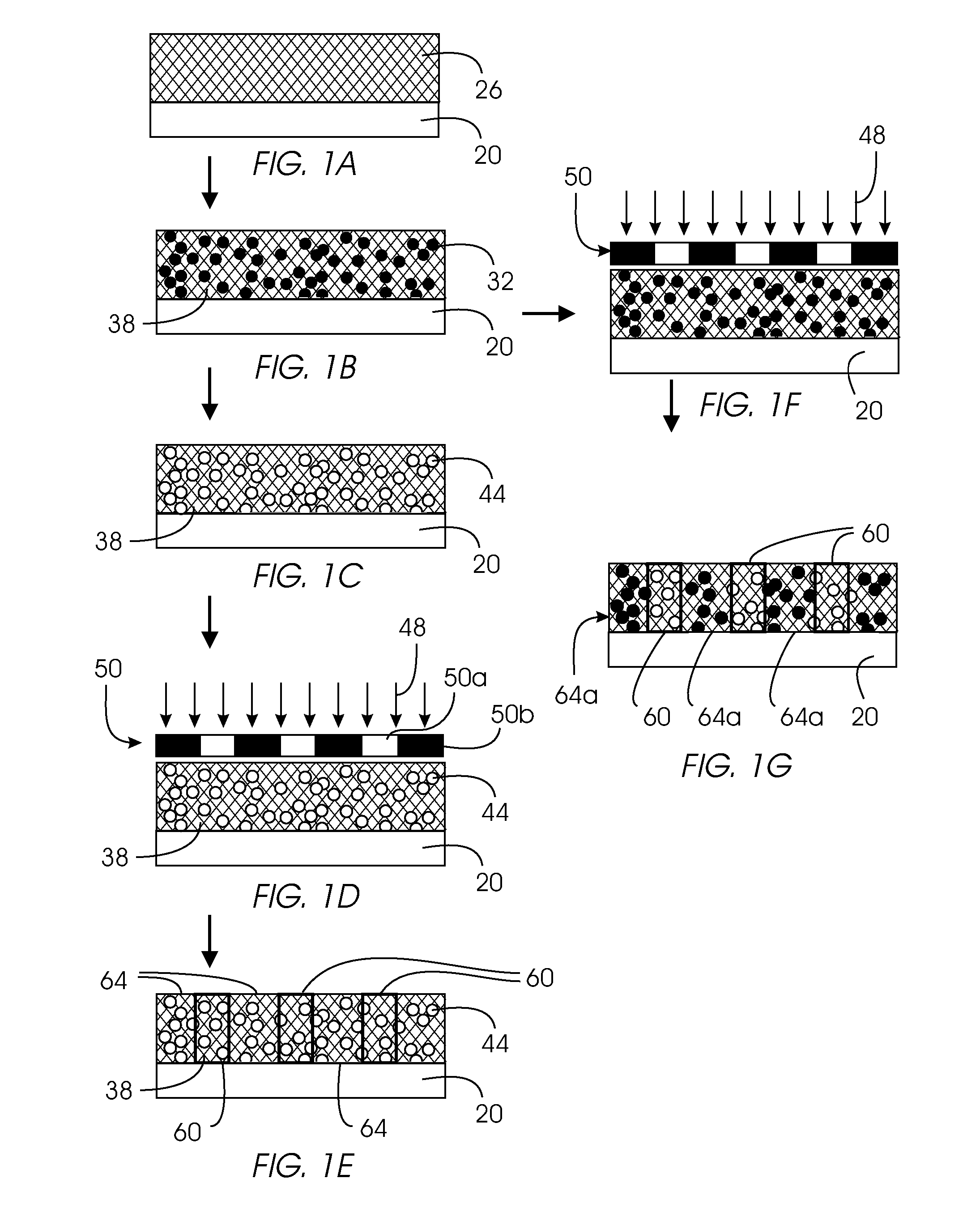

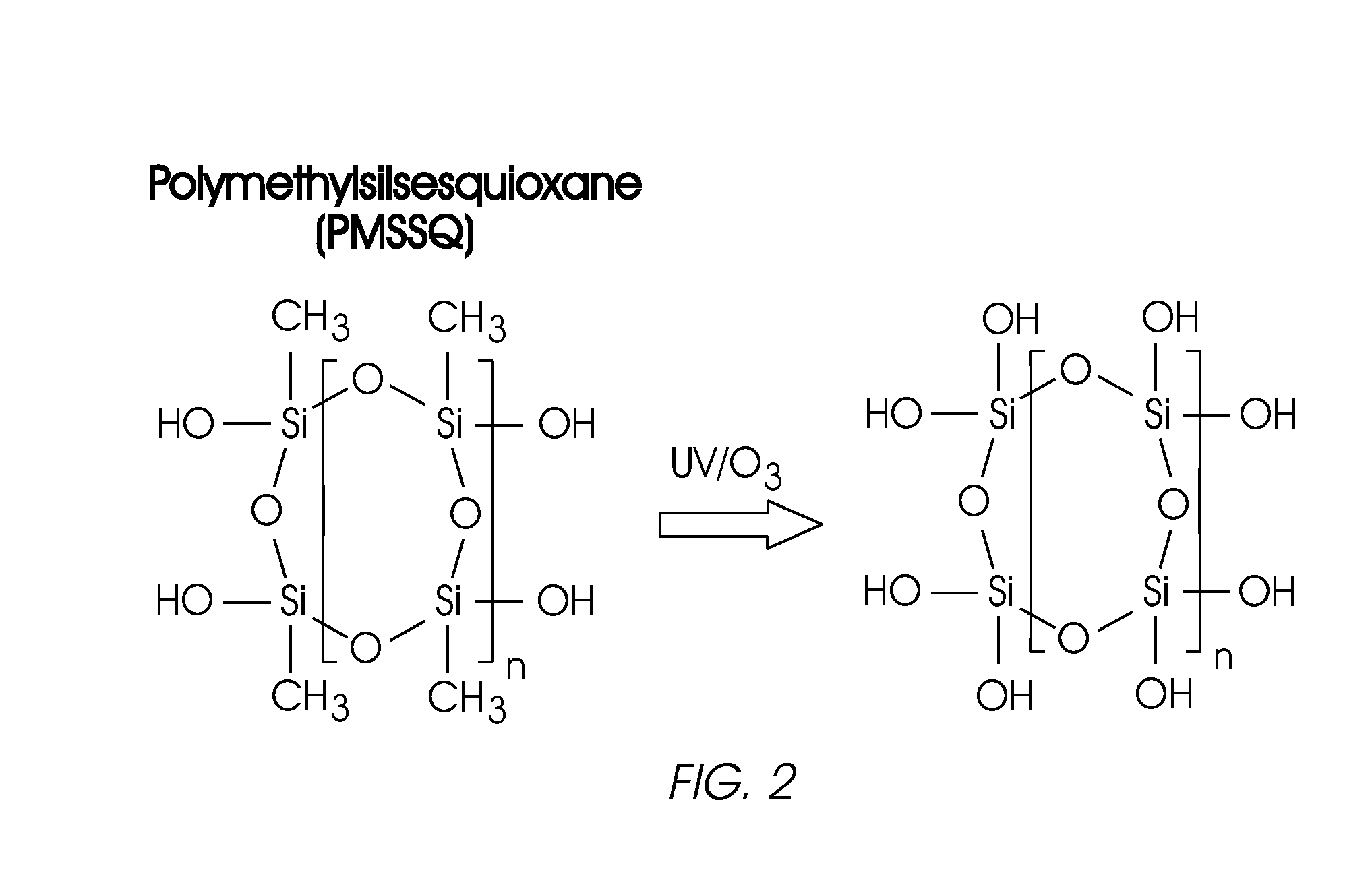

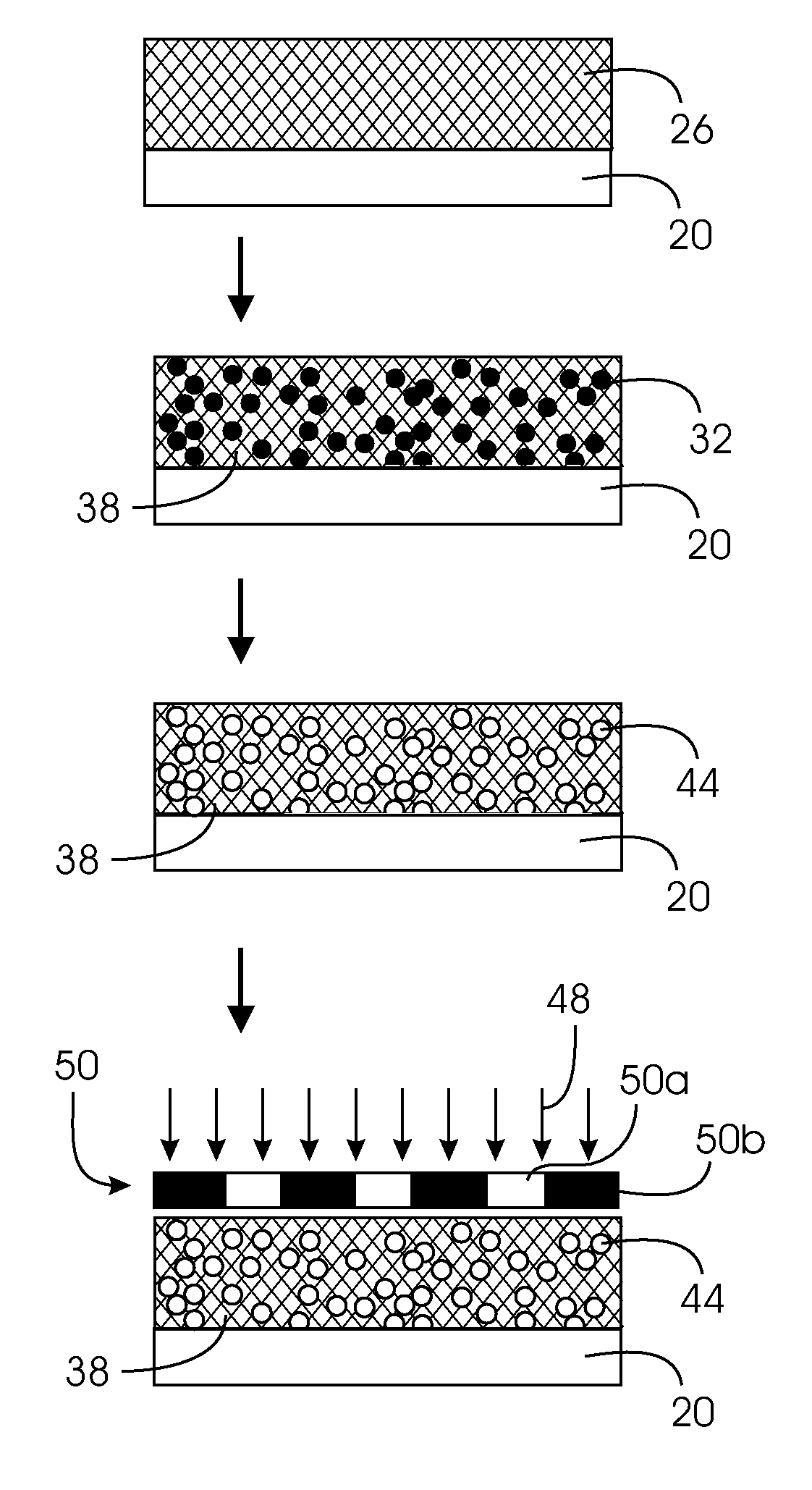

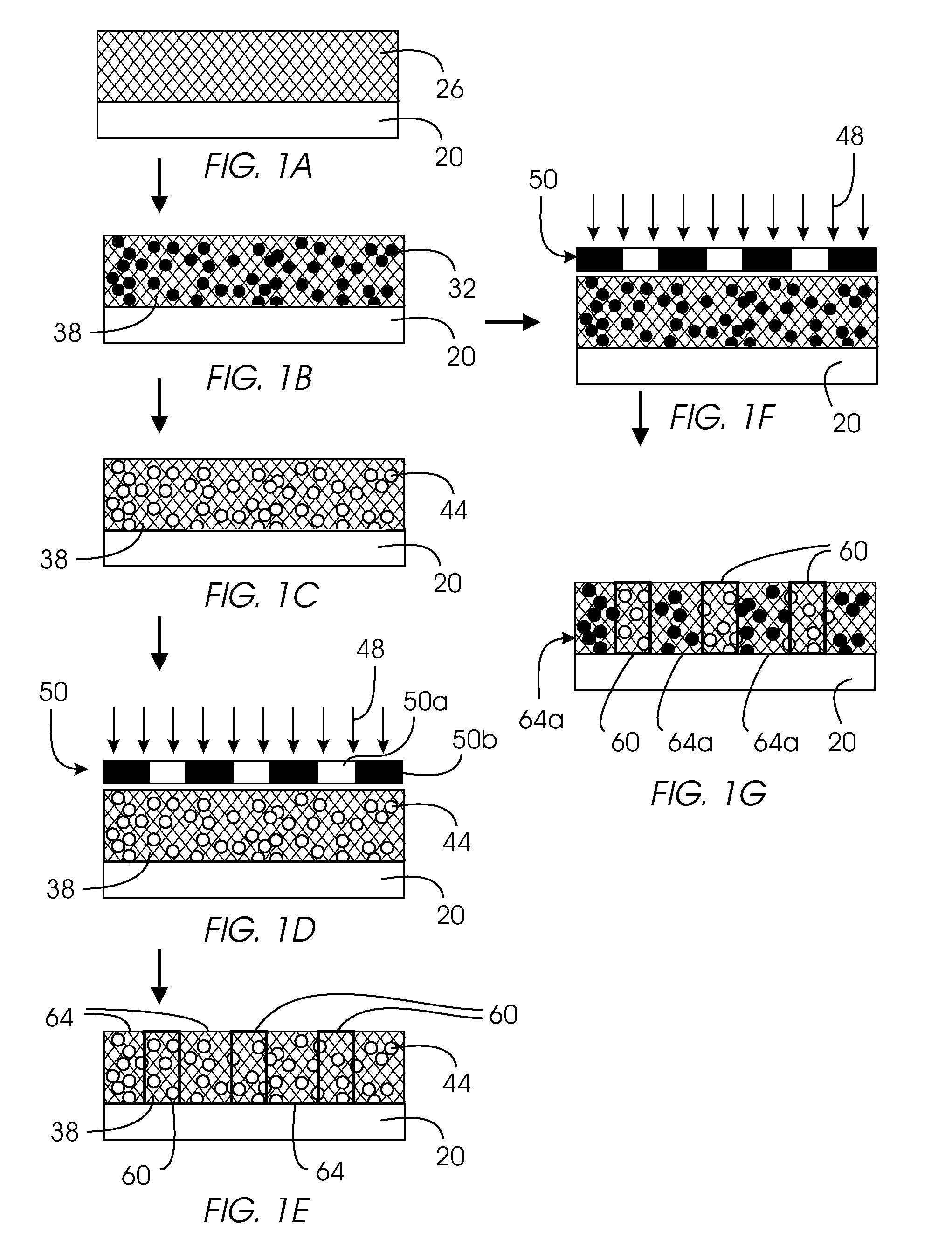

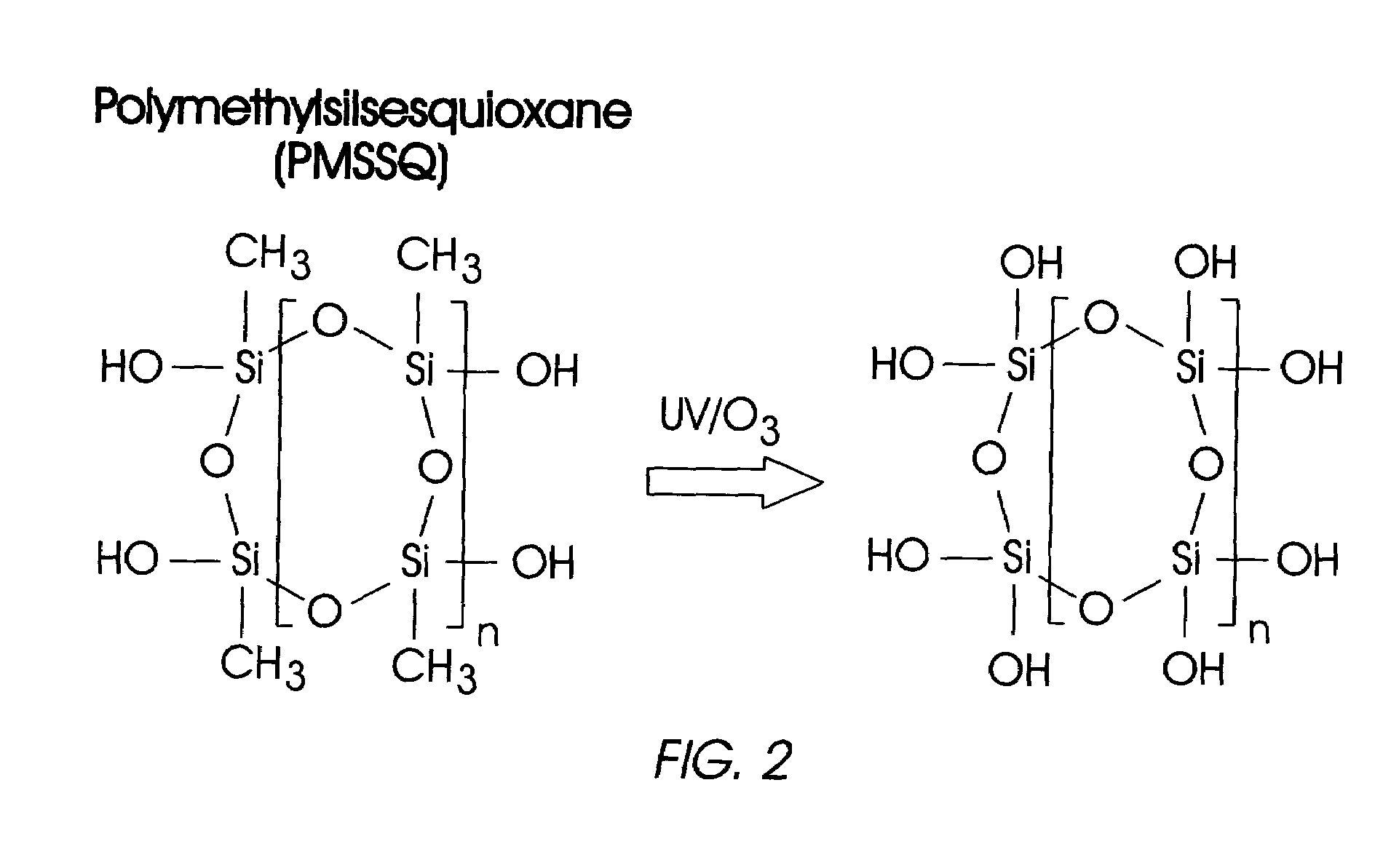

Patterned, high surface area substrate with hydrophilic/hydrophobic contrast, and method of use

InactiveUS20070231559A1The process is simple and effectivePotential absorptionEnergy modified materialsLayered productsGas phaseUltraviolet lights

Nanoporous structures are constructed that have hydrophilic regions separated by hydrophobic regions. The porous, hydrophilic regions have reaction sites suitable for use in a bioassay application and have a higher density of reaction sites than that of a non-porous (2-D) surface. The structure may be made by depositing a layer of a matrix material (e.g., an organosilicate) and a porogen, and then crosslinking the matrix material to form a nanohybrid composite structure. The porogen is decomposed to form pores within the matrix material, and a reactive gas phase species (e.g., ozone) is patternwise directed onto a surface of the matrix material. Ultraviolet light (directed through a mask) activates the gas phase species to form a reactive species that then reacts with the matrix material to make it hydrophilic. The porogen may be decomposed thermally or by exposing it to an oxidizing atmosphere in the presence of ultraviolet light.

