Rectorite/thermoplastic polyurethane elastomer nano composite material and preparing method

A technology of thermoplastic polyurethane and nanocomposite materials, which is applied in the field of polymer processing, can solve the problems of TPUR's performance and service life not being fully utilized, TPUR's raw material modification and innovation capabilities not being fully developed, and molecular structure complexity. Achieve the effects of improved friction performance, wide applicability, and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

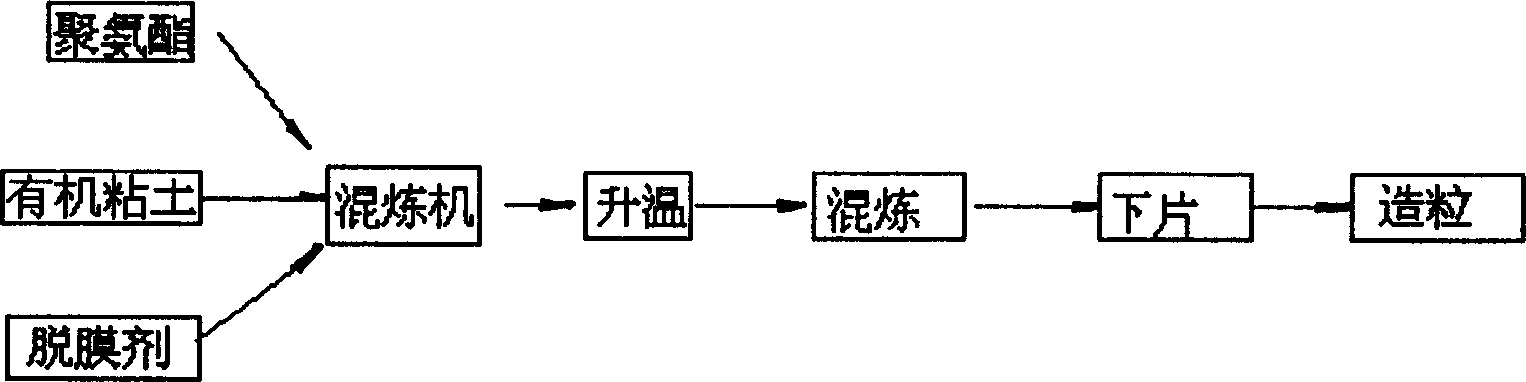

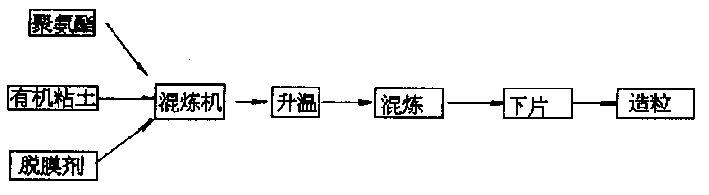

[0027] Melt 100 parts of polyester-type thermoplastic polyurethane elastomer TPUR with a hardness of 85A on a two-roll kneader, control the temperature of the two-rolls at 145°C, add 2 parts of release agent, 8 parts of organic rectorite clay, pre-mix, thin After passing through for 30 minutes, the tablet was lowered with an appropriate thickness, and the nanocomposite material was obtained by granulation. Implementation example 2

Embodiment 2

[0028] Melt 100 parts of polyether-type thermoplastic polyurethane elastomer TPUR with a hardness of 85A on a double-roller kneader, control the temperature of the double-rollers at 120°C, add 2 parts of release agent, 8 parts of organic rectorite clay, pre-mix, thin After passing through for 30 minutes, the tablet was lowered with an appropriate thickness, and the nanocomposite material was obtained by granulation.

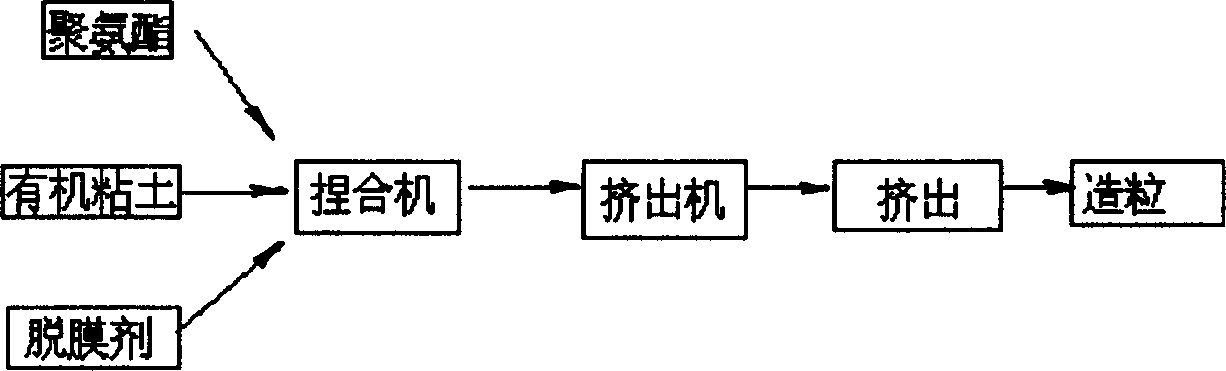

[0029] see figure 2 , the present invention blends 100-150 parts of thermoplastic polyurethane elastomer TPUR, 1-5 parts of release agent, and 1-10 parts of organic rectorite clay on a high-speed kneader, and then melts and extrudes it on a twin-screw extruder. The temperature of the front section of the screw extruder is 80°C-110°C, the temperature of the middle section is 130°C-150°C, the temperature of the back section is 145°C-170°C, the temperature of the head is 80°C-100°C, and the extruded material can be obtained by granulating Clay Nanocomposites. Imp...

Embodiment 3

[0030] Blend 100 parts of polyester thermoplastic polyurethane elastomer TPUR, 2 parts of release agent, and 8 parts of organic rectorite clay on a high-speed kneader, and then melt and extrude it on a twin-screw extruder. Process parameters: front temperature 80°C , the temperature in the middle section is 130°C, the temperature in the back section is 145°C, and the temperature in the head is 80°C. The extruded material is granulated to obtain the clay nanocomposite material. Implementation Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com