3D printing method of TPU 9370AU plastic particles

A technology of TPU9370AU and plastic particles, which is applied in the field of 3D printing to achieve the effects of lower melting temperature, good chemical resistance and high resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

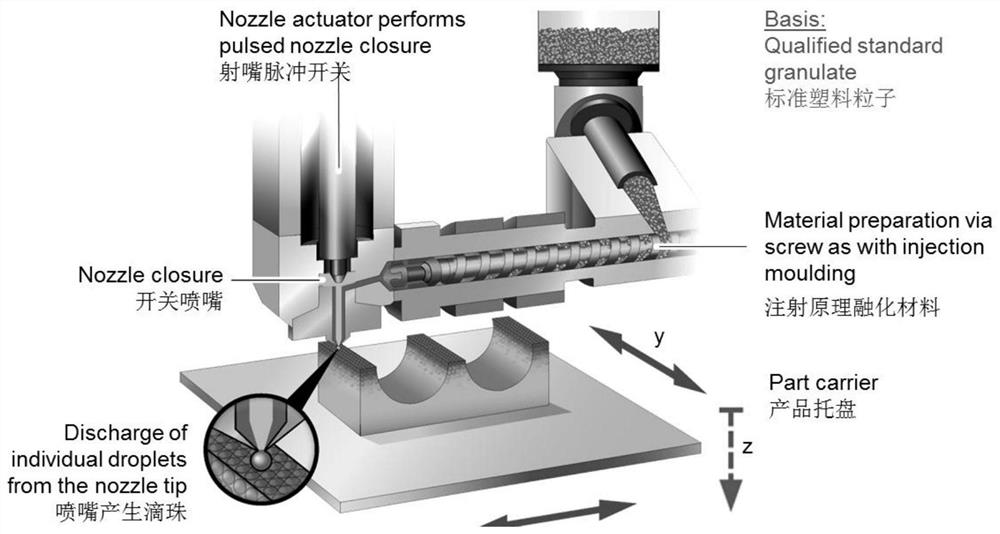

[0023] 1. The 3D printing equipment used in this example is ARBURG freeformer200-3X, figure 1 It is a schematic diagram of the device APF principle.

[0024] 2. The present embodiment adopts the following method to prepare the TPU9370AU product:

[0025] (1) Prepare TPU9370AU plastic pellets

[0026] TPU9370AU plastic granules can be obtained by metering, mixing, plasticizing, and pelletizing polymer resin and various additives and additives to make granular plastics, and then using the wavefront method to repair the three-dimensional model.

[0027] The TPU9370AU plastic particles used in this implementation are purchased standard TPU9370AU plastic particles.

[0028] (2) 3D printing

[0029] In this embodiment, the following method is used to 3D print TPU9370AU plastic particles to prepare TPU9370AU product test samples;

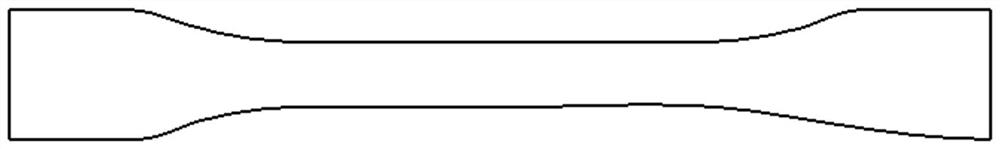

[0030] Test splines on the target by computer (three views such as Figure 2-4 As shown, the dimension drawing is shown in Figure 5 The 3D CAD mode...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com