Owner:IBM CORP

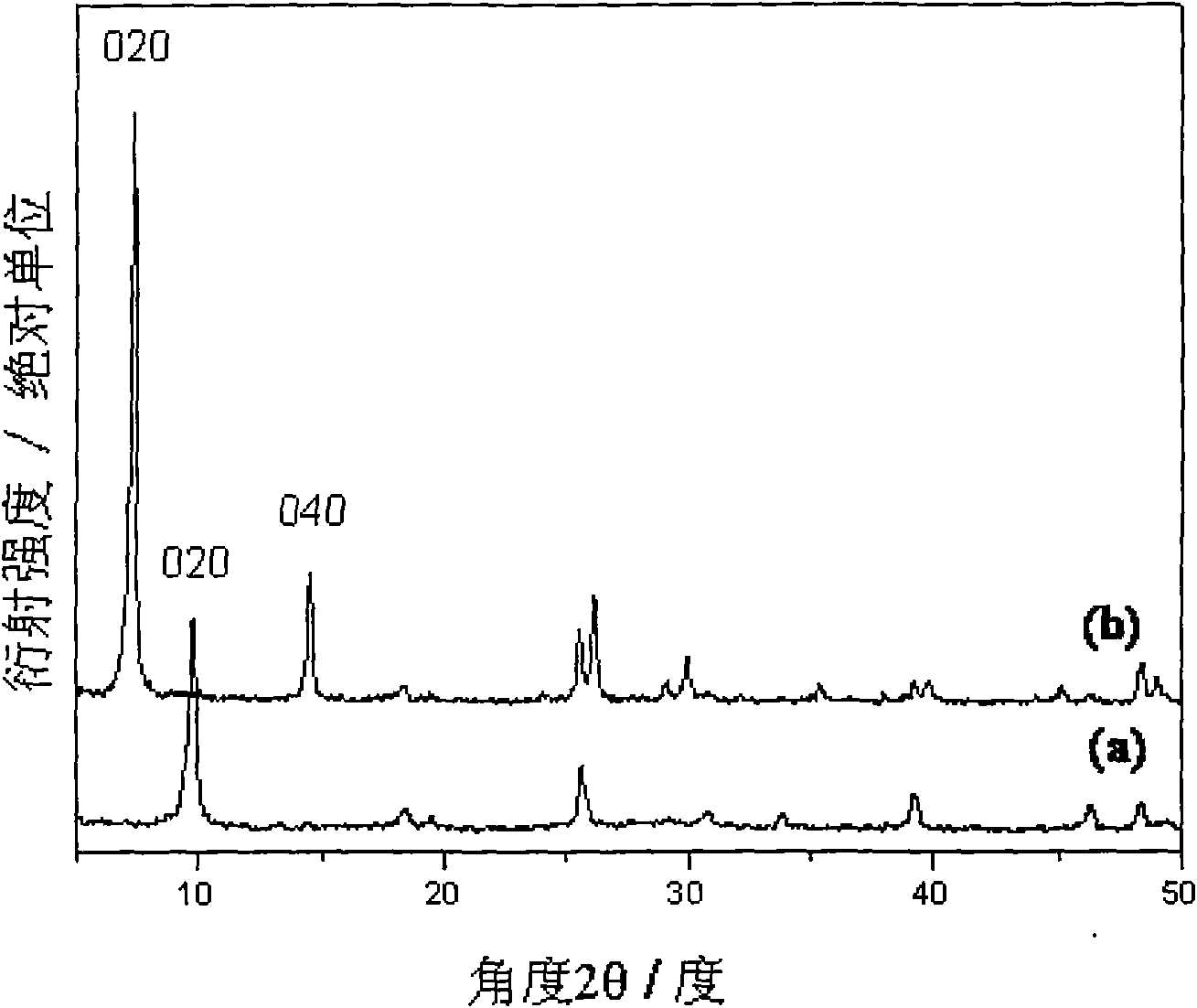

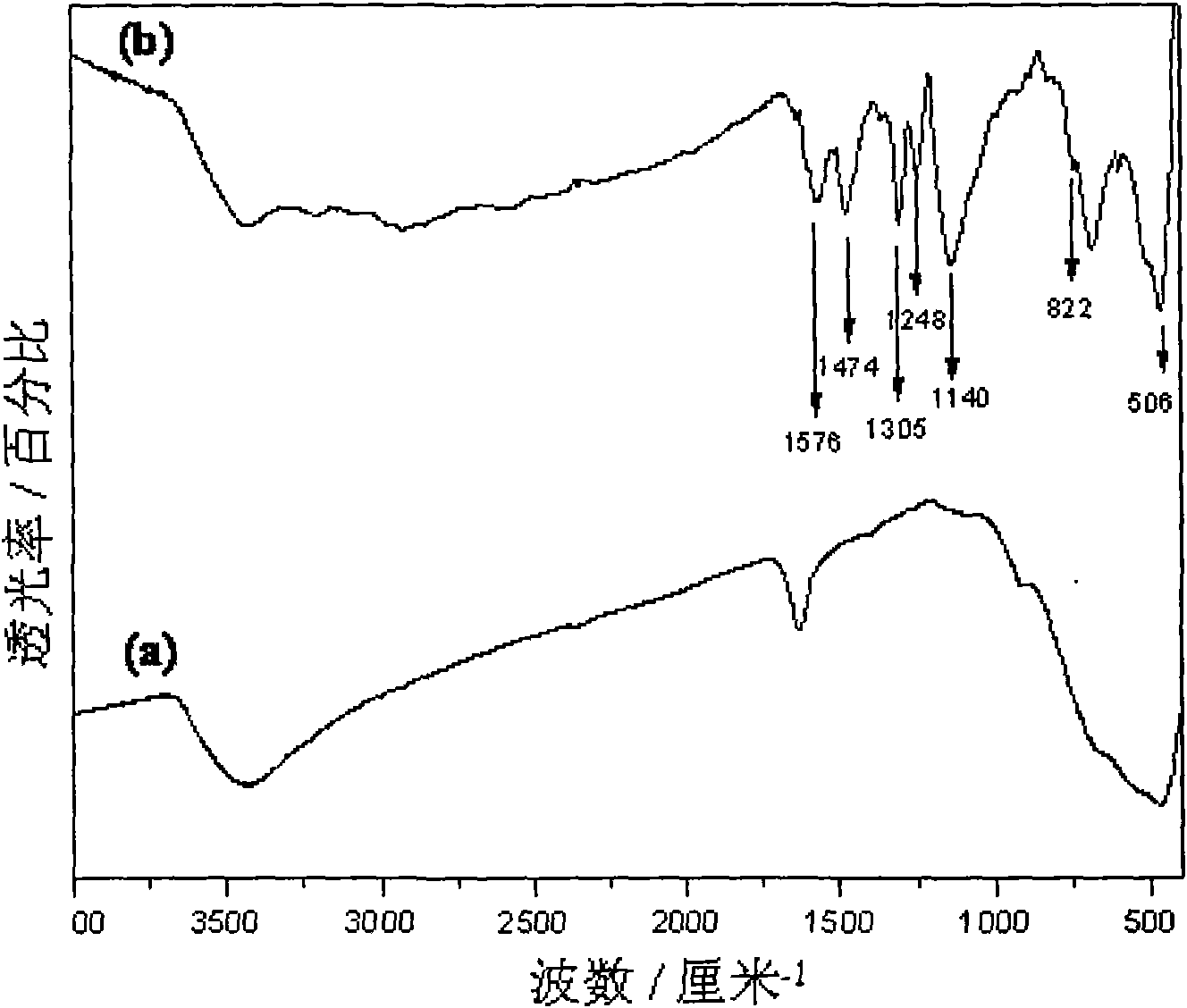

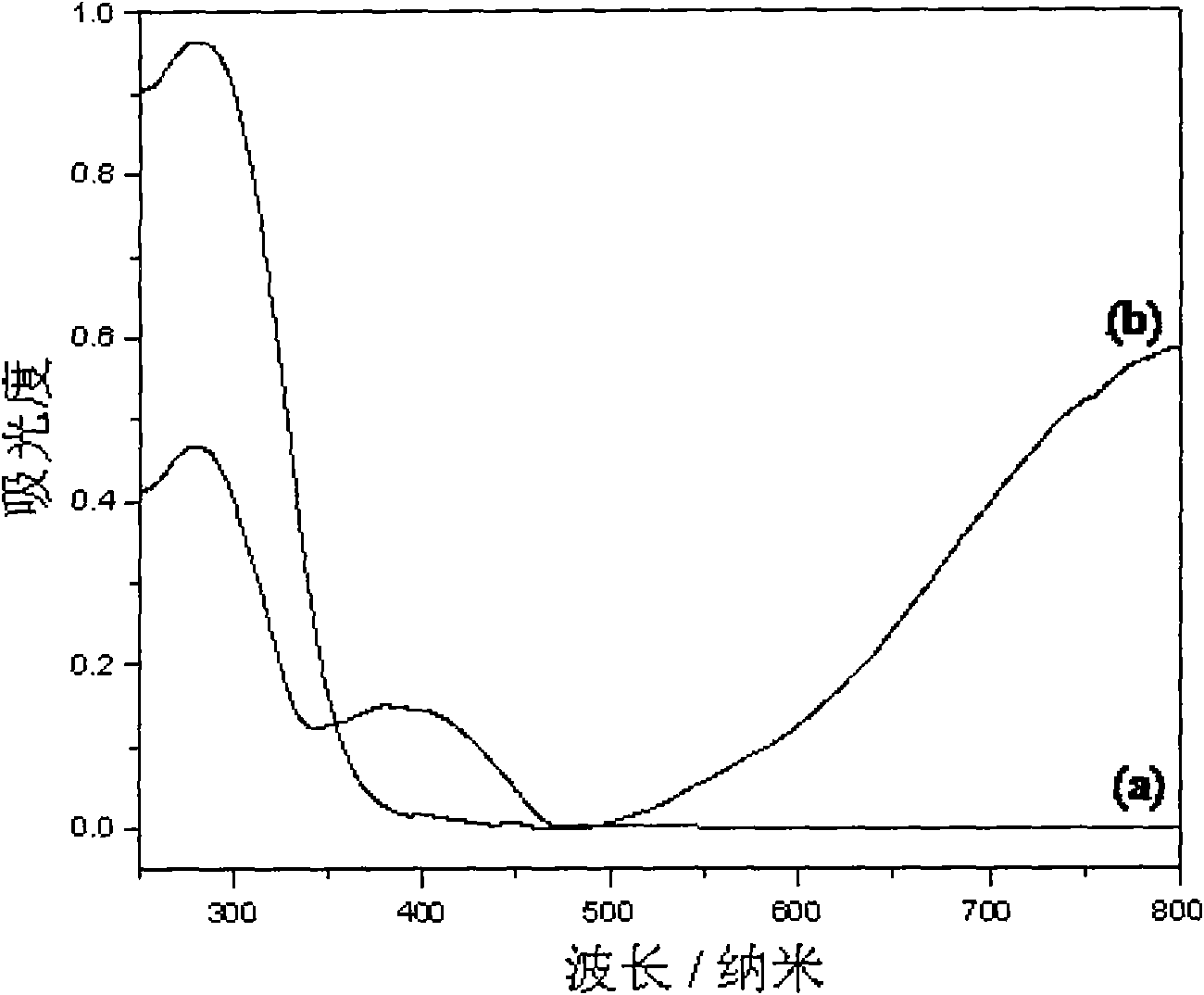

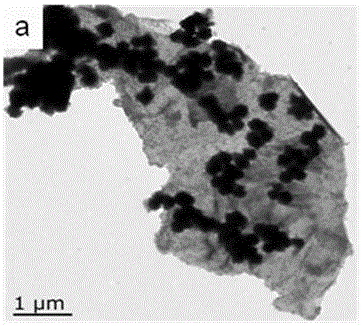

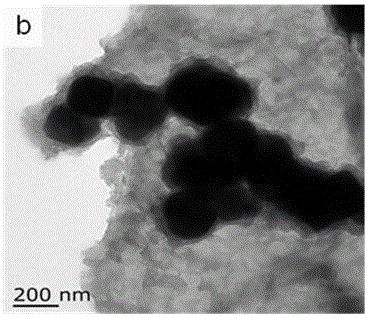

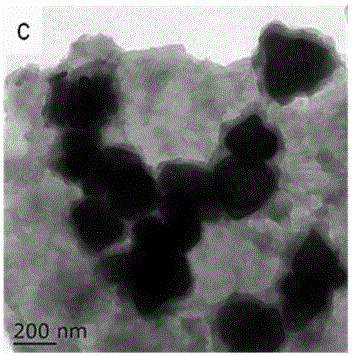

Nano composite material of polyaniline intercalation titanate and preparation method thereof

InactiveCN101565544ALarge overcoming forceOvercoming unfavorable factors such as difficulties in inserting layersProtonationAniline

A nano composite material of polyaniline intercalation titanate and a preparation method thereof belong to the technical field of organic / inorganic nano composite materials and the preparation thereof. The chemical composition of the nano composite material is PANI / HxTi2-x / 4 vacancy x / 4O4.H2O, wherein PANI is polyaniline, the mass ratio of which is 7.0 percent to 8.0 percent in the composite material; HxTi2-x / 4 vacancy x / 4O4.H2O is protonated layered titanate, vacancy is a titanium vacancy in the layer plate, and x is more than or equal to 0.65 and less than or equal to 0.75. The nano composite material can expand the photoelectrical response range to a visible region and reduce the probability of composition of photo-induced electrons and photo-induced holes. Aniline monomer is inserted between the layers of HxTi2-x / 4 vacancy x / 4O4.H2O by acid radical reaction, and simultaneously, the aniline between the layers is polymerized in the presence of oxygen, thus obtaining the product. The nano composite material has application value in the filed of photocatalysis, solar batteries, photoelectric sensors and the like.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of graphene/Fe3O4/polyaniline ternary wave-absorbing composite material

The invention discloses a preparation method of a graphene / Fe3O4 / polyaniline ternary wave-absorbing composite material, and relates to the technical field of ternary composite conductive material production. The method is characterized in that a process using aniline monomer to directly reduce graphene oxide is used, and the coordination interaction of the graphene oxide and Fe3O4 is used to prepare the graphene / Fe3O4 / polyaniline ternary composite material, so that the goal of greenization of the nano composite material preparation and compounding and refinement of the wave-absorbing material structure can be realized. In the composite material, polyaniline organically wraps the surface of the compound of Fe3O4 and graphene to form a specific layer-by-layer assembled structure. The specific surface area is greatly increased by the laminated graphene sheets, and more interfacial polarization and interfaces are caused by the layered structure and the core-shell structure. The prepared ternary composite material is capable of realizing impedance matching and is beneficial to the attenuation effect of electromagnetic waves by the additional interfacial polarization and multiple interfaces caused by the layer-by-layer assembled structure.

Owner:YANGZHOU UNIV

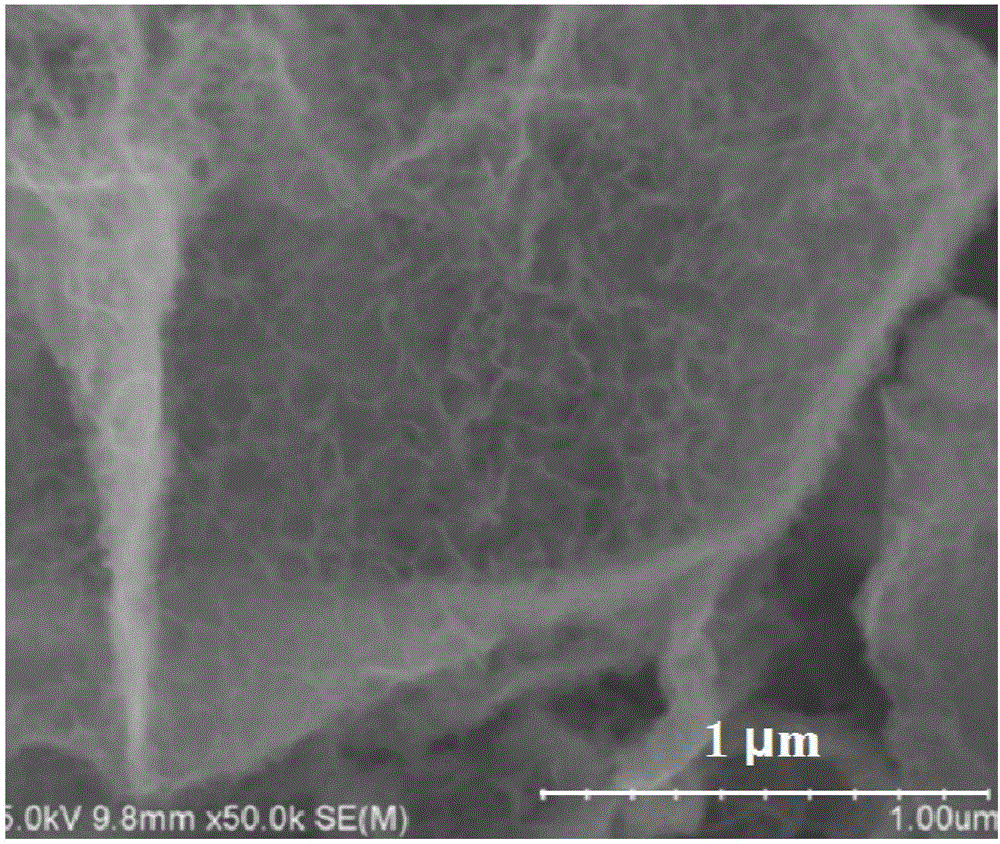

Nickel hydroxide/graphene nano composite, preparation method thereof, supercapacitor electrode and supercapacitor

ActiveCN106158405APrevent heavy accumulationImprove the utilization of specific surface areaMaterial nanotechnologyHybrid capacitor electrodesCapacitanceGraphene nanocomposites

The invention discloses a nickel hydroxide / graphene nano composite, a preparation method thereof, a supercapacitor electrode and a supercapacitor. The composite is formed by base material graphene and a nickel hydroxide nanosheet growing on the surface of the graphene in situ, and the composite integrally has a three-dimensional porous structure. A graphene-based composite is prepared by loading a transition metal hydroxide on the surface of the graphene with high specific surface area and excellent conductivity in a composition manner. Due to synergistic effect of all componenta of the composite, all components can mutually enhance advantages and avoid disadvantages; and meanwhile, long circle life, high power density and high stability of an electric double-layer capacitor and high specific capacitance characteristic of a pseudocapacitor are combined, thereby improving the comprehensive performances of the supercapacitor.

