Modified phenolic resin and preparation method thereof

A phenolic resin and modification technology, which is applied in coatings, electrical components, circuits, etc., can solve the problems of easy crystal points and particles, increase the cost of coatings, and high prices, and achieve good leveling agent and feel, and improve thermal stability. Stability, compatibility improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

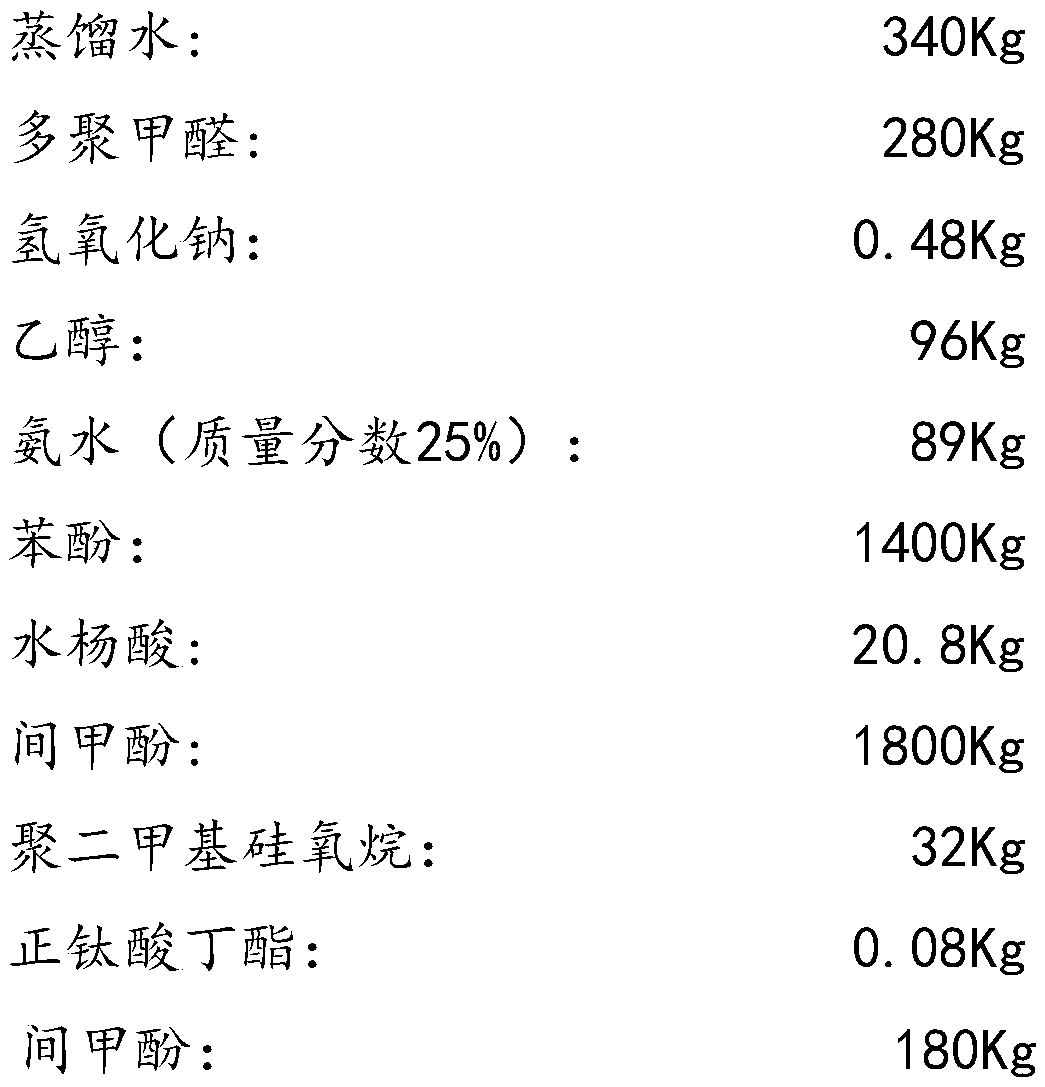

[0033] Raw material preparation (by mass)

[0034]

[0035] Introduce nitrogen protection into the cleaned reaction device, add distilled water, paraformaldehyde, sodium hydroxide, and ethanol while stirring, and raise the temperature to 65°C while feeding, and keep warm at this temperature. After 30 minutes, the contents of the kettle clarify;

