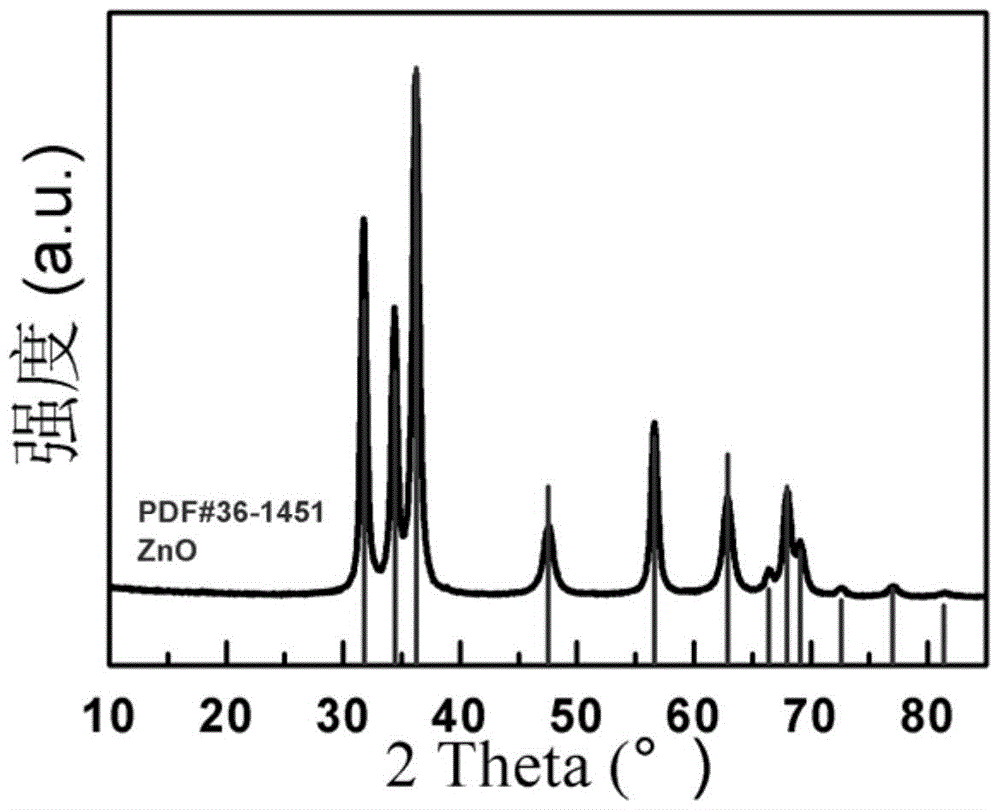

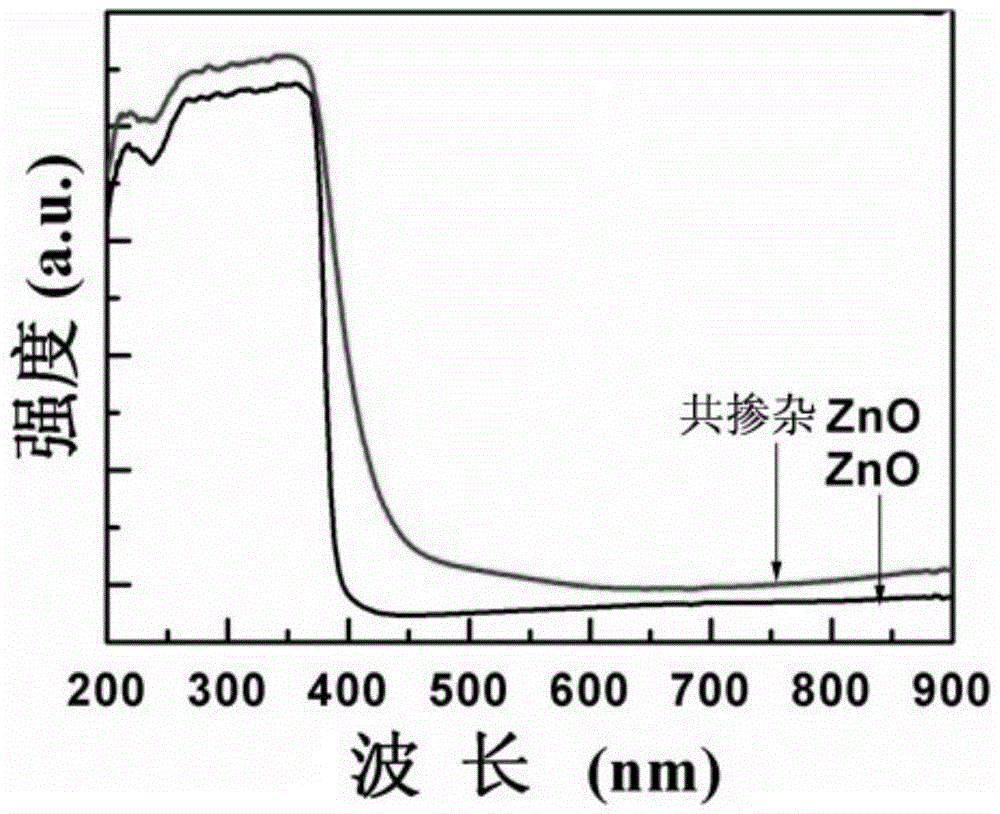

Zinc oxide-based photocatalyst material co-doped with boron and fluorine and its preparation method and application

