Low-sugar candied jack fruit strips and making method thereof

A technology of jackfruit shreds and a production method, which is applied in confectionary, confectionery industry, food science, etc., can solve the problems of environmental pollution, waste of resources, and low effective utilization rate of by-products of jackfruit processing, and shorten the time of soaking sugar and reduce the The effect of increasing the dosage and increasing the added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

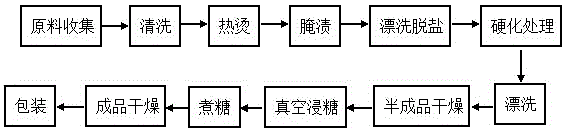

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 makes low-sugar pineapple shredded preserved fruit

[0058] 1. Raw material collection: Collect fresh, non-deteriorated jackfruit, cut it with a knife, peel off the pulp, and cut off the jackfruit shreds with scissors as the raw material for making preserved fruit;

[0059] 2. Cleaning of raw materials: Put the collected jackfruit shreds into a container, wash them with clean water, and drain the water;

[0060] 3. Blanch: Put the jackfruit shreds in boiling water for 5 minutes, then remove, drain, and cool;

[0061] 4. Pickling and preservation: the cooled jackfruit shreds are pickled and preserved in a mixed solution of 25% salt and 0.2% sodium metabisulfite;

[0062] 5. Rinse and desalinate: Take 20g of pickled jackfruit shreds, according to the mass ratio of it to water at 1:5, rinse and desalinate with water at a flow rate of 0.24L / h for 4h;

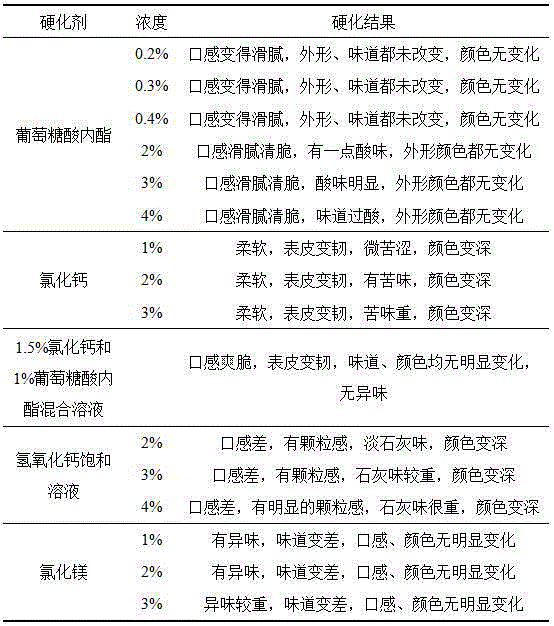

[0063] 6. Hardening treatment: Put the rinsed jackfruit shreds into 1.5% CaCl 2 and 1% gluconolactone mix...

Embodiment 2

[0070] Example 2 Making low-sugar pineapple shredded preserved fruit

[0071] 1. Raw material collection: Collect fresh, non-deteriorated jackfruit, cut it with a knife, peel off the pulp, and cut off the jackfruit shreds with scissors as the raw material for making preserved fruit;

[0072] 2. Cleaning of raw materials: Put the collected jackfruit shreds into a container, wash them with clean water, and drain the water;

[0073] 3. Blanch: Put the jackfruit shreds in boiling water for 3 minutes, then remove, drain, and cool;

[0074] 4. Pickling and preservation: the cooled jackfruit shreds are pickled and preserved in a mixed solution of 10% salt and 1.0% sodium metabisulfite;

[0075] 5. Rinse and desalinate: Take 20g of pickled jackfruit shreds, according to the mass ratio of it to water at 1:3, rinse and desalinate with water at a flow rate of 0.24L / h for 3h;

[0076] 6. Hardening treatment: Put the rinsed jackfruit shreds into 0.5% CaCl 2 and 2.5% gluconolactone mix...

Embodiment 3

[0083] Example 3 Making low-sugar pineapple shredded preserved fruit

[0084] 1. Raw material collection: Collect fresh, non-deteriorated jackfruit, cut it with a knife, peel off the pulp, and cut off the jackfruit shreds with scissors as the raw material for making preserved fruit;

[0085] 2. Cleaning of raw materials: Put the collected jackfruit shreds into a container, wash them with clean water, and drain the water;

[0086] 3. Blanch: Put the jackfruit shreds in boiling water for 5 minutes, then remove, drain, and cool;

[0087] 4. Pickling and preservation: the cooled jackfruit shreds are pickled and preserved in a mixed solution of 15% salt and 0.8% sodium metabisulfite;

[0088] 5. Rinse and desalinate: Take 35g of pickled jackfruit shreds, according to the mass ratio of it to water at 1:4, rinse and desalinate with water at a flow rate of 0.24L / h for 3h;

[0089] 6. Hardening treatment: put the rinsed jackfruit shreds into 1.0% CaCl 2 and 2.0% gluconolactone mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com