Organic silicon modified TPU medical catheter and preparation method thereof

A medical catheter and silicone technology, applied in catheters and other directions, can solve the problems of not suitable for medical interventional catheters, easy migration, rubber is not easy to cut, break, etc., to improve biocompatibility and hydrophilic lubricity, improve low temperature Flexibility, the effect of preventing silicone migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

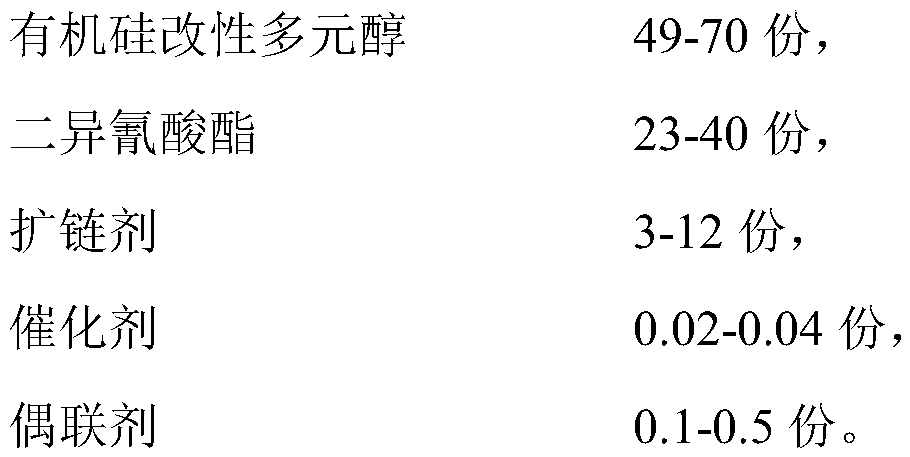

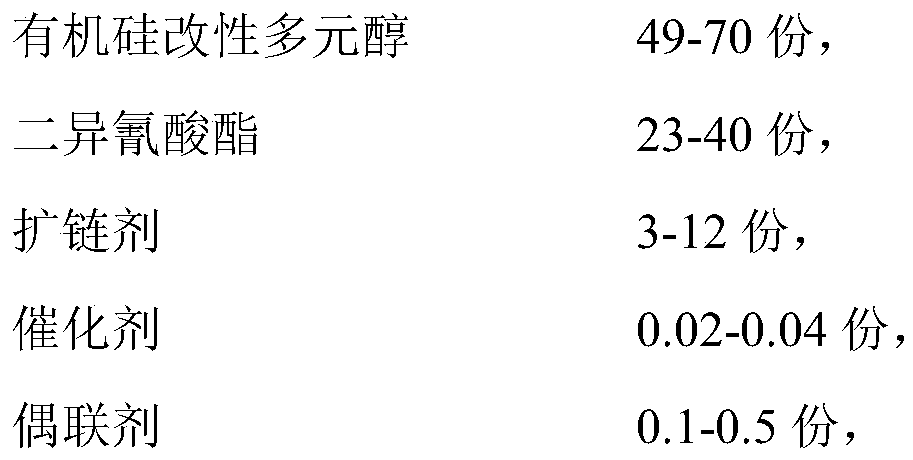

Method used

Image

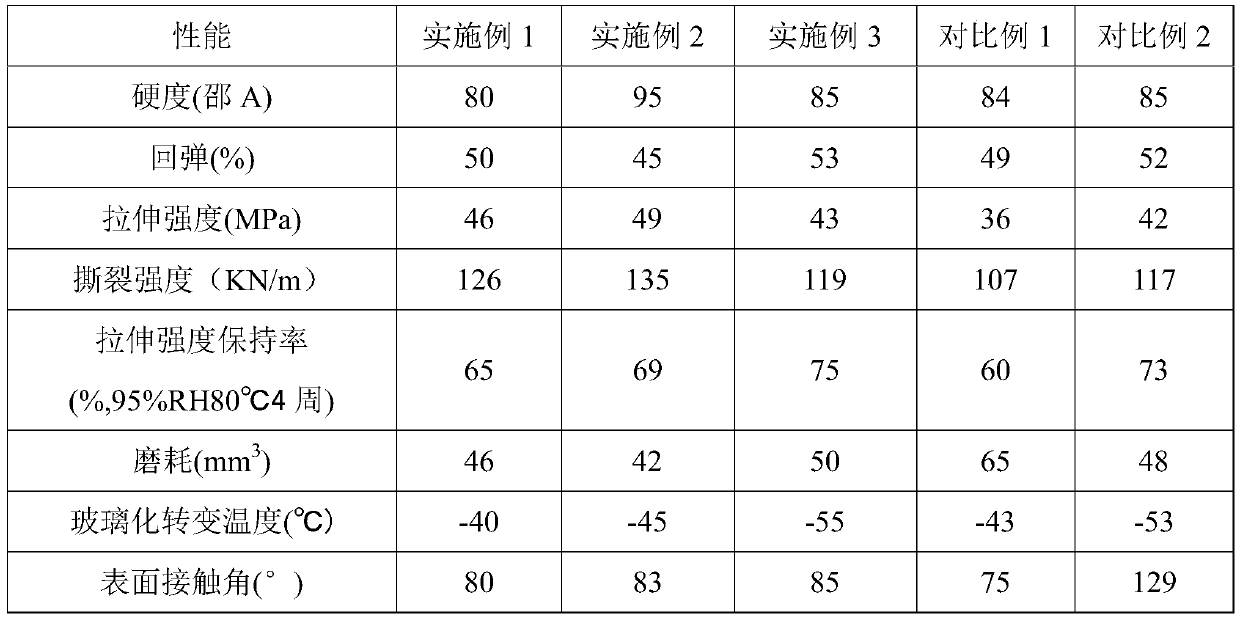

Examples

Embodiment 1

[0031] Prepare organosilicon modified TPU medical catheter according to the following method:

[0032] (1) During the synthesis of polybutylene adipate, 3-aminopropyltriethoxysilane, which accounts for 20% of the total mass of raw materials, is added, stirred and heated under nitrogen protection to obtain organosilicon-modified polybutylene adipate alcohol esters.

[0033] (2) In terms of parts by mass, add 69.90 parts of silicone-modified polybutylene adipate (PBA, M=3000) and 0.1 part of coupling agent KH-550 to reactor A, keeping the temperature at 100°C; Add 23.60 parts of MDI-100 to Reactor B and keep the temperature at 70°C; Add 6.36 parts of 1,4-butanediol to Reactor C and keep the temperature at 50°C; the isocyanate index is controlled at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with precise metering, and ...

Embodiment 2

[0035] Prepare organosilicon modified TPU medical catheter according to the following method:

