Preparation method of protonized ionic liquid modified rubber/inorganic filler composite material

A technology of protonated ions and inorganic fillers, which is applied in the field of preparation of protonated ionic liquid modified rubber/inorganic filler composite materials, can solve the problems of interface bonding limiting the performance and influence of composite materials, and achieves improved processing performance and enhanced interfacial interaction. effect, the effect of reducing Mooney viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

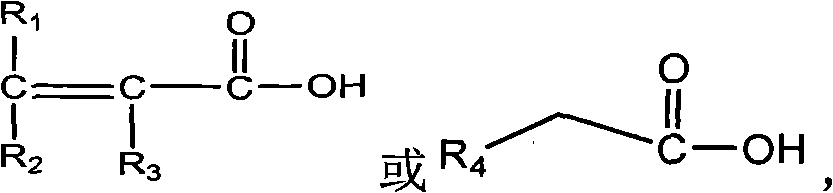

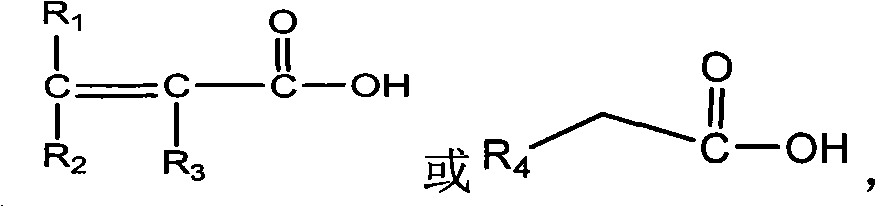

Method used

Image

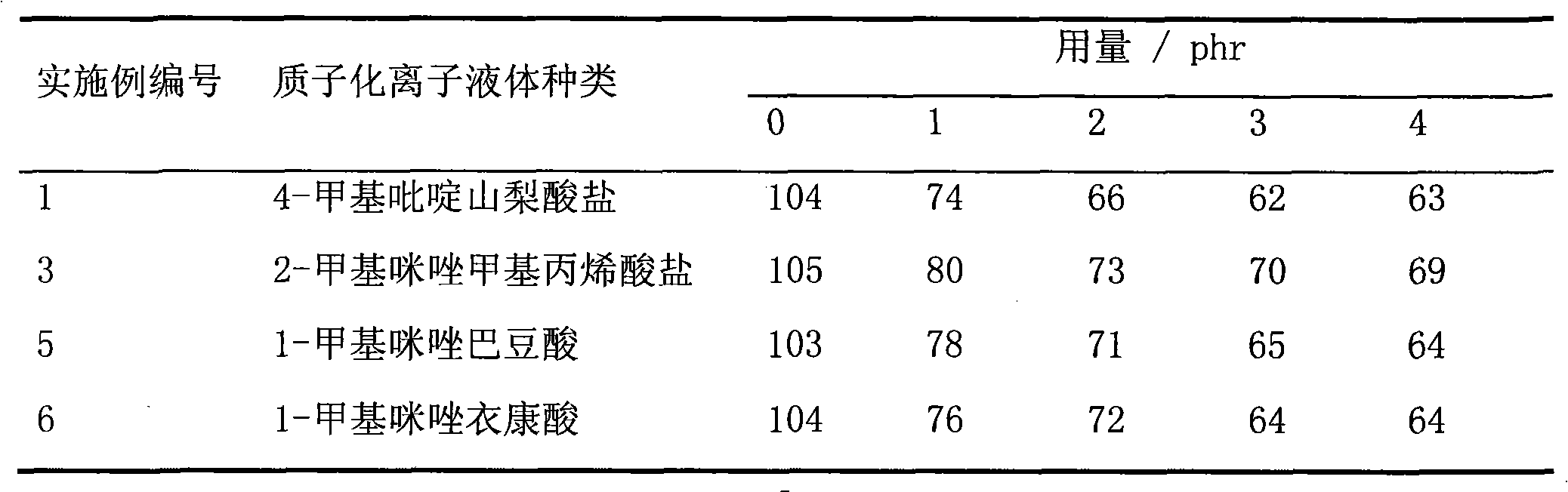

Examples

Embodiment 1

[0033] (1) 4-picoline sorbate prepared by mixing 4-picoline and sorbic acid in a molar ratio of 1:1 and reacting at 25° C. for 1 hour.

[0034] (2) According to the basic formula of rubber: styrene-butadiene rubber 100, white carbon black 40, zinc oxide 5, stearic acid 1, dicumyl peroxide (DCP) 1, anti-aging agent 4010na 1.5, 4-picoline sorbic acid salt variable. After blending on a double-roll mill, park overnight and then vulcanize on a flat vulcanizer at 170°C×10min to obtain a 4-picoline sorbate-modified styrene-butadiene rubber / silica composite material.

Embodiment 2

[0036] (1) 1-methylimidazole sorbate prepared by mixing 1-methylimidazole and sorbic acid in a molar ratio of 1:1 and reacting at 25° C. for 1 hour.

[0037] (2) According to the basic formula of rubber: styrene-butadiene rubber 100, halloysite 40, zinc oxide 5, stearic acid 1, dicumyl peroxide (DCP) 1, anti-aging agent 4010na 1.5, 1-methylimidazole sorbic acid salt variable. After blending on a double-roll mill, park overnight and vulcanize on a flat vulcanizer at 170°C×6min to prepare 1-methylimidazolium sorbate-modified styrene-butadiene rubber / halloysite composite material

Embodiment 3

[0039] (1) 2-methylimidazole and α-methacrylic acid were mixed according to a molar ratio of 1:1, and reacted in an ice-water bath for 0.5 hours to obtain colorless and transparent 2-methylimidazole methacrylate.

[0040] (2) According to the basic formula of rubber: styrene-butadiene rubber 100, silica 40, zinc oxide 5, stearic acid 1, cumene peroxide (DCP) 1, antioxidant MB 1.5, 1-methylimidazole methacrylic acid salt variable. After blending on a double-roll mill, park overnight and then vulcanize on a flat vulcanizer at 170°C×8min to prepare 2-methylimidazolium methacrylate modified styrene-butadiene rubber / white carbon black composites.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com