Owner:嘉兴企远网信息科技有限公司

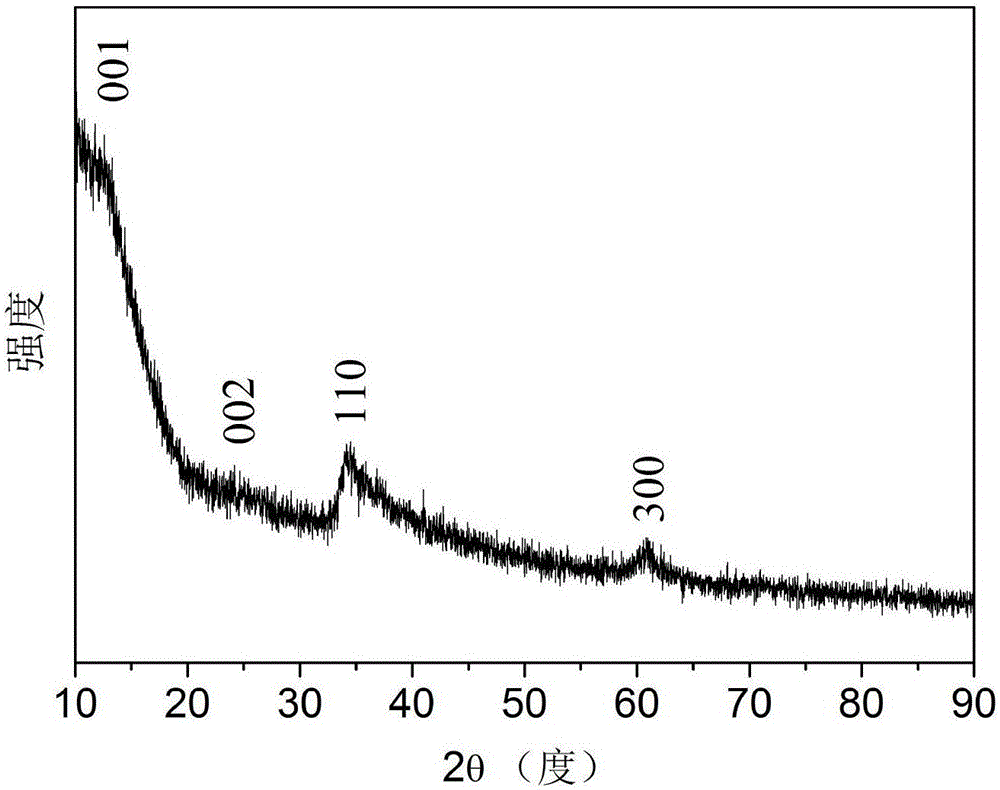

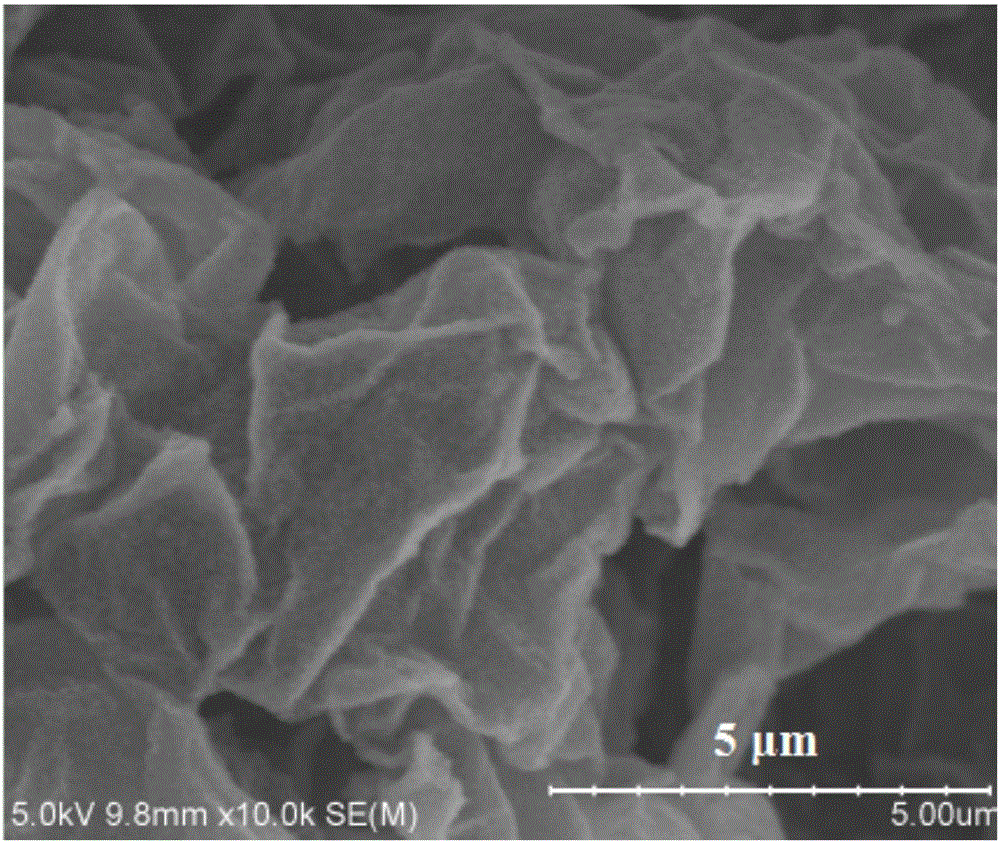

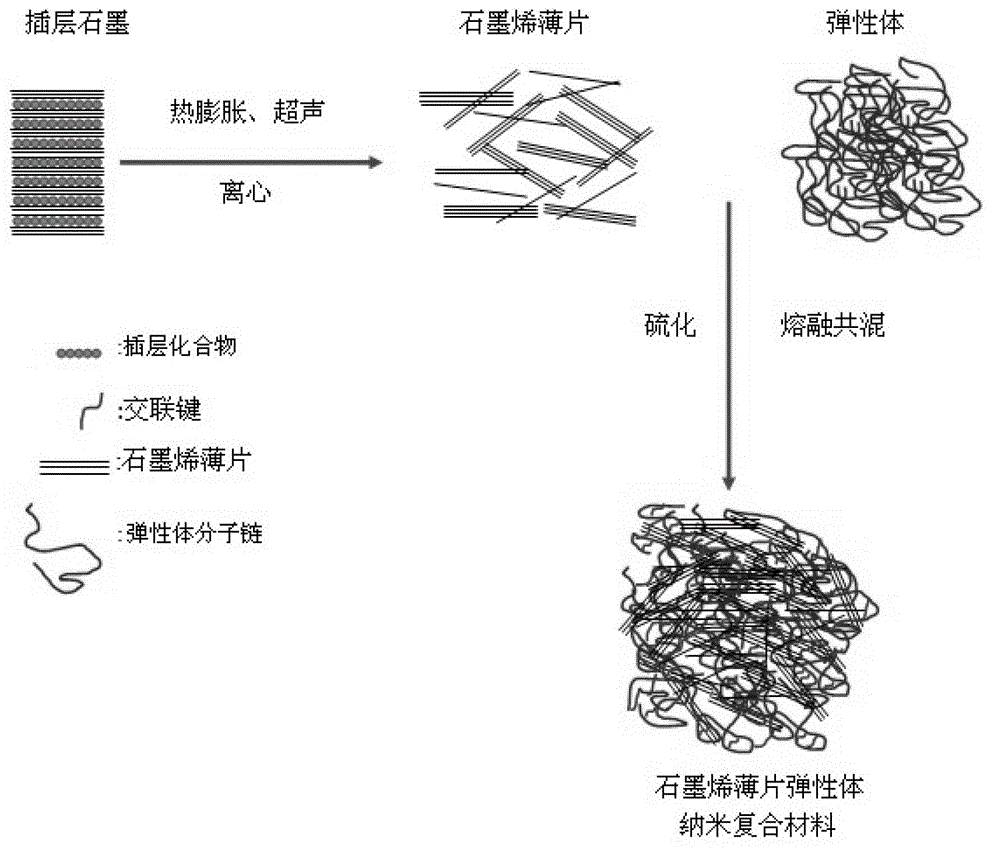

Simple preparation method of graphene sheet nano composite material

InactiveCN102942743AIncrease productionLow costMaterial nanotechnologyGrapheneElastomerGraphene nanocomposites

The invention relates to a simple and efficient preparation method of a graphene sheet nano composite material. Industrial intercalated graphite is used as a raw material to prepare a graphene sheet with 3-4 graphene single sheets, thickness of 2-4 nm and oxygen content of only 7% through thermal expansion, ultrasonic dispersion and centrifugal drying; and the graphene sheet is then subjected to melt blending with a rubber matrix to prepare an elastic nano composite material with uniformly dispersed graphene sheets. On the premise of stable enhancement on mechanical properties of the composite material, the electric conduction and thermal conductivity of the composite material are also remarkably enhanced. According to the invention, intercalated graphite is used as a main raw material to substitute commonly used chemically synthesized graphite oxide; the method has simple process, high yield and low cost, can produce graphene nano composite material directly through melt blending, and can be applied to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

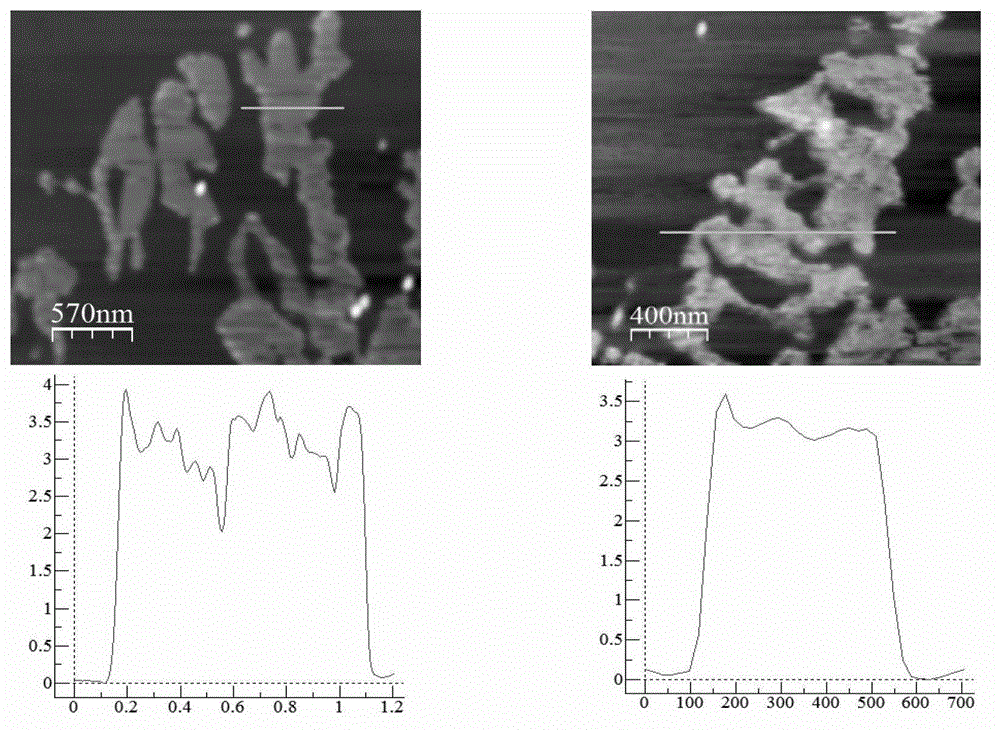

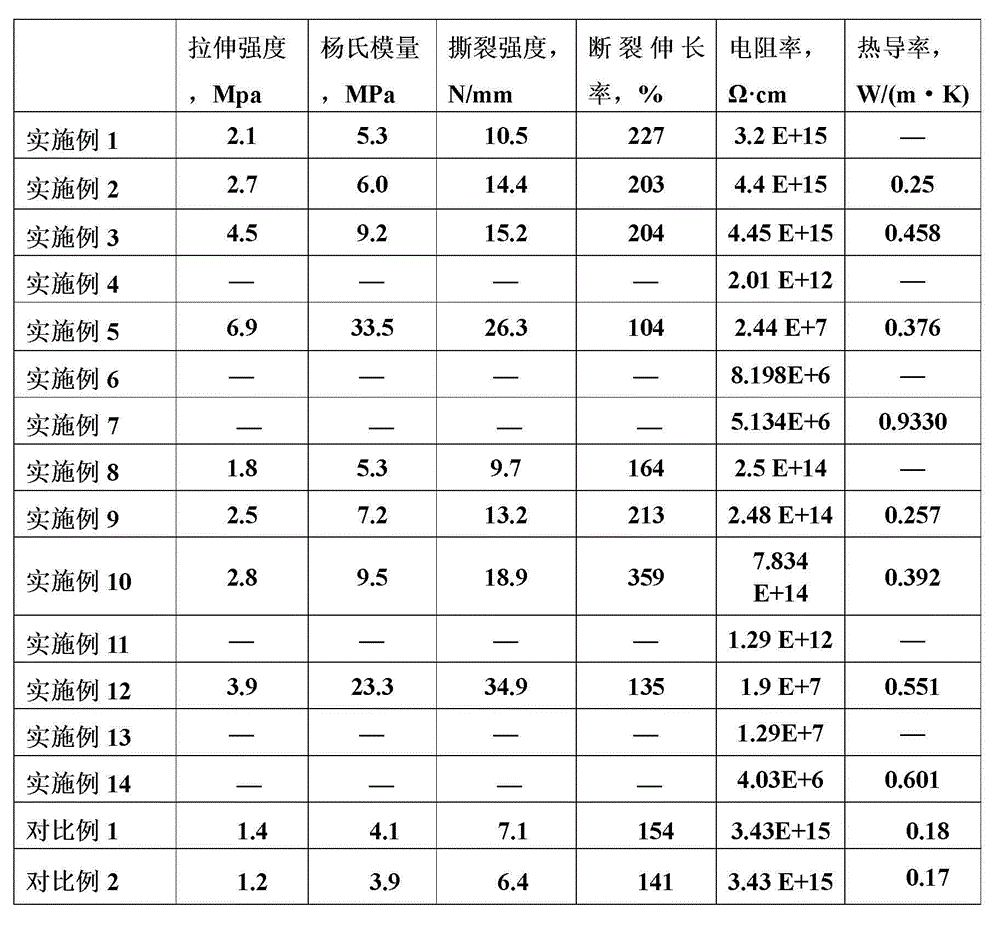

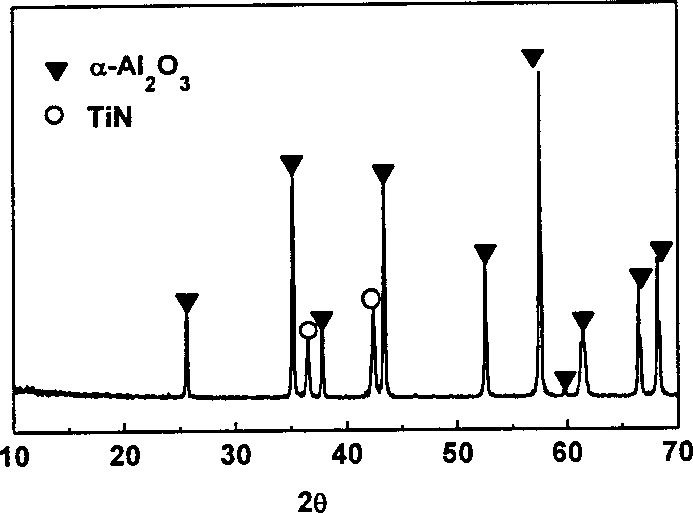

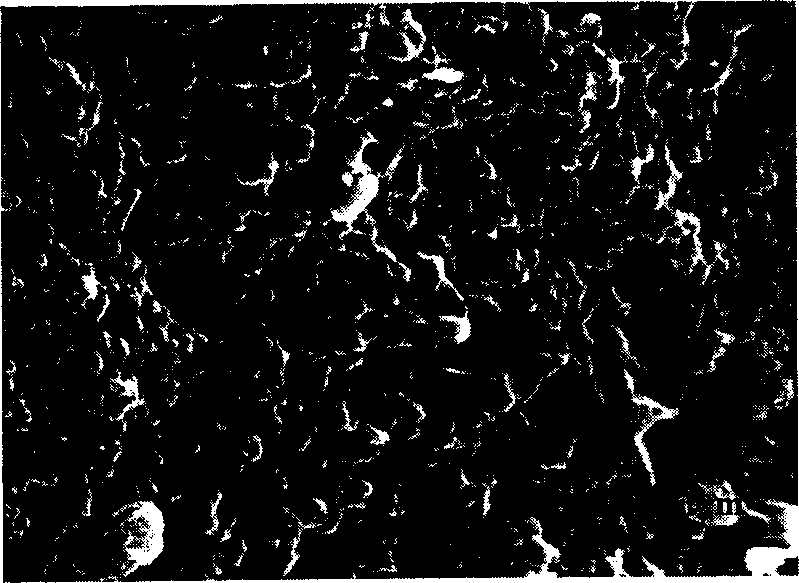

Prepn of conductive composite nanometer titanium nitride-alumina material

The method for preparing conductive nano titanium nitride-aluminium oxide composite material includes the following steps: using titanium-contained compound and aluminium-contained compound and adopting coprecipitatino method to prepare nano titanium nitride-aluminium oxide composite powder body firstly, in the atmosphere of ammonia gas placing said nano titanium nitride-aluminium oxide compositepowder body into the tubular reactor to make high-temp. nitridation to obtain nano titanium nitride-aluminium oxide composite powder body, finally, adopting hot-pressing and sintering process to obtain conductive nano titanium nitride-aluminium oxide composition material. Its composition range is that TiN / Al2O3 (volume ratio) is 5 / 95-25 / 75, under the optimization condition its resistance is 1.5-8X10 to the minus third ohm.cm. Said nano material possesses good microstructare and higher conductivity, and the titanium nitride nano granule size is less than 100 nanometers.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

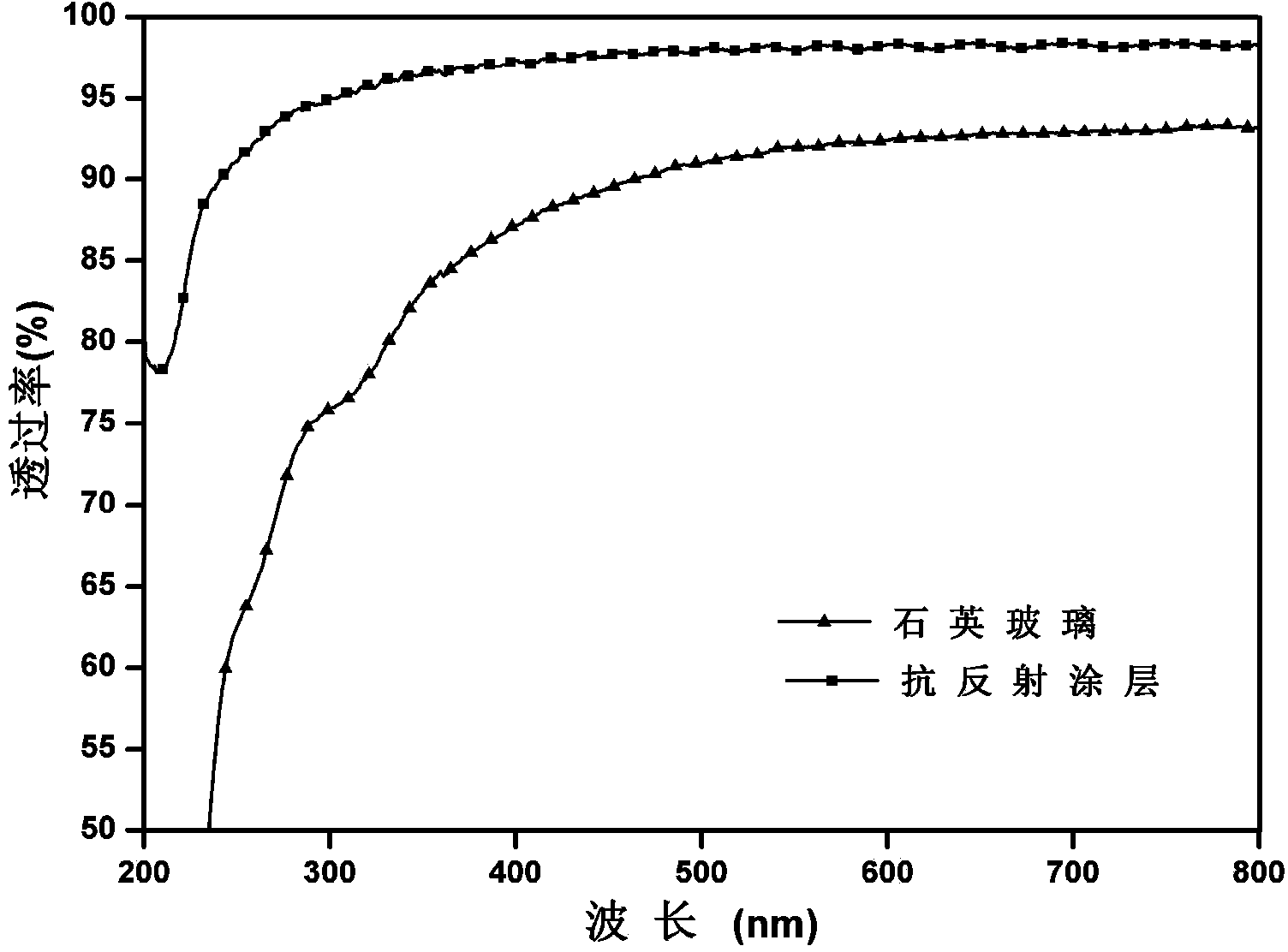

Anti-reflection coating constructed based on cage type silsesquioxane and preparing method and application thereof

ActiveCN104007491AImprove anti-reflection abilityIncrease temperatureCoatingsReaction layerSurface layer

The invention belongs to the technical field of nanometer hybrid composite materials and discloses an anti-reflection coating constructed based on cage type silsesquioxane and the preparing method and application thereof. The preparing method of the anti-reflection coating comprises the steps that a base reaction layer is constructed with 10-methacrylonitrile acyloxy propyl group cage type silsesquioxane and 8-aminophenyl group cage type silsesquioxane and then is precured, a surface layer is constructed with fluorinated acrylate prepolymer and 8-methacrylonitrile acyloxy propyl group cage type silsesquioxane, the two layers are co-cured under a certain condition, and stress is generated by means of the difference in reaction volume shrinkage of the two layers. The prepared anti-reflection coating is of a nanometer island structure, and the anti-reflection performance is improved remarkably. The anti-reflection coating can be widely applied to optical devices which require high anti-reflection performance.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Patterned, high surface area substrate with hydrophilic/hydrophobic contrast, and method of use

InactiveUS7282241B2The process is simple and effectivePotential absorptionEnergy modified materialsLayered productsGas phaseUltraviolet lights

Nanoporous structures are constructed that have hydrophilic regions separated by hydrophobic regions. The porous, hydrophilic regions have reaction sites suitable for use in a bioassay application and have a higher density of reaction sites than that of a non-porous (2-D) surface. The structure may be made by depositing a layer of a matrix material (e.g., an organosilicate) and a porogen, and then crosslinking the matrix material to form a nanohybrid composite structure. The porogen is decomposed to form pores within the matrix material, and a reactive gas phase species (e.g., ozone) is patternwise directed onto a surface of the matrix material. Ultraviolet light (directed through a mask) activates the gas phase species to form a reactive species that then reacts with the matrix material to make it hydrophilic. The porogen may be decomposed thermally or by exposing it to an oxidizing atmosphere in the presence of ultraviolet light.

