Method for preparing nano MnO2 composite electrode for high-conductivity super-capacitor

A technology for supercapacitors and composite electrodes, which is applied in the field of preparation of nano-MnO2 composite electrodes for high-conductivity supercapacitors. It can solve the problems of high theoretical specific capacity characteristics, poor cycle reversibility, and low conductivity, which are beneficial to industrialization. Large-scale production, low equipment requirements, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

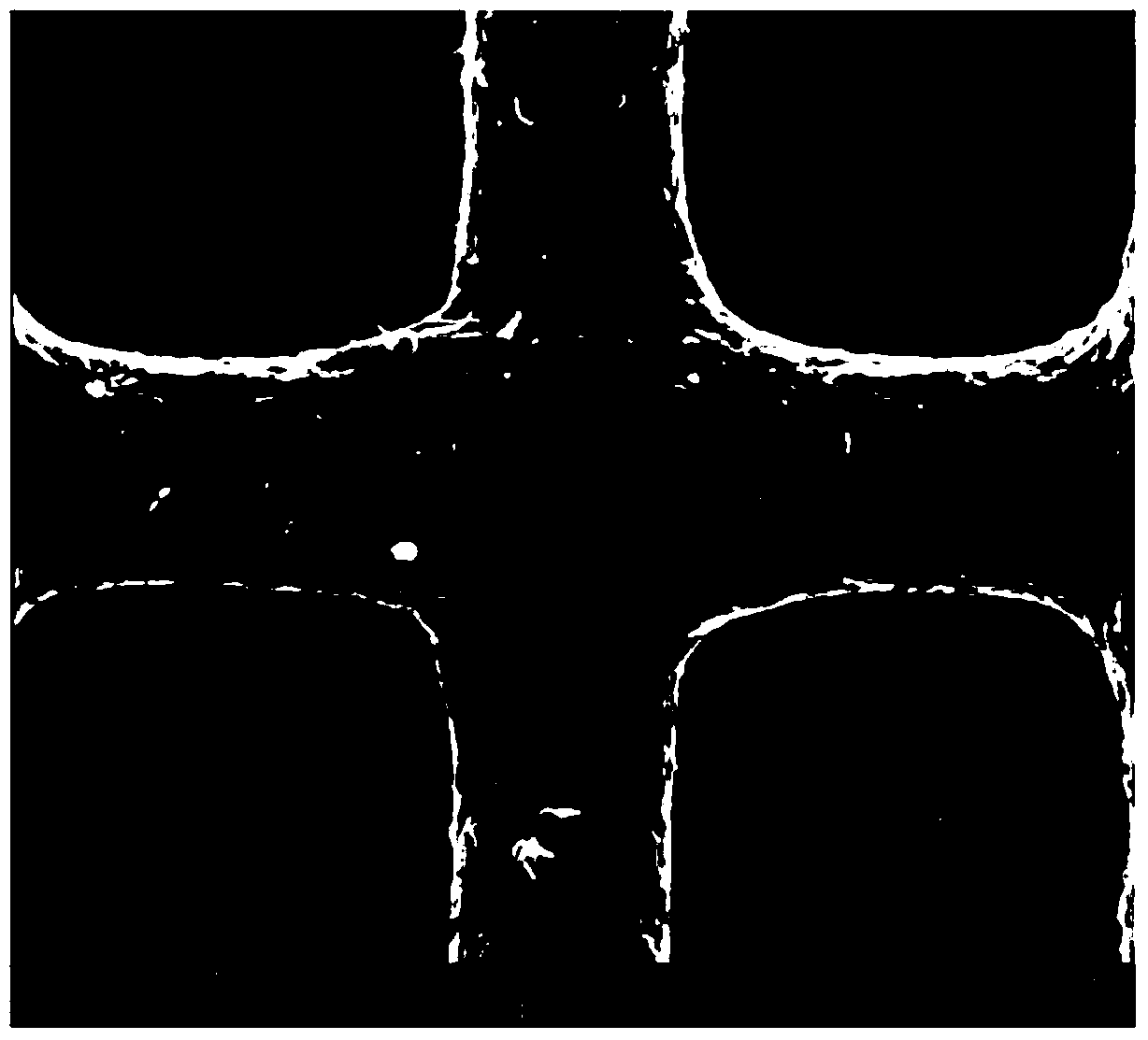

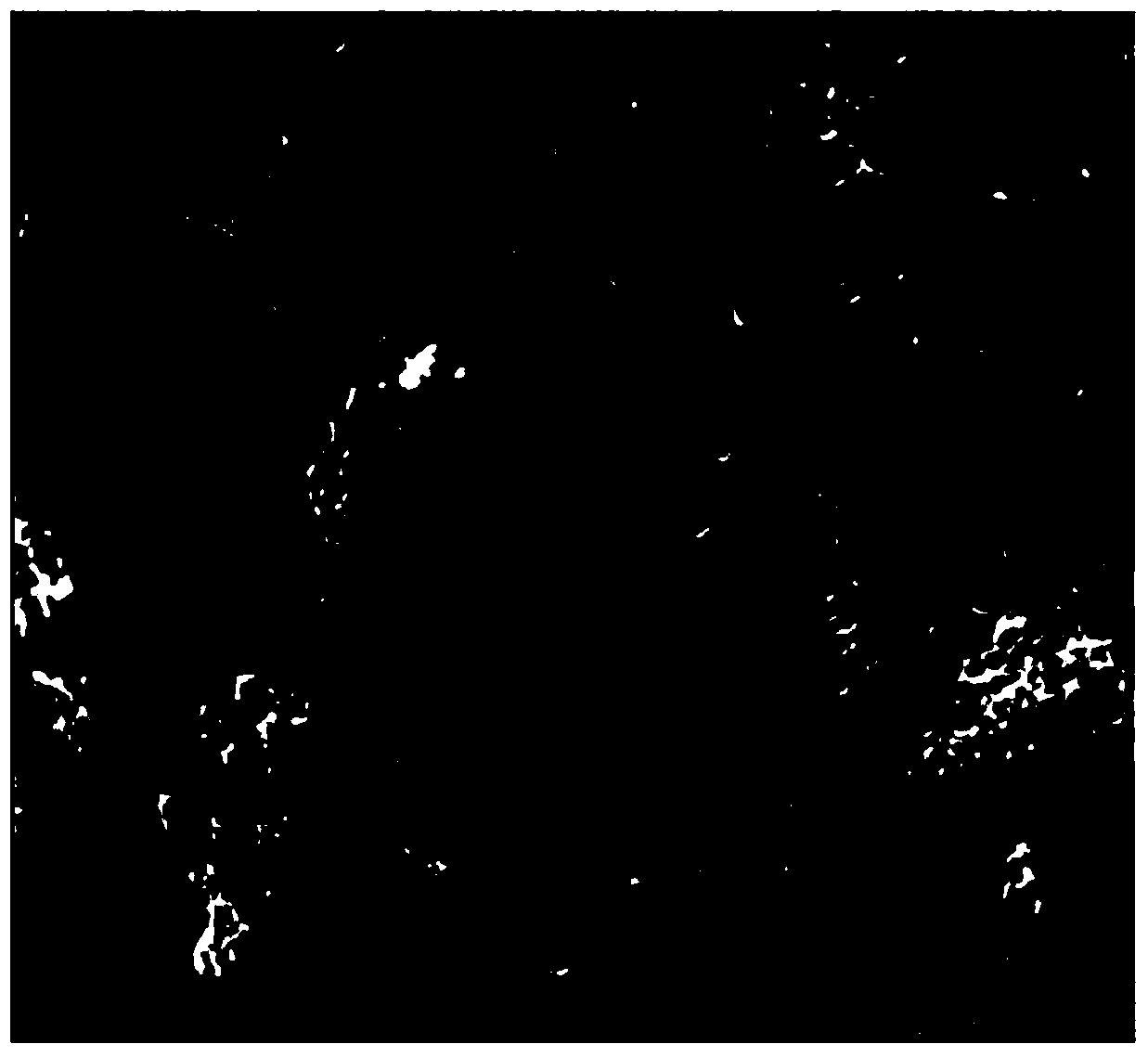

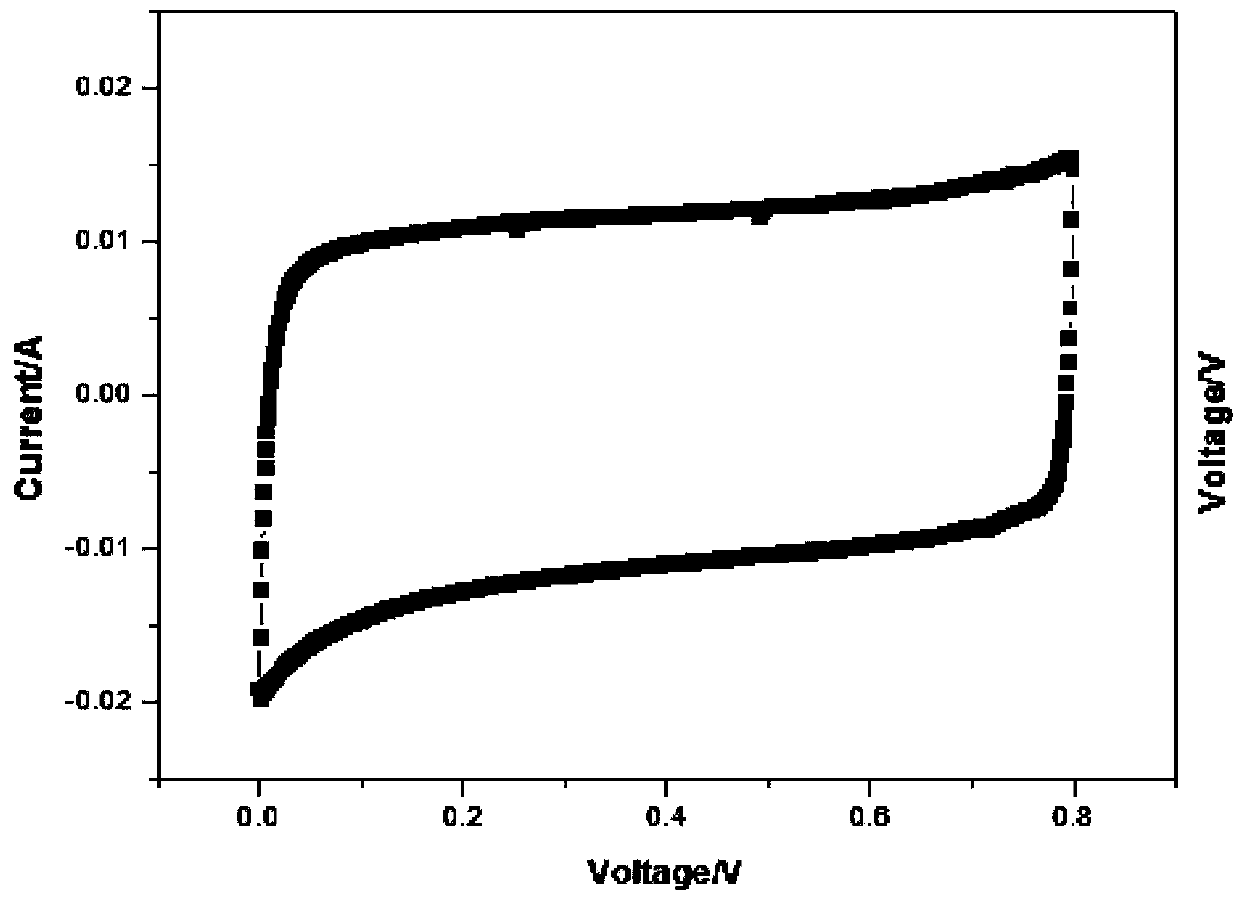

[0020] Take 5g of multi-walled carbon nanotubes, add them to the mixed acid of sulfuric acid and nitric acid with a molar ratio of 3:1, use an ultrasonic cleaner to sonicate for 30min, heat to 60°C and centrifuge for 1h, then dilute with deionized water after acidification treatment The multi-walled carbon nanotubes were centrifuged at 8000 rpm for 10 minutes, washed repeatedly with deionized water until the pH value of the supernatant was 7, and then the multi-walled carbon nanotubes were taken out and dried for later use; 1g of acid-washed multi-walled carbon nanotubes