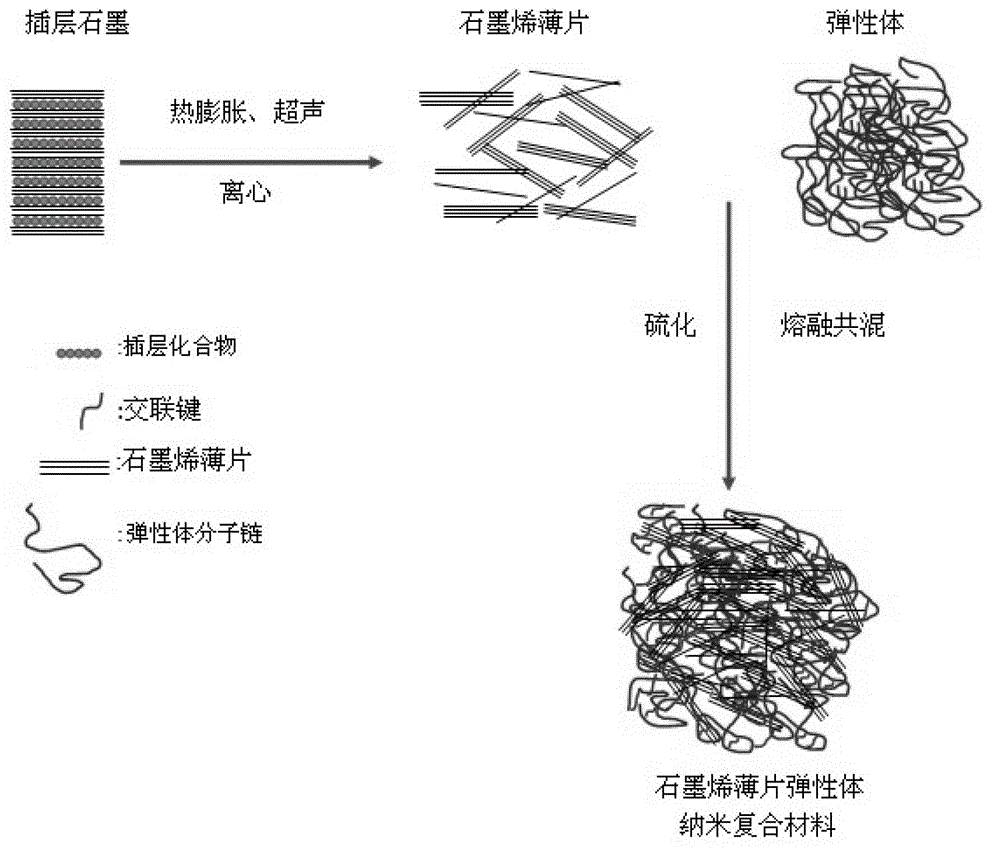

Simple preparation method of graphene sheet nano composite material

A technology of nanocomposite materials and graphene flakes, applied in the direction of graphene, nanotechnology for materials and surface science, nanocarbon, etc., to achieve the effect of large output, low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 1g of intercalated graphite into the preheated crucible, transfer the crucible containing the sample to a furnace at 700°C and heat it for 60s, transfer the obtained expanded product to a metal container containing 100ml of acetone, and first stir it mechanically 10 minutes, followed by ultrasonic dispersion for 1 hour in an ultrasonic cleaner (200W, 42kHz). The graphene flakes were separated from the acetone solution by centrifugation, and dried to constant weight in a blast oven and a vacuum oven successively.

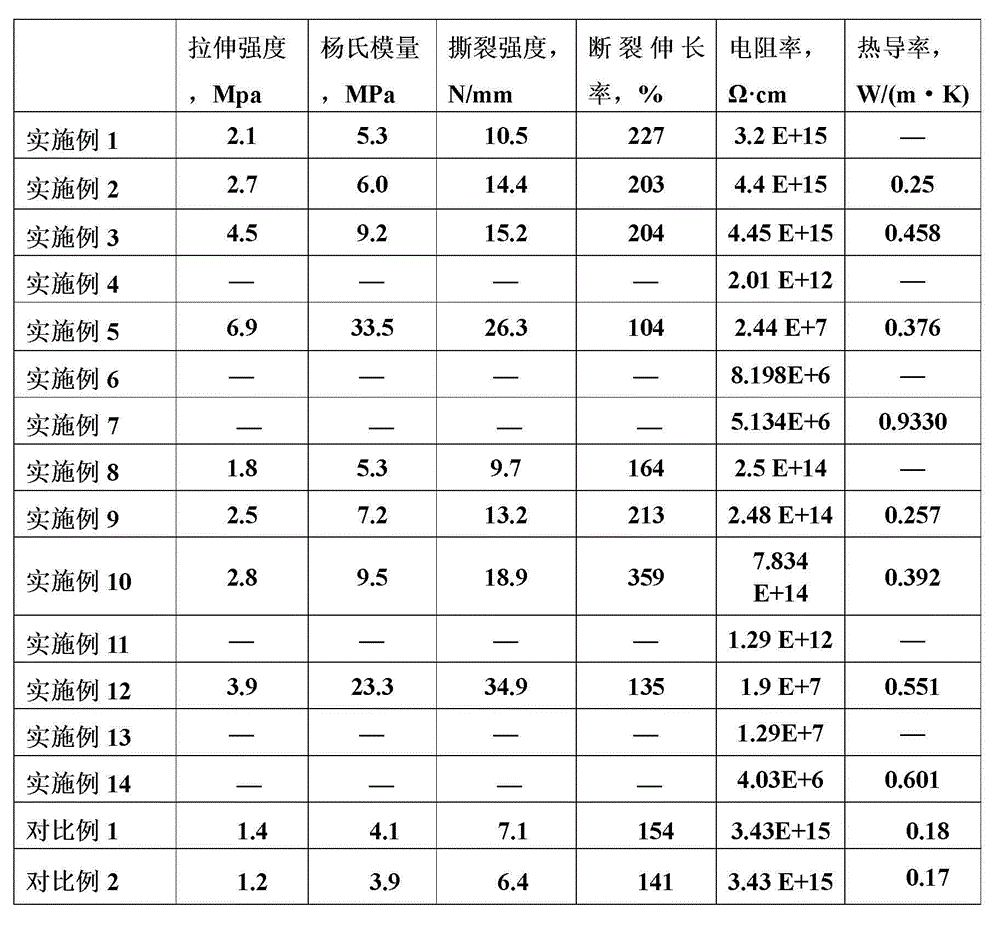

[0026] Mix the 5g graphene flakes obtained above, 100g EPDM rubber, 4gDCP, 1g sulfur, and 1g HVA-2 (N,N'-m-phenylene bismaleimide) on a double-roller mill The mixed rubber is obtained, and the mixed rubber is molded and vulcanized at 150° C. to prepare a graphene EPDM composite material. The thermal conductivity and mechanical properties of the composite materials are shown in Table 1.

Embodiment 2

[0028] The difference from Example 1 is that the amount of graphene flakes is 10g, and all the other process conditions and operating steps are the same as in Example 1. The thermal conductivity and mechanical properties of the composite materials are shown in Table 1.

Embodiment 3

[0030] The difference from Example 1 is that the amount of graphene flakes is 20g, and all the other process conditions and operating steps are the same as in Example 1. The thermal conductivity and mechanical properties of the composite materials are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com