Owner:INT BUSINESS MASCH CORP

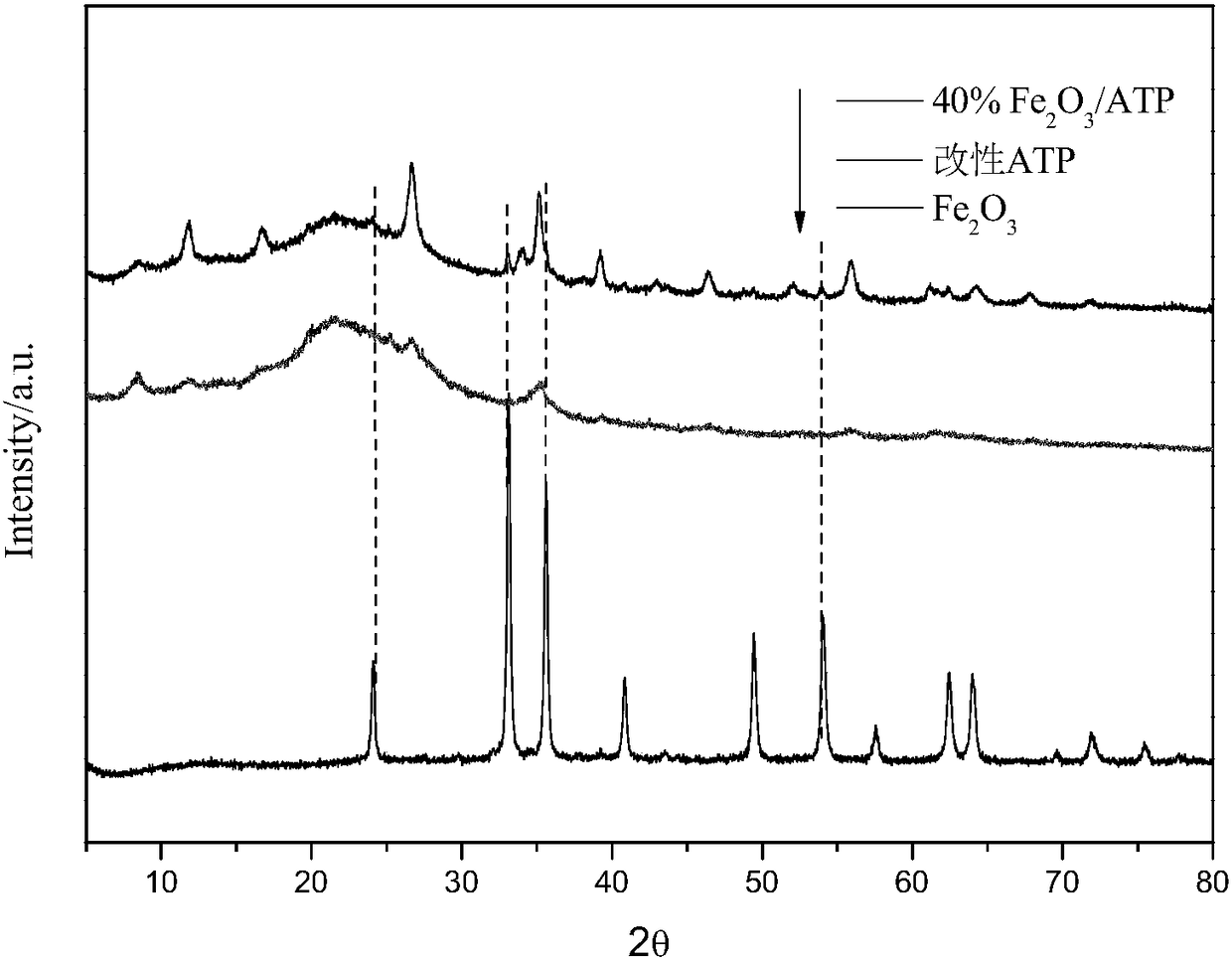

Preparation method and application of attapulgite composite photocatalyst

ActiveCN108479777AAchieving Visible Light ResponseThe synthesis method is simpleCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsWater bathsOxide composite

The invention belongs to the technical field of photocatalysis synthesis of ammonia, and particularly relates to a preparation method and an application of a modified attapulgite / transition metal oxide nano composite. The preparation method comprises the steps of: (1) performing acid treatment on purified attapulgite clay, replacing part of cations in an attapulgite octahedral structure and part of cations between layers with H<+>, (2) putting the acidified attapulgite clay in a transition metal salt solution for sufficient reaction in a water bath at 60-100 DEG C, and (3) putting a reaction solution in a microwave hydrothermal chemical reactor for reaction, and then performing centrifugation, washing and drying to form a finished product. The modified attapulgite / transition metal oxide composite can serve as the catalyst and is applied to the field of the photocatalysis synthesis of ammonia; compared with the traditional industrial synthesis of ammonia, the preparation method is simple; and the energy consumption is greatly reduced.

Owner:CHANGZHOU UNIV

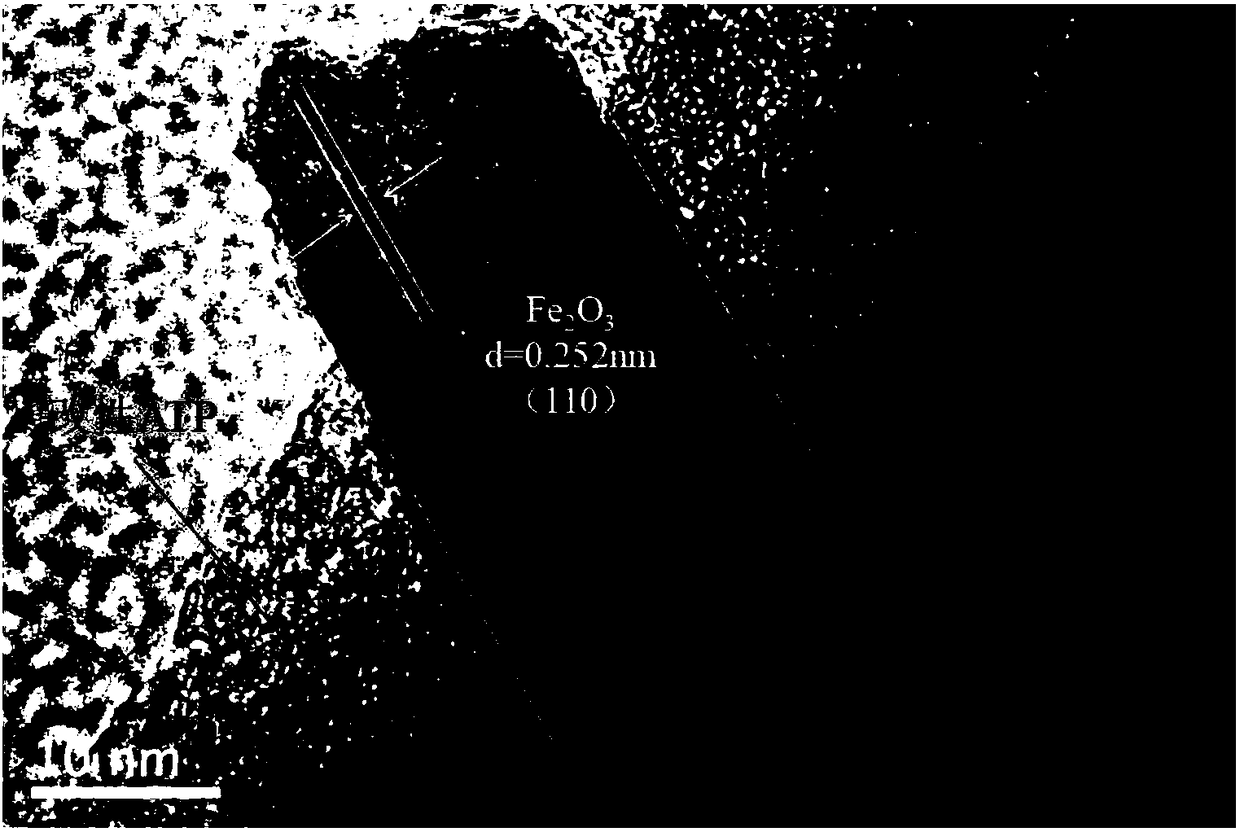

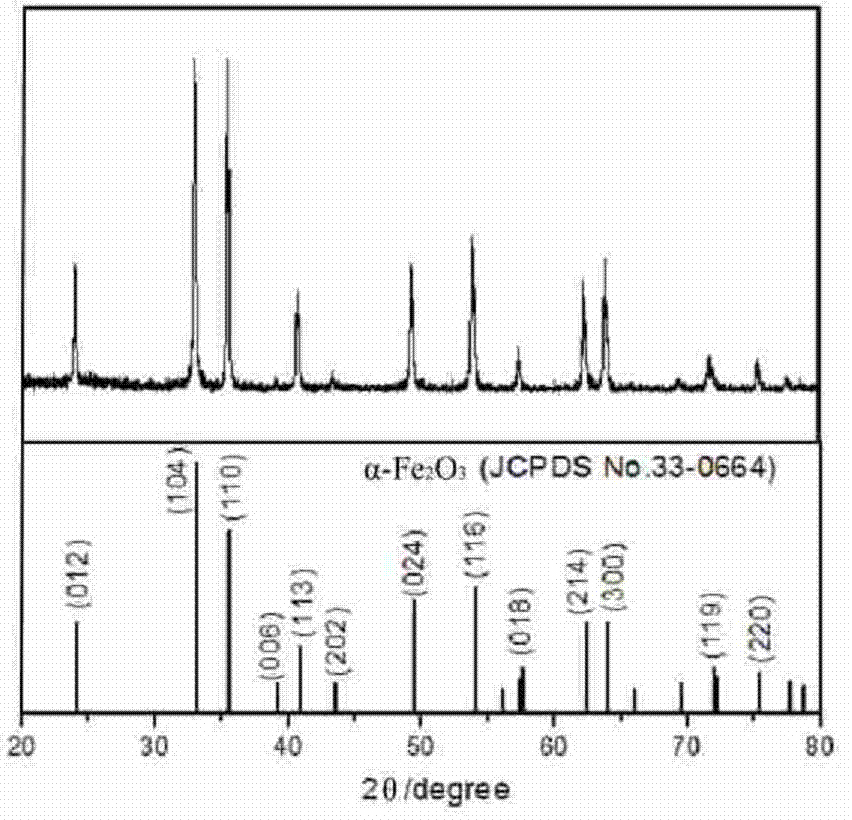

A preparing method of a nanometer Fe2O3/rGO composite material and applications of the composite material

InactiveCN104124442ALow costThe synthesis process is simpleMaterial nanotechnologyCell electrodesAqueous ethanolGlycerol

The invention relates to the field of preparation of nanometer composite materials, and particularly relates to a preparing method of a nanometer Fe2O3 / rGO composite material and applications of the composite material. The preparing method includes steps of: dissolving Fe2SO4-7H2O into a liquid mixture comprising water and glycerol to form a mixed solution A; dispersing graphite oxide into water and performing ultrasonic dispersion to form a solution B; adding the solution B into the mixed solution A, and stirring uniformly to form a mixed solution C; adding the mixed solution C into a high-pressure reactor, putting the high-pressure reactor into a temperature environment having a temperature of 140-180 DEG C, and reacting 8-12 h to obtain a reaction product; and washing the product with aqueous ethanol and water separately for several times, adding the product into a vacuum drying oven having a temperature of 60-100 DEG C, and drying for several hours to obtain the nanometer Fe2O3 / rGO composite material. The preparing method has characteristics of cheap and easily available raw materials, low cost, simple and feasible synthesis process, stable product quality and good process repeatability.

Owner:海门市凤龙不锈钢制药设备有限公司

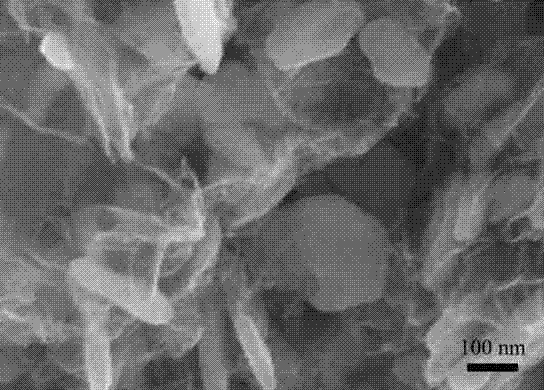

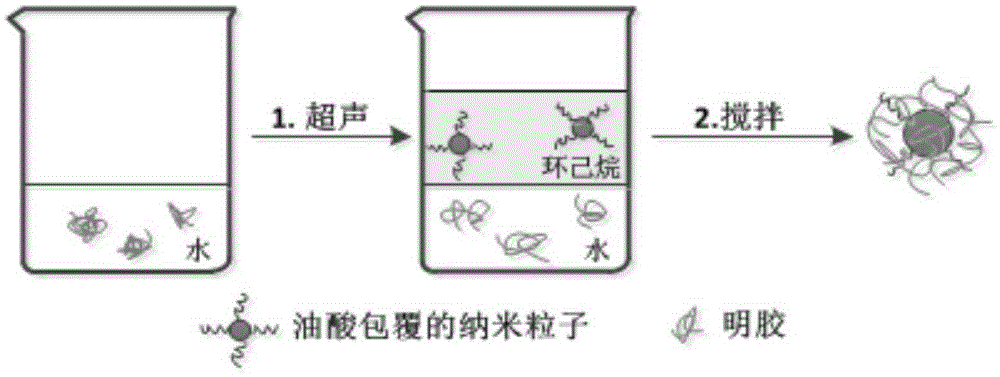

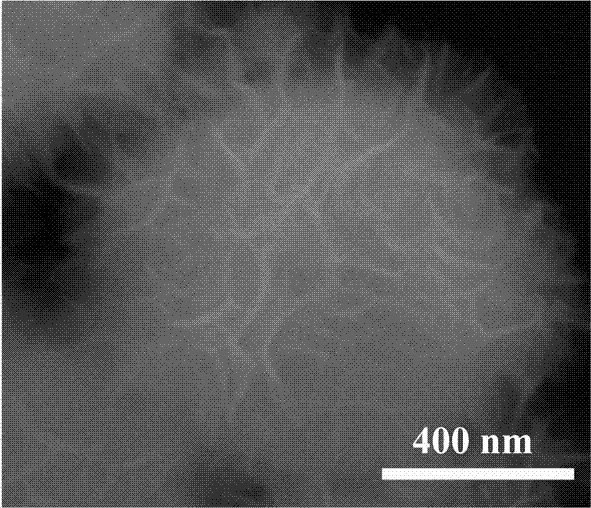

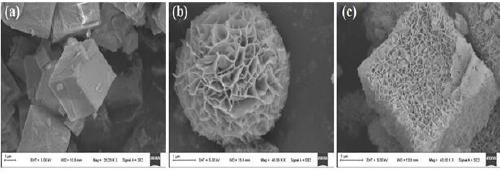

Red light enhanced core-shell upconversion luminescent nano-carrier and preparation method therefor

ActiveCN105385448AFirmly connectedStrong fluorescencePowder deliveryPhotodynamic therapyHydrophobic surfacesNanohybrid composite

The invention provides a red light enhanced core-shell upconversion luminescent nano-carrier and a preparation method therefor. The material has the chemical expression of NaGdF4:Yb,Er,Mn@NaGdF4:Yb@gel, wherein @ represents coating, and gel represents gelatin. The material provided by the invention is technically characterized in that homogeneous and monodisperse nanocrystals are produced by adopting a high-temperature pyrolysis method, which is environment-friendly and is easy and feasible in operation, and hydrophobic surfaces of nanoparticles are coated with gelatin by adopting a self-assembly method, so as to form NaGdF4:Yb,Er,Mn@NaGdF4:Yb@gel, of which the surface is hydrophilic and has a large number of active groups. The nano composite material prepared by the scheme has a red light enhanced luminescence property, maintains relatively strong luminescence total intensity and has a hydrophilic surface with a large number of active groups. The nano-carrier has enhanced red light emission and relatively strong fluorescence intensity and meanwhile has a hydrophilic active surface, thereby being capable of serving as an excellent photosensitizer carrier.

Owner:HARBIN ENG UNIV

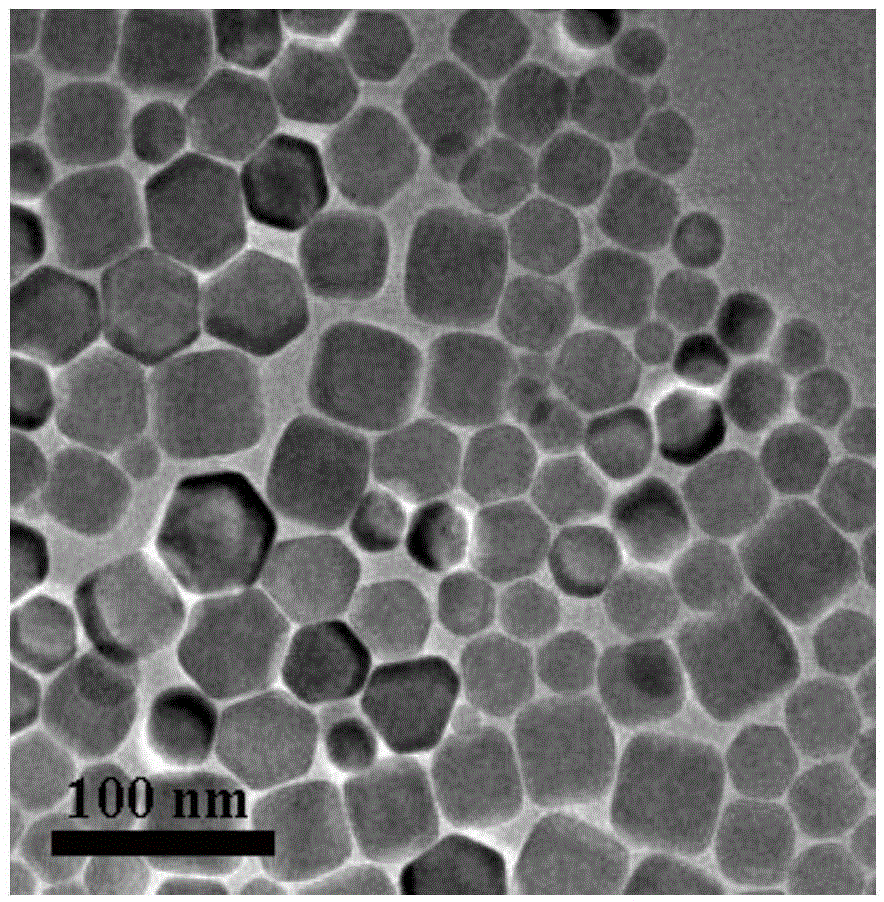

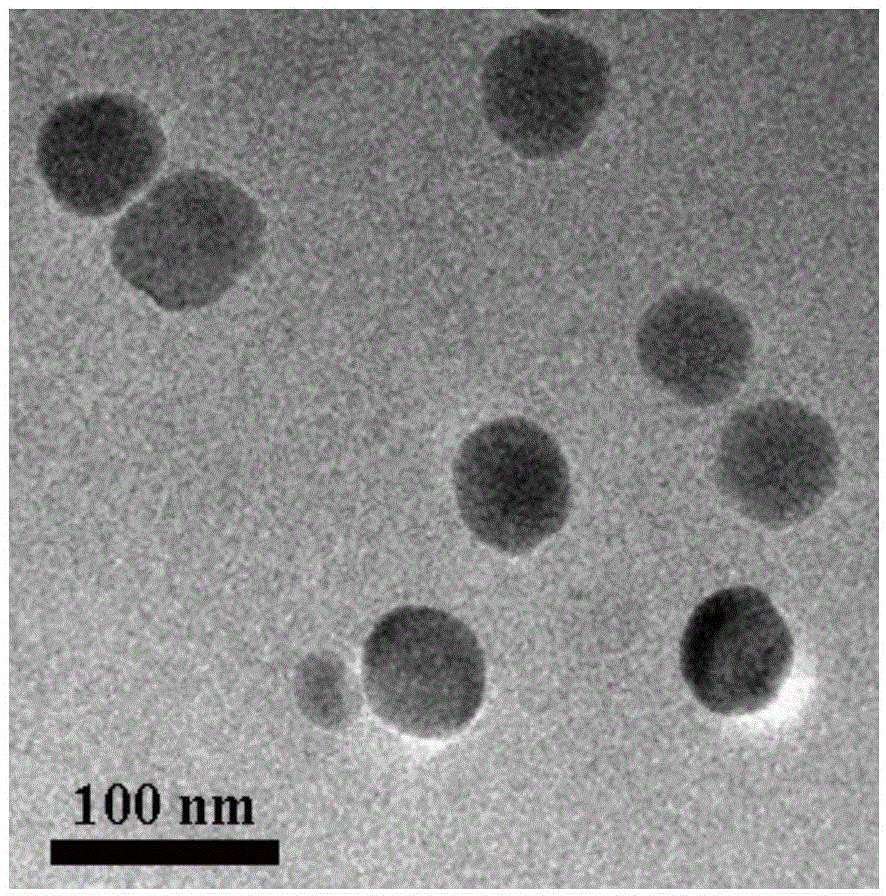

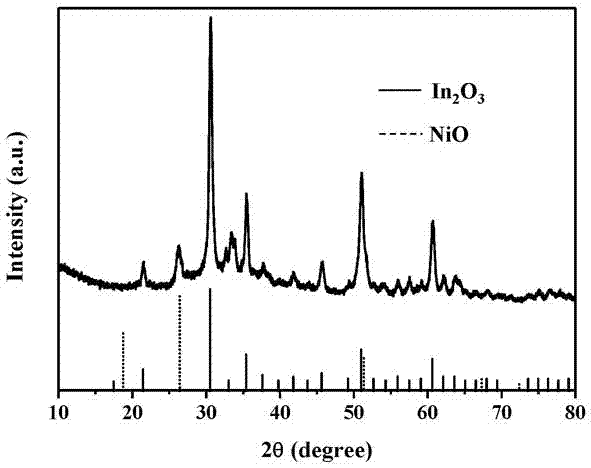

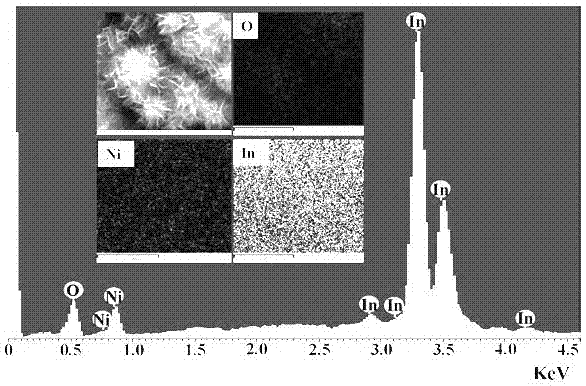

Method for preparing NiO-In2O3 nano composite material

InactiveCN107285392AHigh sensitivityNo pollution in the processMaterial nanotechnologyGallium/indium/thallium compoundsHeterojunctionIndium Trichloride

The invention provides a method for preparing a NiO-In2O3 nano composite material. The method specifically comprises the steps: subjecting indium trichloride tetrahydrate and lauryl amine, which serve as raw materials, to a hydrothermal reaction, and carrying out calcining treatment, so as to obtain indium oxide nanospheres; then, laminating flaky nickel oxide to surfaces of the indium oxide microspheres by taking nickel nitrate hexahydrate, hexamethylene tetramine and trisodium citrate as raw materials, thereby finally obtaining the NiO-In2O3 nano composite material. According to the method, the production process is simple, obtained gas-sensitive materials have p-n heterojunctions formed by indium oxide and nickel oxide, show relatively high sensitivity and rapid response and recovery to acetone and can be applied to the field of acetone gas sensors, and thus, novel gas-sensitive materials with high sensitivity are obtained.