A photocatalyst and co-doping technology, used in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to avoid a large amount of oxidation loss, reduce equipment requirements and energy consumption requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The process flow of this embodiment is as follows: a zinc oxide-based photocatalyst material co-doped with boron and fluorine is obtained through hydrolysis precipitation—washing and drying—peroxidation treatment—washing and drying—reduction treatment. details as follows:

[0032] 1) Hydrolysis and precipitation: First, dissolve ammonium acetate in water, configure 40mmol / L ammonium acetate solution, then add zinc fluoride borate to the solution, the concentration of zinc fluoride borate in the solution is 10mmol / L, violently Stir until a homogeneous solution is formed, and finally, transfer the homogeneous solution into a reaction kettle, and keep it warm at 200°C for 1 hour;

[0033] 2) Washing and drying: Centrifuge the suspension obtained in step 1) to collect the powder, alternately wash it with secondary deionized water and absolute ethanol for 5 times, put it in a drying oven and dry it at 50°C for one day;

[0034] 3) Peroxidation treatment: disperse the powder...

Embodiment 2

[0038] The process flow of this embodiment is as follows: a zinc oxide-based photocatalyst material co-doped with boron and fluorine is obtained through hydrolysis precipitation—washing and drying—peroxidation treatment—washing and drying—reduction treatment. details as follows:

[0039] 1) Hydrolysis precipitation: First, dissolve ammonium acetate in 1,4-butanediol, configure a 40mmol / L ammonium acetate solution, then add zinc borofluorate to the solution, the amount of zinc borofluorate in the solution The concentration is 10mmol / L, stir vigorously until a homogeneous solution is formed, and finally, transfer the homogeneous solution into the reaction kettle, and keep it at 200°C for 20h;

[0040] 2) Washing and drying: Centrifuge the suspension obtained in step 1) to collect the powder, alternately wash it with secondary deionized water and absolute ethanol for 8 times, put it in a drying oven and dry it at 50°C for one day;

[0041] 3) Peroxidation treatment: disperse the...

Embodiment 3

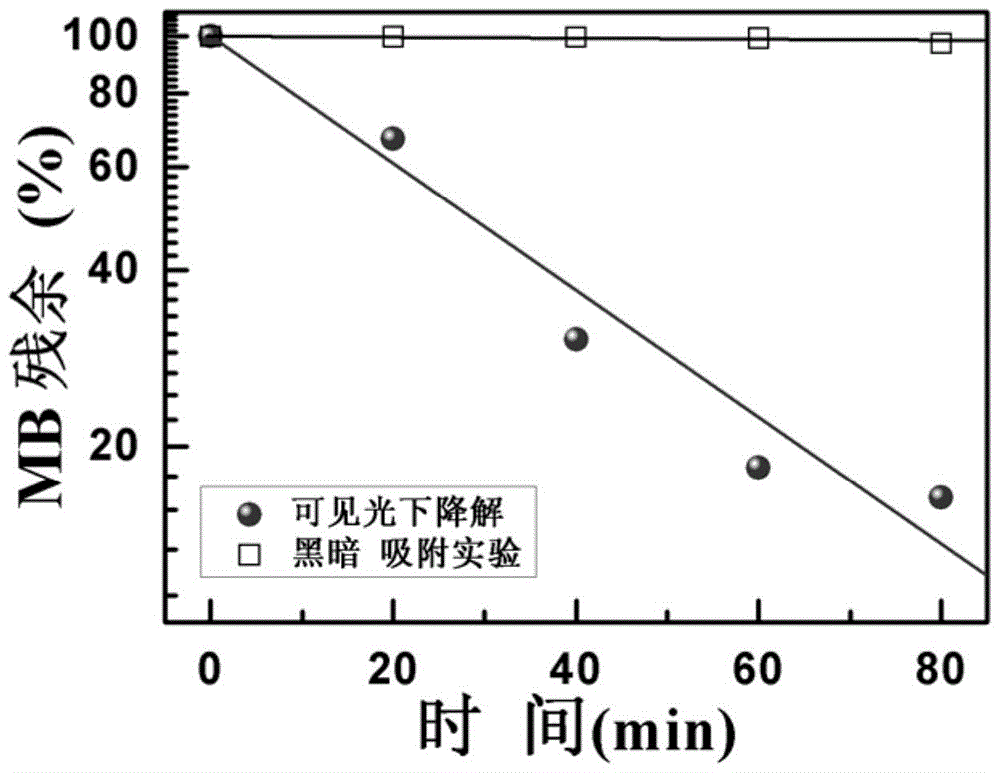

[0045] The boron and fluorine co-doped zinc oxide-based photocatalyst material obtained in Examples 1 and 2 were used for the photocatalytic degradation of methylene blue, and the experimental process was as follows:

[0046] Weigh 100 mg of the obtained boron and fluorine co-doped zinc oxide-based photocatalyst material, disperse it in 100 ml of methylene blue solution with a concentration of 6 ppm in the dark, and place it at a light intensity of about 60 mW / cm 2 Under visible light irradiation (wavelength range 400nm ~ 700nm), samples were taken at regular intervals, centrifuged and the residual methylene blue concentration of the supernatant was measured to obtain the photocatalytic degradation curve of the material under visible light irradiation. In addition, the materials were dispersed in the methylene blue solution of the same concentration in the same proportion, placed in the dark, and points were taken at the same time intervals to obtain the adsorption curve in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com