Nano composite material of polyaniline intercalation titanate and preparation method thereof

A nano-composite material and layered titanate technology, applied in the field of polyaniline intercalated titanate nano-composite materials and their preparation, can solve problems such as intercalation difficulties, achieve high application value, reduce compounding, and improve optoelectronics The effect of conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

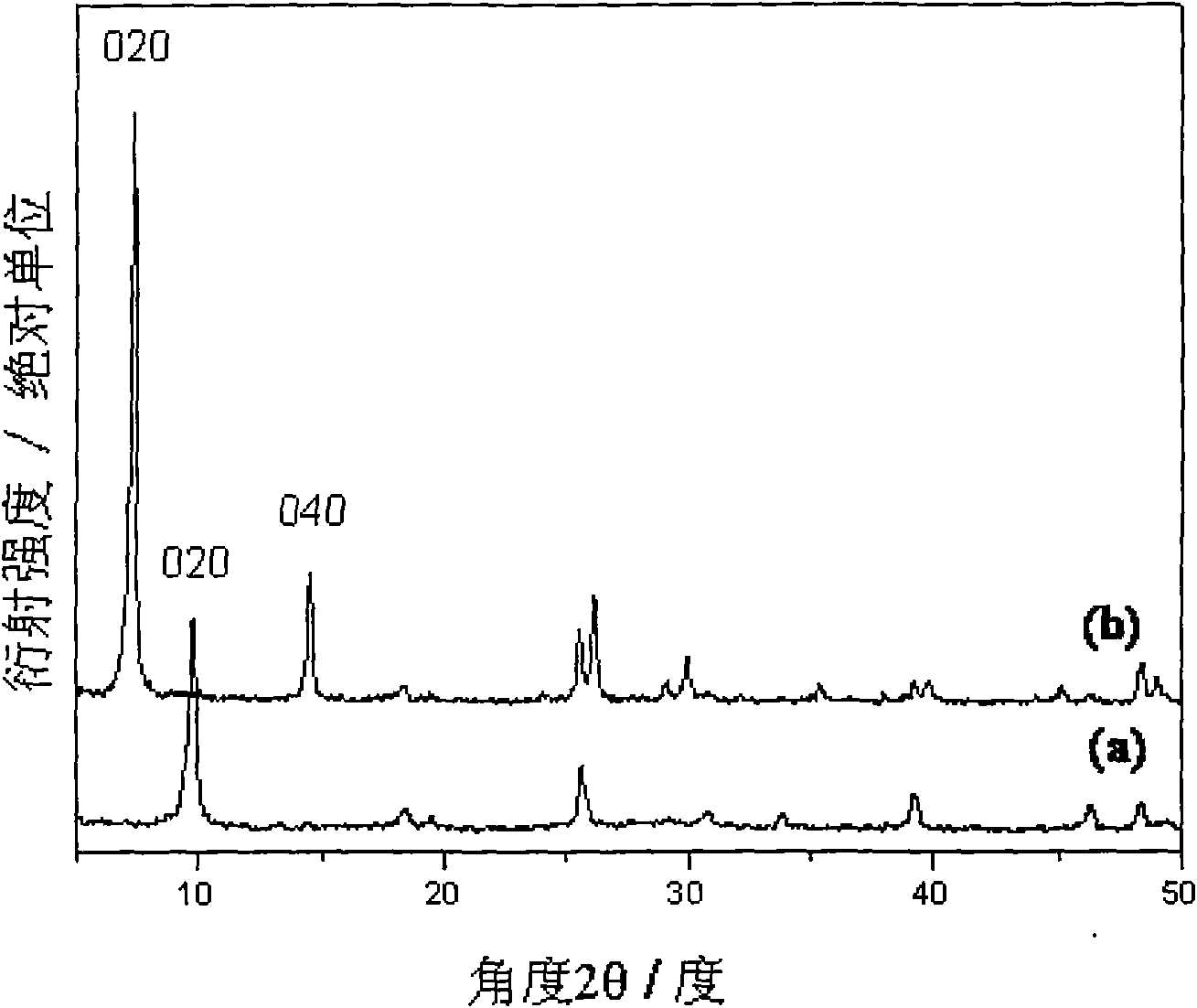

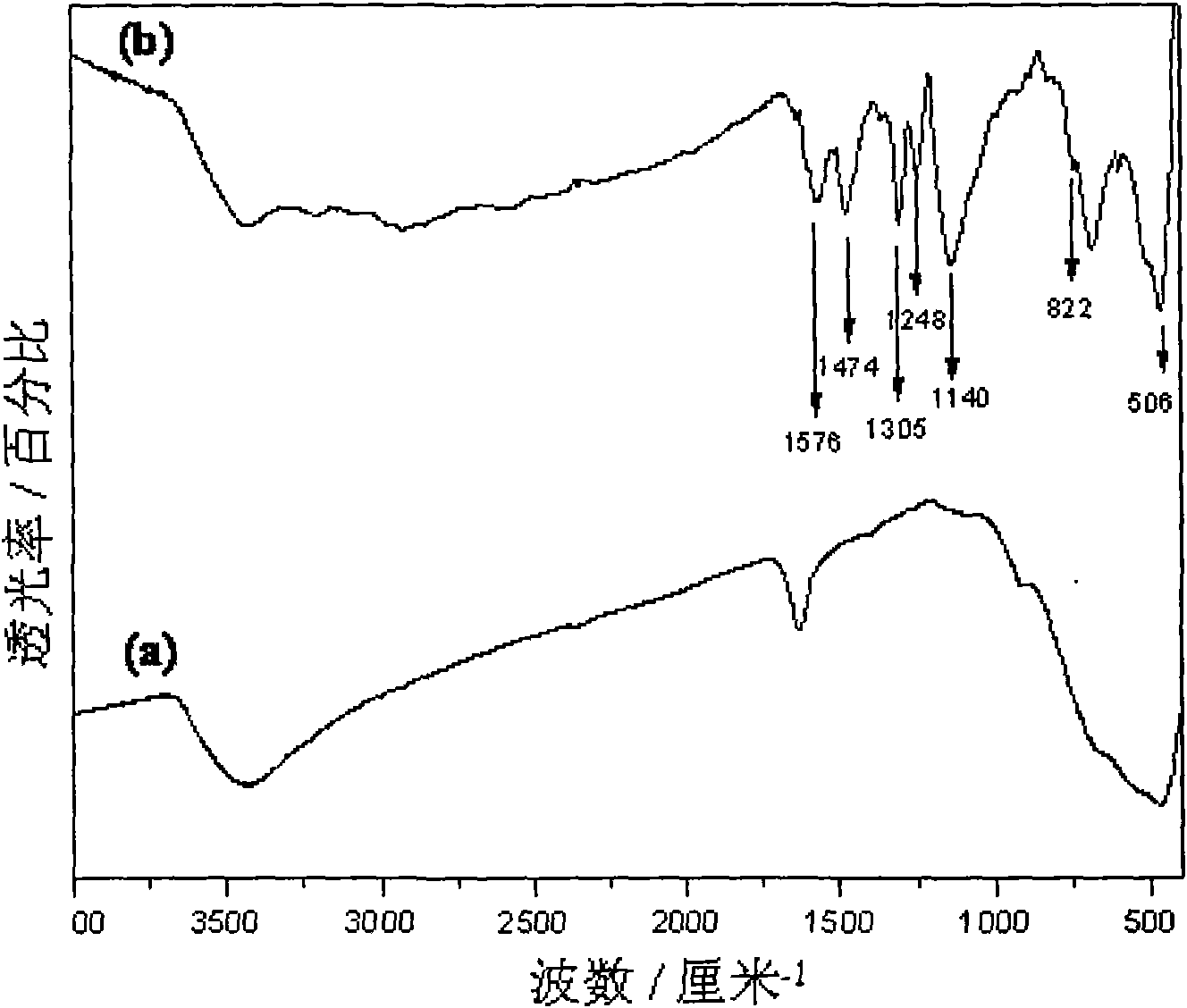

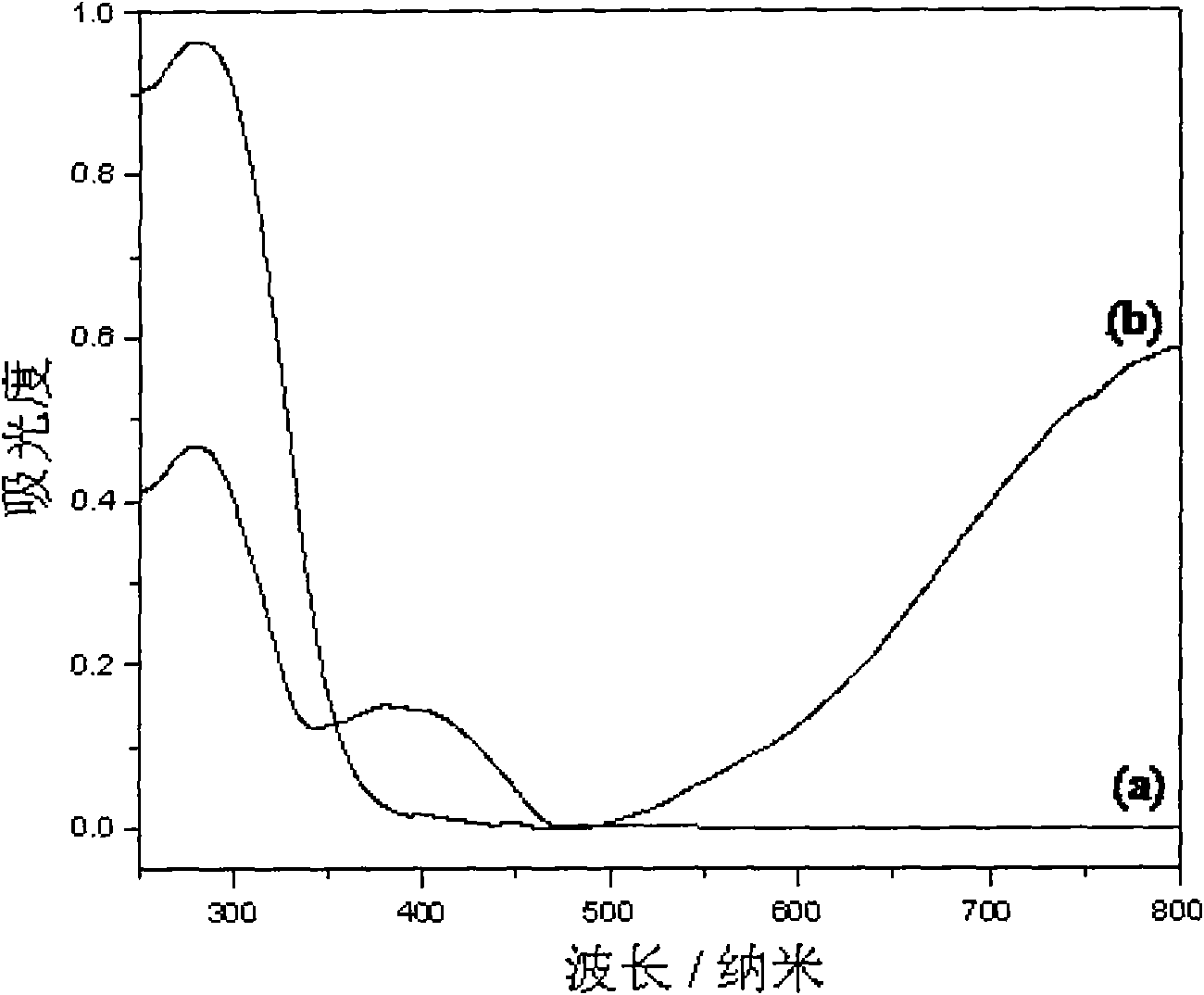

[0027] 3.26g Cs 2 CO 3 and 4.07g TiO 2 After mixing and grinding, put it into a muffle furnace, calcinate at 800°C for 60 minutes, grind it after cooling to room temperature and calcinate at 800°C for 20 hours, and grind it again after cooling to room temperature and calcinate at 800°C for 20 hours , to obtain layered cesium titanate Cs 0.67 Ti 1.83 □ 0.17 o 4 .