Owner:UNIV OF JINAN

Nano composite material of graphene/nylon/elastomer and preparation method thereof

InactiveCN106478939AImprove performanceSolve the problem of fragmentationElastomerHigh volume manufacturing

The invention discloses a preparation method of a graphene / nylon / elastomer nano composite material. The preparation method comprises the following steps: at first, pre-dispersing graphene in molten polyamide monomers; then adding a catalyst and an activator into the mixed melt of pre-dispersed graphene / polyamide monomers, mixing to obtain a blended solution; adding the blended solution into an extruder, carrying out reactions, extruding the reaction products, carrying out granulation to obtain the master batch of a graphene / nylon nano composite material; adding the abovementioned master batch and elastomer master batch into the extruder, melting, blending, and extruding the mixture to obtain the graphene / nylon / elastomer nano composite material. Graphene is evenly dispersed in the graphene / nylon / elastomer nano composite material. The industrial massive production of the nano composite material is realized. The phenomenon that the toughness of a composite material degrades due to added graphene is greatly relieved. Compared with pure nylon, the mechanical properties such as strength, toughness, modulus, and the like, and thermal properties such as thermal degradation temperature and the like, of the provided nano composite material are prominently improved, and thus the application range is enlarged.

Owner:HEFEI GENIUS NEW MATERIALS

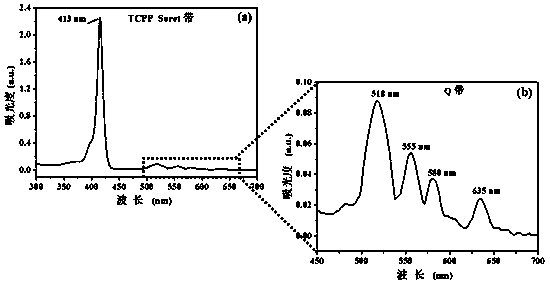

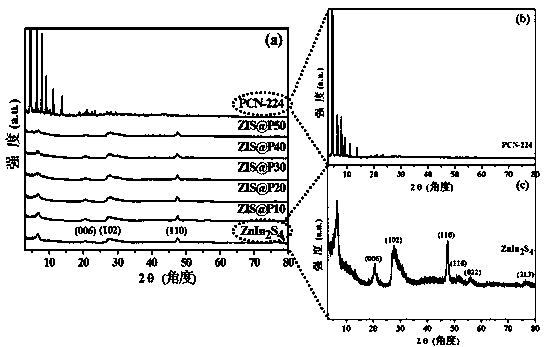

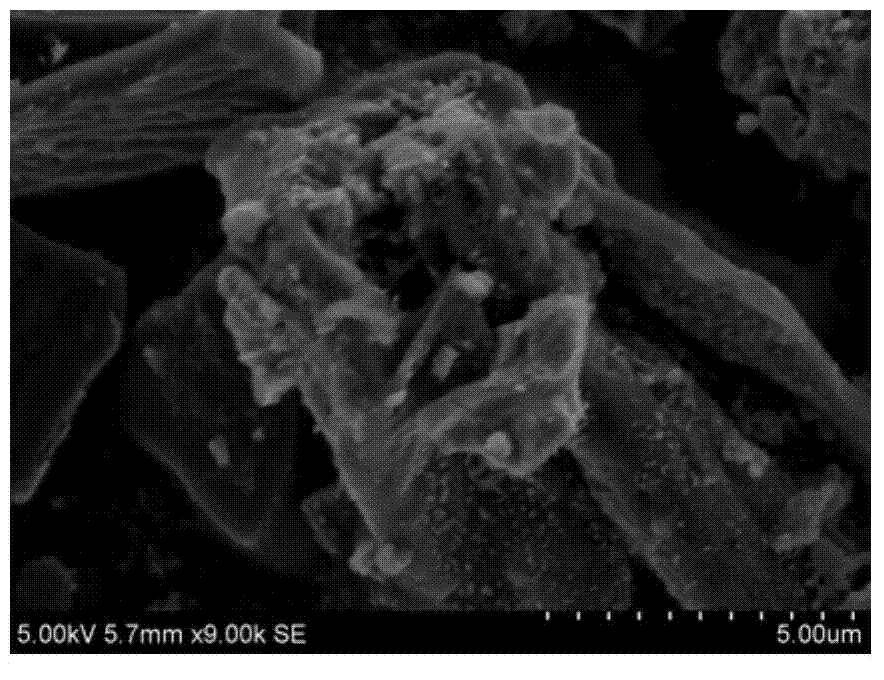

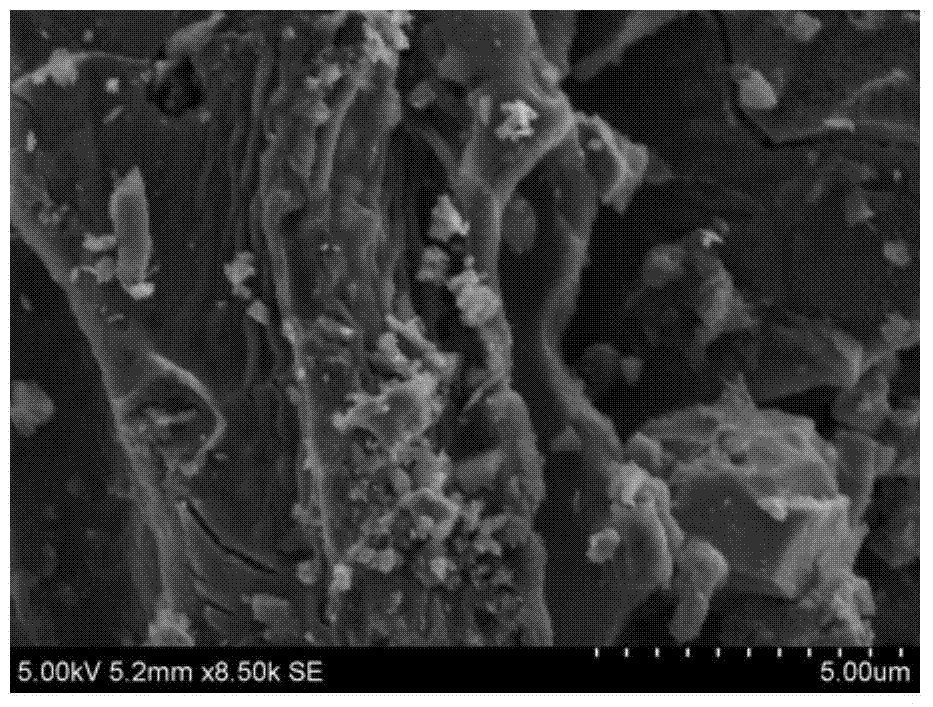

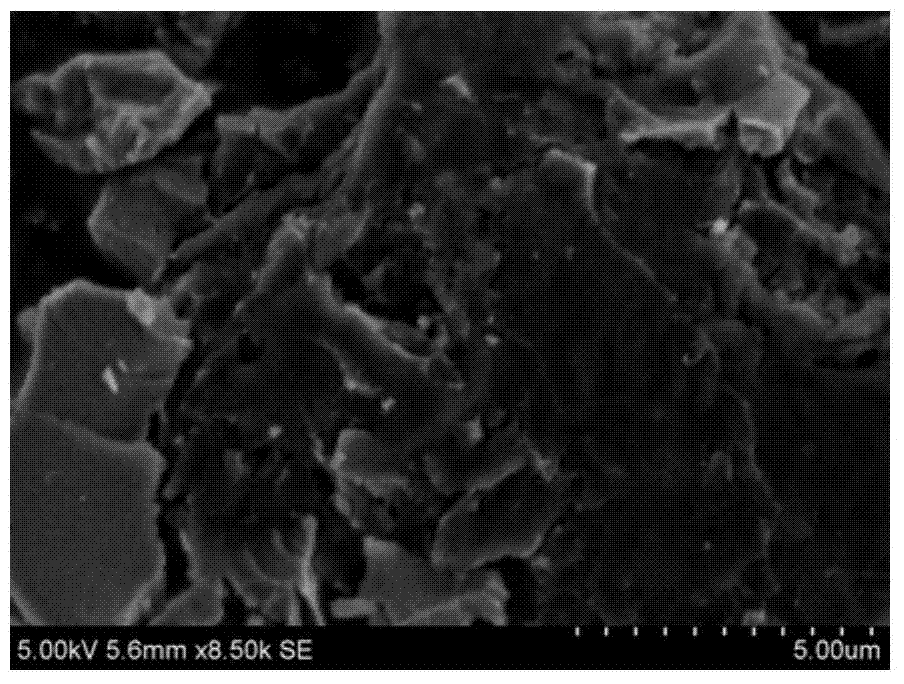

Preparation and application of nanometer composite material based on porphyrin metal organic framework and ternary sulfide

InactiveCN109464986AImprove adsorption capacityImprove responsivenessOther chemical processesOrganic-compounds/hydrides/coordination-complexes catalystsGlycerolPorphyrin

The invention provides a nanometer composite material ZnIn2S4@PCN-224 based on ternary sulfide ZnIn2S4 and porphyrin MOFs (Metal-organic Frameworks). The nanometer composite material is prepared by the following steps: firstly dispersing activated PCN-224 into a N,N-dimethyl formamide-glycerol mixed solution, then adding ZnCl2, InCl3.4H2O and TAA and stirring for 0.5-1.5 hours; and performing heatinsulation treatment on a mixed suspension for 8-12 hours at a temperature of 160-200 DEG C, cooling to a room temperature, washing a solid product with distilled water and ethanol, performing centrifugal separation and precipitation, and drying to obtain solid powder, namely the ZnIn2S4@PCN-224. The nanometer composite material ZnIn2S4@PCN-224 provided by the invention has the benefits that theZnIn2S4 is loaded onto the porphyrin metal-organic framework PCN-224 through a solvo-thermal method, so that on one hand, organic pollutants can be better absorbed, and on the other hand, the separation efficiency of photo-generated electrons and holes is remarkably improved, and the photo-catalytic hydrogen production activity is significantly improved.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method for anti-static modified plastic

The invention provides a preparation method for an anti-static modified plastic and relates to the technical field of production of the anti-static plastic. The preparation method comprises the following steps: adding an organosilicone modified ethyl orthosilicate pre-condensed precursor into a quickly stirred mixed system of graphene microchip and carbon nano tube in the manner of spraying, and then fully mixing with plastic particles, extruding and pelletizing, thereby acquiring a synergic anti-static modified plastic. According to the invention, the gathering problem of graphene microchip and carbon nano tube is solved, the introduction of organic groups in OM-SiO2P can endow the carbon nano tube and the plastic substrate with the interface bonding force, the goal of low filling volume required for reaching the anti-static performance index is achieved and the acquired nanometer composite material has ideal mechanical, thermodynamic and wear-resisting properties.

Owner:扬州市维纳复合材料科技有限公司

Antibacterial active carbon nano composite material and preparation method thereof

InactiveCN103783080AStrong oxidation abilityTo achieve the purpose of antibacterialBiocideCarbon compoundsFiberActivated carbon

The invention provides an antibacterial active carbon nano composite material. The preparation method comprises the following steps: by taking waste fiber plates as a raw material, charring for 1-1.5 hours at 550-600 DEG C; activating the obtained carbide crushed by introducing vapor at 700-800 DEG C; sieving the activated carbon and dehydrating at constant temperature; then, carrying out TiO2 load on the activated carbon by a sol-gel method; and microwave heating the dried gel under a condition of 500-800w to obtain the antibacterial active carbon nano composite material. The active carbon nano composite material product prepared by the method provided by the invention is high in density, good in thermal stability, high in content of loaded TiO2 and uniform in dispersion of the loaded TiO2, has broad-spectrum antibacterial property, and also has high antibacterial rate, good antibacterial property and durability of antibacterial property.

Owner:BEIJING FORESTRY UNIVERSITY

Nanocomposite material and preparing method and application thereof

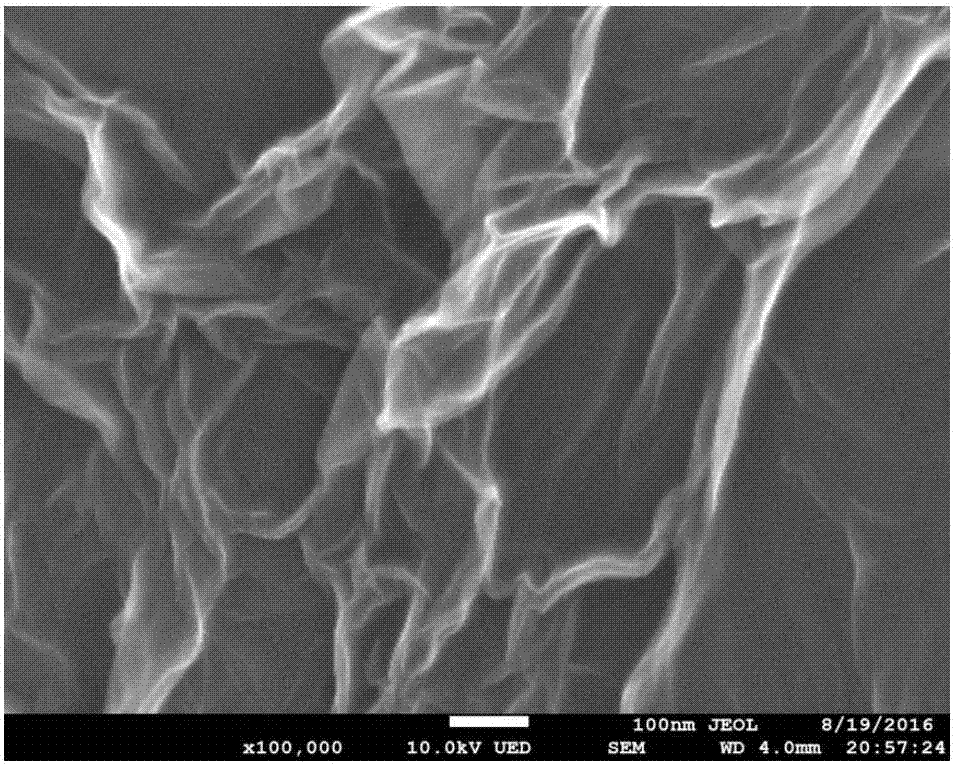

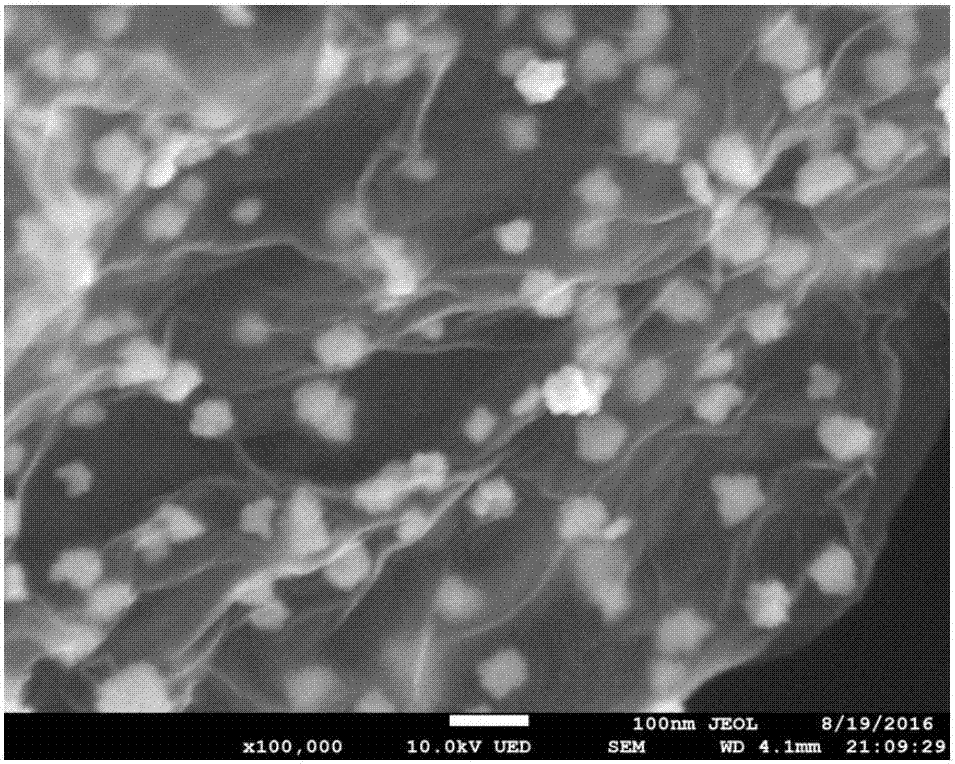

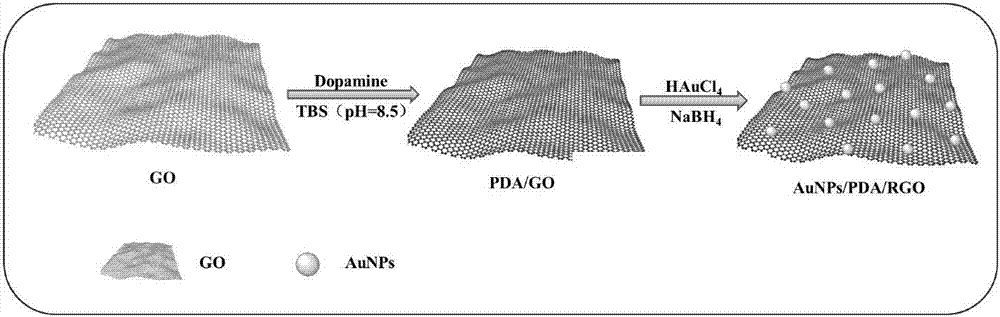

ActiveCN107037102AEasy to makeFlexibleMaterial nanotechnologyMaterial electrochemical variablesTG - TriglycerideMetal particle

The invention provides a nanocomposite material and a preparing method and application thereof. The method comprises the following steps of 1, preparing a multi-layer pore structure carbon nanomaterial modified by polydopamine; 2, distributing nano-metal particles on the modified material obtained in the step 1. According to the nanocomposite material and the preparing method and application thereof, the synthetized nanocomposite material can well fix lipase, thus triglyceride is directly detected, and in addition, according to a sensor prepared through the nanocomposite material, a screen-printed electrode is adopted, so that the nanocomposite material has a good industrialized application prospect. The nanocomposite material can well combine lipase, and the screen-printed electrode of which a work electrode is modified with the nanocomposite material shows good sensitivity, selectivity and capacity of resisting disturbance on the detection of triglyceride. Besides, the preparing process of the nanocomposite material is simple, and the screen-printed electrode has the advantages of being flexible, convenient to carry and the like; because of the disadvantages, a triglyceride sensing chip has a wide industrialized application prospect.

