Preparation and application of a kind of goqds/tio2/wo3 photocatalyst

A photocatalyst, 2H2O technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, water/sludge/sewage treatment, etc., can solve the problem of not eliminating toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

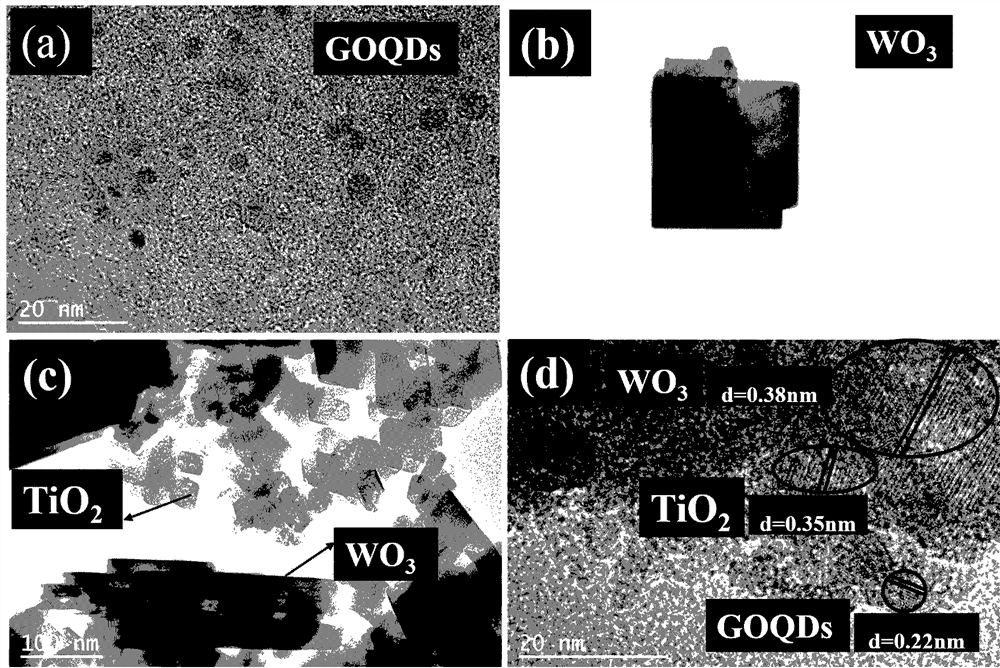

Image

Examples

Embodiment 1

[0016] Take 30ml of GOQDs solution and sonicate and add 0.3771g of Na 2 WO 4 • 2H 2 O, stir vigorously for about 1h to make Na 2 WO 4 • 2H 2 O is completely dissolved; put 80ml of absolute ethanol on the magnetic stirrer, add 1ml of butyl titanate dropwise while stirring, and add 0.4ml of HF, stir for 30min; mix the two solutions and stir for 1~2h Transfer to a 100ml hydrothermal autoclave for hydrothermal reaction (160°C, 24h), wash the obtained product with pure water and absolute ethanol several times to neutrality, and then dry it in a constant temperature drying oven at 60°C. Get GOQDs / TiO 2 / WO 3 photocatalyst material.

[0017] Take 80ml of reverse osmosis concentrated water for photocatalytic reaction, adjust its pH to 6 and add 35.2mg of GOQDs / TiO 2 / WO 3 Photocatalyst, avoid light and stir for 30 minutes, then transfer to photocatalytic reaction device, measure Cd in reverse osmosis concentrated water after 80 minutes of light 2 + and Pb 2+ Concentration,...

Embodiment 2

[0019] GOQDs / TiO 2 / WO 3 The preparation method of the photocatalyst material is as in Example 1.

[0020] Take 80ml of reverse osmosis concentrated water for photocatalytic reaction, adjust its pH to 7 and add 41.6mg of GOQDs / TiO 2 / WO 3 Photocatalyst, avoid light and stir for 30 minutes, then transfer to photocatalytic reaction device, measure Cd in reverse osmosis concentrated water after 60 minutes of light 2 + and Pb 2+ Concentration, after determination, C(Pb 2+ )=0.007 mg / l, C(Cd 2+ )=0.132 mg / l, Pb 2+ The removal rate: 97.96%, Cd 2+ The removal rate is: 65.85%.

Embodiment 3

[0022] GOQDs / TiO 2 / WO 3 The preparation method of the photocatalyst material is as in Example 1.

[0023] Take 80ml reverse osmosis concentrated water for photocatalytic reaction, adjust its pH to 4 and add 48.0mg of GOQDs / TiO 2 / WO 3 Photocatalyst, avoid light and stir for 30 minutes, then transfer to photocatalytic reaction device, measure Cd in reverse osmosis concentrated water after 40 minutes of light 2 + and Pb 2+ Concentration, after determination, C(Pb 2+ )=0.007 mg / l, C(Cd 2+ )=0.124 mg / l, Pb 2+ The removal rate: 97.96%, Cd 2+ The removal rate is: 67.73%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com