Preparation method and application of attapulgite composite photocatalyst

A technology of attapulgite and composite light, which is applied in the application field of photocatalytic synthesis of ammonia, can solve the problems of low photocatalytic efficiency and poor visible light response ability, and achieve the effects of simple synthesis method, energy saving and improved catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, weigh 2g of attapulgite and dissolve it in 100ml of 3mol / L hydrochloric acid solution, ultrasonically dissolve it, place it in a water bath, treat it at 70°C for 10 hours, and filter it with a circulating vacuum pump. Dry at ℃ for 16 hours to obtain the attapulgite pretreated product; then take 0.0015mol ferric chloride and place it in a 100mL beaker containing 50mL deionized water, stir and dissolve, add 1g of the above pretreated attapulgite, and stir again to dissolve , placed in a water bath at 70°C and stirred for 8 hours; finally, transfer the reaction solution in the beaker to a 100mL microwave hydrothermal reaction kettle at 160°C for 2 hours, and filter with a circulating vacuum pump. After drying for 16 hours, the iron oxide / modified attapulgite composite material was obtained, that is, 40% Fe 2 o 3 / ATP sample.

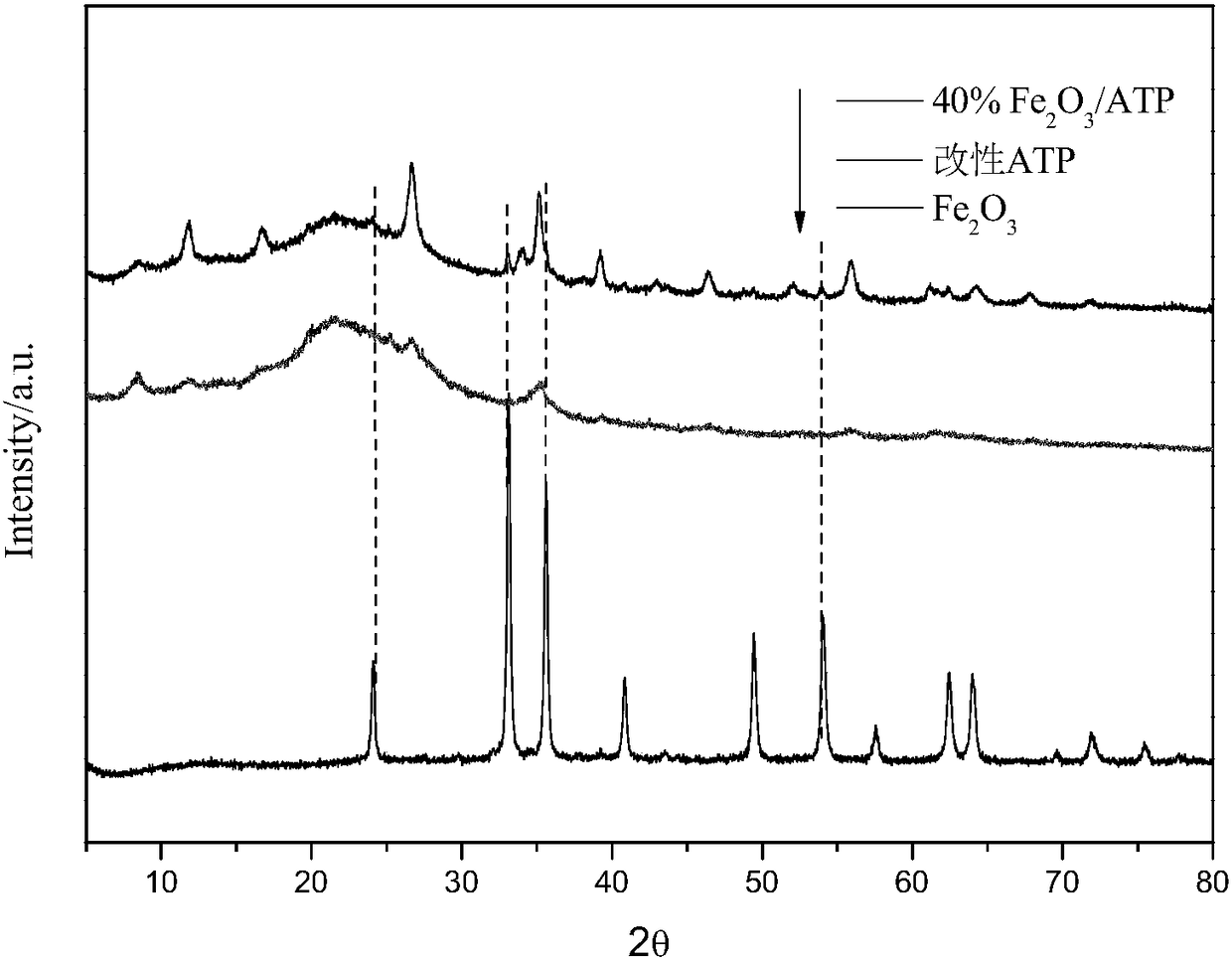

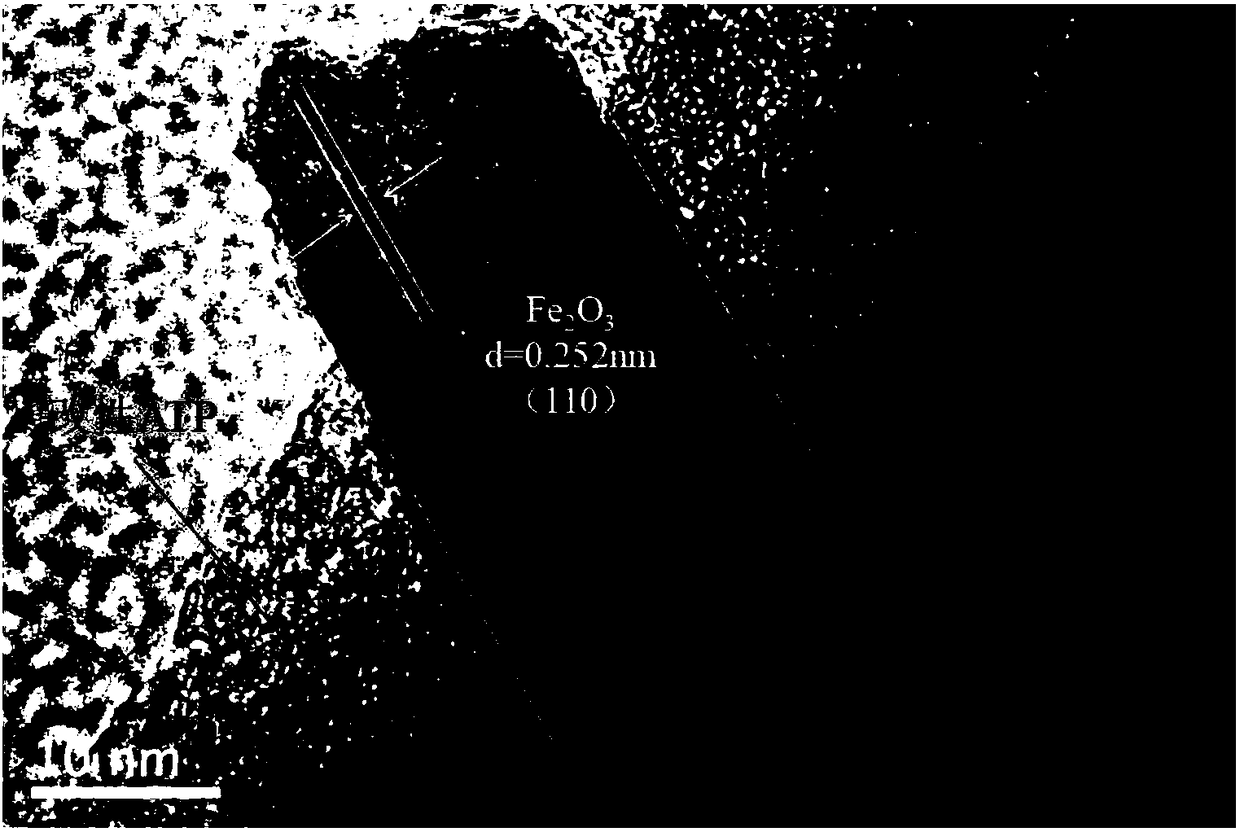

[0029] The iron oxide / modified attapulgite composite material prepared in this embodiment was subjected to X-ray powder diffraction experim...

Embodiment 2