Owner:SOUTHWEST UNIVERSITY

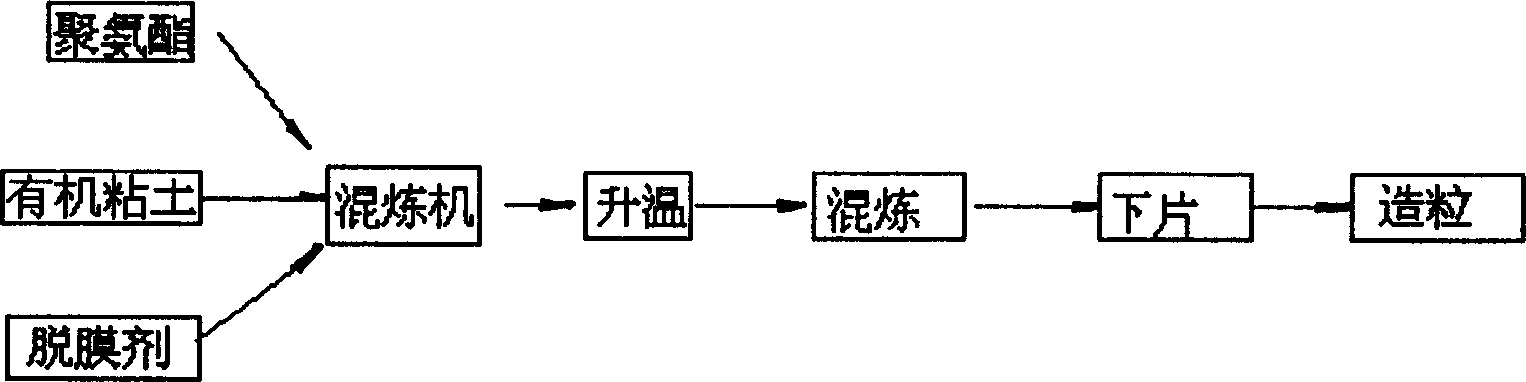

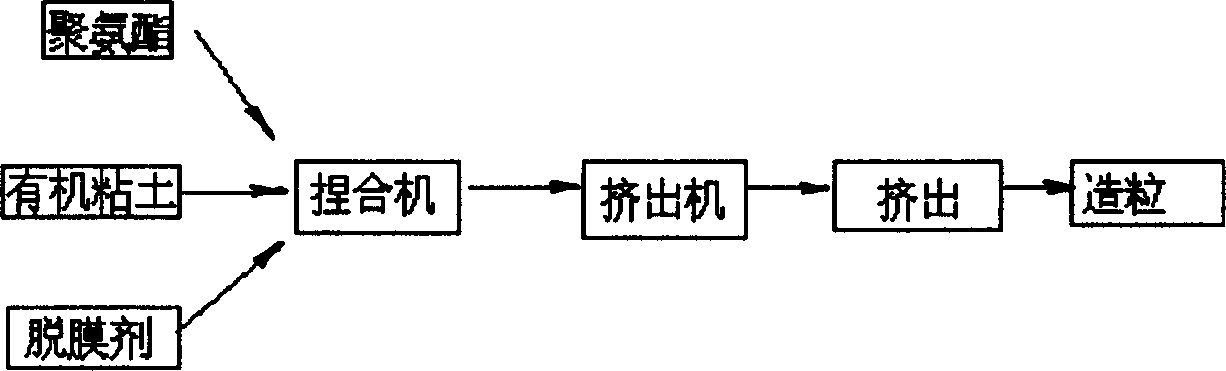

Rectorite/thermoplastic polyurethane elastomer nano composite material and preparing method

InactiveCN1473876AImprove mechanical propertiesHigh tear strengthChemical compositionHeat resistance

Owner:马晓燕

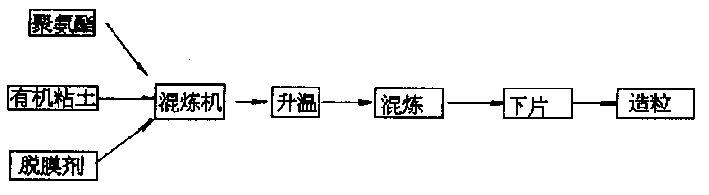

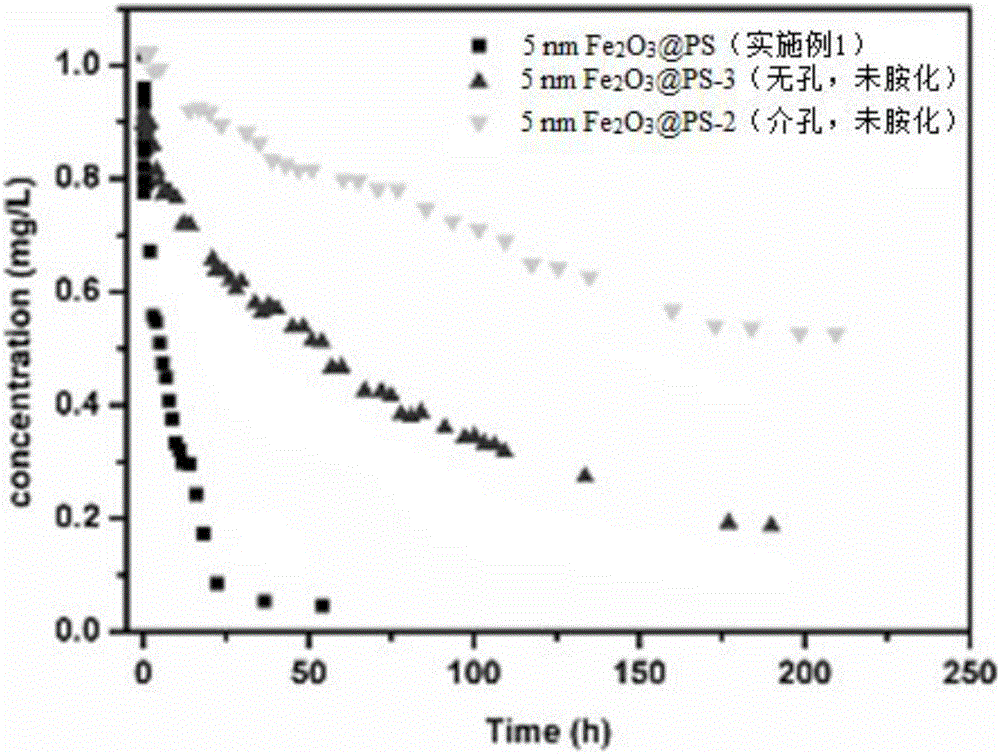

Resin based mesoporous nano composite material, preparation method and applications thereof

ActiveCN106179264AConducive to industrial mass productionThe method is simpleOther chemical processesWater/sewage treatment by sorptionMaterial synthesisNanoparticle

