Bamboo fibre composition and method for producing the same

A manufacturing method, bamboo fiber technology, applied in fiber raw material processing, natural cellulose pulp/paper, papermaking, etc., can solve problems such as improper processing, carbonization blackening, and long flow molding time, so as to achieve good and stable material properties, Not easy to carbonize and burn black, good fluidity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

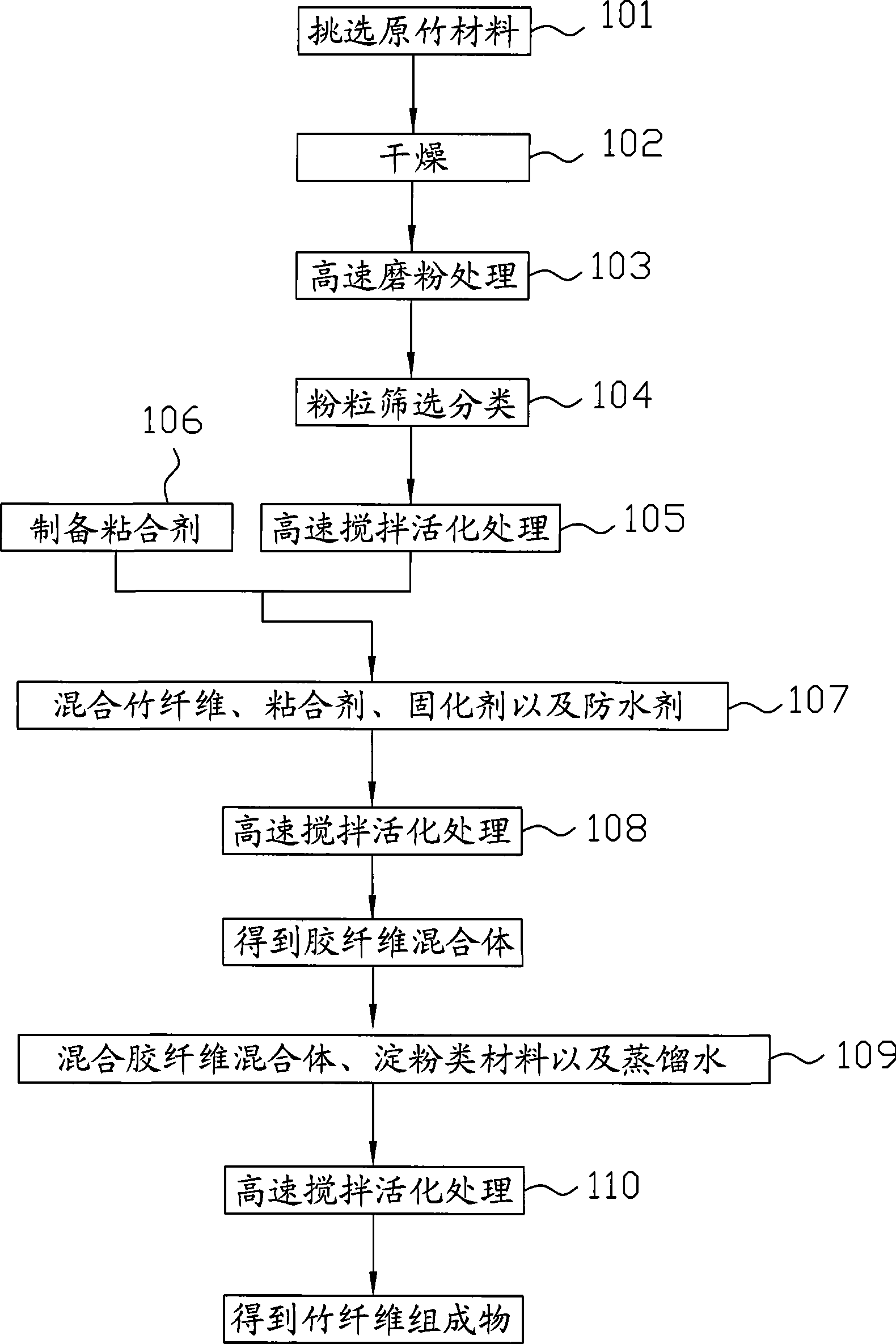

[0012] Below in conjunction with accompanying drawing and embodiment the present invention is described in detail:

[0013] The best embodiment of the bamboo fiber composition of the present invention, can be used as the raw material of bamboo fiber container, utensil, and described bamboo fiber article refers to the non-food utensils such as bucket, vase, electric appliance casing, 3C product, and comprises: The bamboo fiber of 35~55wt% (weight %), the binder of 25~50wt%, the curing agent of 0.4~0.7wt%, the waterproofing agent of 0.4~0.8wt%, the starch material of 12~18wt%, and 2 ~4 wt% distilled water.

[0014] refer to figure 1 , the best embodiment of the manufacture method of bamboo fiber composition of the present invention, comprises:

[0015] (1) Prepare bamboo fiber: carry out step 101, at first select raw bamboo material, be suitable for selecting the raw bamboo that becomes useful more than three years for use, because the growth of too young bamboo material is im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com