Preparation method of nano metal oxide functionalized carbon nanotubes and gas sensor

A nano-metal, carbon nanotube technology, applied in carbon nanotubes, nanocarbons, chemical instruments and methods, etc., can solve the problems of poor selectivity, affecting accuracy, complicated operation, etc., achieving low cost, high precision, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

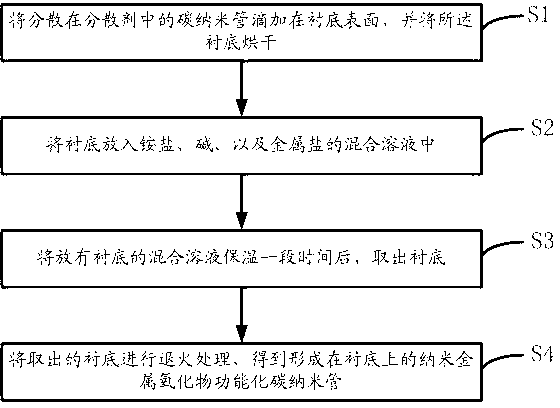

[0037] ginseng figure 1 , to introduce a specific embodiment of the preparation method of the nanometer metal oxide functionalized carbon nanotubes of the present invention. In this embodiment, the method includes the following steps:

[0038] S1. Adding carbon nanotubes dispersed in a dispersant onto the surface of the substrate dropwise, and drying the substrate.

[0039]The dispersant is used to disperse the carbon nanotubes, so that the carbon nanotubes are evenly distributed in the dispersant, and ensure the uniformity of the distribution of the carbon nanotubes on the substrate after the substrate is dried in subsequent operations. The dispersant can be, for example, water, or dimethylformamide (DMF), or sodium dodecyl sulfate (SDS) aqueous solution, or ethanol, or ethylene glycol, or triton aqueous solution. When drying the substrate, the temperature range is controlled at 1~600°C, and the time range is 1s~15h. The temperature when drying the substrate corresponds to...

Embodiment 1

[0054] Weigh 0.6875g of sodium hydroxide, and dissolve 2.675g of ammonium chloride in 250ml of deionized water. Take 20ml of the prepared solution and pour it into the sample bottle, then take 0.09g of nickel chloride and put it into the sample bottle, and fully dissolve it. Here, the molar ratio range of ammonium chloride, nickel chloride and sodium hydroxide is controlled between 100:10:1~1:10:100. Dry the substrate with carbon nanotubes added dropwise and put it into a sample bottle, put the sample bottle into a water bath at 55°C, keep it warm for 5min, then take out the substrate, dry it and anneal it at 400°C After 2 hours of heat preservation, the nano-nickel oxide functionalized carbon nanotube (NiO / CNT) material was finally obtained. The structural photos of the prepared nano-nickel oxide functionalized carbon nanotube material under the scanning electron microscope are as follows: Figure 4 (500nm class accuracy) and Figure 5 (250nm-level precision), the obtained...

Embodiment 2

[0057] Put 4mg of sodium hydroxide, 0.21g of ammonium chloride, 0.26g of zinc chloride and 20ml of deionized water into the sample bottle to dissolve, then dry the substrate with carbon nanotubes dropped into the sample bottle and put the sample bottle in a water bath at 55°C for 1h, then take out the substrate, dry it and anneal at 400°C for 2h, and finally get nano-zinc oxide functionalized carbon nanotubes (ZnO / CNT) Material. The structural photo of the prepared nano-zinc oxide functionalized carbon nanotube material under the scanning electron microscope is as follows: Figure 6 (500nm class accuracy) and Figure 7 (250nm-level precision), the obtained homogeneous nano-zinc oxide functionalized carbon nanotubes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com