[0036] Turn on the cooling to lower the temperature of the kettle to 38°C, and gradually add ammonia water to the kettle at a constant speed for 20 minutes;

[0037] After the ammonia water was added dropwise, the raw material phenol was added after stirring for 15 minutes. The exothermic reaction raised the temperature of the kettle to a maximum of 78.2°C. After the temperature of the kettle remained stable, it began to manually raise the temperature to 92°C, and kept at this temperature for 2 hours;

[0038] After the heat preservation is over, turn on the cooling, lower the temperature of the kettle to 75°C and add salicylic ac...

Embodiment 2

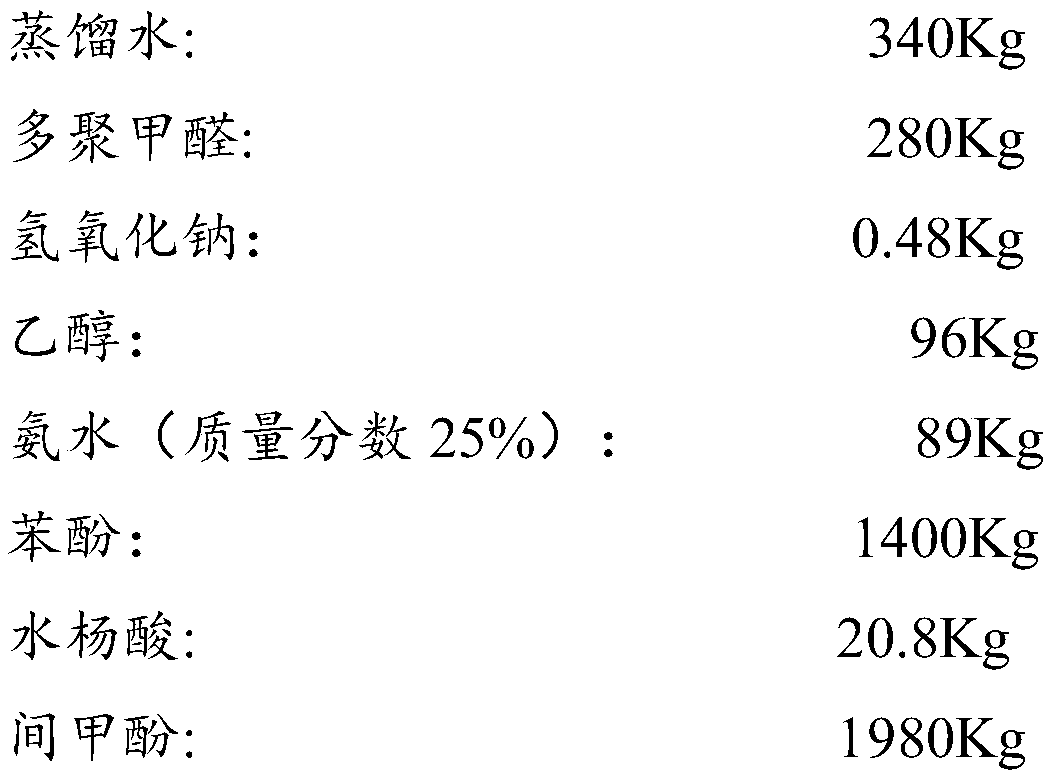

[0044] Raw material preparation (by mass)

[0045]

[0046] Introduce nitrogen protection into the cleaned reaction device, add distilled water, paraformaldehyde, sodium hydroxide, and ethanol while stirring, and raise the temperature to 65°C while feeding, and keep warm at this temperature. After 30 minutes, the contents of the kettle clarify;

[0047] Turn on the cooling to lower the temperature of the kettle. The temperature of the kettle is 37.8°C and gradually add ammonia water to the kettle at a uniform speed. The dripping time is about 19 minutes;

[0048] After the dropwise addition of ammonia water is completed, the raw material phenol is added after stirring for 15 minutes. The exothermic reaction causes the temperature of the kettle to rise up to 77.5°C. After the temperature of the kettle remains stable, the temperature is manually raised to 92°C, and the temperature is kept at this temperature for 2 hours;

[0049] After the heat preservation is over, turn on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com