Carbon nanotubes were dispersed into 1L of deionized water by ultrasound, and a small amount of Na was added 2 SO 4 Configured as 0.1g / L electrolyte. Use 100 mesh stainless steel mesh electrodes as cathode and anode, add 0.3V / cm between cathode and anode 2 DC voltage, deposited for 10min, obtained stainless steel mesh with multi-walled carbon nanotubes; weighed 0.1molMnSO 4 and 0.05molH 2 SO 4 , adding mo...

Embodiment 2

[0023] Take 5g of multi-walled carbon nanotubes, add them to the mixed acid of sulfuric acid and nitric acid with a molar ratio of 3:1, use an ultrasonic cleaner to sonicate for 30min, heat to 60°C and centrifuge for 1h, then dilute with deionized water after acidification treatment The multi-walled carbon nanotubes were centrifuged at 8000 rpm for 10 minutes, washed repeatedly with deionized water until the pH value of the supernatant was 7, and then the multi-walled carbon nanotubes were taken out and dried for later use; 1g of acid-washed multi-walled carbon nanotubes Carbon nanotubes were dispersed into 1L of deionized water by ultrasound, and a small amount of Na was added 2 SO 4 Configured as 0.15g / L electrolyte. Use 100 mesh stainless steel mesh electrodes as cathode and anode, add 0.05V / cm between cathode and anode 2 The DC voltage was deposited for 30 minutes to obtain a stainless steel mesh adsorbed with multi-walled carbon nanotubes; weigh 0.1mol of MnNO 3 and 0....

Embodiment 3

[0025] Take 5g of multi-walled carbon nanotubes, add them to the mixed acid of sulfuric acid and nitric acid with a molar ratio of 3:1, use an ultrasonic cleaner to sonicate for 30min, heat to 60°C and centrifuge for 1h, then dilute with deionized water after acidification treatment The multi-walled carbon nanotubes were centrifuged at 8000 rpm for 10 minutes, washed repeatedly with deionized water until the pH value of the supernatant was 7, and then the multi-walled carbon nanotubes were taken out and dried for later use; 1g of acid-washed multi-walled carbon nanotubes Carbon nanotubes were dispersed into 1L of deionized water by ultrasound, and a small amount of Na was added 2 SO 4 Configured as 0.2g / L electrolyte. Use 100 mesh stainless steel mesh electrodes as cathode and anode, add 1V / cm between cathode and anode 2 The DC voltage was deposited for 50 minutes to obtain a stainless steel mesh adsorbed with multi-walled carbon nanotubes; weigh 0.1mol of MnNO 3 and 0.05mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com