Owner:NANJING UNIV

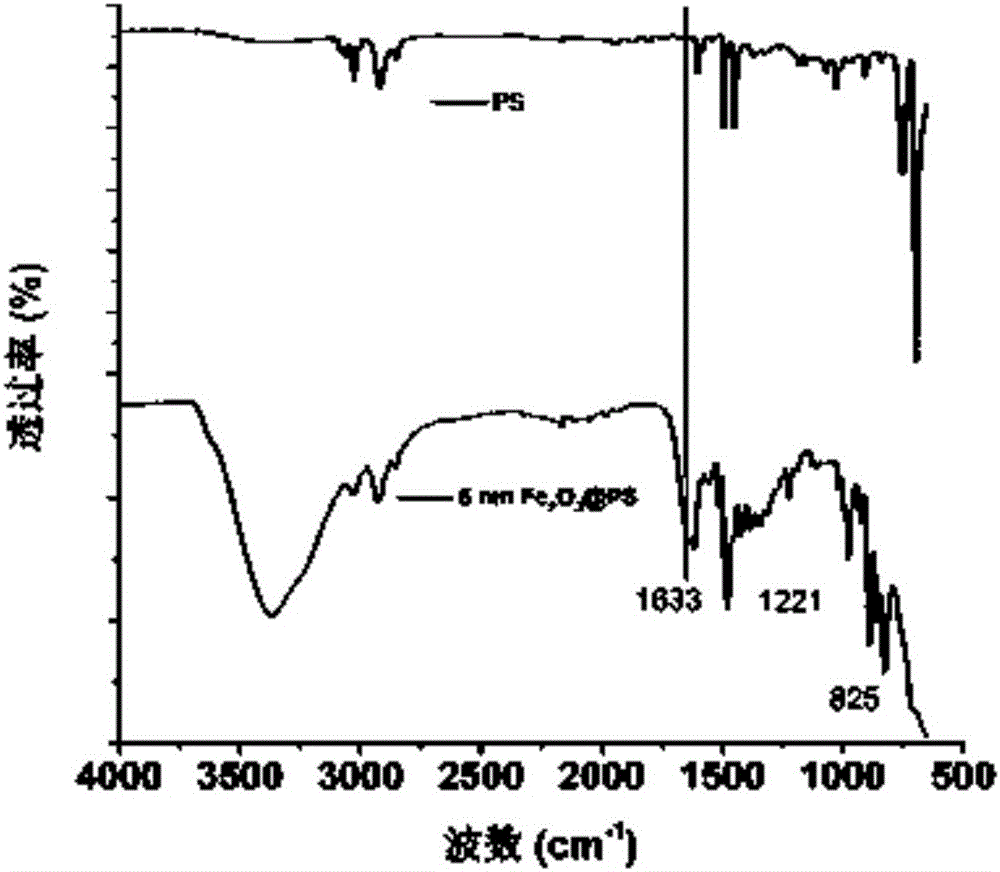

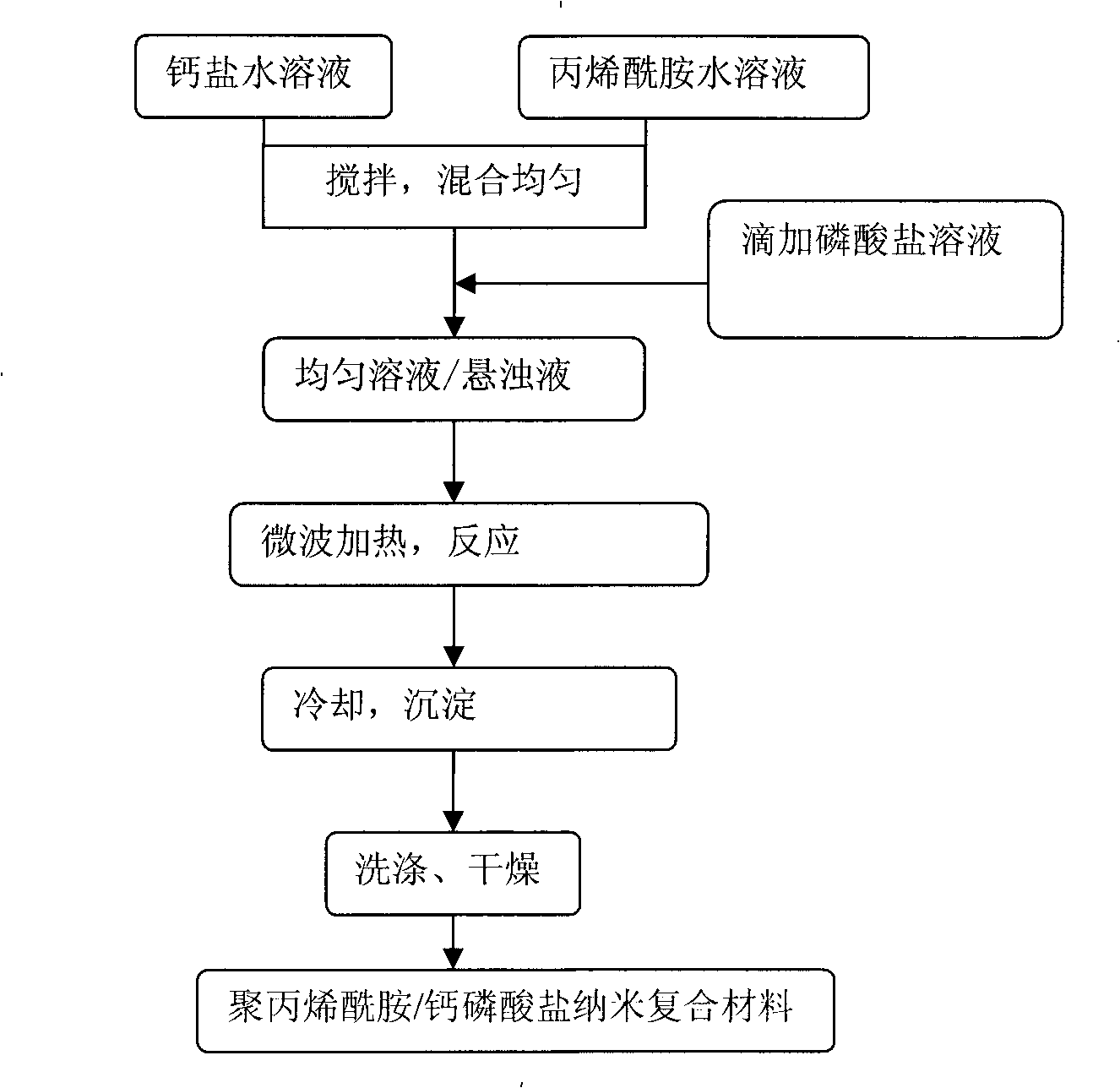

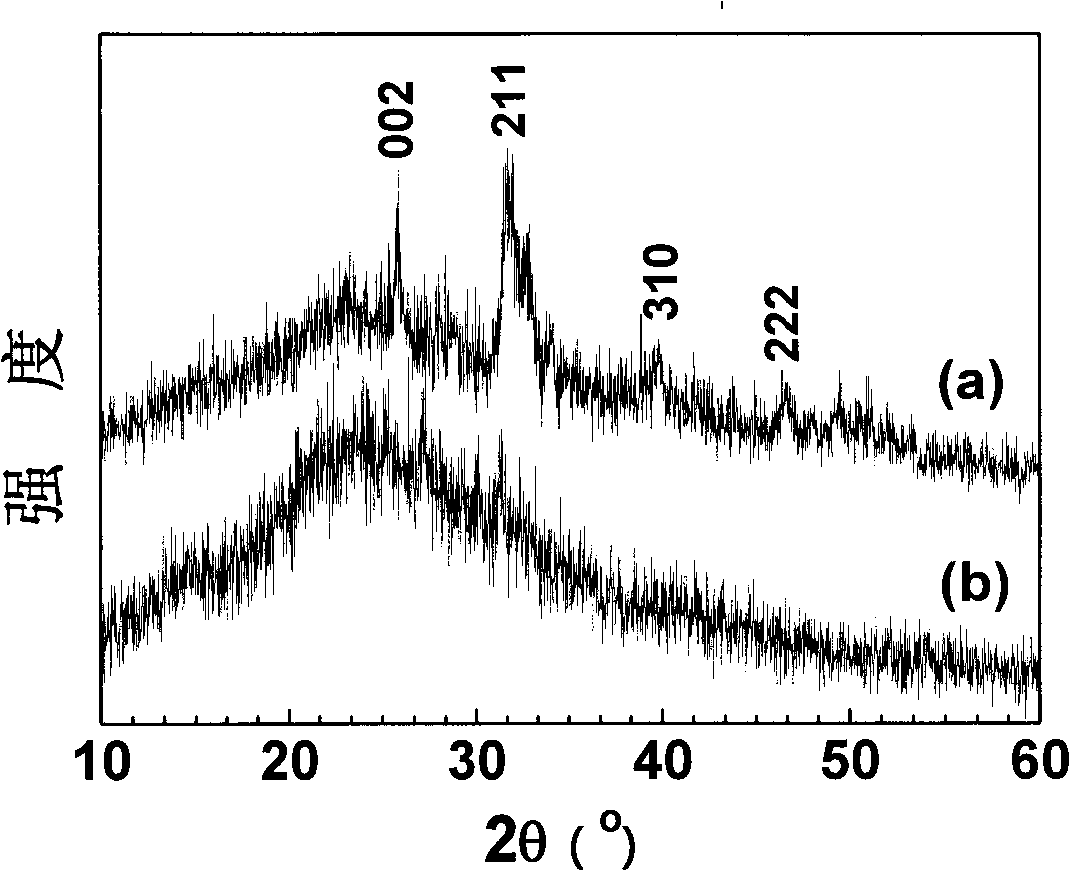

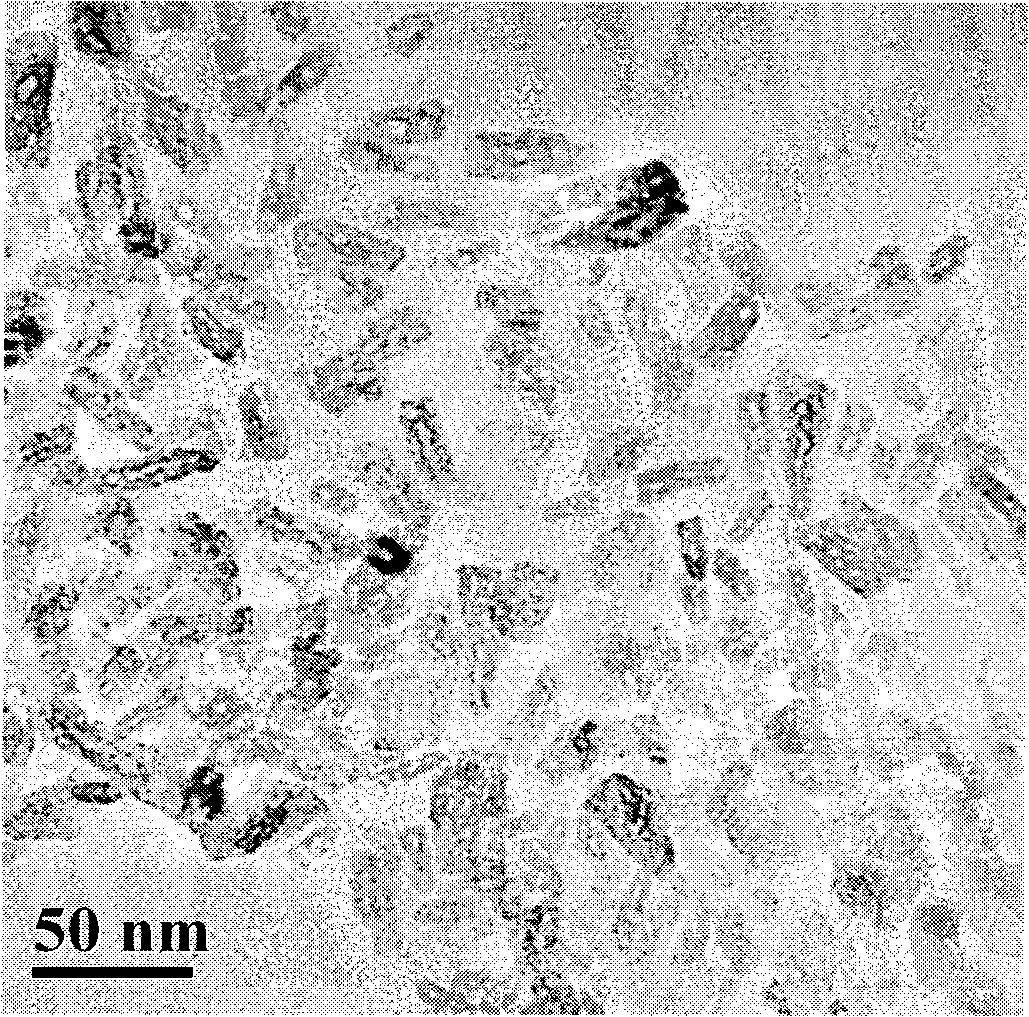

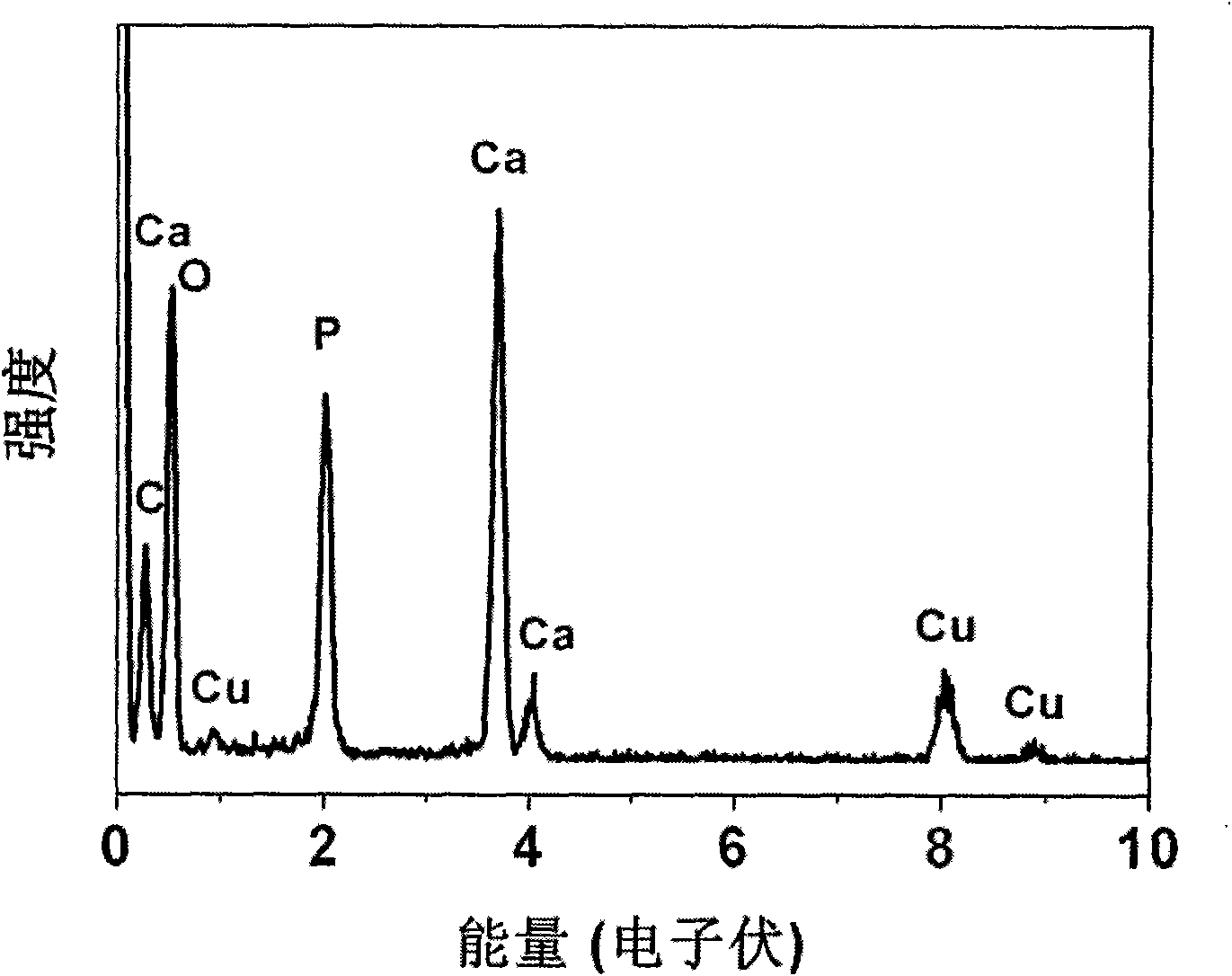

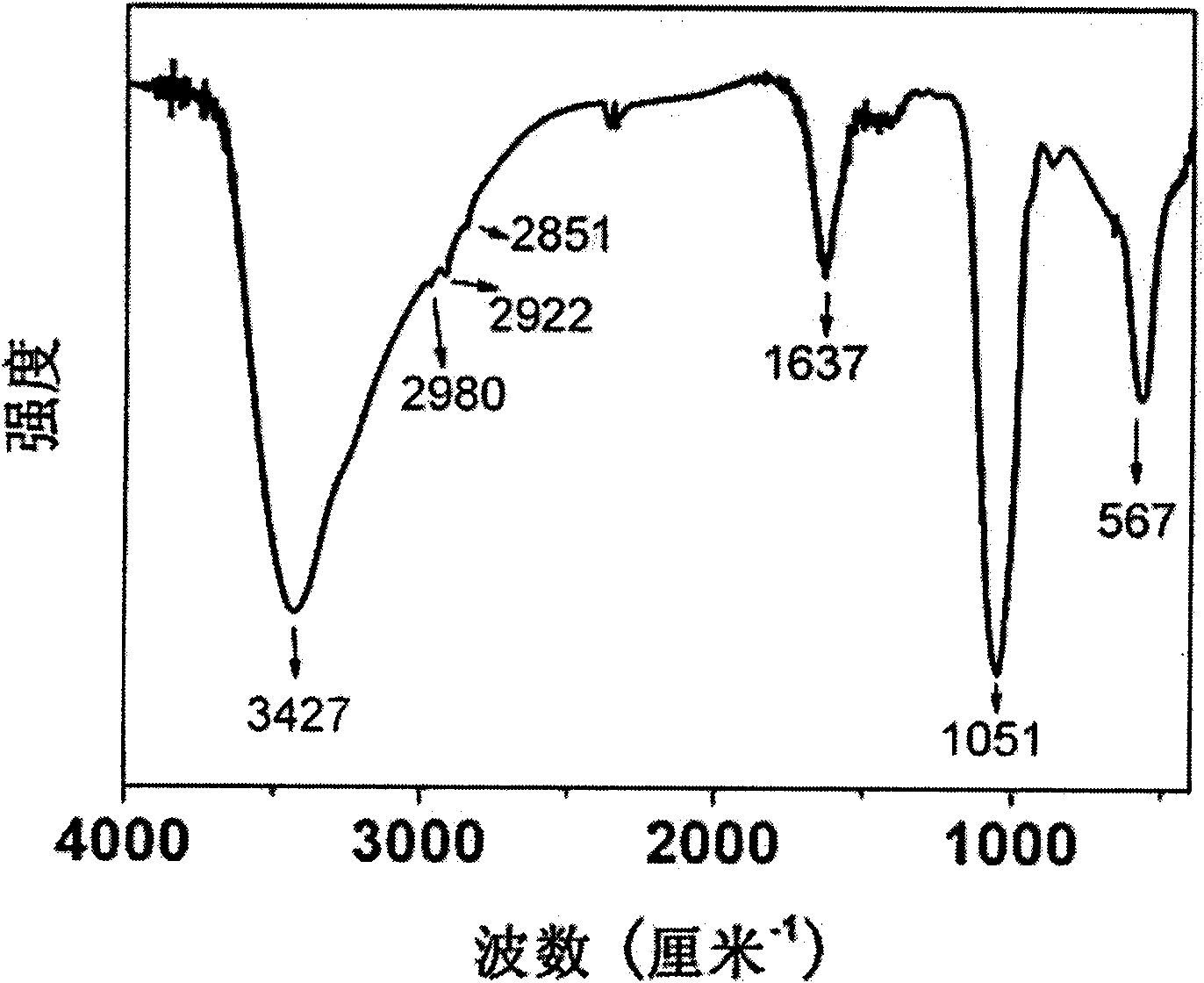

Polyacrylamide/calcium phosphate nano-composite material and microwave auxiliary liquid phase preparation method thereof

InactiveCN101492562ASimple processCraft shortPharmaceutical non-active ingredientsCalcium biphosphateWater soluble

The invention relates to a preparation method for microwave-assisted liquid phase of polyacrylamide / calcium phosphate nano composite material. The preparation method takes water-soluble calcium salt, phosphate and acrylamide as raw materials, takes water as solvent, and obtains the nano composite material of the polyacrylamide and the calcium phosphate of different phases by controlling Ph valve. The two phases in the polyacrylamide / calcium phosphate nano composite material are evenly scattered and the thermal stability is increased. The preparation method has the advantages of simple technique, fast, controllable appearance and phase, low cost, low biotoxicity, environment friendly, etc.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Preparation method of porous carbon base multi-ingredient nanometer composite material

The invention discloses a preparation method of a porous carbon base multi-ingredient nanometer composite material. The method comprises the following steps of performing pretreatment on the natural biological materials with finely grade porous structures; using the materials as templates; performing step immersion by metal salt solution and atmosphere calcination treatment; preparing the multi-ingredient nanometer composite material which has the biological template finely grading structure, uses porous carbon as base bodies and carries different-ingredient nanometer units. The method provided by the invention has the advantages that the used templates are from wide easy-to-obtain natural biological materials; in addition, the carbon source can be easily provided; by selecting different metal salt solution and regulating the process parameters of different soaking processes and calcination processes, the control on multiple ingredients and fine micro-nanometer grading structures of final composite materials can be realized. The preparation method provided by the invention has the advantages that the operation is simple; the cost is low; in addition, flexibility and controllability are realized; the prepared nanometer composite material has wide application prospects in the fields of catalysis, sensing, lithium batteries and the like.

Owner:SHANGHAI JIAO TONG UNIV

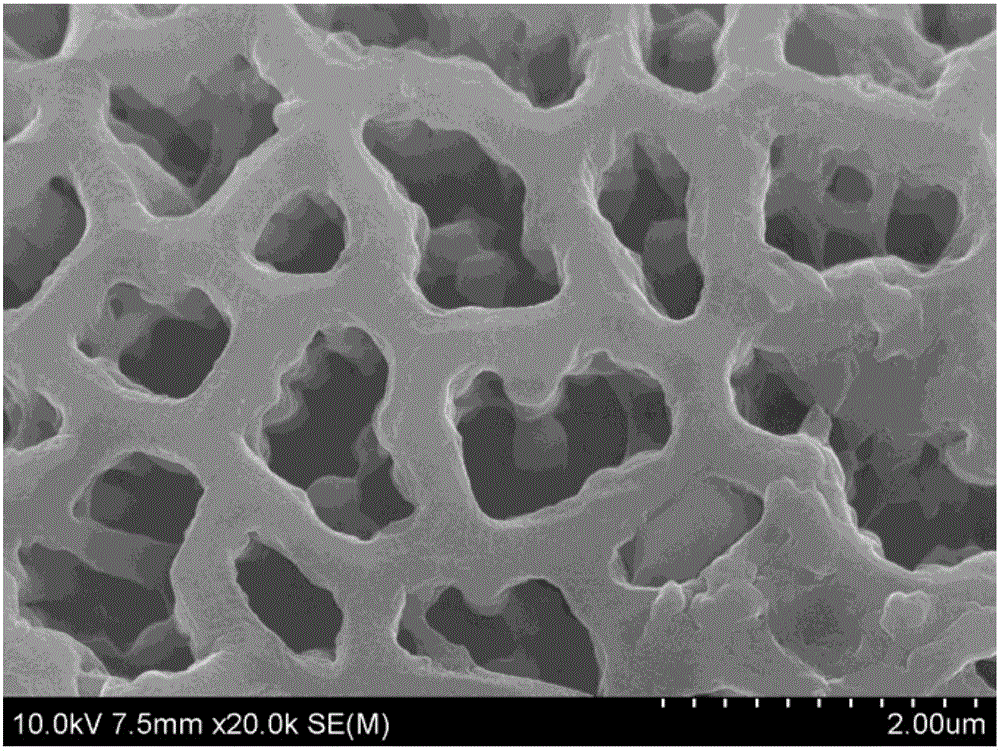

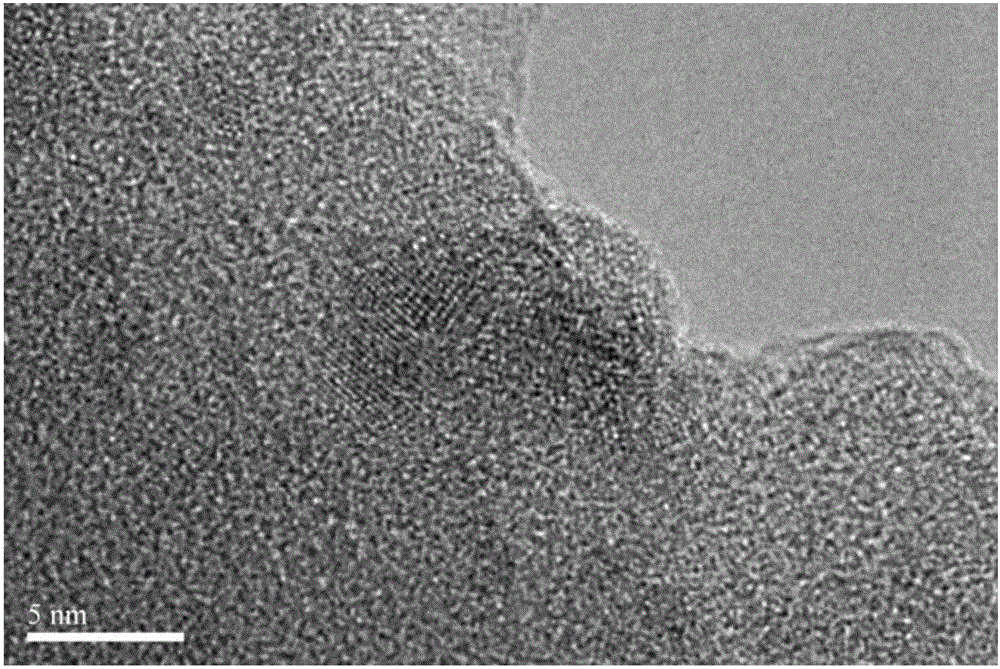

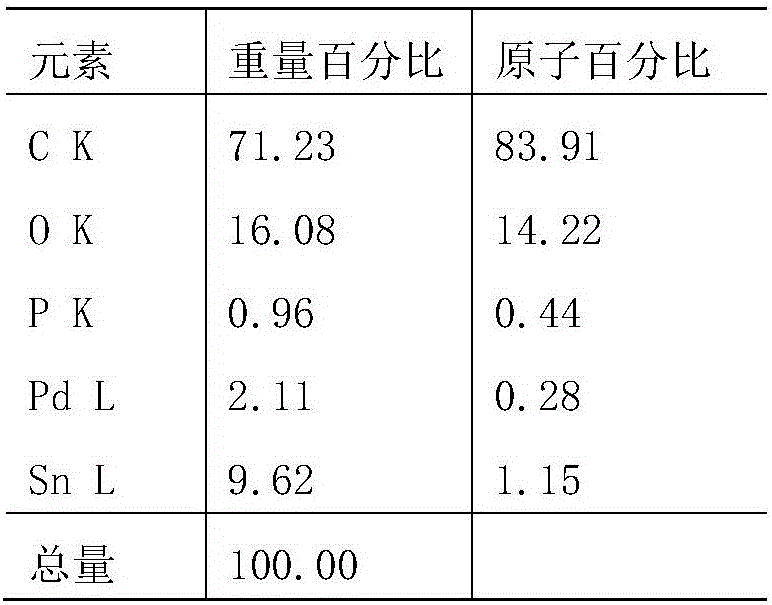

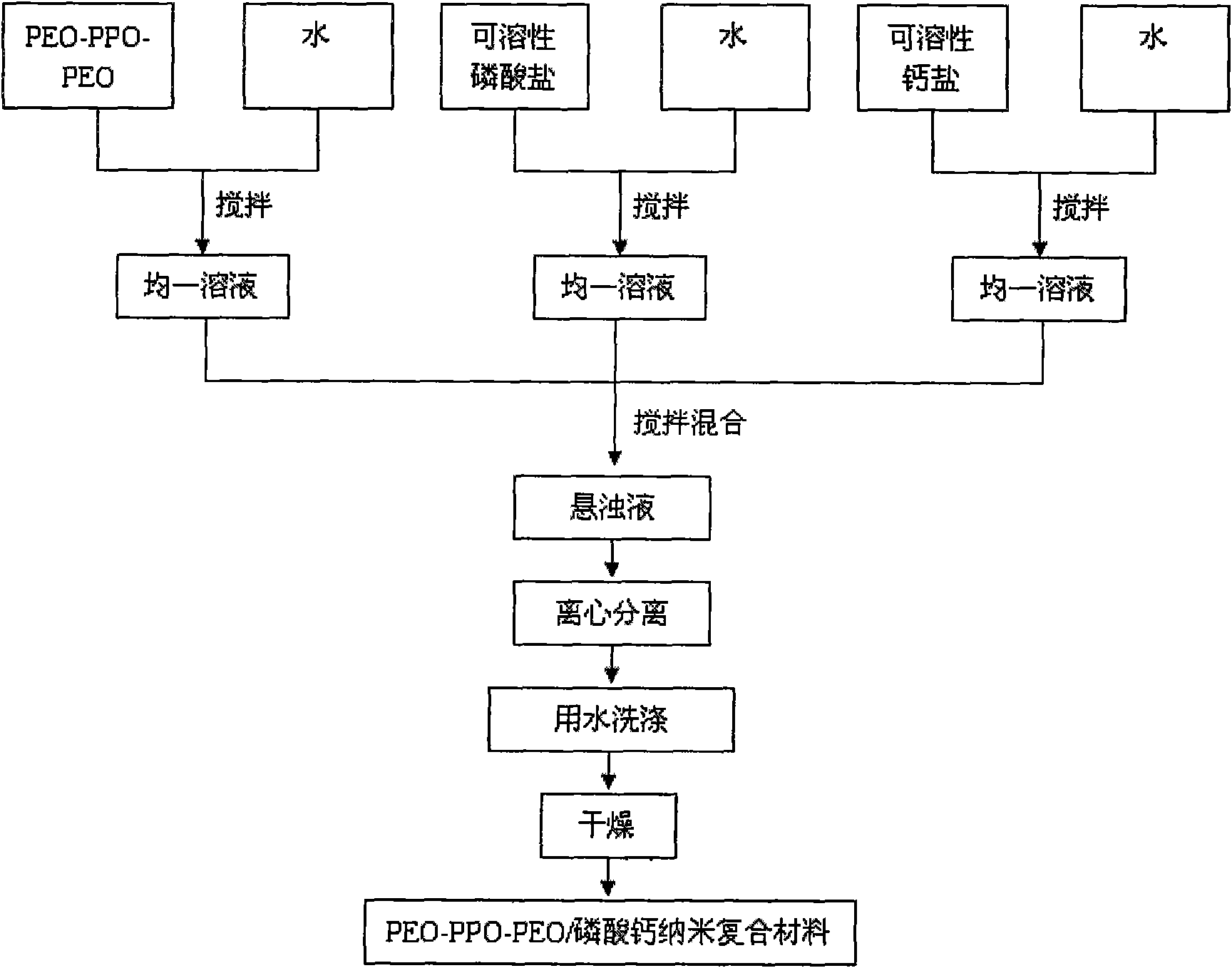

Triblock copolymer PEO-PPO-PEO/calcium phosphate nanometer composite material and preparation method thereof

InactiveCN101613524AHigh drug loadingGood slow releaseInorganic non-active ingredientsWater insolubleWater insoluble drug

The invention relates to the nanometer biomaterial field, in particular to a triblock copolymer PEO-PPO-PEO / calcium phosphate nanometer composite material and a preparation method thereof. The microscopic particles of the nanometer composite material have calcium phosphate coated triblock copolymer PEO-PPO-PEO structure; wherein, the weight percent of triblock copolymer PEO-PPO-PEO is 5-40% of the total weight of the nanometer composite material and the weight percent of calcium phosphate is 60-95% thereof. The nanometer composite material of the invention can be used as drug carrier, has higher drug-loading rate and excellent slow release performance on water-insoluble drugs and has good application prospect in the Biomedical field; the preparation method is characterized of simple process, convenient operation, lower cost and environmentally friendly and can be operated at room temperature.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for preparing intercalation nanocomposite material of polyaniline or polyaniline derivative, and inorganic clay by mechanochemical polymerization method

InactiveCN103265698AHigh intercalation rateChange physical and chemical propertiesPolyaniline derivativesSolubility

The invention discloses an intercalation nanocomposite material of a polyaniline or a polyaniline derivative, and inorganic clay by mechanochemical polymerization method. The method comprises the following steps of: (1) placing inorganic clay into a round-bottom flask with a branch port, vacuum-pumping, fully filling with argon, adding aniline or an aniline derivative, wrapping a tin foil out of the round-bottom flask after magnetically stirring, and stewing out of light under normal temperature, to obtain a blending fluid suspension; (2) grinding the blending fluid suspension, adding an oxidizing agent, covering a mortar with a tunnel in a grinding process, introducing argon into one end of the tunnel, continuously grinding, until to become atropurpureus completely; and (3) washing after reaction, filtrating, and vacuum-drying until constant weight, to obtain the intercalation nanocomposite material of inorganic clay. The prepared nanocomposite not only makes polyaniline or the polyaniline derivative have good dispersibility and high mechanical strength, but also raises water solubility and processing temperature of polyaniline or the polyaniline derivative. The method has advantages of simple preparation method and high polymer intercalation rate, and has a practical application meaning.

Owner:ZHEJIANG UNIV

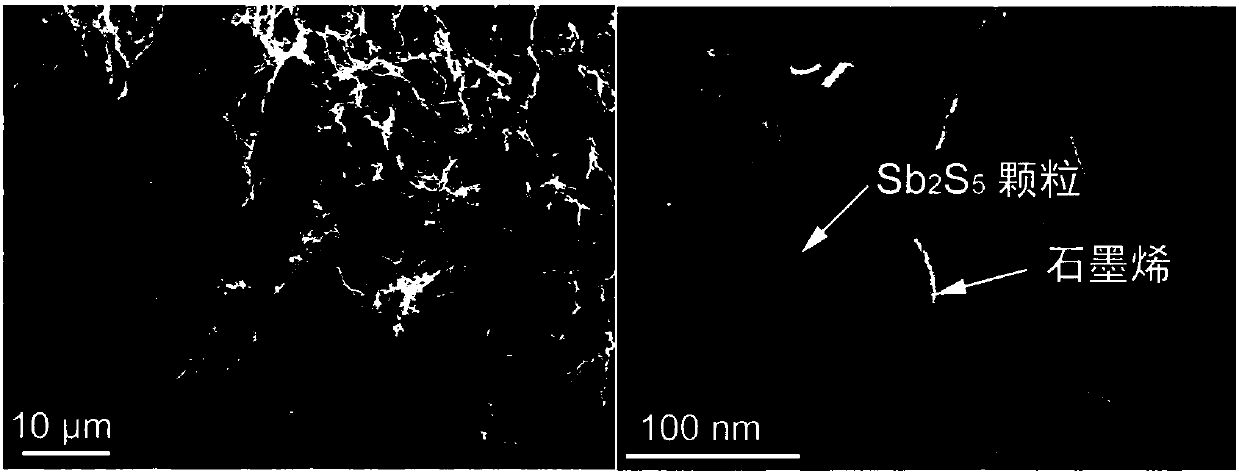

Preparation of self-supported Sb2S5/three-dimensional graphene nanometer composite material and application in sodium ion battery

InactiveCN107611408AShorten the diffusion pathIncrease capacityCell electrodesSecondary cellsHigh rateSodium-ion battery

The invention relates to preparation of a self-supported Sb2S5 / three-dimensional graphene nanometer composite material and application in a sodium ion battery. Sb2S5 nanoparticles and three-dimensional graphene are mixed, and a foamed Sb2s5-GF composite material figure (Figure 2) with self-support characteristic is finally prepared by simple hydrothermal reaction, the whole reaction process is simple and practical, and the controllability of nanoparticle loading capacity is good. When the prepared self-support Sb2s5-GF composite material is applied to the sodium ion battery, an insulation binding agent and a low-capacity conductive agent can be prevented being used, so that the battery performance is improved, and the battery shows high reversible capacity, long cycle lifetime and high rate performance (Figures 6-7). Compared with a traditional sodium ion battery electrode, the self-supported Sb2S5 / three-dimensional graphene nanometer composite material has the advantages that constituents such as a current collector, the binding agent and the conductive agent are not added, the cost is obviously reduced, and the capacity and the energy density of the battery also can be improved.

