Preparation of self-supported Sb2S5/three-dimensional graphene nanometer composite material and application in sodium ion battery

An antimony pentasulfide and composite material technology, applied in secondary batteries, battery electrodes, circuits, etc., can solve problems such as reducing battery energy density, achieve high rate performance, long cycle life, and shorten the diffusion path effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The hydrothermal method is used to prepare antimony pentasulfide nanoparticles and three-dimensional graphene composite materials, and the steps are as follows:

[0036] (1) 44.7mg of Na 3 Sb 4 9H 2 O is dissolved in 9.3mL water to make 0.01mol L -1 The solution.

[0037] (2) 0.8mL graphene oxide (10mg mL -1 ) mixed with the above solution and stirred to form a homogeneous solution.

[0038] (3) Add 2.27mL of HCl (0.1mol L -1 ) and stirred for 2 hours.

[0039] (4) 0.632mL ascorbic acid (1mol L -1 ) was added dropwise to the above solution.

[0040] (5) The mixed solution in the above step 4) was transferred to a 50 mL reactor and heated to 90° C. for 6 hours. After freezing with liquid nitrogen, it was transferred to a freeze dryer for 18 hours to obtain Sb 2 S 5 -GF Composite.

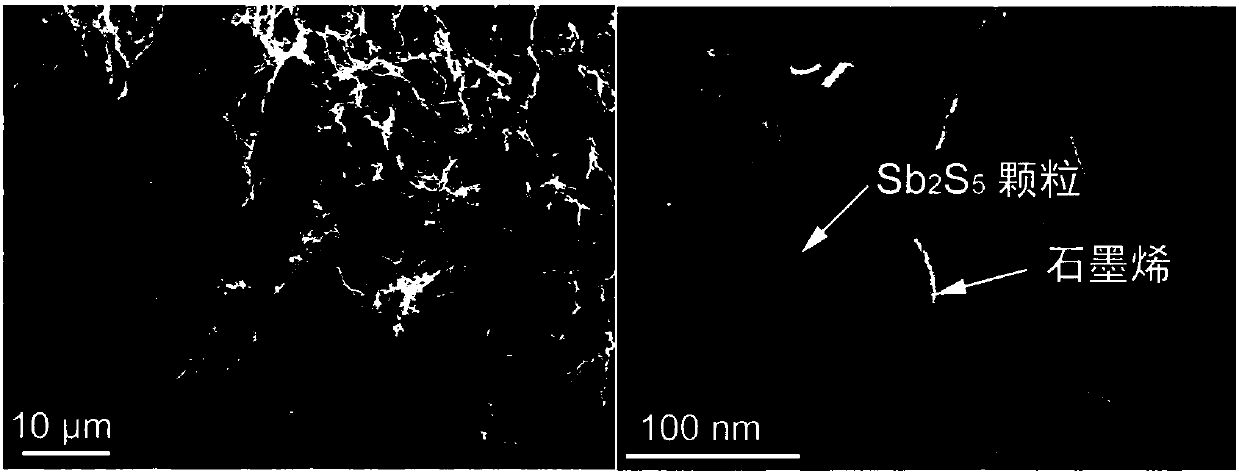

[0041] Sb with self-supporting properties 2 S 5 -GF composite material preparation process such as figure 1 As shown, the obtained sample is antimony pentasulfide nanoparticles ...

Embodiment 2

[0045] Add Na in embodiment 1 3 Sb 4 9H 2 O (0.01mol L -1 ) was set at 5.9mL, and 1.44mL of HCl (0.1mol L -1 ), other with embodiment 1. The mass fraction of antimony pentasulfide in the obtained composite material was 71%. Its scanning electron microscope photograph is shown in Figure 8 . It can be seen from the figure that Sb 2 S 5 The nanoparticles are uniformly distributed on the porous graphene. Use this composite material as negative pole, adopt the same method as embodiment 1 to assemble battery, in 0.2Ag -1 The charge-discharge curve at a current density of Figure 9 Therefore, the reversible specific capacity after 300 cycles is 646mAh g -1 . As can be seen, the resulting specific capacity is relatively low. This is because the proportion of graphene in the composite material increases, and the theoretical specific capacity that graphene can contribute is less. The rate performance of the composite material is as follows Figure 10 As shown, the electr...

Embodiment 3

[0047] Add Na in embodiment 1 3 Sb 4 9H 2 O (0.01mol L -1 ) was set at 15.8mL, and 3.86mL of HCl (0.1mol L -1 ), other with embodiment 1. The mass fraction of antimony pentasulfide in the obtained composite material is 90%. Its scanning electron microscope photograph is shown in Figure 11 . due to Sb 2 S 5 As the load increases, a large amount of Sb can be observed 2 S 5 The particles aggregate on graphene sheets. Use this composite material as negative pole, adopt the same method as embodiment 1 to assemble battery, in 0.2Ag -1 The cycle performance curve under the current density is as follows Figure 12 shown. It can be seen that the resulting initial specific capacity is relatively high. However, because the proportion of graphene in the composite material decreases, the electrical conductivity becomes poorer, and the capacity decays faster. After 300 cycles, the reversible specific capacity is 563mAh g -1 . The rate performance of the composite material i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com