[0028] 1.5g layered cesium titanate Cs 0.67 Ti 1.83 □ 0.17 o 4 Add 80 mL of hydrochloric acid HCl solution with a concentration of 1.0 mol / L and mix and stir for 3 days, replace the hydrochloric acid HCl solution with a concentration of 1.0 mol / L every 24 hours, wash the product with twice distilled water to pH=6.0, and place the product in Dry to constant weight in a desiccator filled with saturated sodium chloride NaCl solution to obtain protonated layered titanate H 0.67 Ti 1.83 □ 0.17 o 4 ·H 2 O.

[0029] 1 g of protonated layered titanate H dried to constant weight 0.67 Ti 1.83 □ 0.17 o 4 ·H ...

Embodiment 2

[0034] 3.26g Cs 2 CO 3 and 4.39g TiO 2 After mixing and grinding, put it into a muffle furnace, calcinate at 900°C for 30 minutes, grind it after cooling to room temperature and calcinate at 900°C for 24 hours, and grind it again after cooling to room temperature and calcinate at 900°C for 24 hours , to obtain layered cesium titanate Cs 0.73 Ti 1.82 □ 0.18 o 4 .

[0035] 2.5g layered cesium titanate Cs 0.73 Ti 1.82 □ 0.18 o 4 Add to 300mL hydrochloric acid HCl solution with a concentration of 1.5mol / L and mix and stir for 4 days, replace the hydrochloric acid HCl solution with a concentration of 1.5mol / L every 24 hours, wash the product with twice distilled water to pH=7.0, and place the product in Dry to constant weight in a desiccator filled with saturated sodium chloride NaCl solution to obtain protonated layered titanate H 0.73 Ti 1.82 □ 0.18 o 4 ·H 2 O.

[0036] Protonated layered titanate H dried to constant weight at 1 g 0.73 Ti 1.82 □ 0.18 o 4 ·H 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com