Treatment method of mixture containing long-chain dicarboxylic acid, long-chain dicarboxylic acid dibutyl ester mixture and application thereof

A long-chain dibasic acid and dibutyl acid technology, which is applied in the field of recycling and reuse of mixtures, can solve problems such as waste of resources, and achieve the effect of solving waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

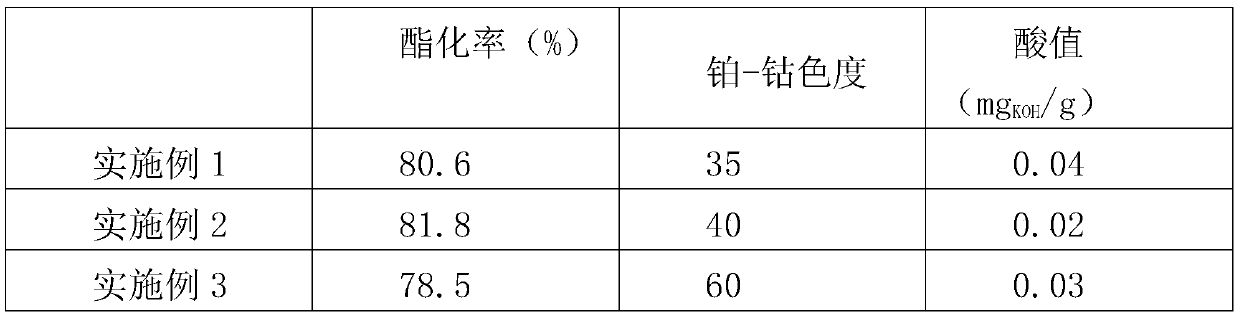

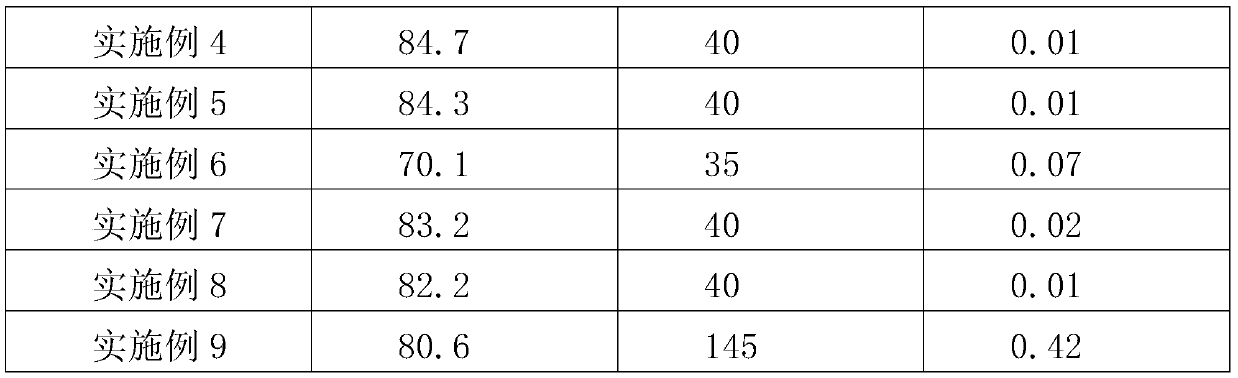

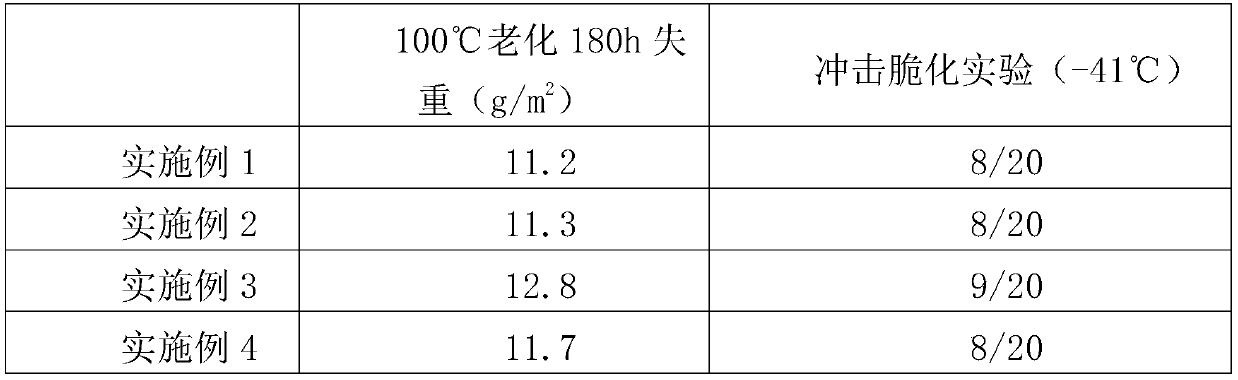

Embodiment 1

[0106] Take DC12 (dodecane dibasic acid) fermentation broth, extract and refine DC12, and dry the mixture containing long-chain dibasic acid (extraction and refining example 1) at 110°C until the water content is 1 wt%, to obtain 1.626kg of dry matter, dry The effective acid content in the substance is 81.34wt%, the content of long-chain dibasic acids (composed of DC10, DC11, DC12, DC13, DC14 and DC15) is 71.76%, and the content of heteroacids is 9.58%. The mass ratio of long-chain dibasic acid to heteroacid is 7.5:1.

[0107] The above dry matter was added to a 5L reaction kettle, and 1.25kg of n-butanol and 58g of p-toluenesulfonic acid monohydrate were added simultaneously. Under the condition that the liquid phase temperature was 120°C, the esterification was refluxed for 5 hours, and 460 g of the mixed solution of n-butanol and water was separated. The acid value of the reaction solution was tested, and the esterification rate was 60.2%. Add 500 g of n-butanol, continue ...

Embodiment 2