[0036] (1) In the synthesis process of polycaprolactone polyol, heptamethyltrisiloxane accounting for 15% of the total mass of raw materials was added, stirred and heated under the protection of nitrogen to obtain silicone-modified polycaprolactone polyol.

[0037] (2) In parts by mass, add 49.74 parts of silicone-modified polycaprolactone (PCL, M=2000) and 0.5 parts of coupling agent KH-560 to reactor A, keeping the temperature at 100°C; Add 38.27 parts of MDI-100 to Reactor B and keep the temperature at 70°C; add 11.47 parts of 1,4-butanediol to Reactor C and keep the temperature at 50°C; the isocyanate index is controlled at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with precise metering, and injected into the twin-scr...

Embodiment 3

[0039]Prepare organosilicon modified TPU medical catheter according to the following method:

[0040] (1) During the synthesis of polytetramethylene ether glycol, add hexamethylcyclotrisiloxane accounting for 25% of the total mass of raw materials, stir and heat up under nitrogen protection to obtain organosilicon-modified polytetramethylene ether glycol .

[0041] (2) In terms of parts by mass, 64.72 parts of silicone-modified polytetramethylene ether glycol (PTMG, M=1000) and 0.4 parts of coupling agent KH-550 are added to reaction kettle A, and the temperature is maintained at 100°C; add 28.91 parts of MDI-100 to Reactor B, keep the temperature at 70°C; add 5.94 parts of 1,6-hexanediol into Reactor C, keep the temperature at 60°C; control the isocyanate index at 1.005. After the temperature of each reactor is stabilized, the raw material components in Reactor A, Reactor B and Reactor C are mixed through a high-speed rotating mixing head through the infusion system with pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com