Resin based mesoporous nano composite material, preparation method and applications thereof

A nanocomposite material and composite material technology are applied in the fields of nanocomposite material synthesis technology and water treatment application, which can solve problems such as difficult preparation, and achieve the effects of easy regulation, easy regulation of content and strong hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

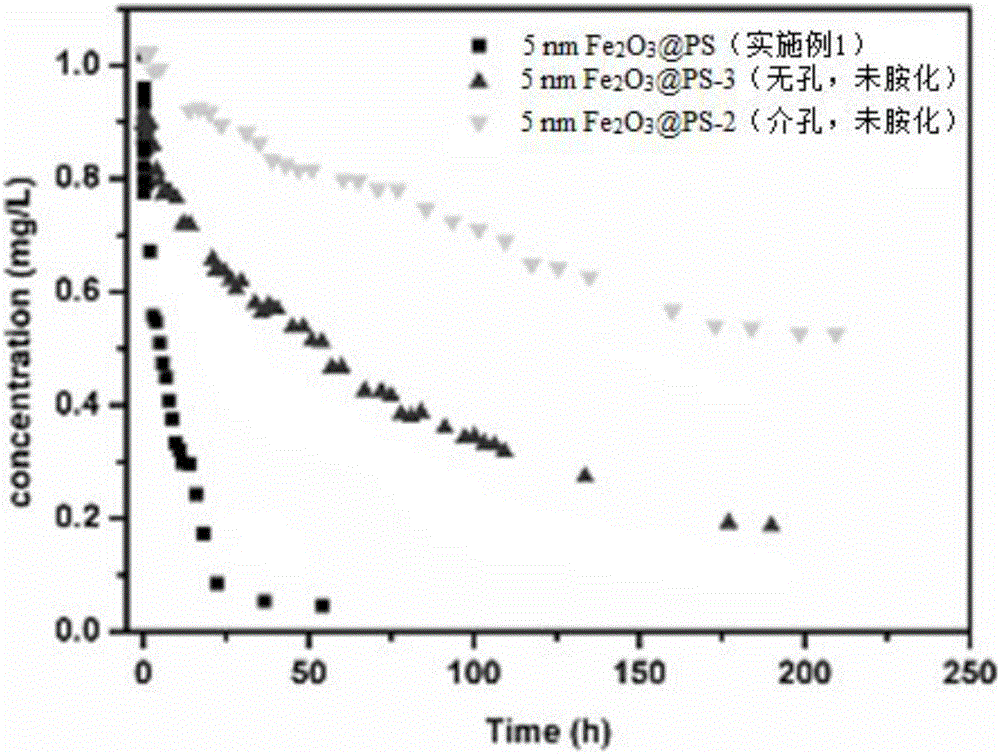

Embodiment 1

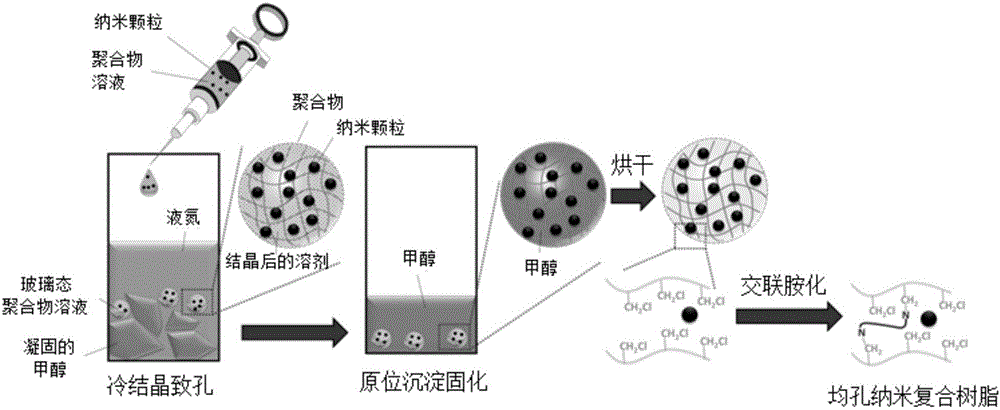

[0041] The preparation steps of resin-based mesoporous nanocomposites are as follows (such as figure 1 shown):

[0042] (1) Take 30g of polystyrene (PS) with a molecular weight of 190,000, mix it with 10g of chloromethyl polystyrene (CMPS), dissolve it in 200mL of N,N-dimethylformamide (DMF), add 6g of The diameter is the nano iron oxide particle (self-made) of 5nm, stirs and makes it fully dissolve to make mixed solution;

[0043] (2) Add 1000mL of methanol in batches to the liquid nitrogen to make it completely solidified, and then add the mixed solution drop by drop into the liquid nitrogen; leave it for 16 hours to make the liquid nitrogen volatilize completely and the methanol completely melt, take out the solid form in the container Resin pellets, washed with ethanol several times and then dried at 50°C to obtain solid pellets;

[0044] (3) Add solid pellets into 1,6-hexamethylenediamine ethanol solution with a mass concentration of 10%, treat at 50°C for 24 hours, wash ...

