Preparation process of bicomponent castor oil polyurethane waterproof coating

A polyurethane waterproofing and preparation process technology, applied in the coating and other directions, can solve the problems of difficulty in isocyanate moisture absorption and curing, affecting the adhesion of the film coating to the substrate, and the appearance of the film coating is not good. Layer performance, improve appearance, good decorative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

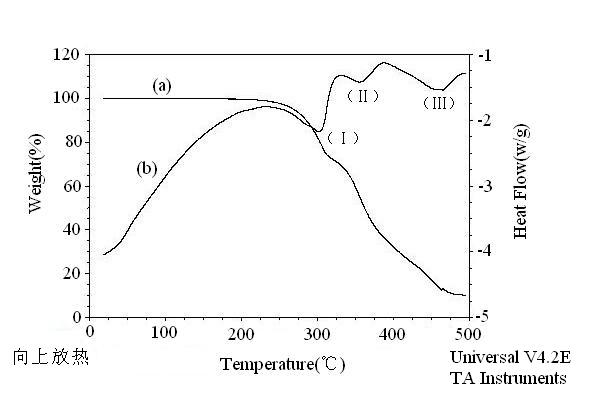

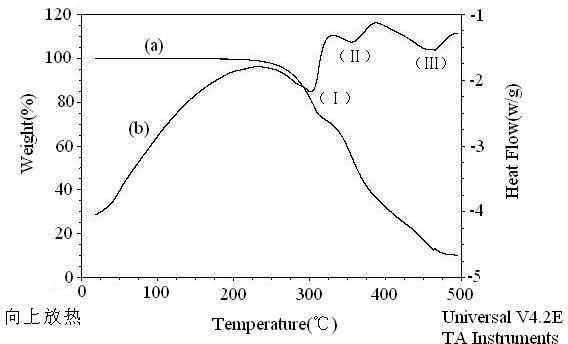

Image

Examples

Embodiment 1

[0021]White exposed waterproof coating: the specific ratio is: component A: castor oil 20.0%, 2,4-toluene diisocyanate 38.07%, xylene 8.6%, azobisisobutyronitrile 0.2%; component B: two Glycol 8.0.%, titanium dioxide 15.5%, talcum powder 2.0%, ultramarine 0.05%, coupling agent YB-201A (the titanate coupling agent of Changzhou Yabang Yayu Auxiliary Co., Ltd. can be used) 0.08%, Formic acid methacrylate 7.0%, antioxidant 1010 0.1%, UV-292 0.1%, hydroquinone 0.1%, stannous octoate 0.1%, triethylenediamine 0.1%. Mix component A and component B, add an appropriate amount of diluent, stir evenly, let stand for 30 minutes, cast on the glass template and spray on the steel plate at room temperature, keep the temperature at 30°C for 7 days. The surface drying time of the coating on the glass formwork is 2 hours, and the surface drying time of the coating on the steel plate is 2 hours; the glossiness of the coating on the steel plate is 60.3, and the hardness is 3H; the coating film on ...

Embodiment 2

[0023] White exposed waterproof coating: the specific ratio is: component A: castor oil 30.07%, 2,4-toluene diisocyanate 20.0%, xylene 8.6%, azobisisobutyronitrile 0.2%; component B: two Glycol 8.0.%, titanium dioxide 15.5%, talcum powder 2.0%, ultramarine 0.05%, coupling agent YB-201A (the titanate coupling agent of Changzhou Yabang Yayu Auxiliary Co., Ltd. can be used) 0.08%, Formic acid methacrylate 7.0%, antioxidant 1010 0.1%, UV-292 0.1%, hydroquinone 0.1%, stannous octoate 0.1%, triethylenediamine 0.1%. Mix component A and component B, add an appropriate amount of diluent, stir evenly, let stand for 30 minutes, cast on the glass template and spray on the steel plate at room temperature, keep the temperature at 30°C for 7 days. The surface drying time of the coating on the glass formwork is 3 hours, and the surface drying time of the coating on the steel plate is 2 hours; the glossiness of the coating on the steel plate is 60.4, and the hardness is 3H; the coating film on...

Embodiment 3

[0025] White exposed waterproof coating: the specific ratio is: component A: castor oil 27.0%, 2,4-toluene diisocyanate 14.85%, xylene 4.2%, ethyl acetate 2.1%, azobisisobutyronitrile 0.3% ; Component B: 8.5% diethylene glycol, 16.5% titanium dioxide, 3.0% talcum powder, 0.15% ultramarine blue, coupling agent YB-201A (the titanate coupling of Changzhou Yabang Yayu Auxiliary Co., Ltd. agent) 0.5%, methacrylic acid formic acid 21.8%, antioxidant 1010 0.2%, UV-292 0.3%, hydroquinone 0.2%, stannous octoate 0.2%, triethylenediamine 0.2%. Mix component A and component B, add an appropriate amount of diluent, stir evenly, let stand for 30 minutes, cast on the glass template and spray on the steel plate at room temperature, keep the temperature at 30°C for 7 days. The surface drying time of the coating on the glass formwork is 2 hours, and the surface drying time of the coating on the steel plate is 1.5 hours; the glossiness of the coating on the steel plate is 72.8, and the hardness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com