[0032] First, weigh 2g of attapulgite and dissolve it in 100ml of 3mol / L hydrochloric acid solution, ultrasonically dissolve it, place it in a water bath, treat it at 70°C for 10 hours, and filter it with a circulating vacuum pump. Dry at ℃ for 15 hours to obtain the attapulgite pretreated product; then take 0.002mol ferric chloride and place it in a 100mL beaker containing 50mL deionized water, stir and dissolve, add 1g of the above pretreated attapulgite, and stir again to dissolve , placed in a water bath at 70°C and stirred for 8 hours; finally, transfer the reaction liquid in the beaker to a 100mL microwave hydrothermal reactor at 160°C for 3 hours, and then filter with a circulating vacuum pump. After drying for 18 hours, the iron oxide / modified attapulgite composite material was obtained, and the subsequent detection was as in Example 1.

Embodiment 3

[0034] First weigh 2g of attapulgite clay and dissolve it in 100mL of 3mol / L hydrochloric acid solution, put it in a water bath after ultrasonically dissolving, treat it at 70°C for 10h, and filter it with a circulating vacuum pump. Dry at 70°C for 16 hours to obtain the attapulgite clay pretreatment product; then take 0.003mol of ferric chloride and place it in a 100mL beaker containing 50mL of deionized water, stir to dissolve and add 1g of the attapulgite clay after the above pretreatment, Stir again to dissolve, put it in a water bath at 70°C and stir for 10 hours; finally, transfer the reaction solution in the beaker to a 100mL microwave hydrothermal reactor at 170°C for 3 hours, and then use a circulating vacuum pump to filter the filter cake. Dry at 70° C. for 16 hours to obtain the iron oxide / modified attapulgite composite material. Subsequent testing is as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com