Embodiment 2

[0047] The preparation steps of the resin-based mesoporous nanocomposite are similar to those in Example 1, but the 5 nm iron oxide particles (self-made) in Example 1 are replaced by 10 nm iron oxide particles (self-made).

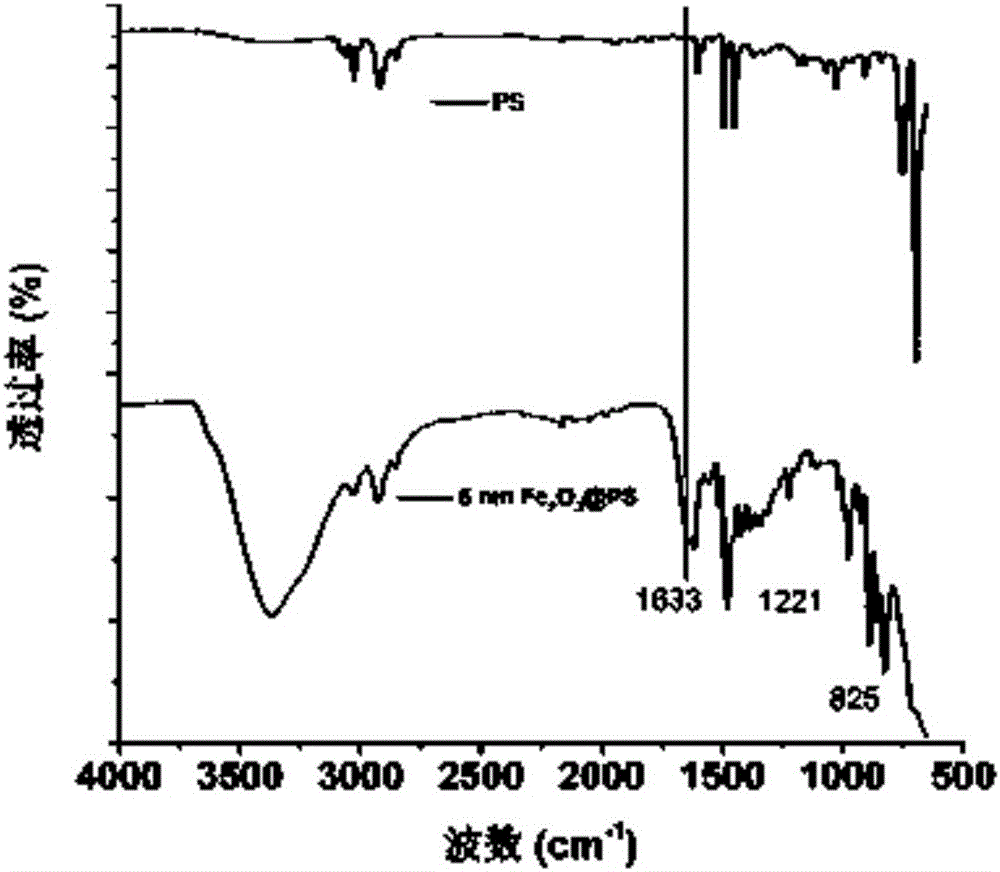

[0048] The resin-based mesoporous nanocomposite material obtained in this example is spherical, reddish brown, with a diameter of about 1.7 mm, and most of the absorption peaks in the infrared spectrum are the same as those of polystyrene (PS); but at 1635 and 1223 cm -1 with 820cm -1 There are new peaks appearing at , corresponding to -N-H bending vibration, C-N stretching vibration and characteristic absorption peaks of Fe-O, indicating that the resin-based skeleton of the composite material is aminated polystyrene, and the composite material contains nano-iron oxide. by N 2 -Adsorption-desorption instrument measures the pore structure, showing that its specific surface area is 200m 2 / g, the pore diameter is about 21nm, and the pore distribution of th...

Embodiment 3

[0050] The preparation steps of the resin-based mesoporous nanocomposite are similar to those in Example 1, but the 5nm iron oxide particles (self-made) in Example 1 are replaced by 30nm nanometer iron oxide particles (self-made).

[0051] The resin-based mesoporous nanocomposite material obtained in this example is spherical, reddish brown, with a diameter of about 2.7 mm, and most of the absorption peaks in the infrared spectrum are the same as those of polystyrene (PS); but at 1643 and 1230 cm -1 with 828cm -1 There are new peaks appearing at , corresponding to -N-H bending vibration, C-N stretching vibration and characteristic absorption peaks of Fe-O, indicating that the resin-based skeleton of the composite material is aminated polystyrene, and the composite material contains nano-iron oxide. by N 2 -Adsorption-desorption instrument measures the pore structure, showing that its specific surface area is 50m 2 / g, the pore diameter is about 11nm, and the pore distributio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com