[0112] Take DC13 (tridecane dibasic acid) fermentation broth, extract and refine DC13, and dry the mixture containing long-chain dibasic acid (extraction and refining example 1) at 110°C until the water content is 1 wt%, to obtain 1.205kg of dry matter, wherein The effective acid content is 73.18wt%, the long-chain dibasic acid content is 62.35% (composed of DC11, DC12, DC13, DC14 and DC15), and the heteroacid content is 10.83%. The mass ratio of long-chain dibasic acid and heteroacid is 5.8:15.8:1.

[0113] The above-mentioned dry matter was added into a 5L reaction kettle, and 1.755kg of n-butanol and 51g of p-toluenesulfonic acid monohydrate were added at the same time. Under the condition that the liquid phase temperature was 125°C, the esterification was refluxed for 7 hours, and 582 g of the mixed solution of n-butanol and water was separated, and the acid value of the reaction solution was detected to calculate the esterification rate.

[0114] Under the conditions of ...

Embodiment 3

[0118] Take DC11 (undecane dibasic acid) fermentation broth, extract and refine DC11, and dry the mixture containing long-chain dibasic acid (extraction and refining example 1) at 110°C until the water content is 1 wt%, to obtain 1.931kg of dry matter, dry The effective acid content in the substance is 78.04wt%, the long-chain dibasic acid content is 51.94% (composed of DC10, DC11, DC12, DC13, DC14 and DC15), and the heteroacid content is 26.1%. The mass ratio of long-chain dibasic acid and heteroacid is 2:1.

[0119]The above dry matter was added into a 5L reaction kettle, and 1.855kg of n-butanol and 60g of 98% concentrated sulfuric acid were added simultaneously. Under the condition that the liquid phase temperature was 118° C., the esterification was refluxed for 4 hours, and 665 g of the mixed solution of n-butanol and water was separated. The acid value of the reaction solution was tested, and the esterification rate was 68.9%. Add 700g of n-butanol, continue to reflux ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com