Owner:NANKAI UNIV

Syndiotactic polystyrene/polyamide/clay nano composite material

The present invention relates to a syndiotactic polystyrene / polyamide / clay nano composite material, and is mainly aimed at resolving the problems of large brittleness, low impact strength and poor comprehensive performance in the previous composite materials. Said invention utilizes adoption of its technical scheme of that its adopts the intercalation combination-comixing combination method to prepare solfonated syndiotactic polystrene / clay nano composite firstly, then the syndiotactic polystyrene, polyamide and solfonated syndiotactic polystyrene / clay nano composite are melt-mixed and combined so as to better resolve said problems. Said nano plastic alloy has high impact strength, high strength and high heat-resisting property, and said invention can be used in industrial production of said nano composite material.

Owner:CHINA PETROLEUM & CHEM CORP +2

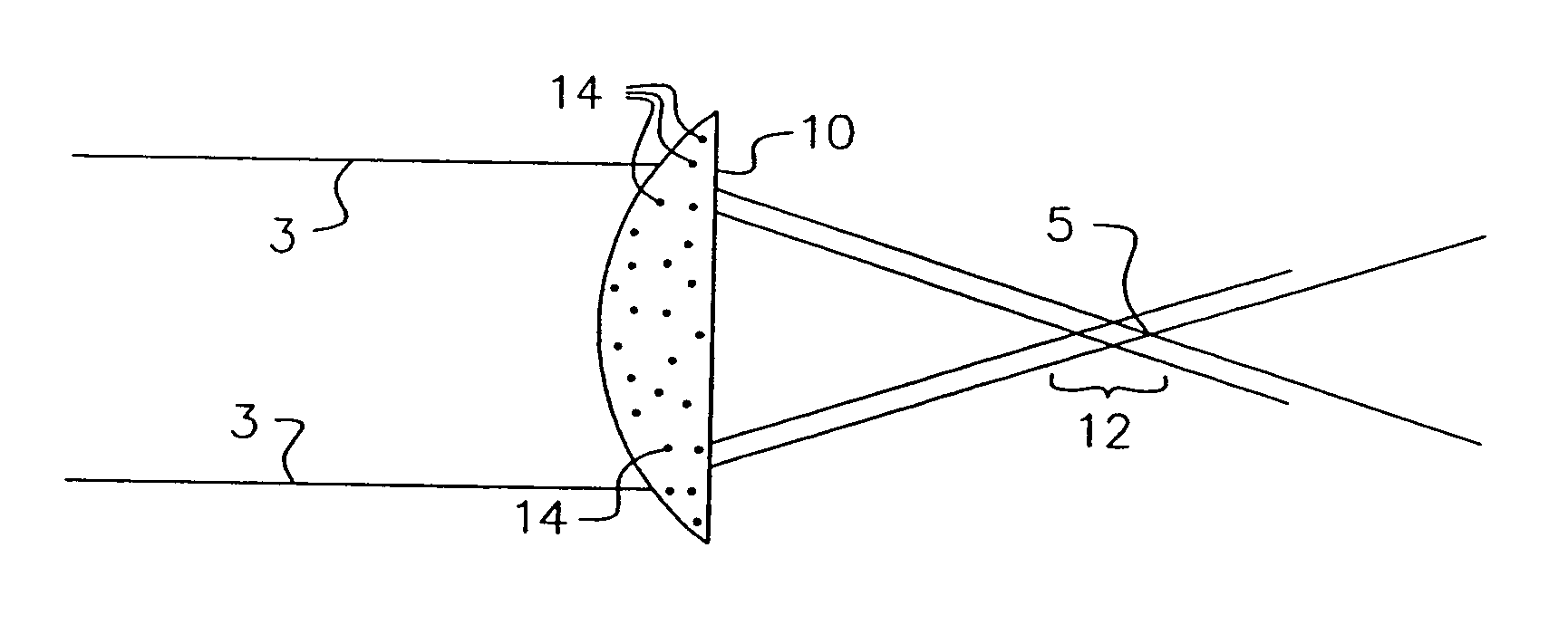

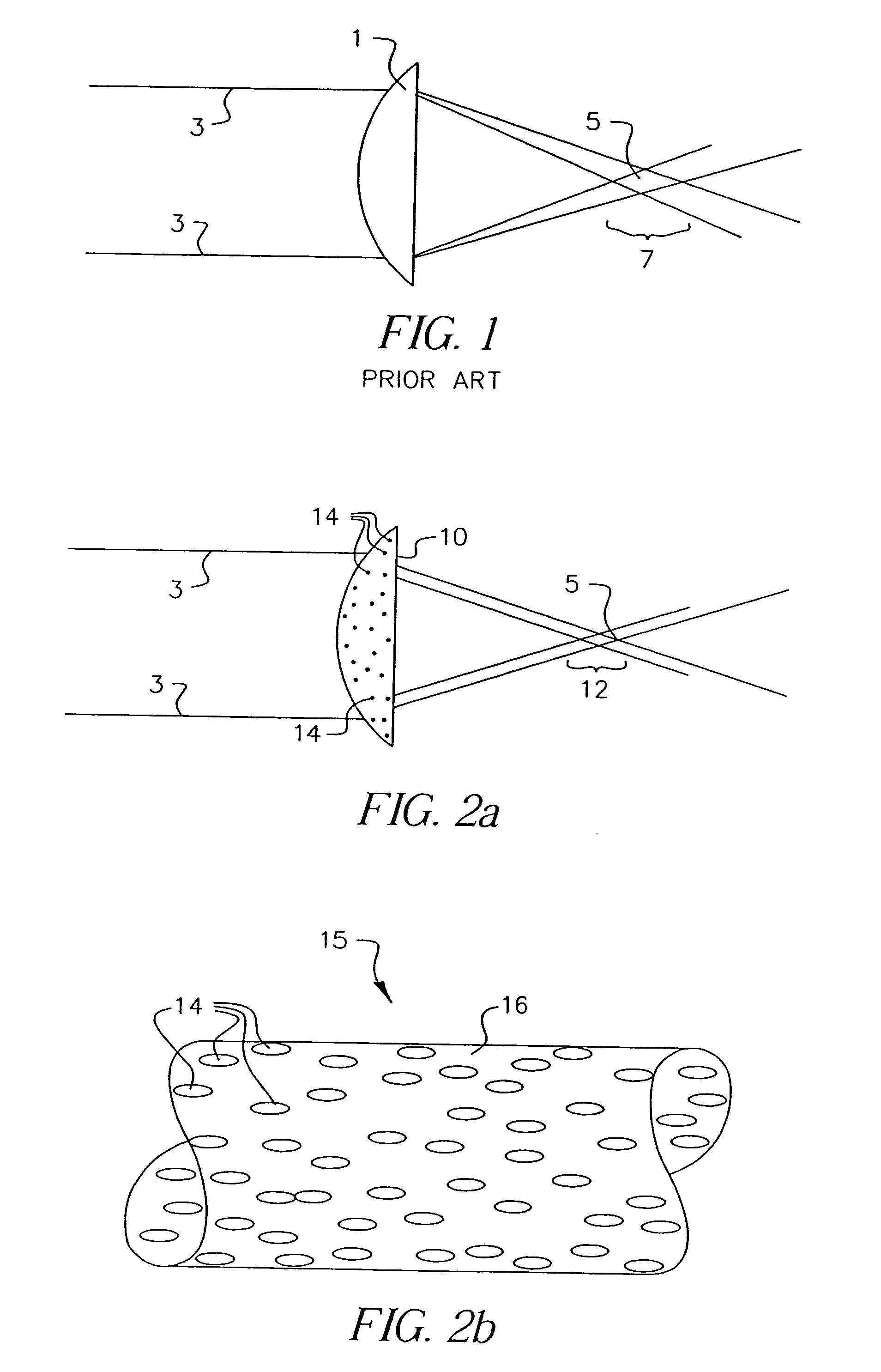

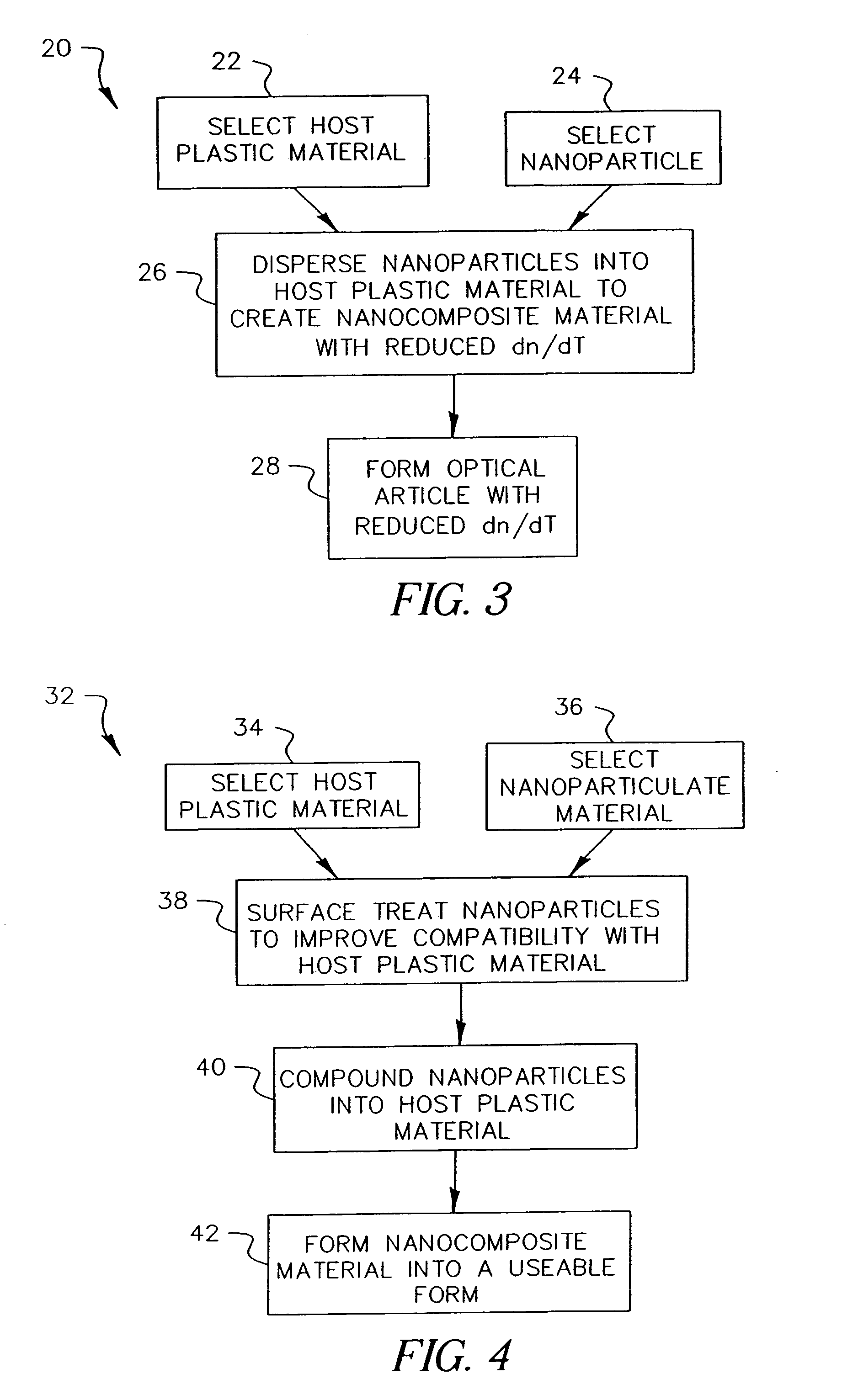

Reduced temperature sensitive polymeric optical article and method of making same

InactiveUS7045569B2Low dn/dTFocal length stabilizationMaterial nanotechnologyNanostructure manufacturePlastic materialsNanoparticle

An optical nanocomposite material has a nanoparticulate filler dispersed in a host plastic material. According to the method of making the nanocomposite material, a predetermined temperature sensitive optical vector, such as refractive index, of the plastic host material and nanoparticulate filler are directionally opposed resulting in a nanocomposite material having significantly improved stability of the refractive index with respect to temperature.

Owner:APPLE INC

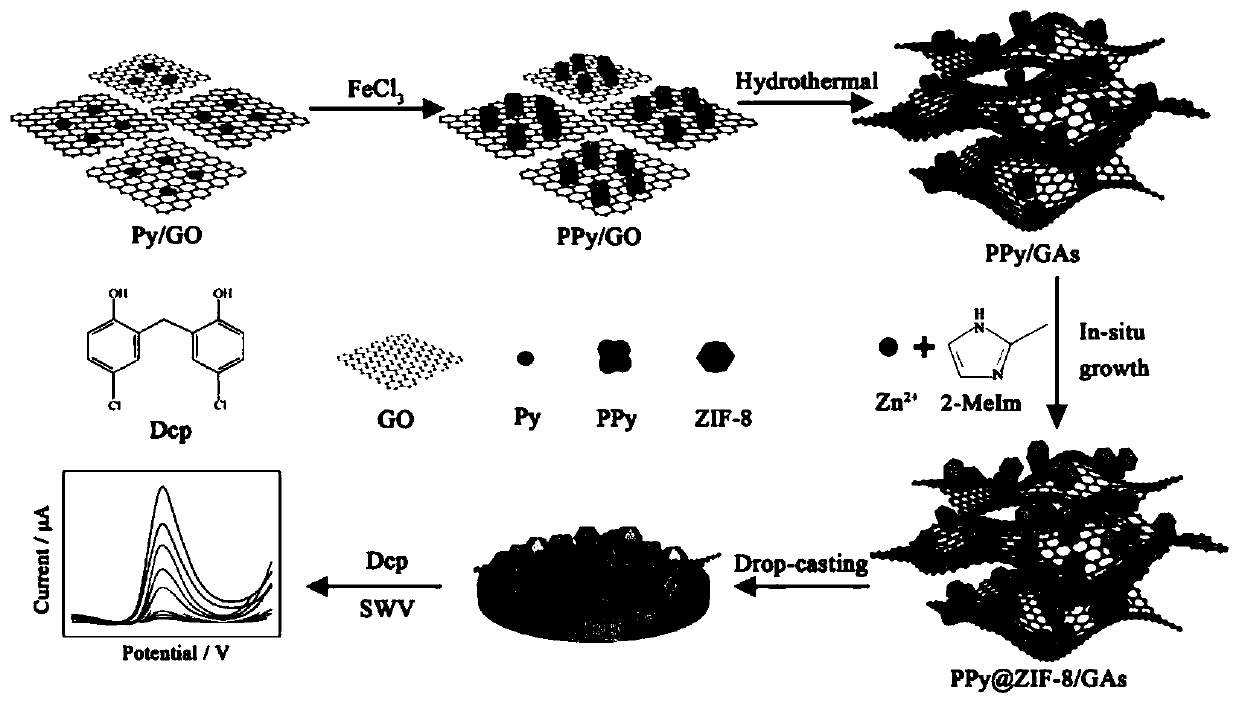

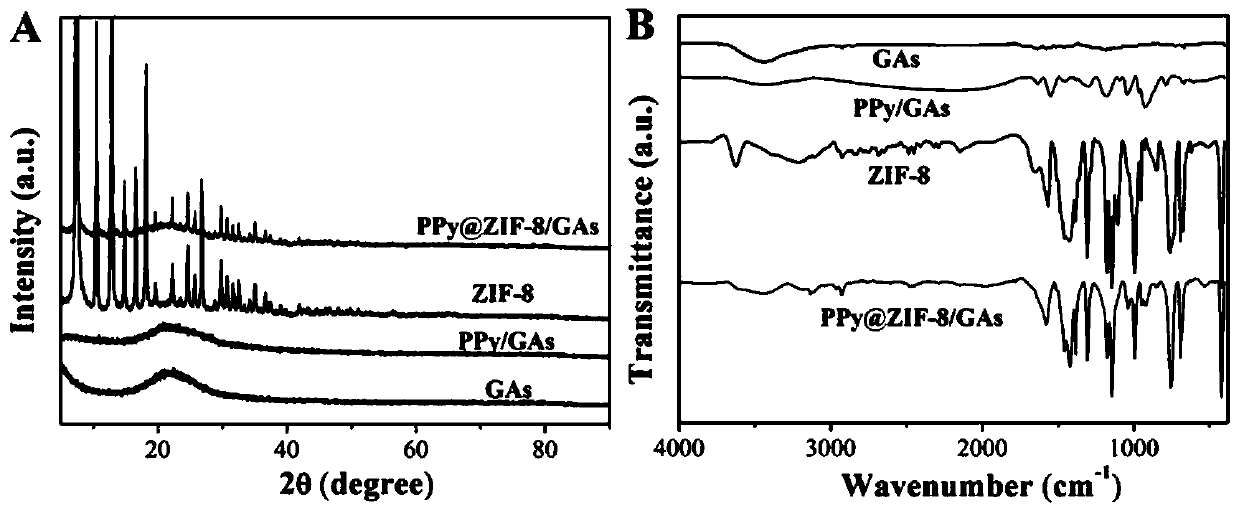

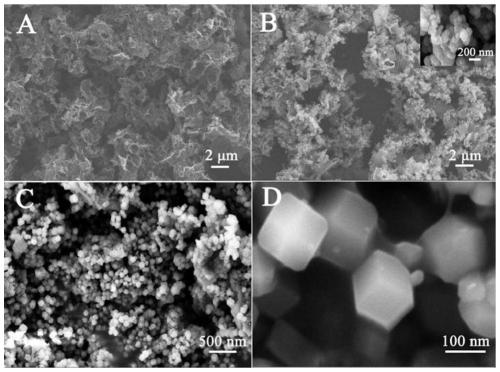

Preparation method and application of polypyrrole@ZIF-8/graphene nano composite material

ActiveCN109880363ACatalytic activity exceedsGood electrochemical propertiesMaterial analysis by electric/magnetic meansElectrochemical biosensorGraphene nanocomposites

The invention belongs to the technical field of nano new materials, and particularly relates to a preparation method and application of a polypyrrole@ZIF-8 / graphene nano composite material. During preparation, PPy is used as a bridge between GAs and ZIF-8 for reinforced bonding, the PPy@ZIF-8 / GAs composite material is successfully synthesized through an in-situ growth method. The catalytic activity of the system exceeds that of a single-component system, and the electrochemical characteristics of the nano material are improved. The PPy@ZIF-8 / GAs nano composite material is successfully synthesized, the prepared composite material is applied to an electrochemical biosensor for rapidly detecting Dcp, the detection stability on the Dcp is good, the anti-interference capability is good, the detection limit is low, and the lower detection limit is 16 pM.

Owner:QUFU NORMAL UNIV

Preparation method and application of chiral helical polyaniline@MOF nano composite material

ActiveCN110361432ALow costThe process is simple and easy to controlMaterial electrochemical variablesNitrateEnantiomer

The invention discloses a preparation method of a chiral helical polyaniline@MOF nano composite material and the application of the composite material to the detection of chiral drug enantiomers and belongs to the technical field of nano composite material and chiral electrochemical sensing detection. The preparation method comprises the following main steps that: cobalt nitrate is mixed with a precursor solution for preparing helical polyaniline; the cobalt nitrate reacts with the precursor solution at a constant temperature of 20 DEG G overnight; an obtained product is added into a 2-methylimidazole solution; a self-assembly reaction is carried out under a normal temperature condition, so that the chiral helical polyaniline@MOF nano composite material can be prepared. A chiral sensor constructed by adopting the composite material is used for sensitively detecting the content of L-tyrosine and D-tyrosine enantiomers. The chiral sensor can be prepared by a simple method; the chiral sensor is easy to operate; and the chiral detection effect of the chiral sensor is remarkable.

Owner:UNIV OF JINAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com